Patents

Literature

31results about How to "Inhibition of water absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drilling fluid and preparation method thereof

ActiveCN103773332ANo biological toxicityInhibition of hydrationDrilling compositionEpoxyPolymer science

The invention discloses a drilling fluid and a preparation method thereof. The drilling fluid comprises, by weight, 2.0 to 6.0 parts of bentonite, 0.1 to 1 part of sodium carboxymethylcellulose, 0.2 to 0.8 part of a zwitter-ion sulphonate copolymer, 0.03 to 0.4 part of sodium hydroxide, 0.1 to 0.8 of a polyamine polymer, and 100 parts of water; the polyamine polymer is a polymer of terminal diamine, a cyclic ether, and an epoxy alkyl halide. The preparation method comprises following steps: the polyamine polymer is prepared firstly, wherein the polyamine polymer is prepared via copolymerization of terminal diamine, the cyclic ether, and the epoxy alkyl halide; and then an aqueous solution containing bentonite, sodium carboxymethylcellulose, the zwitter-ion sulphonate copolymer, sodium hydroxide, the polyamine polymer, and water is prepared according to the stoichiometric ratio so as to obtain the drilling fluid. The drilling fluid is excellent in system inhibition performance and collapse resistance, and contains no sylvite, so that subsequent processing on high salt content is unnecessary.

Owner:CHINA PETROLEUM & CHEM CORP +1

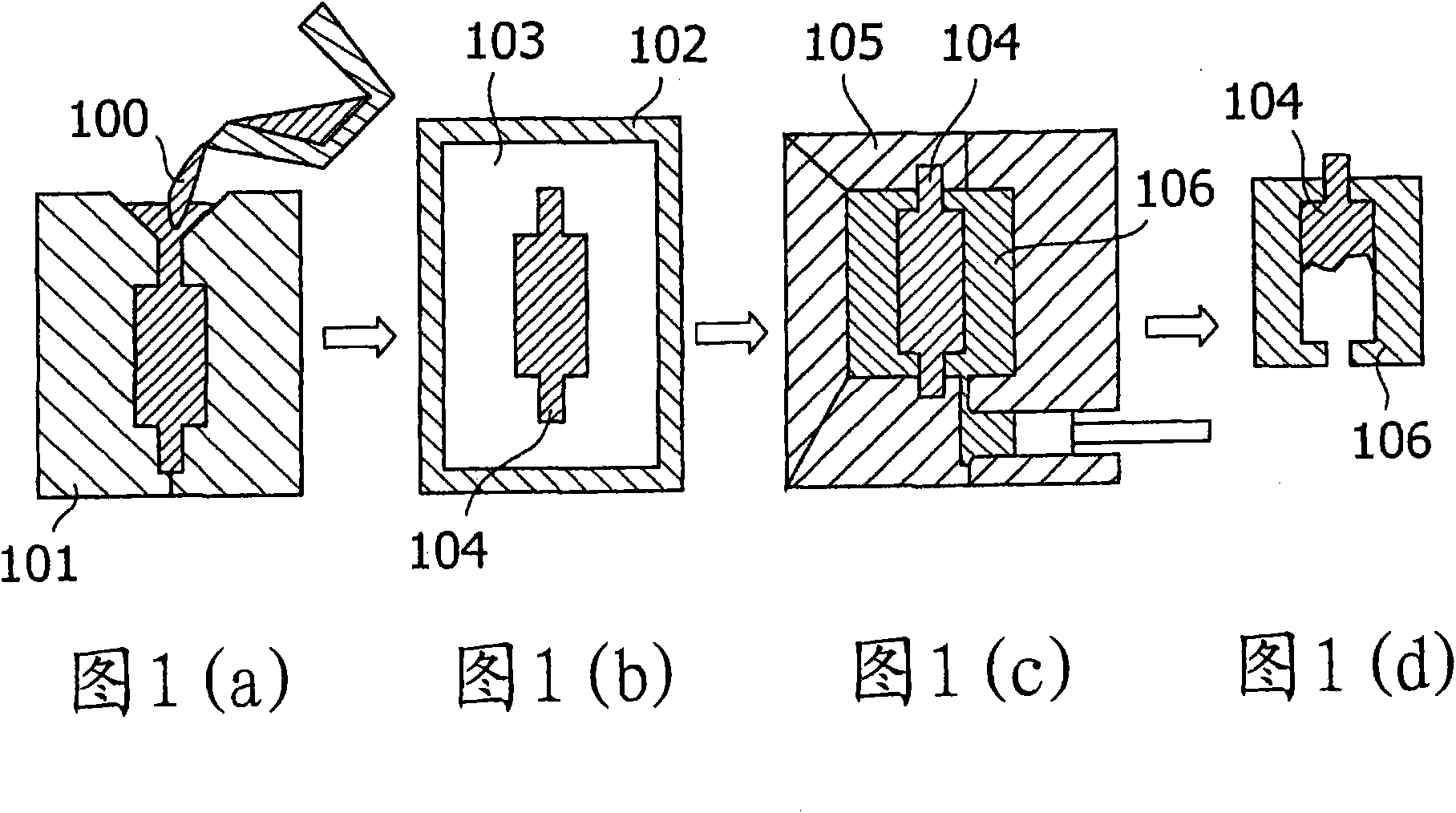

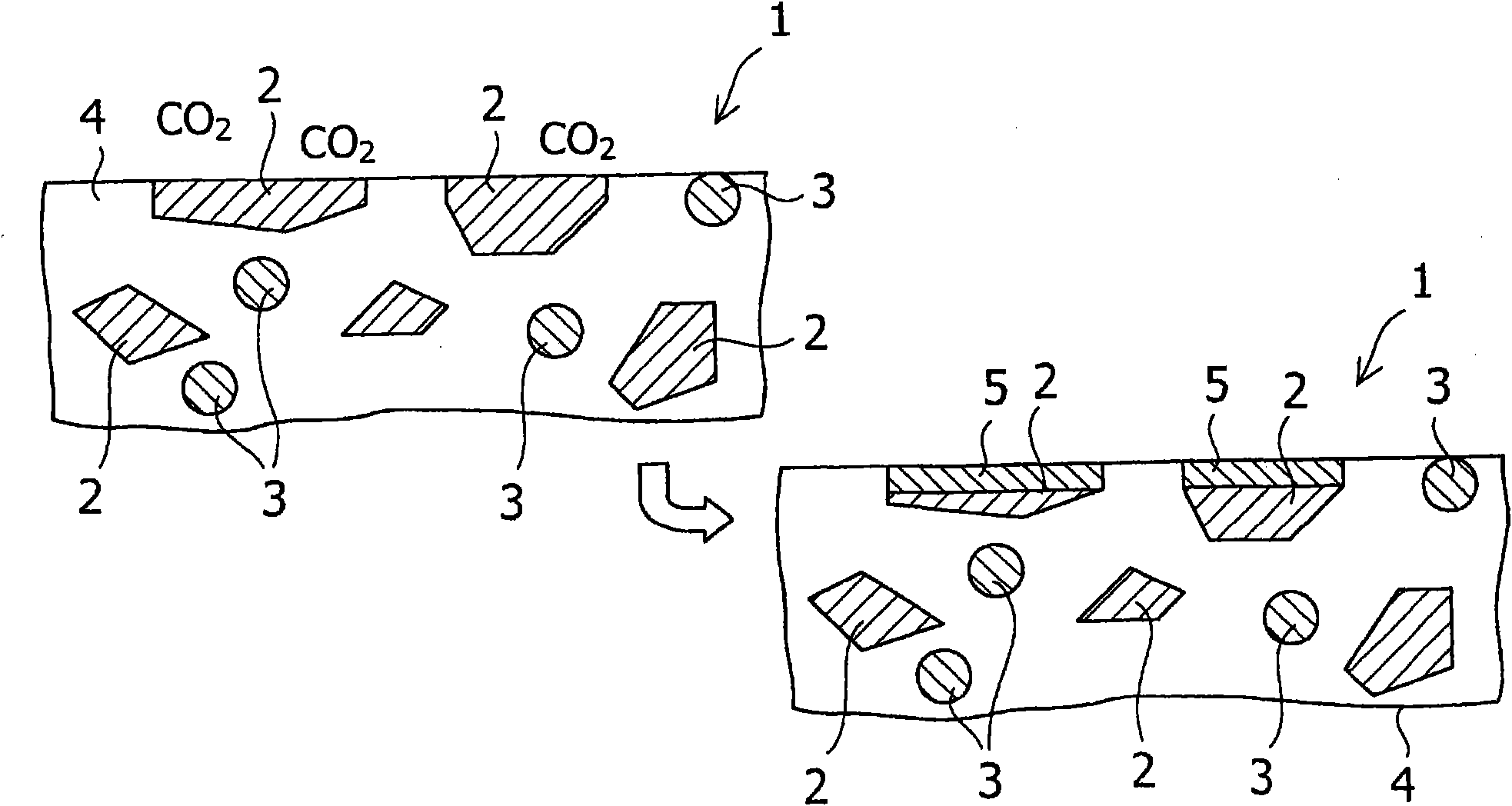

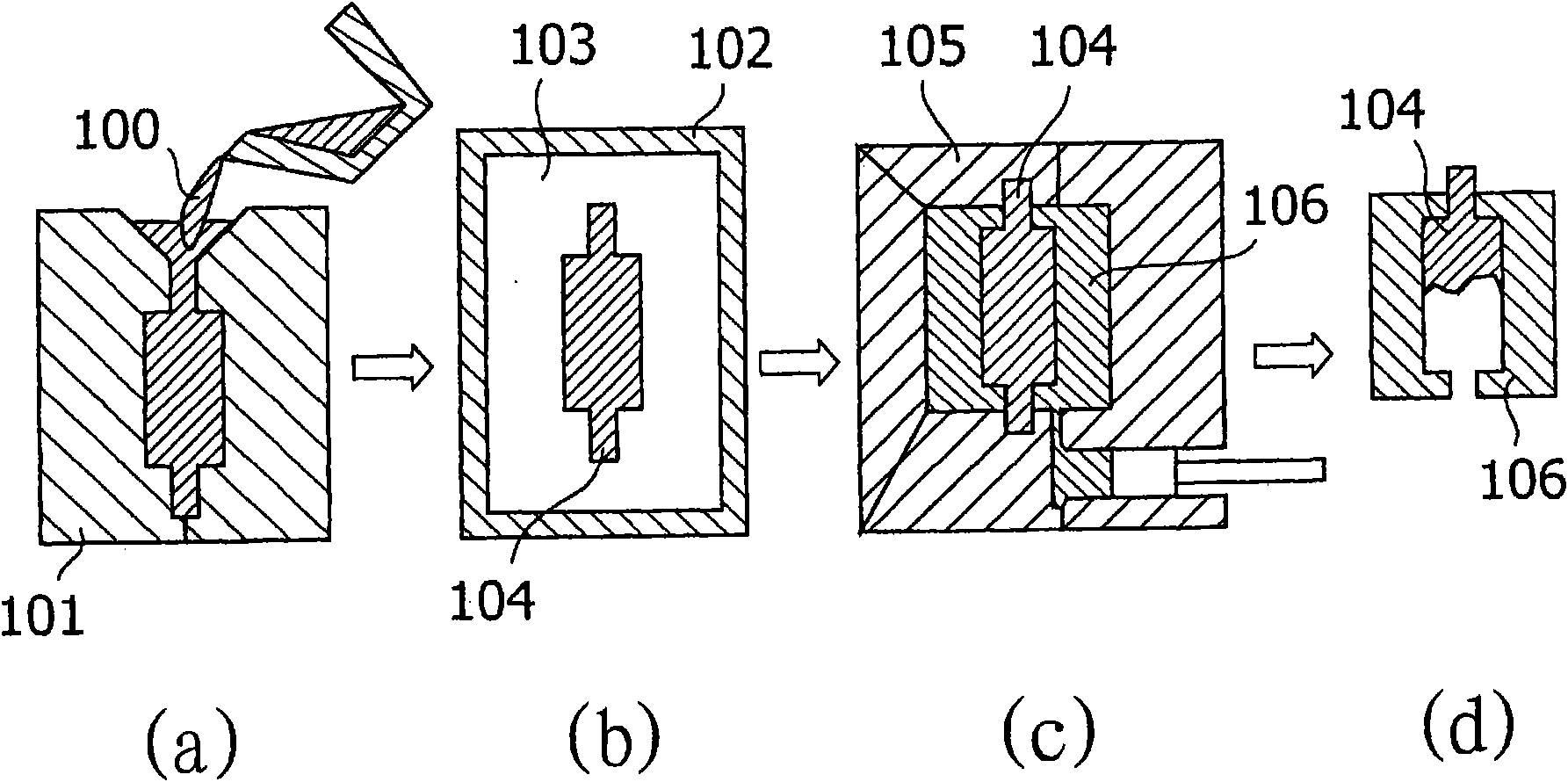

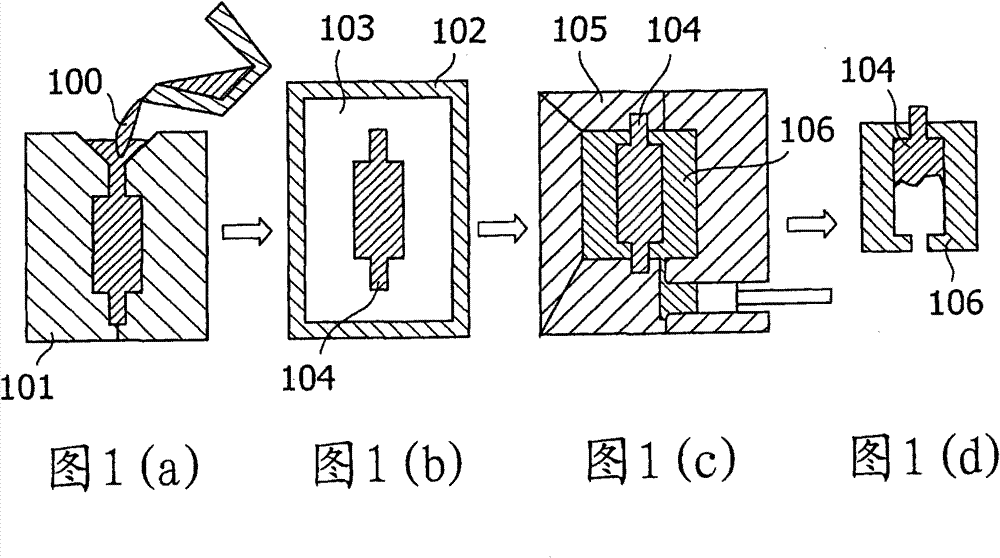

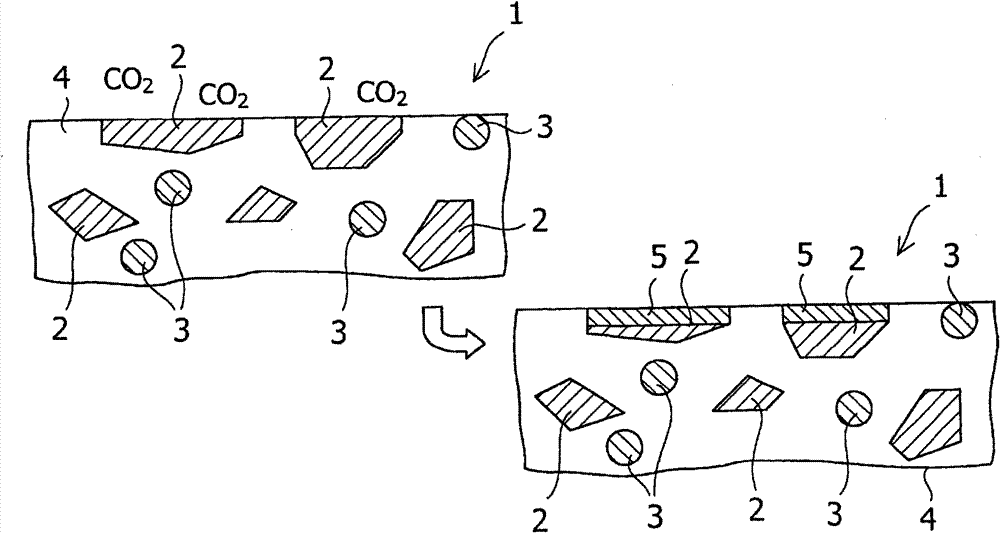

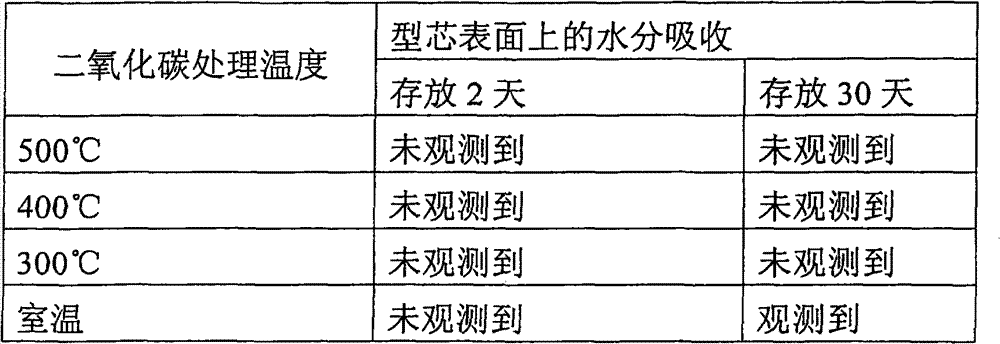

Collapsible mold and method of manufacturing the same

InactiveCN101844206AImprove surface propertiesInhibition of water absorptionFoundry mouldsFoundry coresMoisture absorptionCarbon dioxide

The invention relates to a collapsible mold and a method of manufacturing the same. In a collapsible mold and a method of manufacturing the same, the collapsible mold has extremely low moisture-absorption properties, does not change in surface properties thereof due to absorption of moisture and swelling, and is storable for a long time without absorbing moisture and swelling. Specifically, the method manufactures a collapsible mold containing at least any of calcium oxide and magnesium oxide. The method includes a step of bringing the collapsible mold into contact with carbon dioxide immediately after a step of burning the collapsible mold or a step of casting the collapsible mold.

