Cathode material coated with co-embedded film, preparation method and lithium ion battery

A cathode material and coating technology, which is applied in the field of battery materials, can solve problems such as difficult deposition of three-dimensional powder particles, uneven powder coating, and affecting the conductivity of materials, so as to achieve high capacity and cycle performance, block electrolyte erosion, reduce The effect of modified costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing a positive electrode material coated with a co-embedded film, comprising the following steps:

[0036] S1. Put the positive electrode material into the reaction chamber of the atomic layer deposition equipment, set the pressure of the reaction chamber to 0.001-1.0 tor, and the temperature to 25-400° C. and keep it for 1-5 hours;

[0037] S2. Feed precursor A into the reaction chamber, the feed time is 0.01-10s, the reaction time is 1-30s, the reaction times is 1-10 times, and then purge gas is fed to purge excess precursor Body A and by-products;

[0038] S3, feed precursor B into the reaction chamber, the feed time is 0.01-10s, the reaction time is 1-30s, the reaction times is 1-10 times, and then feed the cleaning gas to purge the excess precursor Body B and by-products;

[0039] S4. Steps S2 and S3 are repeated, and the number of repetitions is 0 to 4 times;

[0040] S5. Feed precursor C into the reaction ...

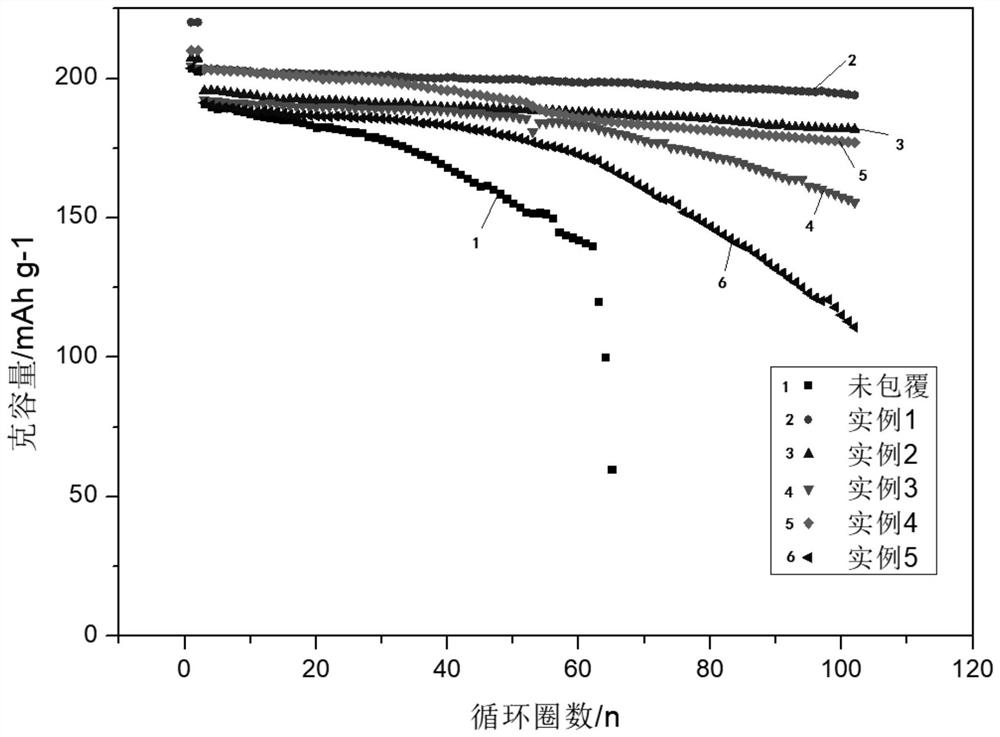

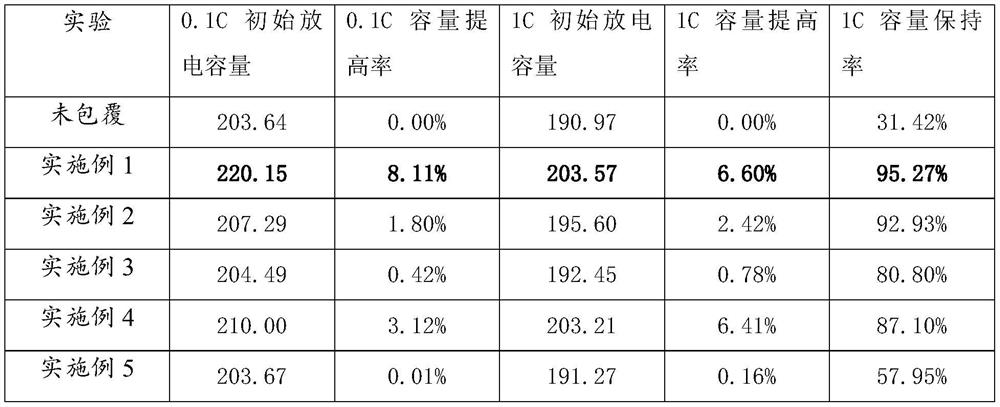

Embodiment 1

[0049] This embodiment provides a positive electrode material coated with a co-embedded film, which is prepared according to the following method:

[0050] (1) Weigh 10 g of the high-nickel ternary material 811 and put it into the reaction chamber of the atomic layer deposition equipment, evacuate to 0.01 torr, set the reaction temperature to 250° C., and hold the time to 2.0 h.

[0051] (2) Use trimethyl phosphate as precursor A, heat the source bottle to 75-85°C, and feed trimethyl phosphate into the reaction chamber for 2 s, 10 s, and 1 reaction time.

[0052] (3) Introduce Ar gas to purge excess trimethyl phosphate and by-products, the purge time is 60s, and the purge times are 2 times.

[0053] (4) with H 2 O is used as the precursor B, and H is introduced into the reaction chamber 2 O, the access time is 1s, the reaction time is 5s, and the number of reactions is 1 time.

[0054] (5) Introduce Ar gas to purge excess H 2 O and by-products, the purging time is 60s, and...

Embodiment 2

[0063] In this embodiment, a positive electrode material coated with a co-embedded film is provided, which is prepared according to the following method:

[0064] (1) Weigh 10 g of the high-nickel ternary material 811 and put it into the reaction chamber of the atomic layer deposition equipment, evacuate to 0.01 torr, set the reaction temperature to 250° C., and hold the time to 2.0 h.

[0065] (2) Use trimethyl phosphate as precursor A, heat the source bottle to 75-85°C, and feed trimethyl phosphate into the reaction chamber for 2 s, 10 s, and 1 reaction time.

[0066] (3) Introduce Ar gas to purge excess trimethyl phosphate and by-products, the purge time is 60s, and the purge times are 2 times.

[0067] (4) with H 2 O is used as the precursor B, and H is introduced into the reaction chamber 2 O, the access time is 1s, the reaction time is 5s, and the number of reactions is 1 time.

[0068] (5) Introduce Ar gas to purge excess H 2 O and by-products, the purging time is 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com