Owner:SUZUKI MOTOR CORP

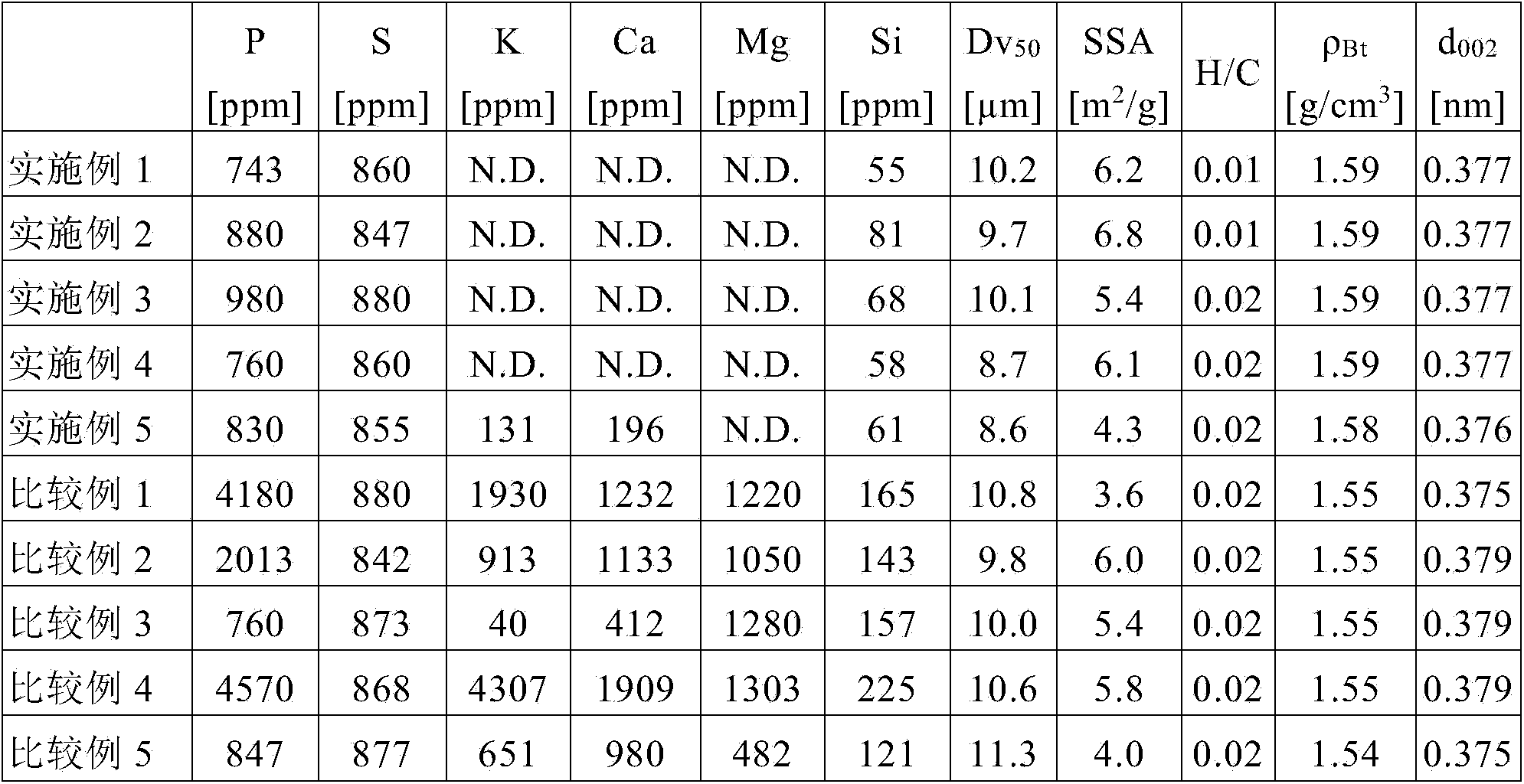

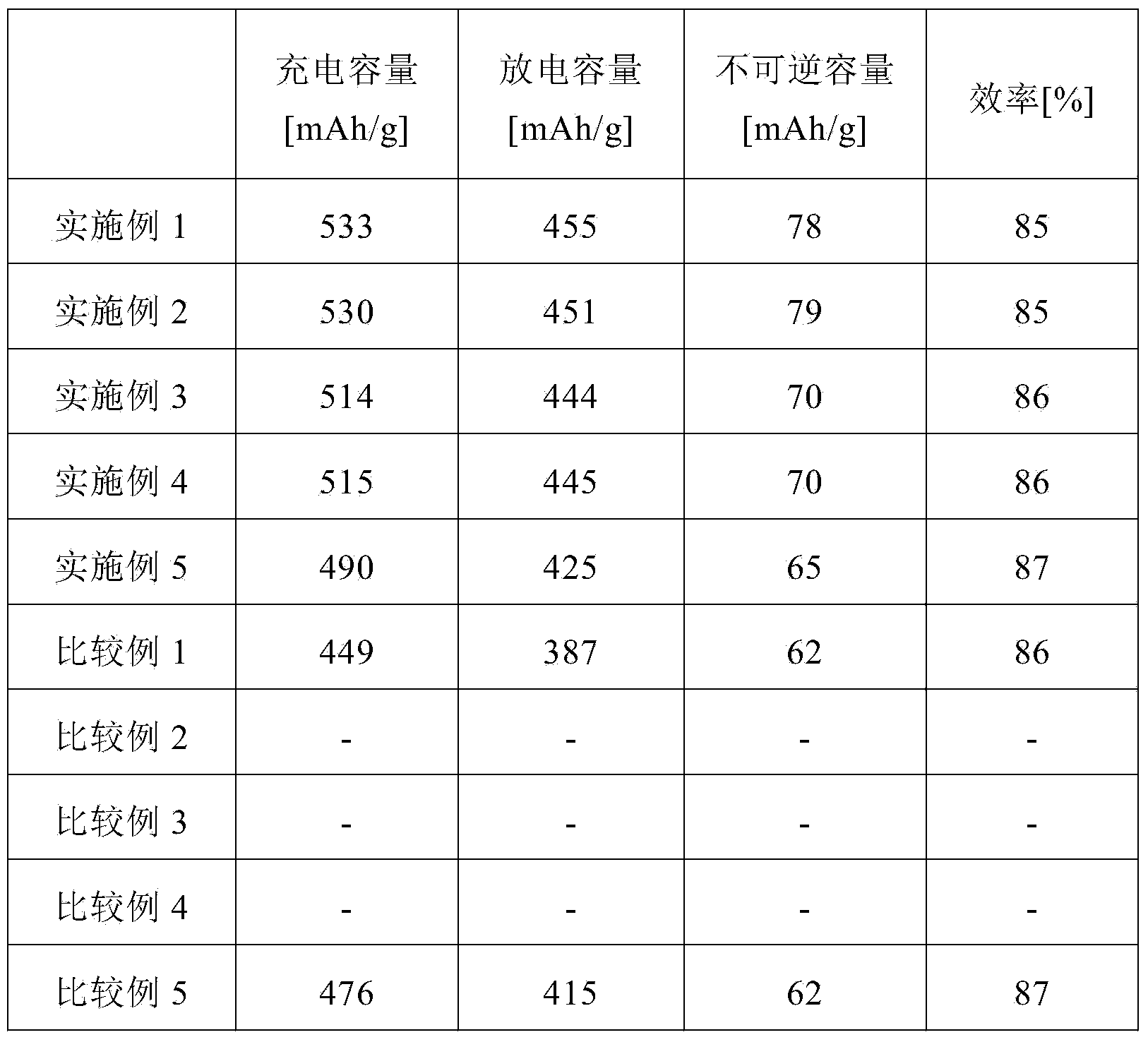

Carbonaceous material for negative electrodes of nonaqueous electrolyte secondary batteries, and method for producing same

ActiveCN104412425AExcellent electrical propertiesImprove securityCell electrodesFinal product manufactureAlkaline earth metalElemental analysis

The purpose of the present invention is to provide: a carbonaceous material for negative electrodes of nonaqueous electrolyte secondary batteries, which uses a plant-derived organic material as a starting material, and from which alkali metals such as potassium element and alkaline earth metals such as calcium element are sufficiently removed by decalcification, so that the carbonaceous material has high purity and excellent discharge capacity and efficiency; a novel production method which is capable of efficiently mass-producing the carbonaceous material; and a lithium ion secondary battery which uses the carbonaceous material. The above-mentioned purpose can be achieved by a carbonaceous material for negative electrodes of nonaqueous electrolyte secondary batteries, which is obtained by carbonizing a plant-derived organic material, and which has an atomic ratio of hydrogen atoms to carbon atoms (H / C) as determined by elemental analysis of 0.1 or less, an average particle diameter (Dv50) of 2-50 mum, an average interplanar spacing of the (002) plane as determined by a powder X-ray diffraction method of 0.365-0.400 nm, a potassium element content of 0.5% by mass or less and a calcium element content of 0.02% by mass or less.

Owner:KUREHA KAGAKU KOGYO KK

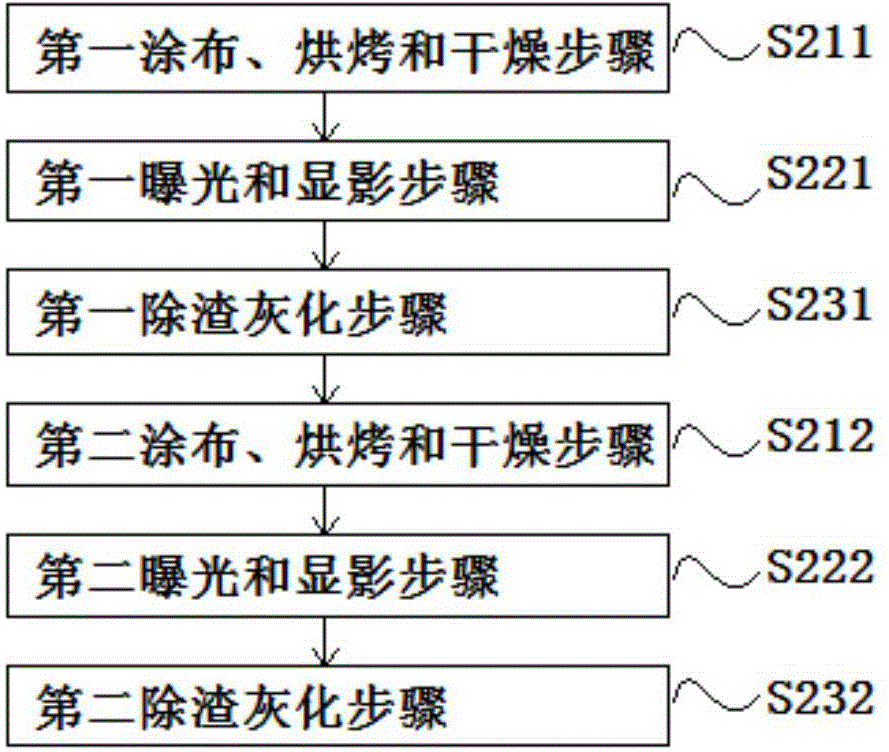

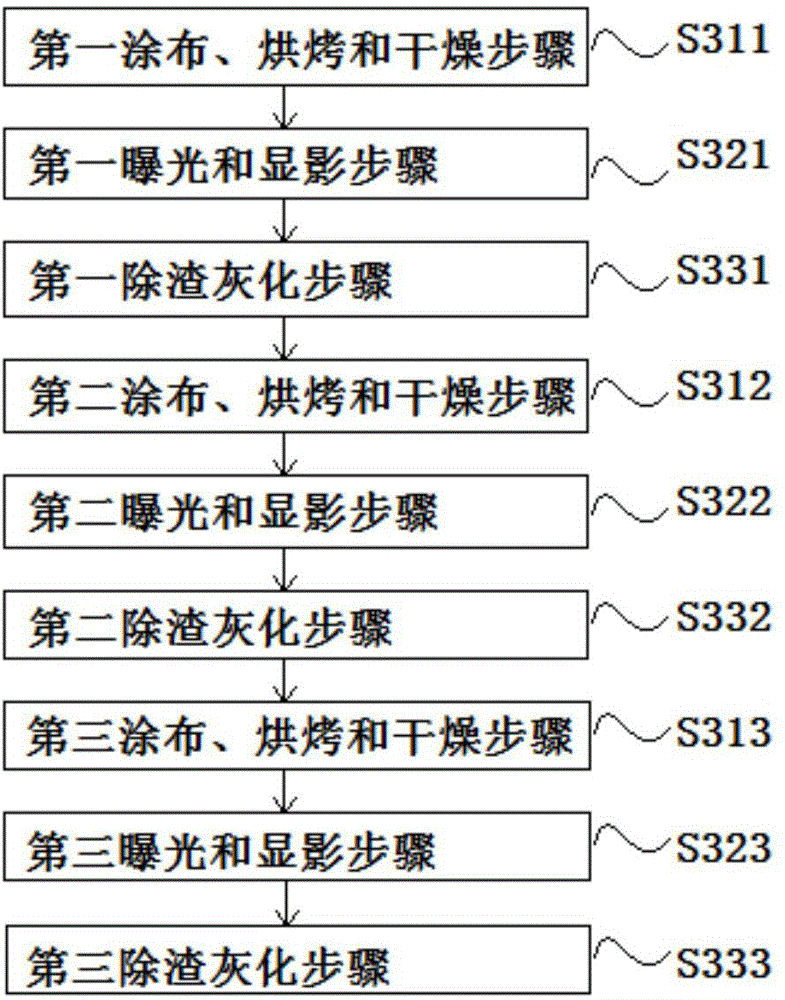

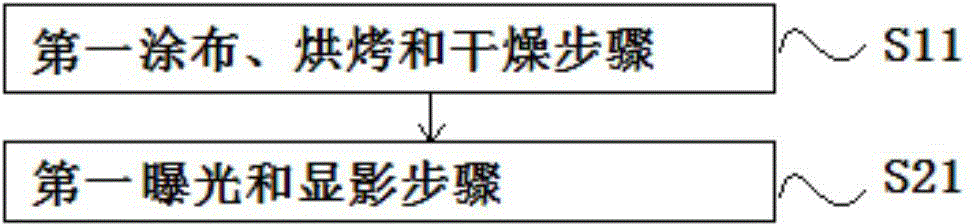

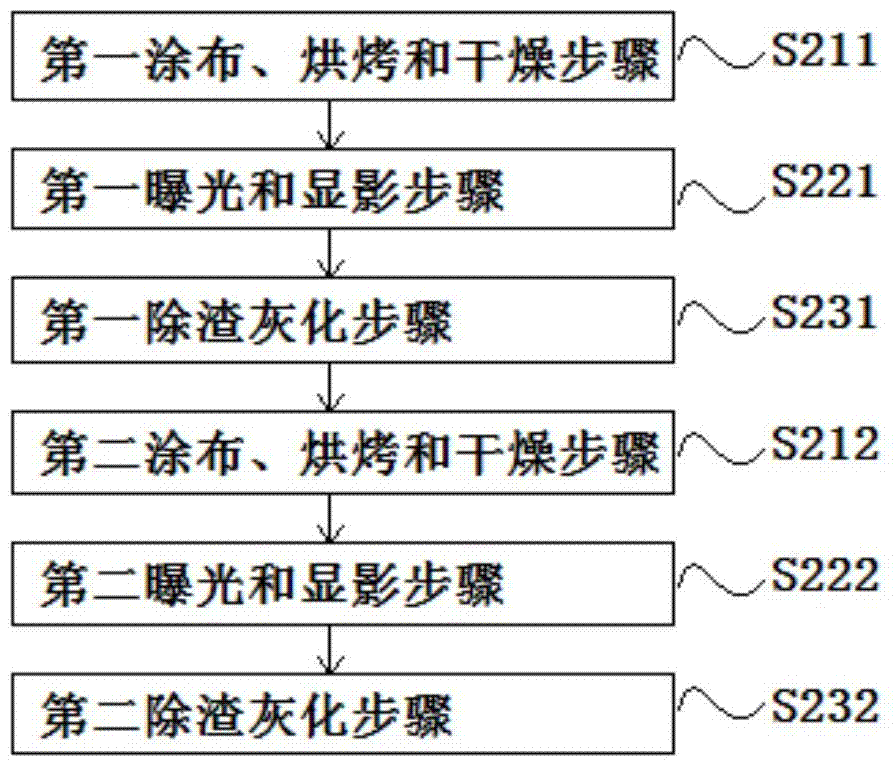

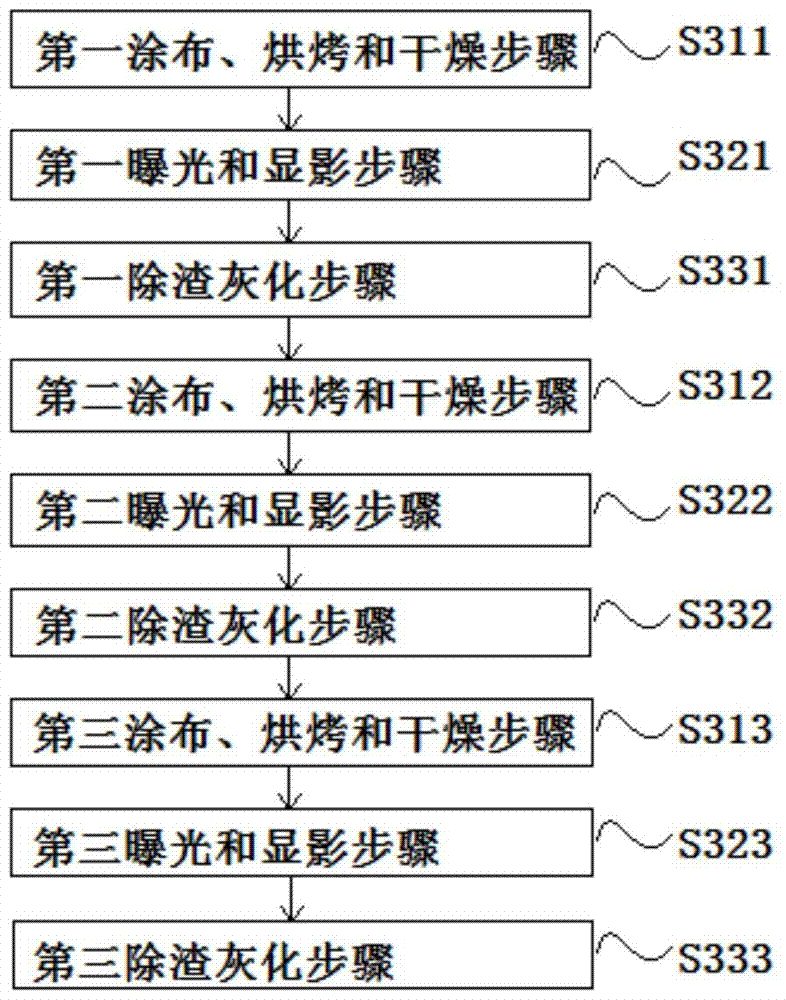

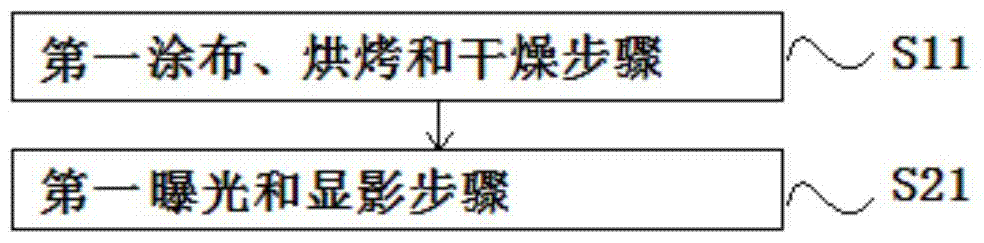

Manufacturing method of semiconductor planarization layer

ActiveCN104658906AAvoid surface hardeningEnsure consistencyPhotomechanical apparatusSemiconductor/solid-state device manufacturingCooking & bakingPhotoresist

The invention provides a manufacturing method of a semiconductor planarization layer. The manufacturing method comprises the following steps: a coating, baking and drying step, that is, a photoresist for forming a planarization layer is coated on a lower layer film and then the baking treatment and drying treatment are performed; an exposure and development step, that is, the exposure treatment and the development treatment are performed on the planarization layer after the coating, baking and drying step; the manufacturing method is characterized in that the coating, baking and drying step is carried out in at least twice according to the required coating thickness of the planarization layer to be manufactured; the exposure and development step is carried out for at least once. The manufacturing method can improve the taper angle of the planarization layer, reduce the undercut phenomenon of the planarization layer, and prevent the breakage of an upper layer film of the planarization layer, so as to improve the reliability of products.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

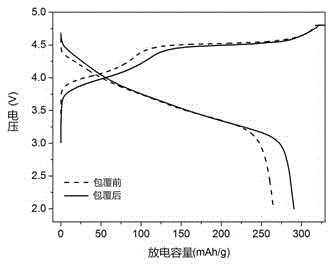

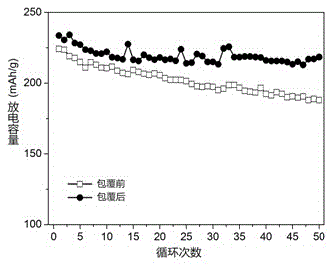

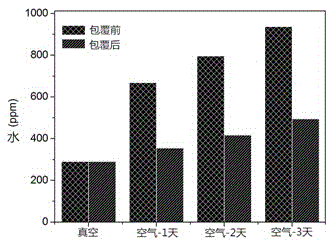

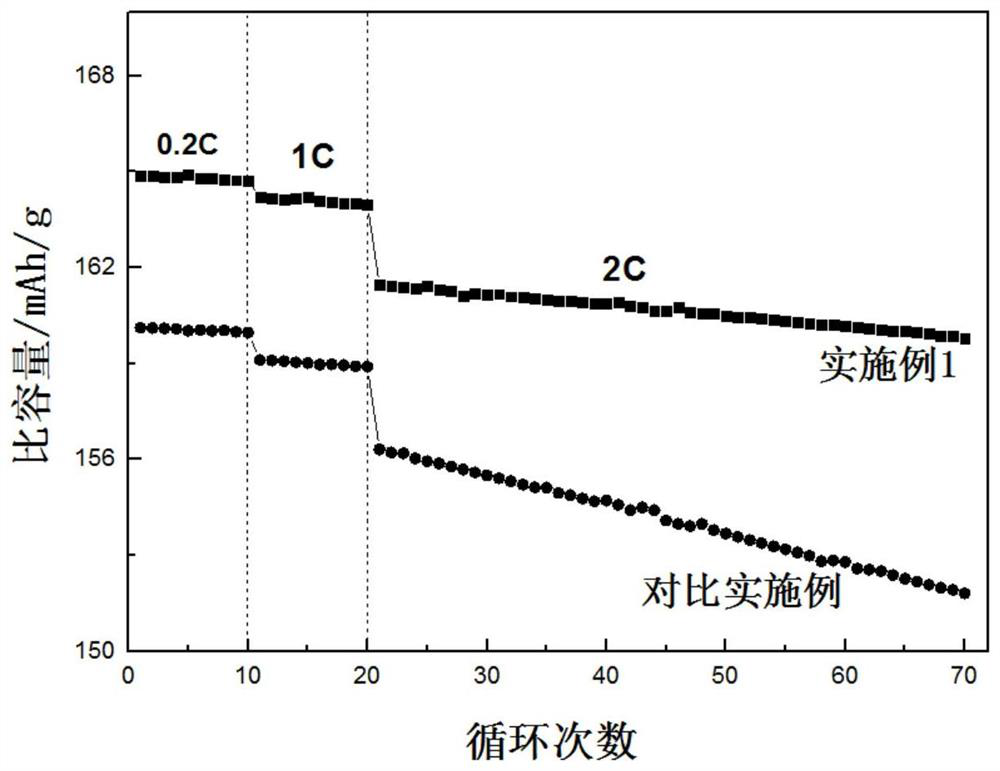

Surface modification method of anode material of lithium ion battery

ActiveCN105576215AImprove the first effectImprove cycle performanceSecondary cellsPositive electrodesCerium nitrateElectrical battery

The invention discloses a surface modification method of an anode material of a lithium ion battery. The surface modification method comprises the following steps of adding a smashed anode material of the lithium ion battery into a mixed solution prepared from cerium nitrate and neodymium nitrate, carrying out ultrasonic stirring after mixing by adding ammonium hydroxide, evaporating water and drying; pressing a dried sample into a flaky product after grinding and smashing the dried product, putting the flaky sample into a tubular furnace in which oxygen is continuously pumped, rising the temperature, calcining in the oxygen, then calcining in argon, and obtaining a finished product. According to the surface modification method disclosed by the invention, the anode material of the lithium ion battery is coated and modified through neodymium-doped nano cerium dioxide, so that the structure stability is maintained, the first cycle efficiency is increased, oxygen deficiency caused by disembedding of lithium ions is filled, and the structure stability of the anode material is maintained; meanwhile, a coating object has higher water absorbing resistance after being subjected to surface hydrophobization treatment.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

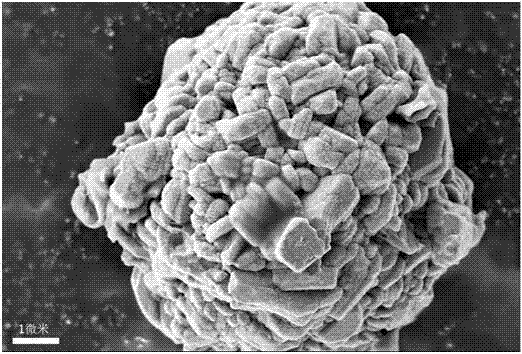

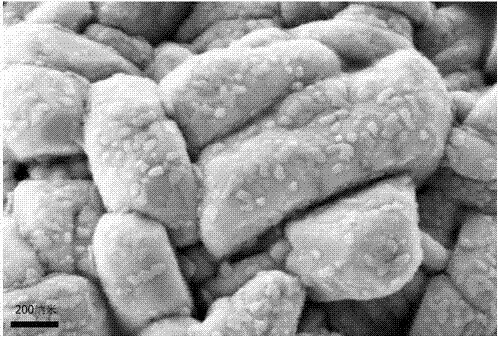

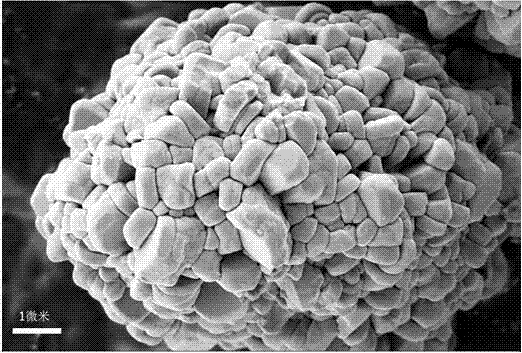

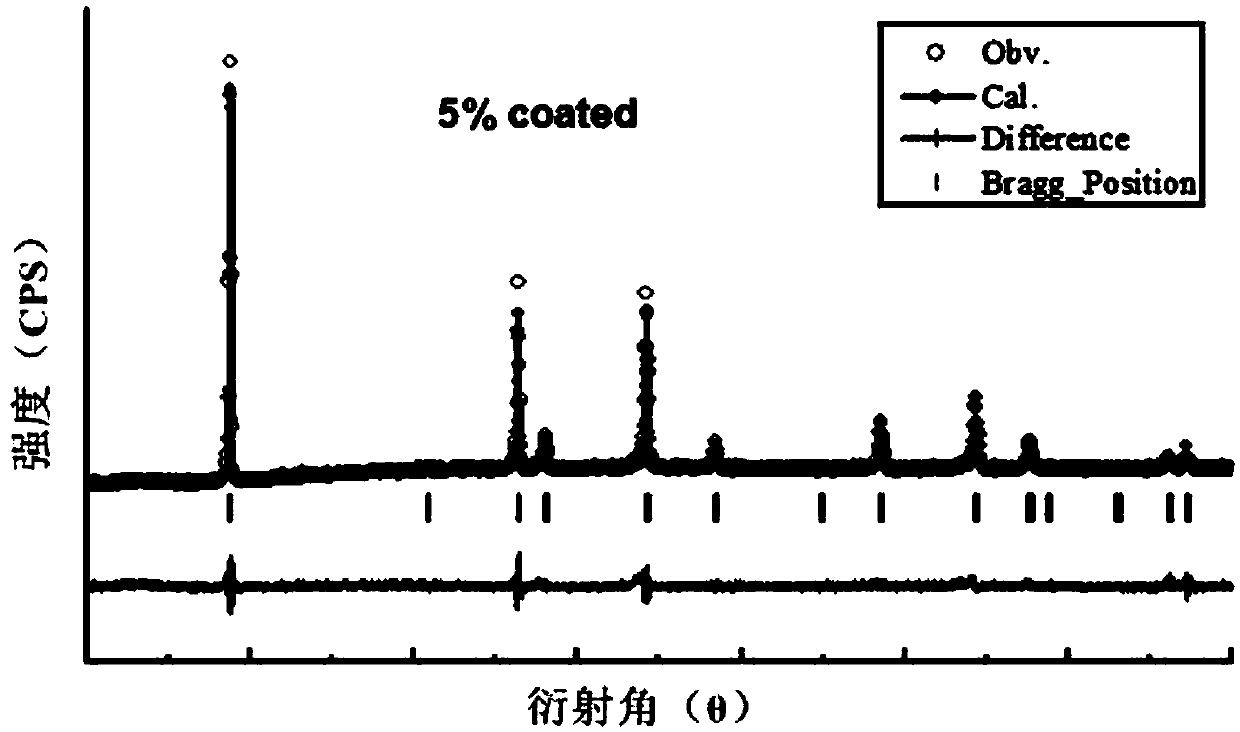

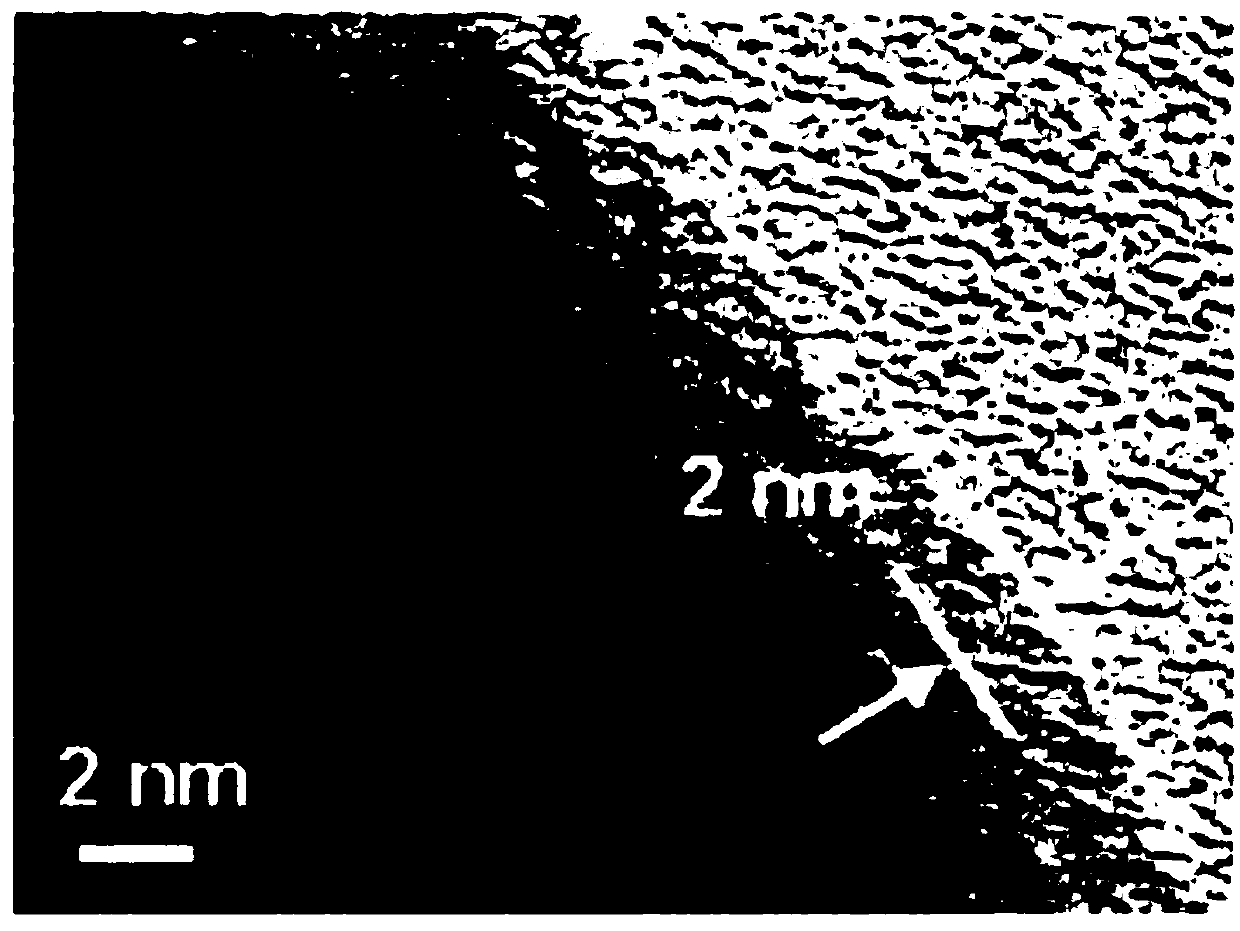

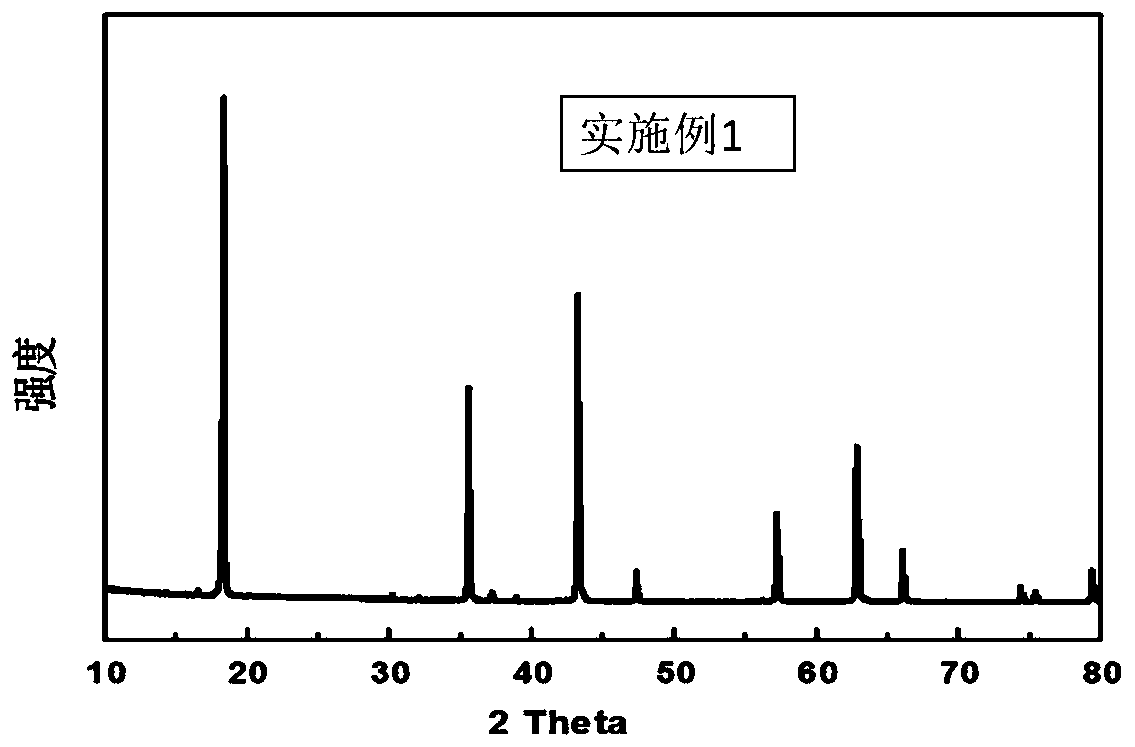

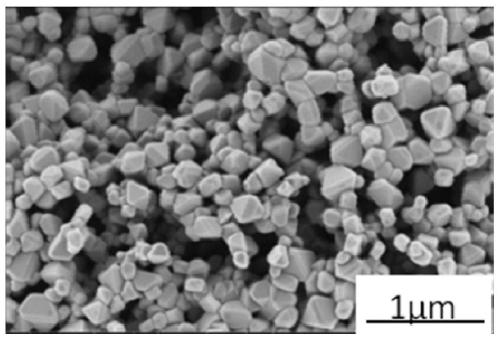

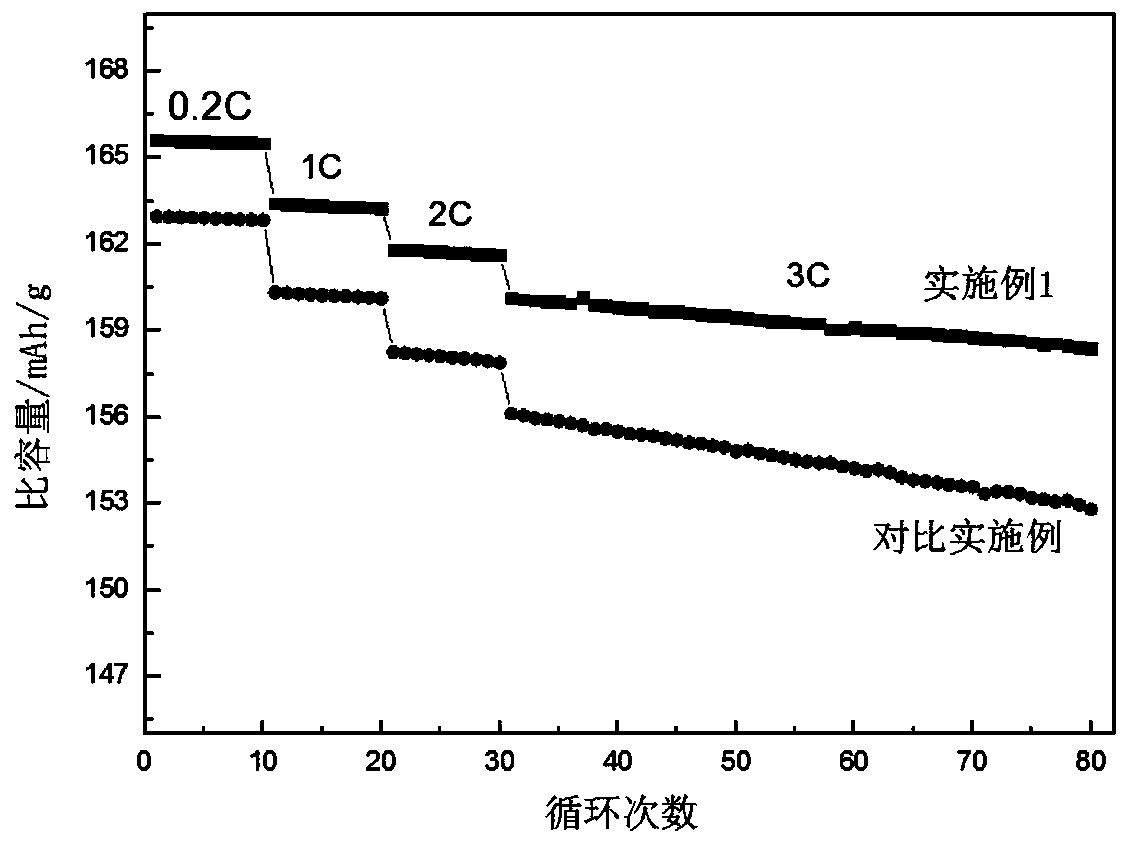

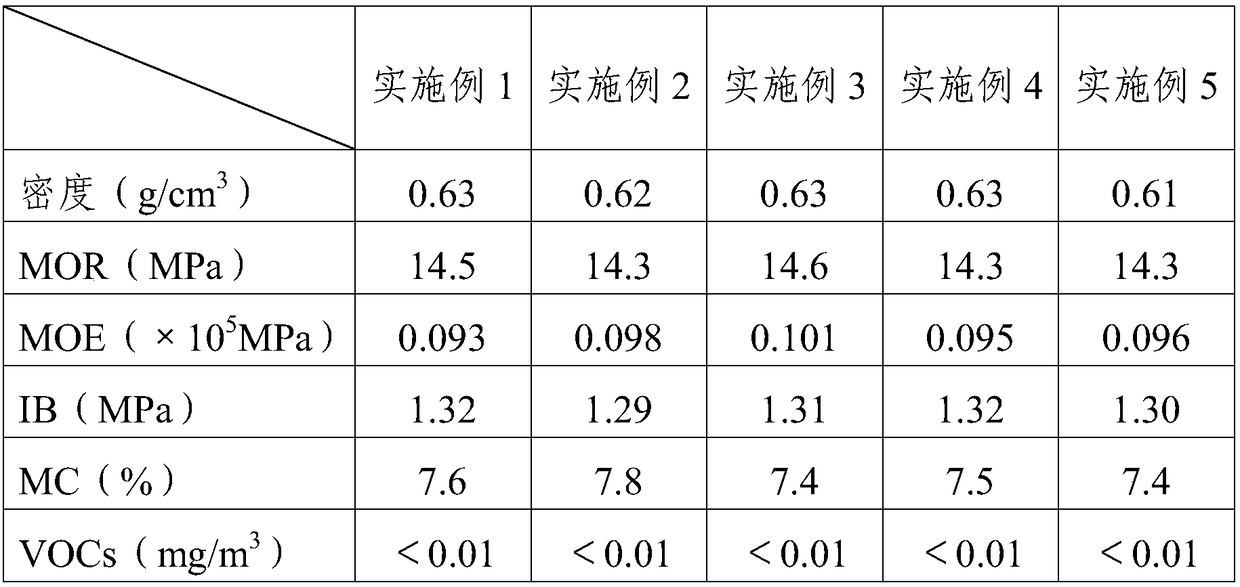

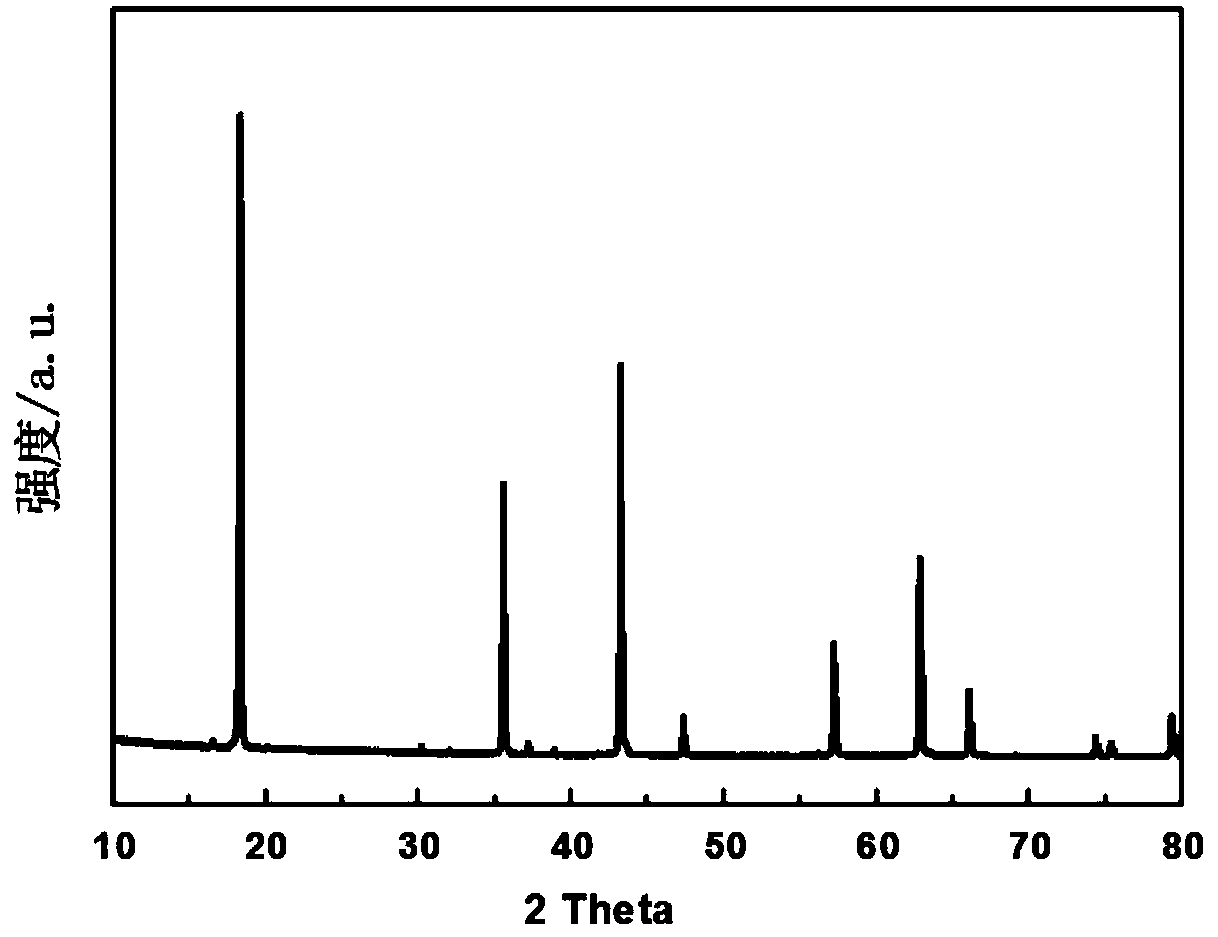

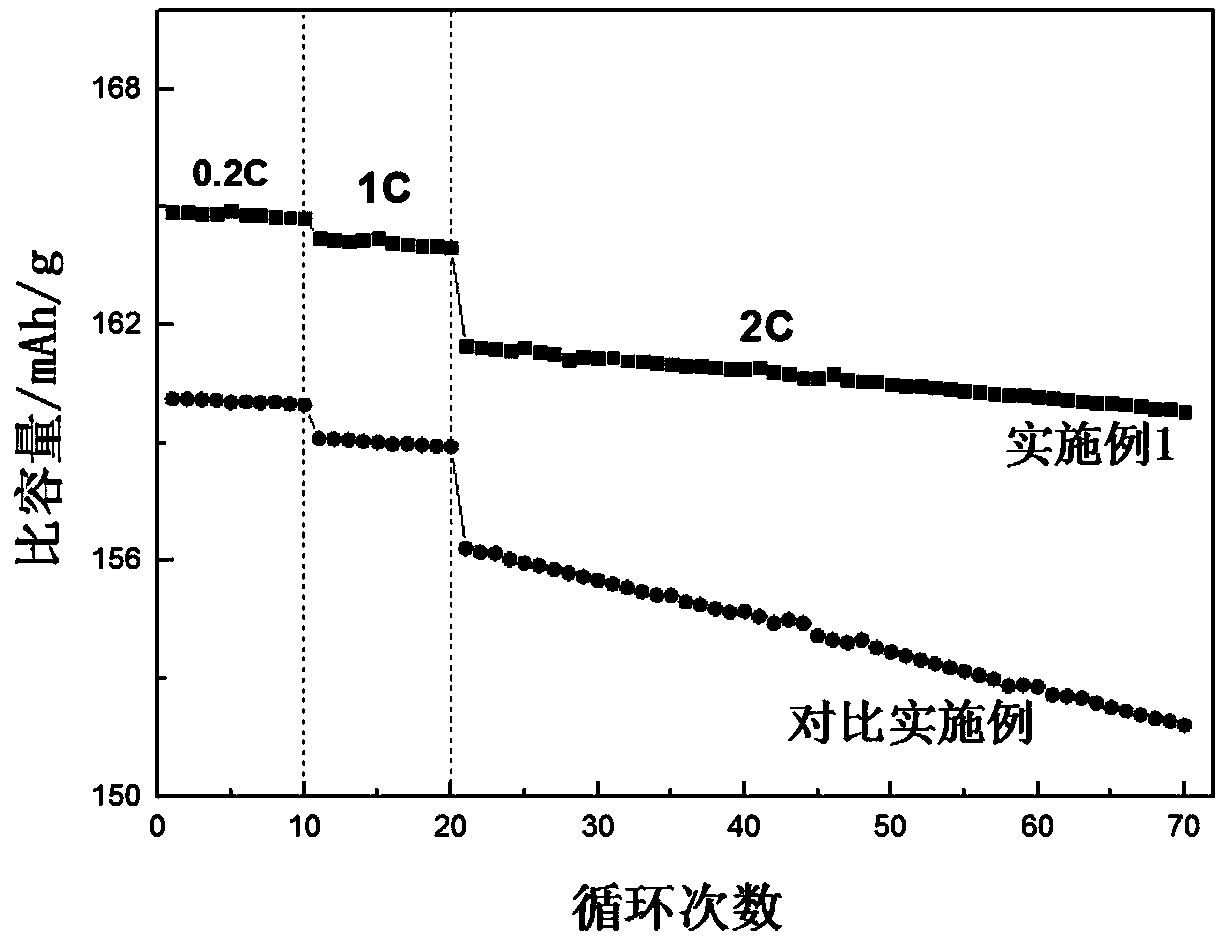

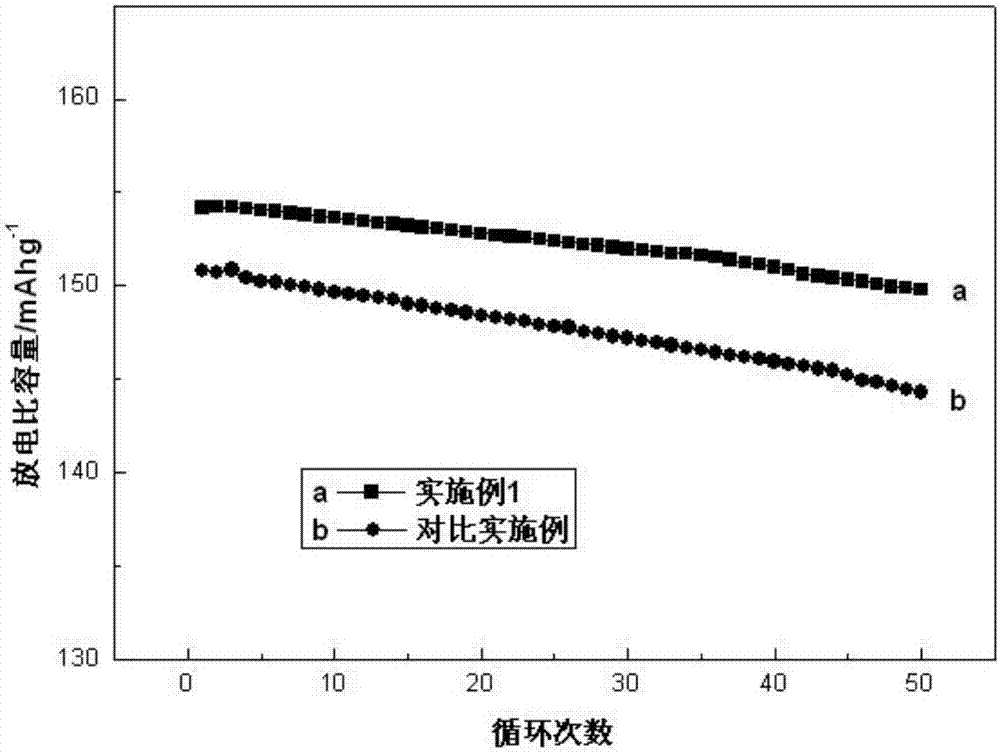

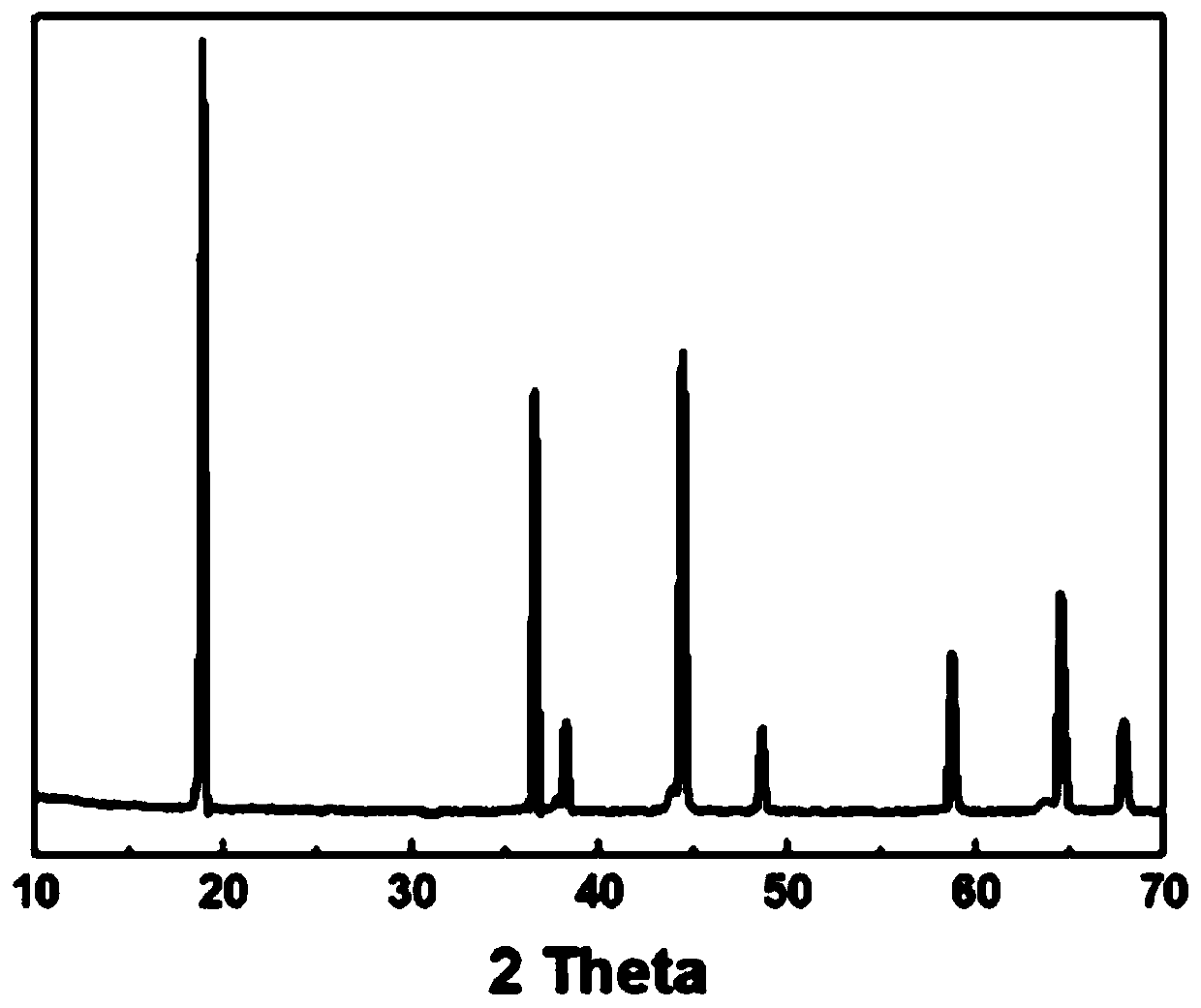

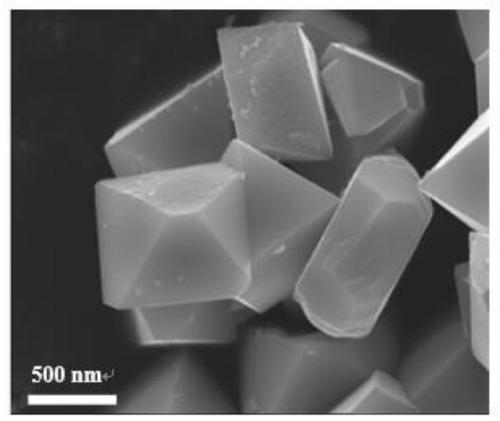

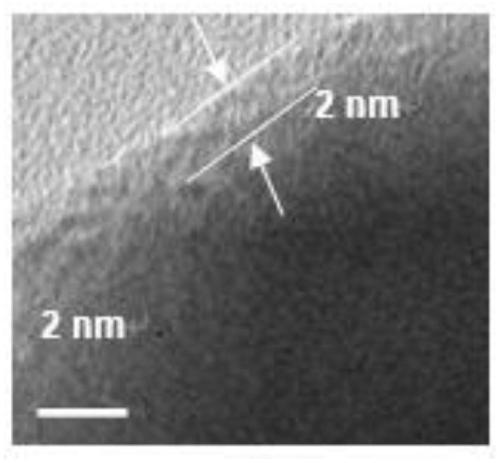

Surface coating type ternary positive electrode material and preparation method thereof

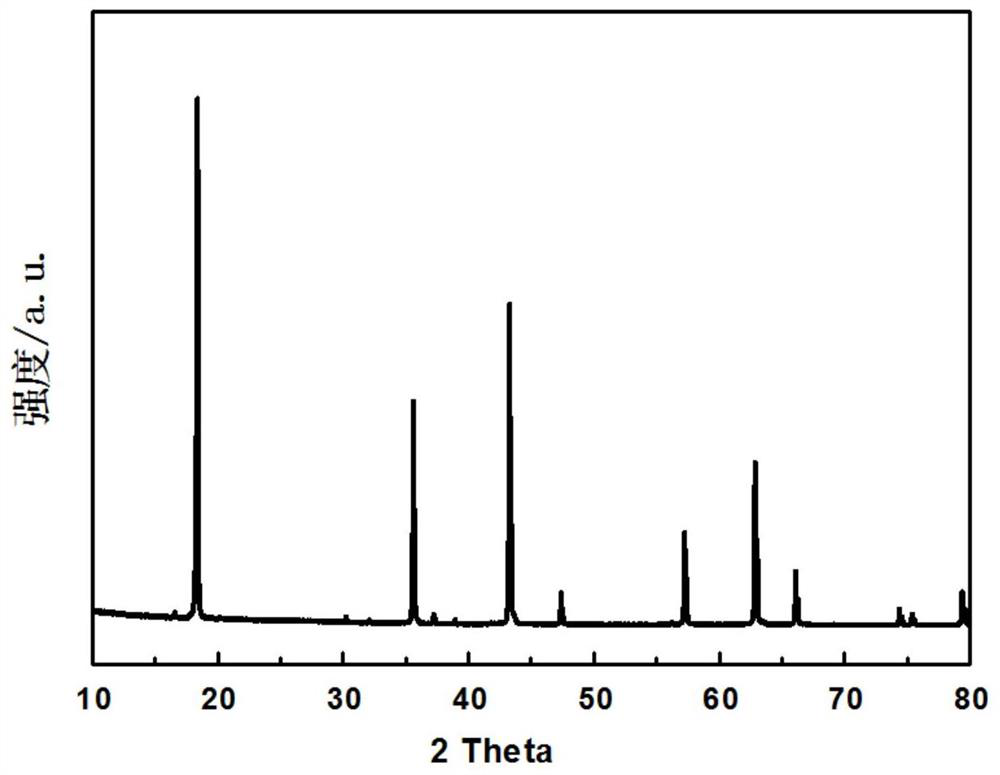

ActiveCN106941162AImprove cycle retentionImprove Interface StabilityMaterial nanotechnologyCell electrodesAlkalinityNanoparticle

The invention discloses a surface coating type ternary positive electrode material and a preparation method thereof, and belongs to the technical field of positive electrode materials of lithium ion batteries. The surface coating type ternary positive electrode material includes particles having the molecular formula of LiNi[x]Co[1-x-y]Mn[y]O[2], and the surface of the LiNi[x]Co[1-x-y]Mn[y]O[2] particles is covered with Li2MTiO4 nanoparticles, wherein M is at least one of metal elements of Ni, Co and Mn. A basic crystal phase structure of LiNi[x]Co[1-x-y]Mn[y]O[2] is not damaged, only the surface is coated with the new-phase nanoparticles, the surface protection is formed, and the stability of the interface of the surface of the positive electrode material and an electrolyte solution is increased, so the material circulation maintaining rate is further improved, and the electrochemical performance is enhanced. The surface alkalinity of the positive electrode material is lowered, the hygroscopic property is suppressed, and the processing performance is improved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

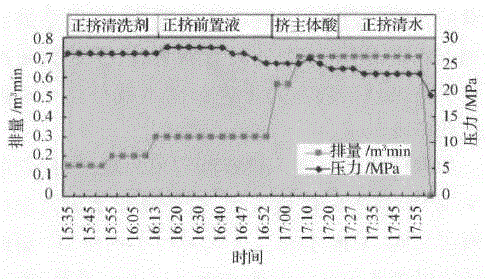

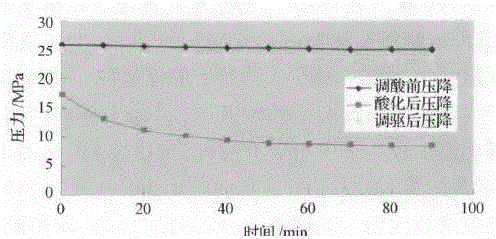

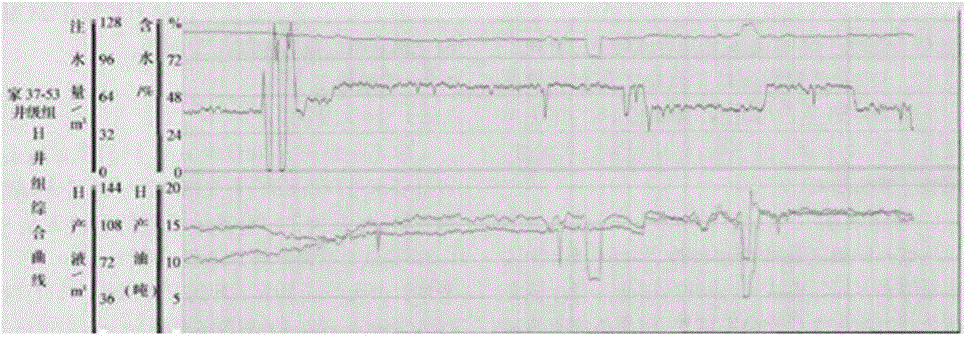

Modified oilfield acid regulation integrated technique

InactiveCN105298436AAdjustable intensityReach \"blockingFluid removalSealing/packingThermodynamicsOil field

The invention discloses a modified oilfield acid regulation integrated technique and aims to provide an oilfield deep profile controlling and flooding technique which allows continuous construction, fewer moving string steps, simple process, low risk and low cost. The acid regulation integrated technique is continuously carried out for construction according to a sequence of temporary plugging process, acid regulation process and profile regulation process. The technique also comprises a cleaner injection process. The technique is suitable for water injection wells, having great inter-reservoir differences, non-uniform inter-reservoir suction profiles, low water injection pressure with high water injection quantity, and severe injected water rush in high permeable layers.

Owner:天津立坤石油技术服务有限公司

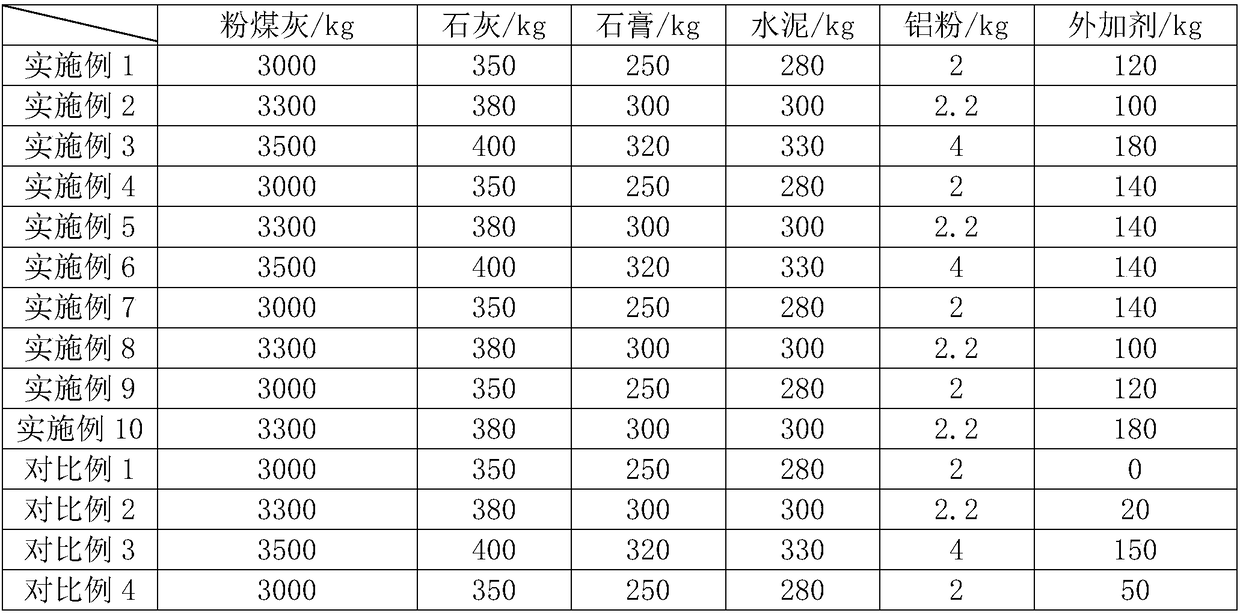

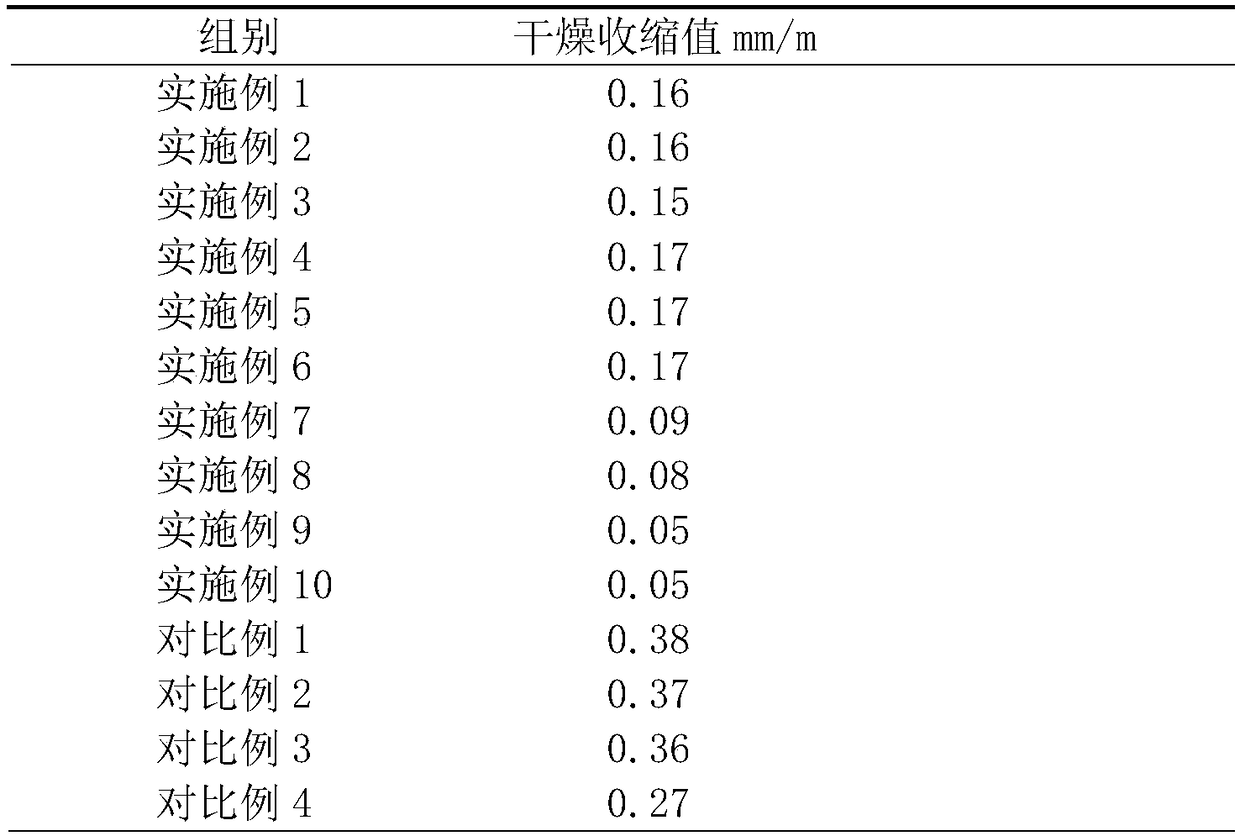

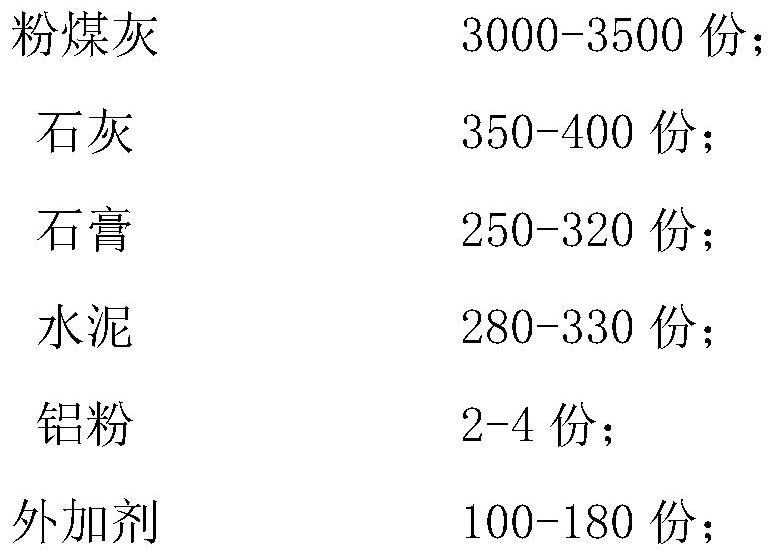

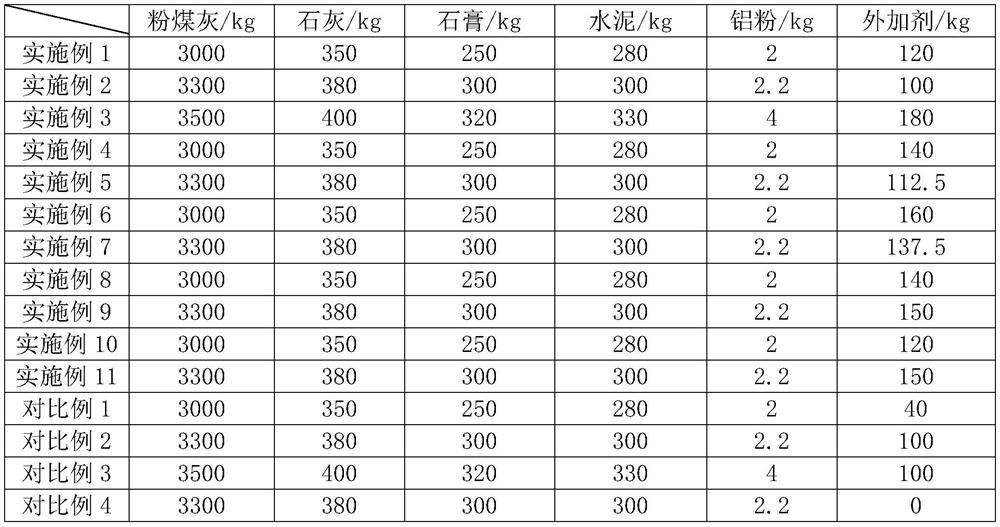

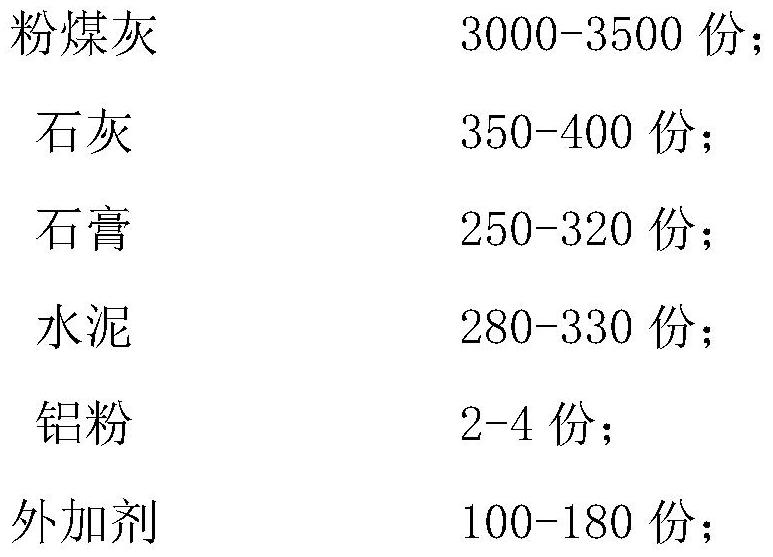

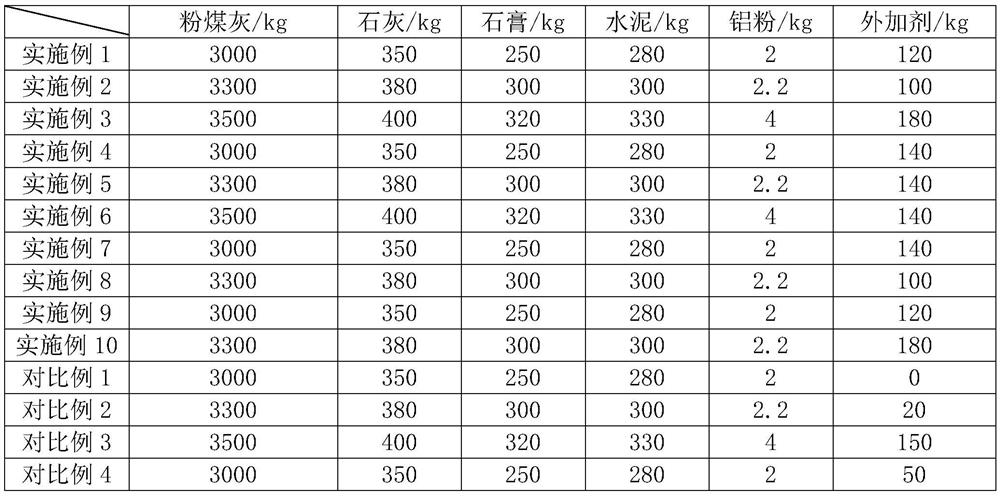

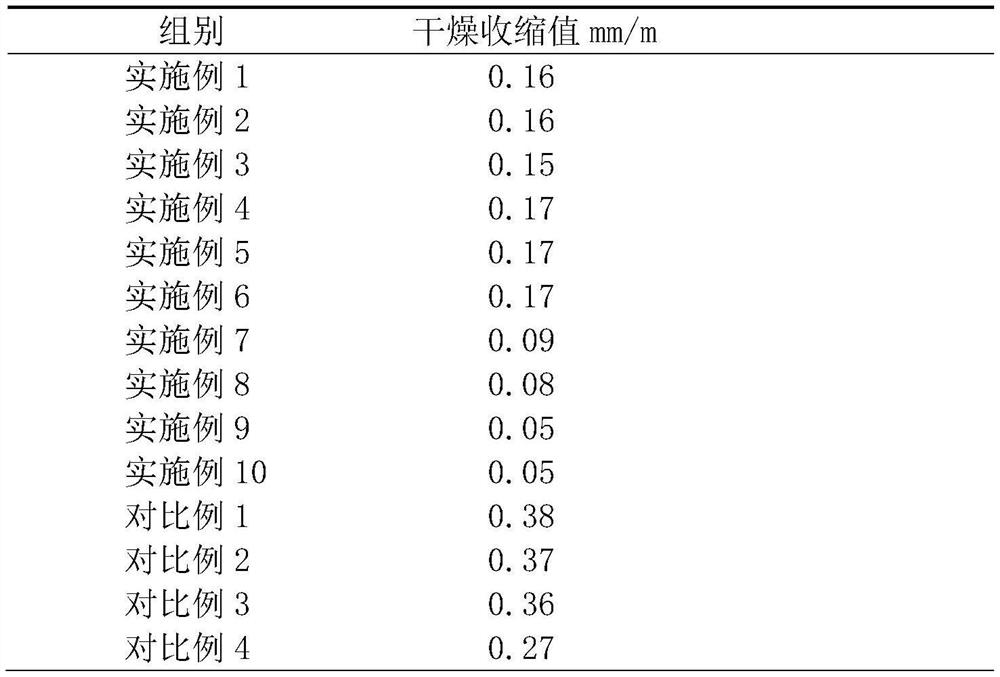

Fly ash autoclaved aerated concrete blocks and production method thereof

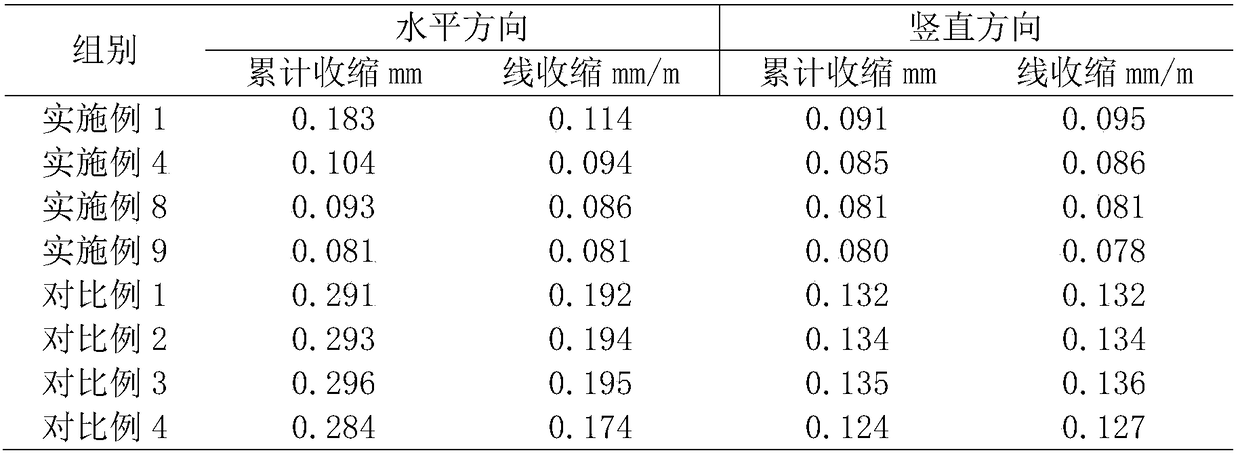

The invention relates to the technical field of preparation of building materials and discloses fly ash autoclaved aerated concrete blocks and a production method thereof. The concrete blocks compriseraw materials including materials and water; the materials include, by weight, 3000-3500 parts of fly ash, 350-400 parts of lime, 250-320 parts of gypsum, 280-330 parts of cement, 2-4 parts of aluminum powder and 100-180 parts of admixture; the admixture includes a butyl acrylate / vinyl acetate / 2-acrylamide-2-methylpropanesulfonic acid terpolymer and calcium stearyl lactate. The concrete blocks and the production method thereof have the following advantages and effects that industrial waste slag fly ash is used as a raw material to reduce the discharge amount and protect the environment; the admixture in the raw materials not only improves the hydrophobicity of pores of the fly ash autoclaved aerated concrete blocks, reduces the amount of water absorbed from coated mortar, but also can effectively reduce the drying shrinkage value of the blocks, reduce the deformation amount of the blocks in a drying process, and the effects that the environment is protected, the drying shrinkage valueis low and phenomena such as cracking and hollowing after the blocks are built into a wall are achieved.

Owner:襄阳华壁新型建材有限公司

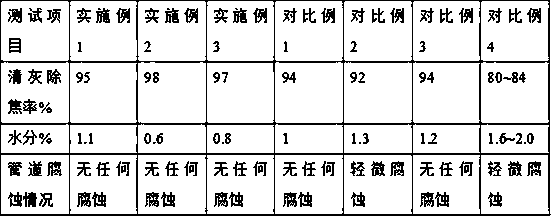

Boiler ash-cleaning and decoking agent and preparation method thereof

InactiveCN108219894AInhibition of donenessInhibited compressive strengthFuel additivesCelluloseChemical treatment

The invention discloses a boiler ash-cleaning and decoking agent and a preparation method thereof, which belong to the technical field of boiler decoking. After a cellulose molecule in a corn stalk ischemically activated, hydroxy sealed in a cellulose crystal is exposed and is initiated through an initiating agent so as to be subjected to grafting reaction with a monomer, and under the action ofthe initiating agent, the activated corn stalk, methyl methacrylate, butyl acrylate and acrylamide are in graft copolymerization synthesis, so that the boiler ash-cleaning and decoking agent is well-behaved in ash powder maturity inhibition, compressive strength, water-retaining property, water-absorbing property and freeze-thaw resistance, has an adsorption effect on ash content in a boiler, andcan be used for fixing ash powder in the boiler so as to remove the ash powder. The boiler ash-cleaning and decoking agent provided by the invention solves the problems that a current boiler ash-cleaning and decoking agent is not remarkable in effect when being used in the coal-fired boiler, forms a vitreous body after being added into a hearth, cannot remove coking but enables the cokes to be even more firm, and is poor in wettability, the cost of the decoking agent is increased due to the use of rare earth oxide, and the raw material source are deficient.

Owner:CHANGZHOU DINGRI ENVIRONMENTAL PROTECTION TECH

Collapsible mold and method of manufacturing the same

InactiveCN101844206BImprove surface propertiesInhibition of water absorptionFoundry mouldsFoundry coresMoisture absorptionCarbon dioxide

In a collapsible mold and a method of manufacturing the same, the collapsible mold has extremely low moisture-absorption properties, does not change in surface properties thereof due to absorption of moisture and swelling, and is storable for a long time without absorbing moisture and swelling. Specifically, the method manufactures a collapsible mold containing at least any of calcium oxide and magnesium oxide. The method includes a step of bringing the collapsible mold into contact with carbon dioxide immediately after a step of burning the collapsible mold or a step of casting the collapsible mold.

Owner:SUZUKI MOTOR CORP

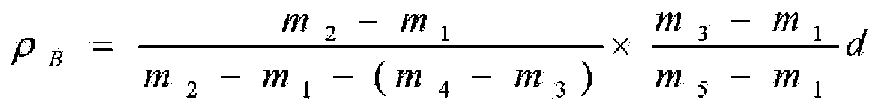

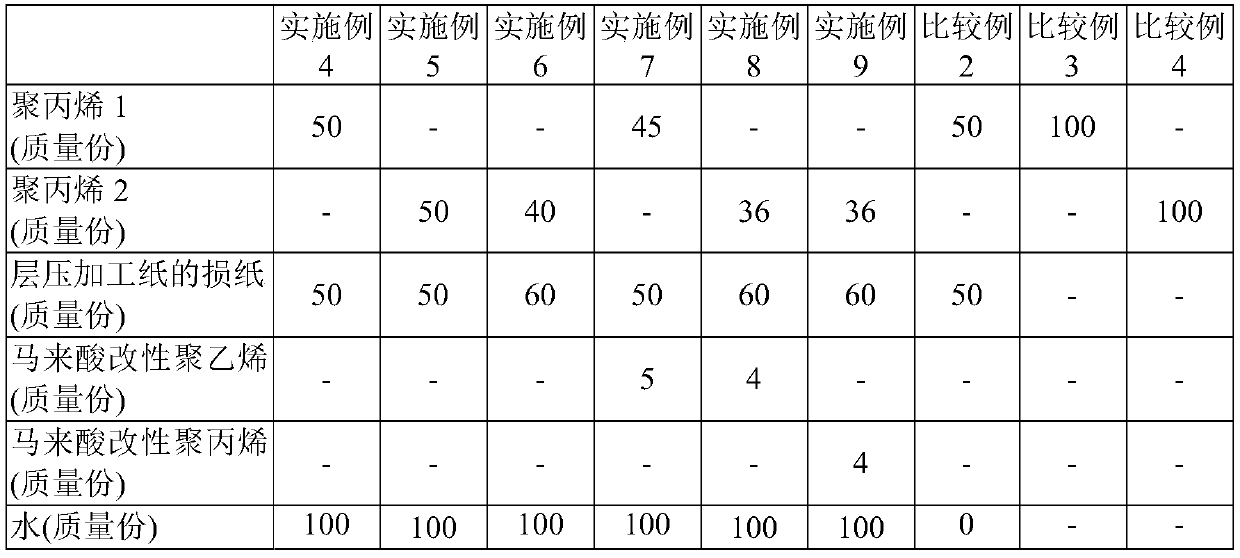

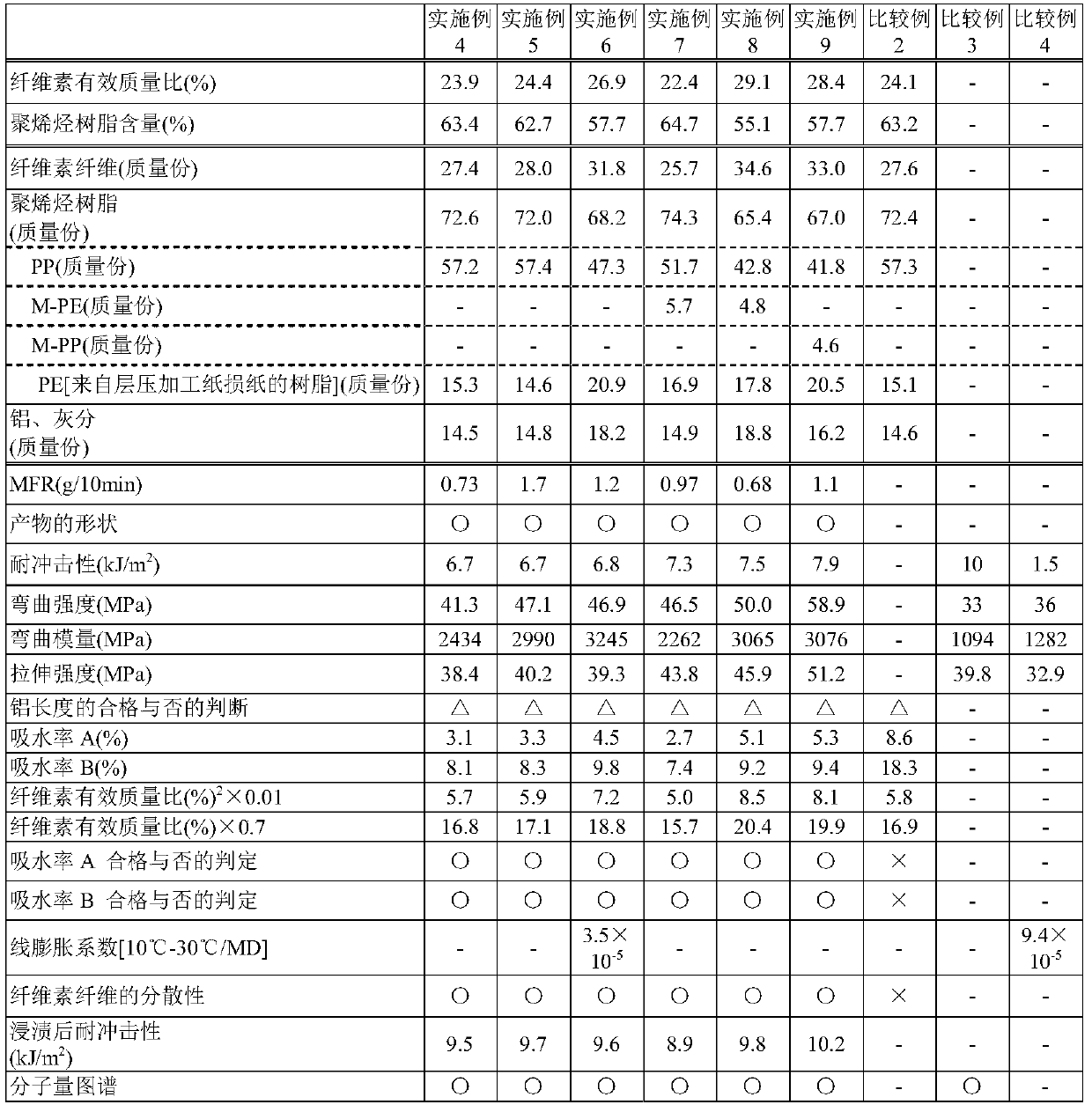

Cellulose fiber-dispersed polyolefin resin composite material, pellet and molded article using same, and method for producing cellulose fiber-dispersed polyolefin resin composite material

InactiveCN111065679AHigh mechanical strengthInhibition of water absorptionPlastic recyclingPolymer sciencePolyolefin

Provided are: a cellulose fiber-dispersed polyolefin resin composite material obtained by dispersing cellulose fibers in a polyolefin resin which contains a polypropylene resin, wherein the proportionof cellulose fibers constitutes 1-70 parts by mass, inclusive, of the 100 parts by mass which is the total mass of the polyolefin resin and the cellulose fibers, and the water absorption rate satisfies the subsequent formula; a pellet and molded article which use the composite material; and a method for producing the composite material. Formula: (water absorption rate)<(cellulose effective mass ratio)2*0.01

Owner:FURUKAWA ELECTRIC CO LTD

Surface modification method for composite lithium nickel manganese oxide positive electrode material

InactiveCN107681146AImprove structural stabilityHigh temperature conductivitySecondary cellsPositive electrodesDissolutionManganese oxide

The invention discloses a surface modification method for a composite lithium nickel manganese oxide positive electrode material. The method comprises the following steps of dissolving a lithium source, a manganese source, a nickel source and a yttrium source into deionized water to form solutions separately, dropwise adding various solutions into a citric acid solution separately, stirring to form a mixed solution, adjusting the pH value and carrying out heating to form dried gel; pre-sintering and grinding the dried gel and carrying out thermal treatment to form a yttrium-doped lithium nickel manganese oxide material; and dispersing [Y<1-x>Mg<x>][Cr<1-x-y>Sn<y>Ga<z>]O3 and the yttrium-doped lithium nickel manganese oxide material into the deionized water at a mass ratio of 0.05:1, stirring to form a mixture and carrying out washing, filtering and annealing treatment to obtain the coated yttrium-doped lithium nickel manganese oxide positive electrode material. The structure stability,the high-temperature conductivity and the cycle performance of the material are improved, side reaction of the material and an electrolyte and dissolution of metal ions can be suppressed, and the interface stability of the material is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

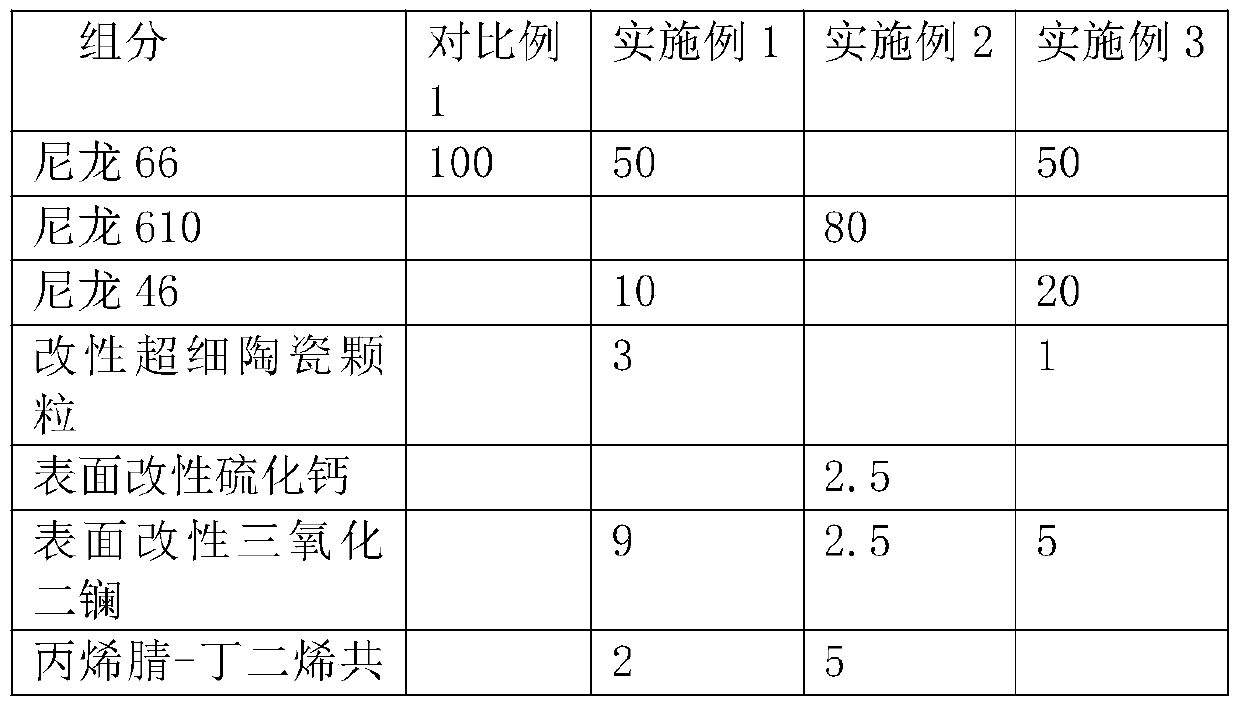

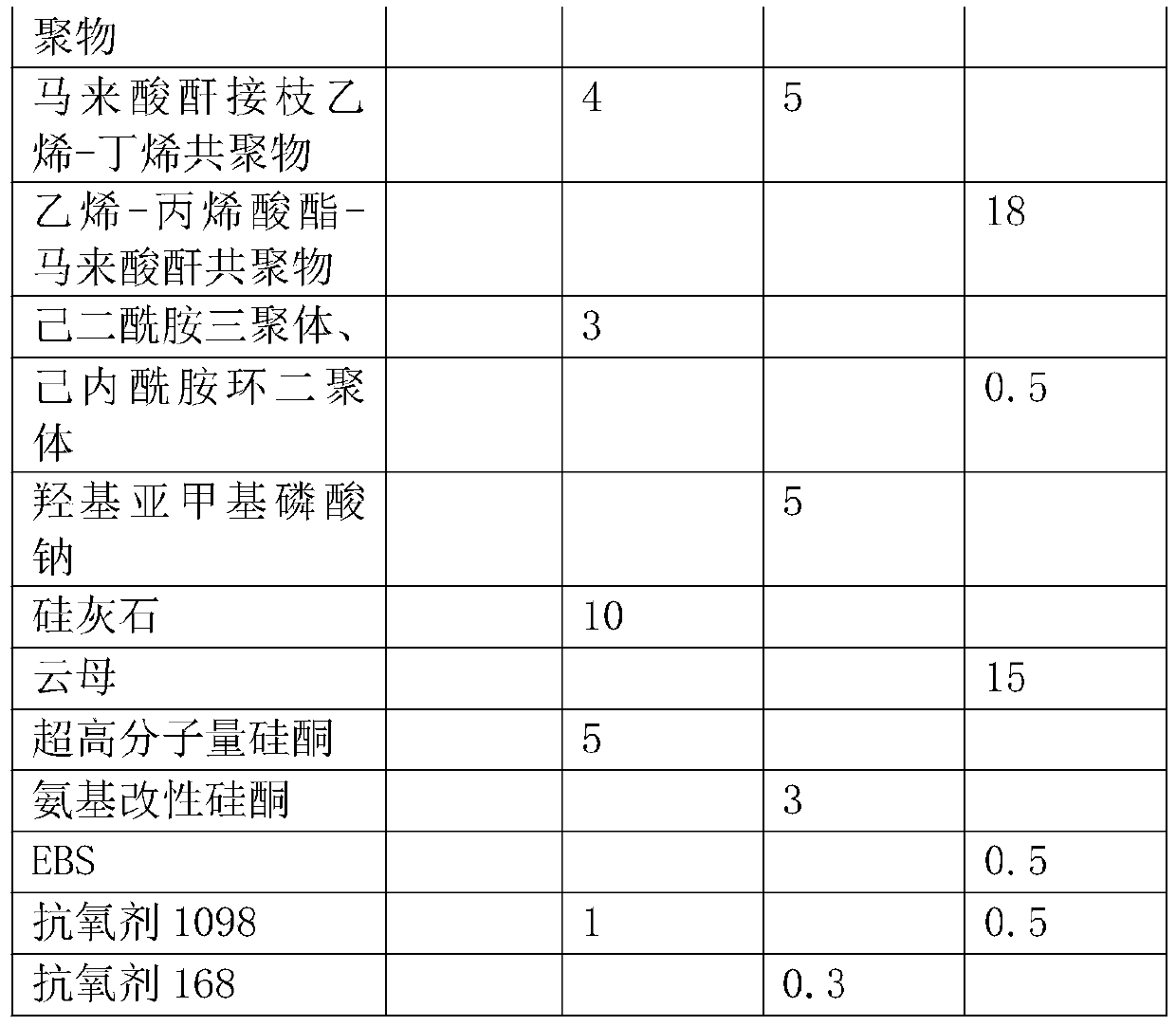

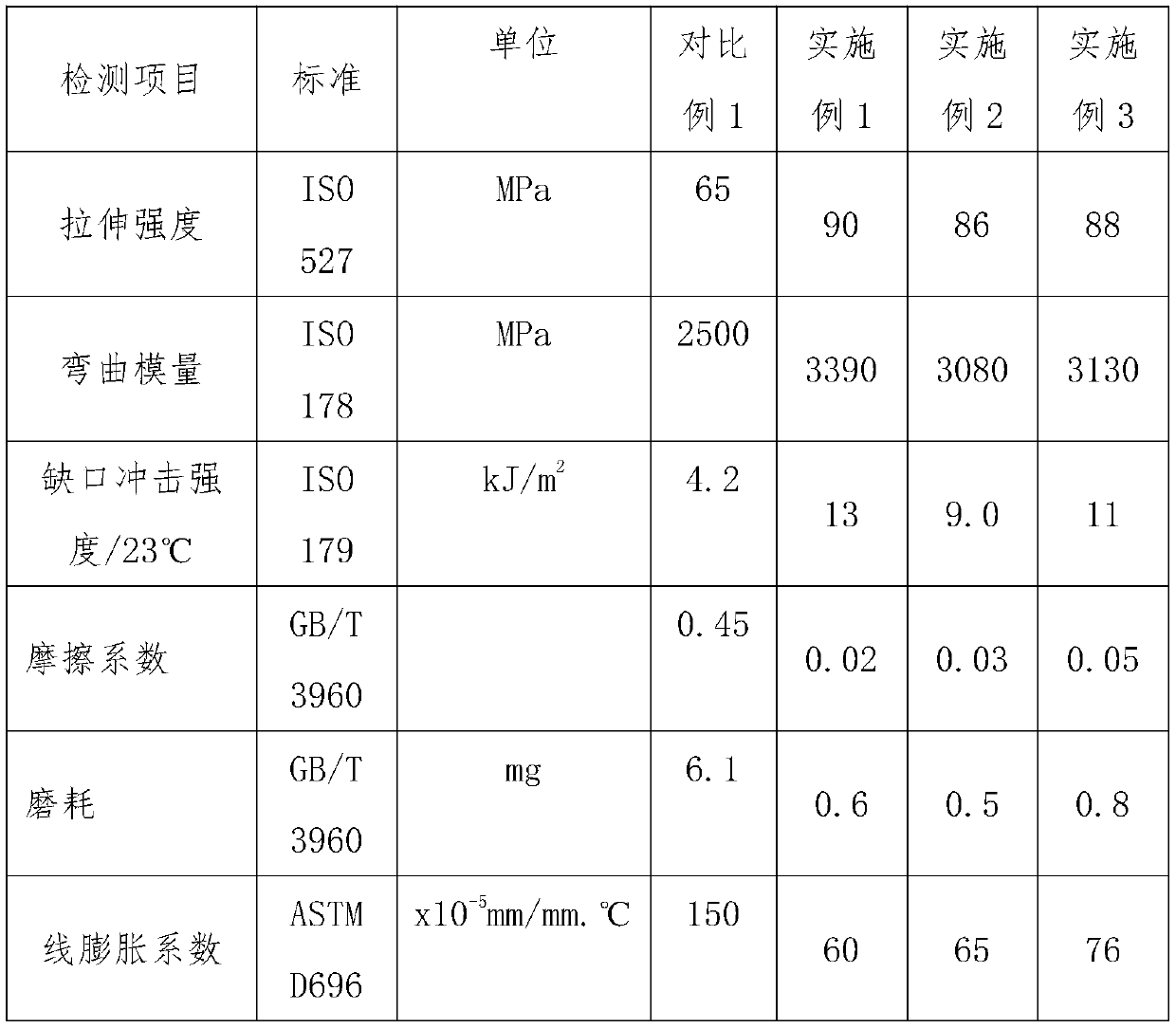

High-wear resistance and high-dimensional stability steering turbine material and preparation method thereof

PendingCN110964317AInhibition of water absorptionSmall coefficient of linear expansionThermal ageingPolyamide

The invention relates to a high-wear resistance and high-dimensional stability steering turbine material and a preparation method thereof. The material comprises the following components by weight: 60-80 parts of polyamide, 5-12 parts of a wear-resistant assistant, 0-15 parts of a filling agent, 6-18 parts of an anti-shrinking agent, 0.5-5 parts of a nucleating agent, 0.5-5 parts of a lubricatingagent and 0.3-1 part of an antioxidant. The high-wear resistance and high-dimensional stability steering turbine material disclosed by the invention has very good mechanical properties, and has the characteristics of self-lubricating properties, small friction coefficient, excellent wear resistance, long service life, easy processing, good molding performance, excellent mechanical properties, goodheat resistance, excellent low-temperature resistance and the like, and a hollow blow molding product has the characteristics of light weight, high strength, good dimensional stability, excellent heat resistance, high apparent quality, high yield, short molding period and the like; in addition, the product also has good long-term thermal aging performance.

Owner:NANJING JULONG SCI&TECH CO LTD

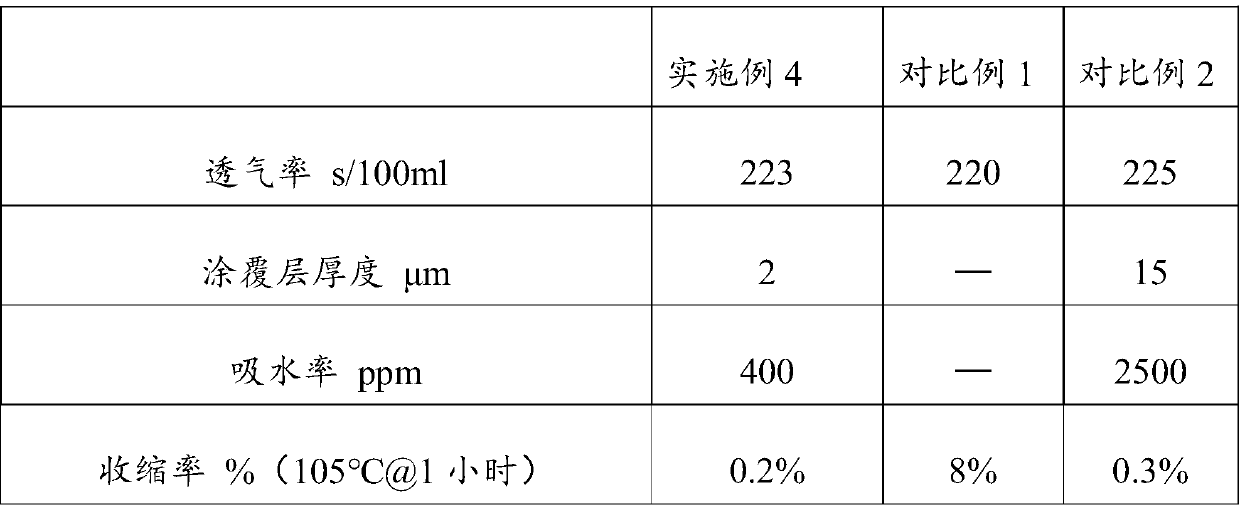

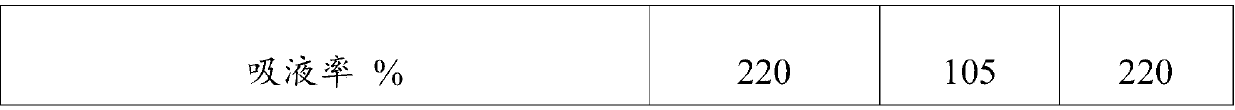

Composite isolation membrane and preparation method thereof

ActiveCN110408075AEfficient Flame RetardancyGood dimensional stabilityFibre typesSecondary cellsSlurryIsolation membrane

The invention belongs to the technical field of high-performance lithium battery isolation membranes, and particularly relates to a composite isolation membrane and a preparation method thereof. The preparation method of the composite isolation membrane includes the following steps that 1, after pretreated metal oxide powder and an organic lubricant are mixed, ball-milling dispersion is performedto obtain a surface-hydrophobic metal oxide; 2, the surface-hydrophobic metal oxide, a binder and water are mixed to obtain coating slurry; 3, the coating slurry coats the surface of the isolation membrane and is dried to obtain the composite isolation membrane. The composite isolation membrane is used for solving the technical defect of large water absorbability of the traditional isolation membrane.

Owner:GUANGDONG UNIV OF TECH

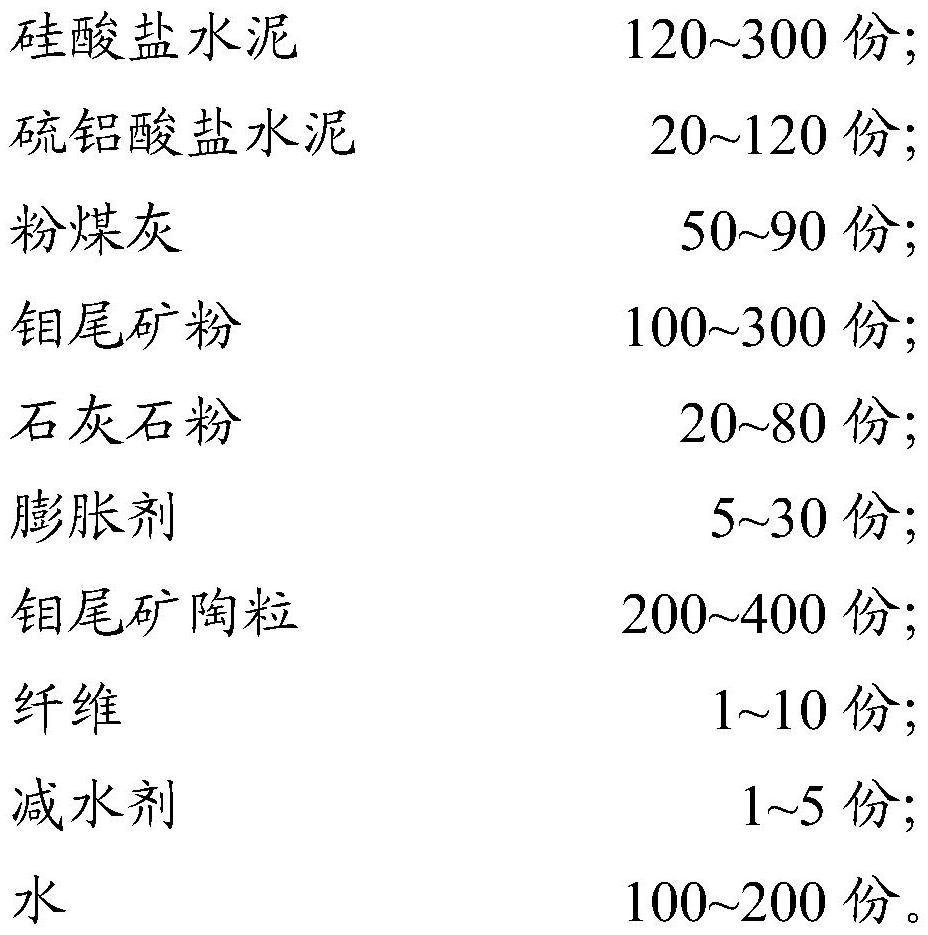

Self-compacting mortar and preparation method thereof

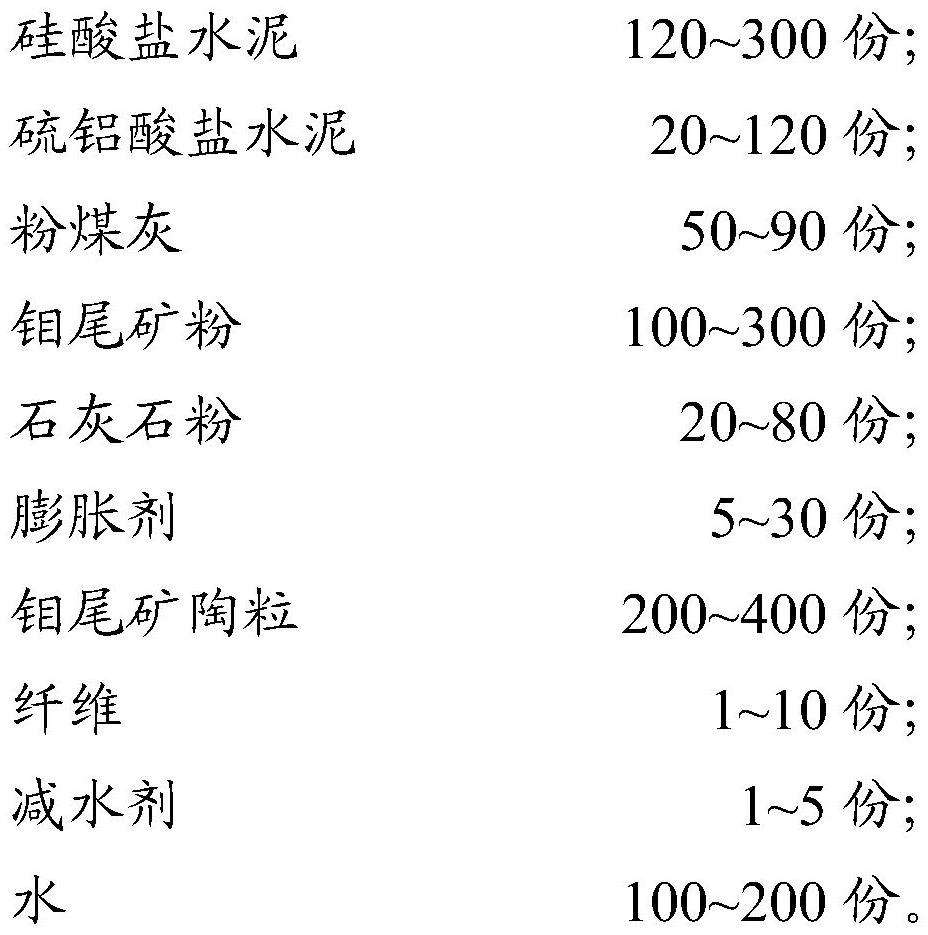

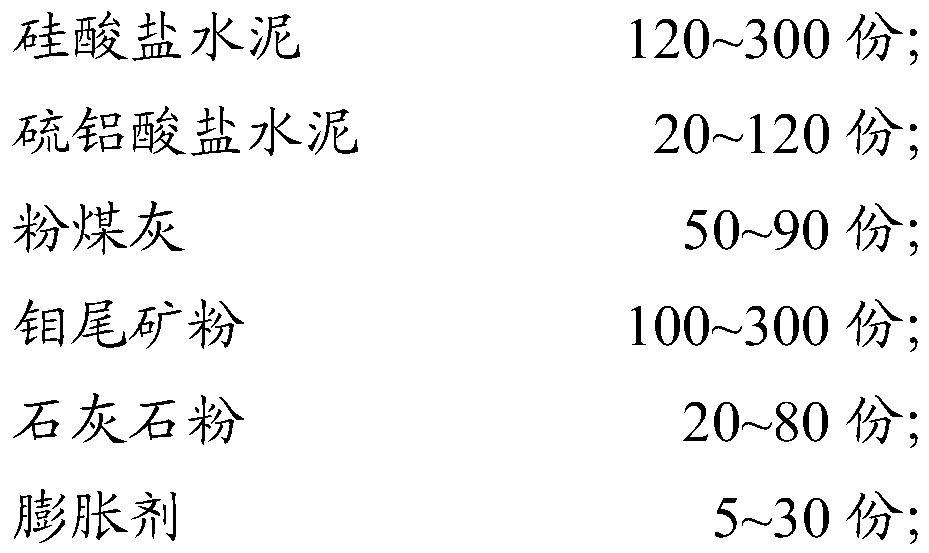

PendingCN112645666ARealize resource utilizationInhibition of water absorptionSolid waste managementAluminateFiber

The invention belongs to the field of building materials, and particularly relates to self-compacting mortar and a preparation method thereof. The self-compacting mortar provided by the invention comprises the following components in parts by weight: 120-300 parts of Portland cement; 20-120 parts of sulphoaluminate cement; 50-90 parts of fly ash; 100-300 parts of molybdenum tailing powder; 20-80 parts of limestone powder; 5-30 parts of an expanding agent; 200-400 parts of molybdenum tailing ceramsite; 1-10 parts of fibers; 1-5 parts of a water reducing agent; and 100-200 parts of water. According to the mortar provided by the invention, the molybdenum tailing powder and the molybdenum tailing ceramsite are used as production raw materials, so that resource utilization of molybdenum tailings is realized; the construction time of the mortar can be adjusted within 20min-1h, the initial setting time is 2-4h, the 28d strength reaches C30-C50, and the volume weight is within 2000kg / m < 3 >; in addition, the mortar does not need to be vibrated manually in the whole casting process, and construction is convenient.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

A kind of fly ash autoclaved aerated concrete block

ActiveCN109320283BSmall drying shrinkageInhibition of water absorptionCeramicwareMaterials preparationSlag

The invention relates to the technical field of building material preparation, and discloses a fly ash autoclaved aerated concrete block. The raw materials include materials and water, and the mass ratio of water and materials is 0.55-0.6:1; Including the following components, 3000-3500 parts of fly ash; 350-400 parts of lime; 250-320 parts of gypsum; 280-330 parts of cement; 2-4 parts of aluminum powder; The invention has the following advantages and effects: using industrial waste slag fly ash as raw material, reducing the discharge of fly ash and protecting the environment; the admixture in the material can improve the hydrophobicity of the pores of the fly ash autoclaved aerated concrete block , reduce its absorption of water from the applied mortar, and can significantly reduce the drying shrinkage value of the fly ash autoclaved aerated concrete block, reduce the deformation of its drying shrinkage, and achieve environmental protection, small drying shrinkage value, masonry The effect of cracking, hollowing and deformation is not easy to appear behind the wall.

Owner:襄阳华壁新型建材有限公司

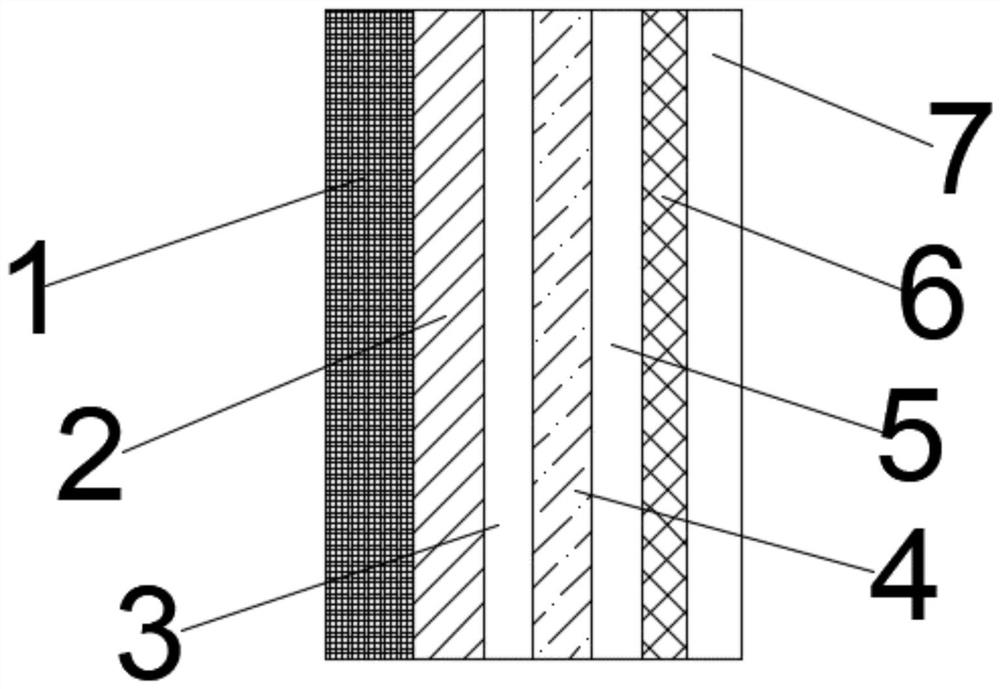

A waterproof building exterior wall insulation structure and its construction method

ActiveCN112049278BGuaranteed waterproof performanceGuaranteed insulation effectCovering/liningsWallsInsulation layerThermal break

The invention relates to the field of building construction, in particular to a waterproof building exterior wall thermal insulation structure and a construction method thereof, comprising an exterior wall body, the surface of the exterior wall body is sequentially provided with a leveling layer, a first bonding layer, thermal insulation layer, second adhesive layer, waterproof layer and protective layer. The invention solves the problem that in the prior art, due to the compressibility and high water absorption rate of rock wool, after it is prepared into a thermal insulation layer structure, the tensile strength is weak and it is easy to absorb a large amount of water to increase the weight of the thermal insulation layer, thereby causing thermal insulation The layer is separated from the wall, and the thermal insulation effect becomes poor.

Owner:瑞洲建设集团有限公司

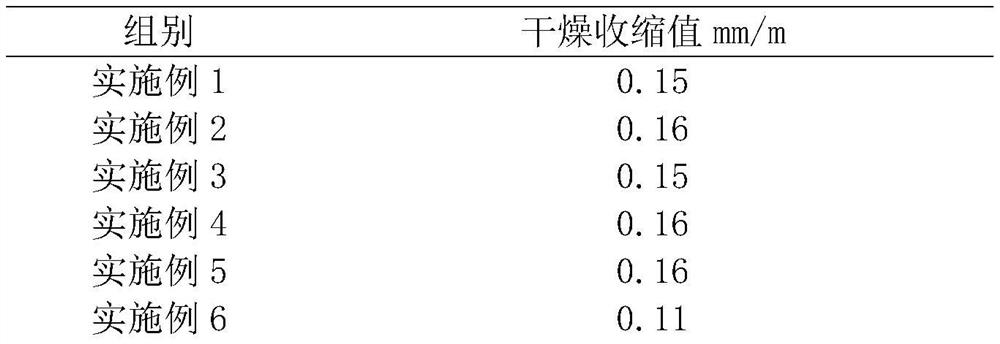

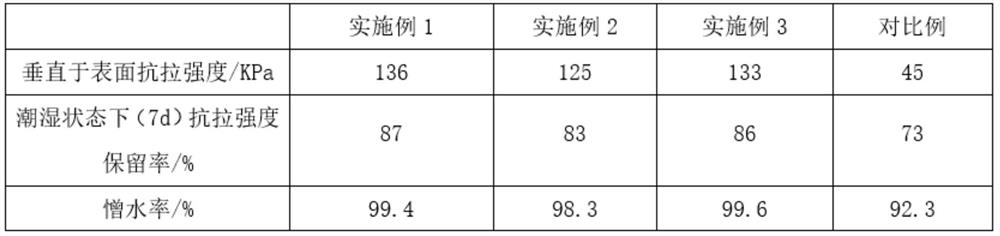

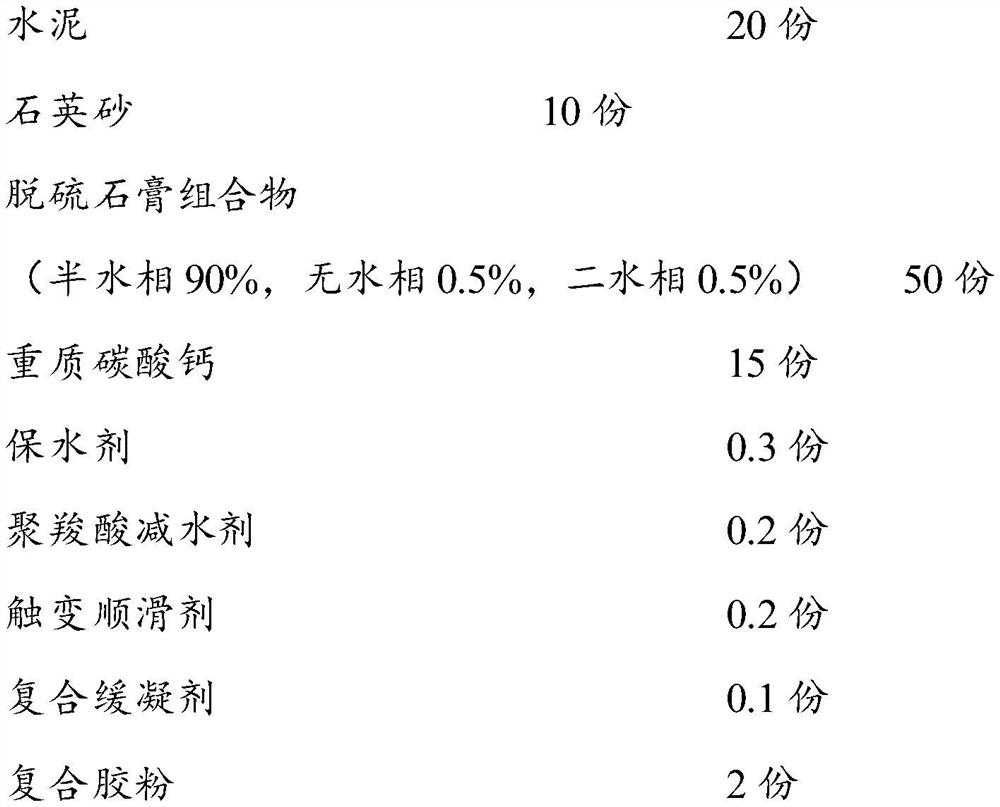

Desulfurization gypsum composition and preparation method, gypsum-based interior wall putty and application

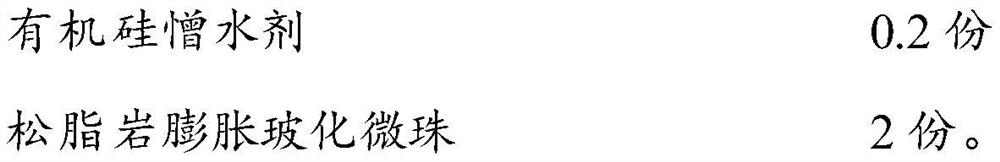

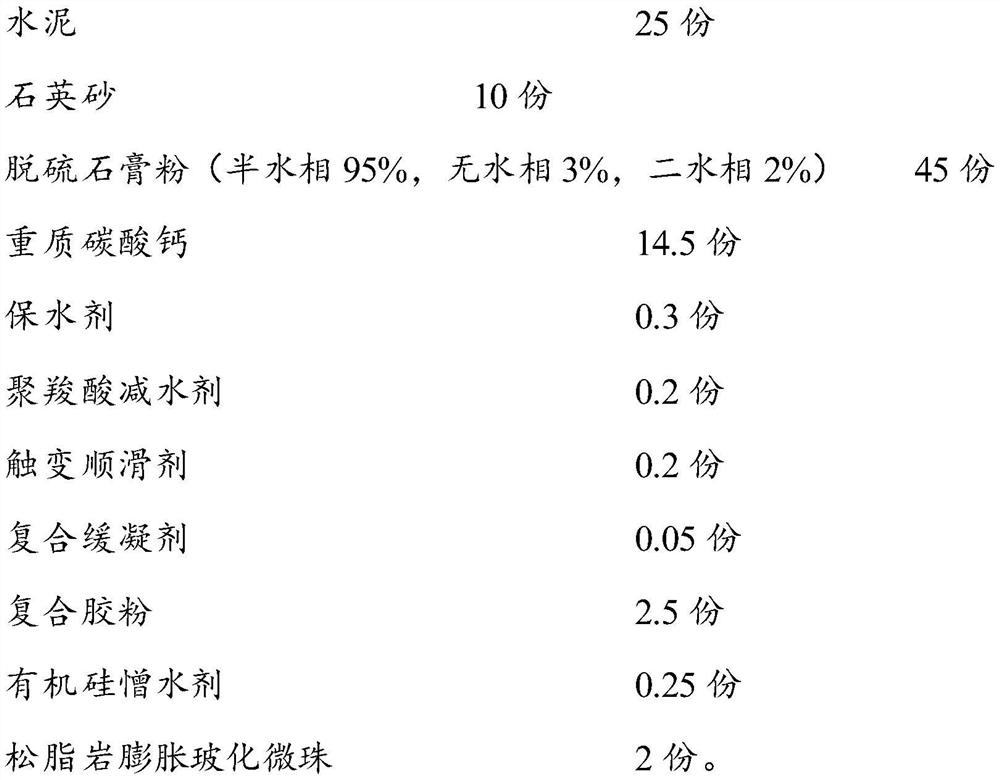

ActiveCN113667344BInhibition of water absorptionImprove waterproof and moisture-proof performanceSolid waste managementFilling pastesHigh humidityPhysical chemistry

The invention provides a desulfurized gypsum composition and a preparation method, a gypsum-based interior wall putty and application thereof, and relates to the technical field of architectural coatings. The desulfurized gypsum composition comprises the following components in terms of mass fraction: hemi-aqueous phase desulfurized gypsum 90 %-95%, anhydrous phase desulfurization gypsum 0.5%-3%, dihydrate phase desulfurization gypsum 0.5%-2%, and the balance is impurities. The desulfurized gypsum composition provided by the present invention is synergized with the hemi-aqueous phase desulfurized gypsum, the anhydrous phase desulfurized gypsum and the di-aqueous phase desulfurized gypsum in a specific mass ratio, which effectively improves the traditional gypsum material, which has strong water absorption and is easily deformed by moisture, causing gypsum to be deformed easily. The technical problem that the base interior wall putty cannot be used in a high humidity environment, when it encounters water, it can also effectively inhibit water absorption, reduce solubility, and improve water and moisture resistance, thereby effectively expanding the application range of gypsum materials.

Owner:ASIA PAINT SHANGHAI +1

A kind of fly ash autoclaved aerated concrete block and its production method

The invention relates to the technical field of preparation of building materials and discloses fly ash autoclaved aerated concrete blocks and a production method thereof. The concrete blocks compriseraw materials including materials and water; the materials include, by weight, 3000-3500 parts of fly ash, 350-400 parts of lime, 250-320 parts of gypsum, 280-330 parts of cement, 2-4 parts of aluminum powder and 100-180 parts of admixture; the admixture includes a butyl acrylate / vinyl acetate / 2-acrylamide-2-methylpropanesulfonic acid terpolymer and calcium stearyl lactate. The concrete blocks and the production method thereof have the following advantages and effects that industrial waste slag fly ash is used as a raw material to reduce the discharge amount and protect the environment; the admixture in the raw materials not only improves the hydrophobicity of pores of the fly ash autoclaved aerated concrete blocks, reduces the amount of water absorbed from coated mortar, but also can effectively reduce the drying shrinkage value of the blocks, reduce the deformation amount of the blocks in a drying process, and the effects that the environment is protected, the drying shrinkage valueis low and phenomena such as cracking and hollowing after the blocks are built into a wall are achieved.

Owner:襄阳华壁新型建材有限公司

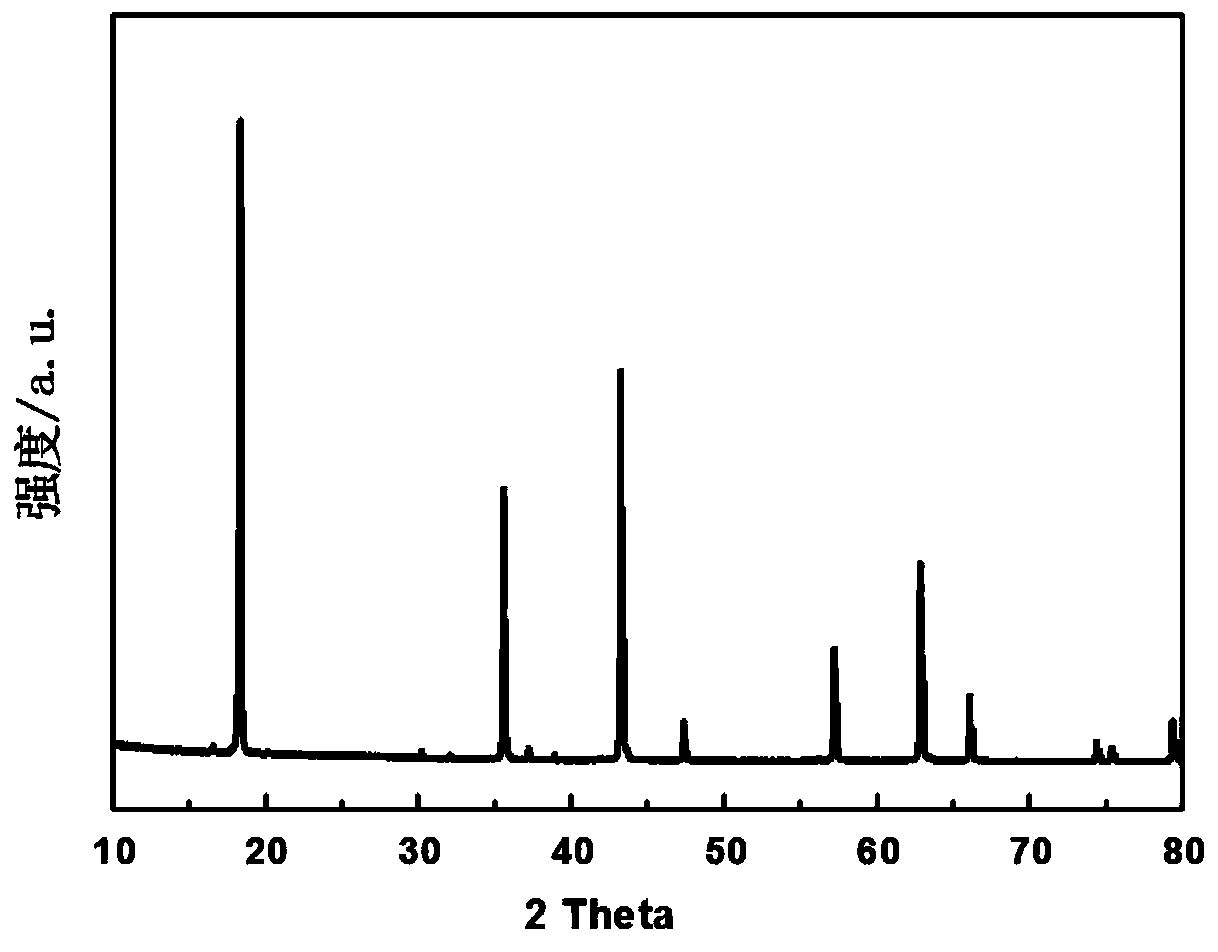

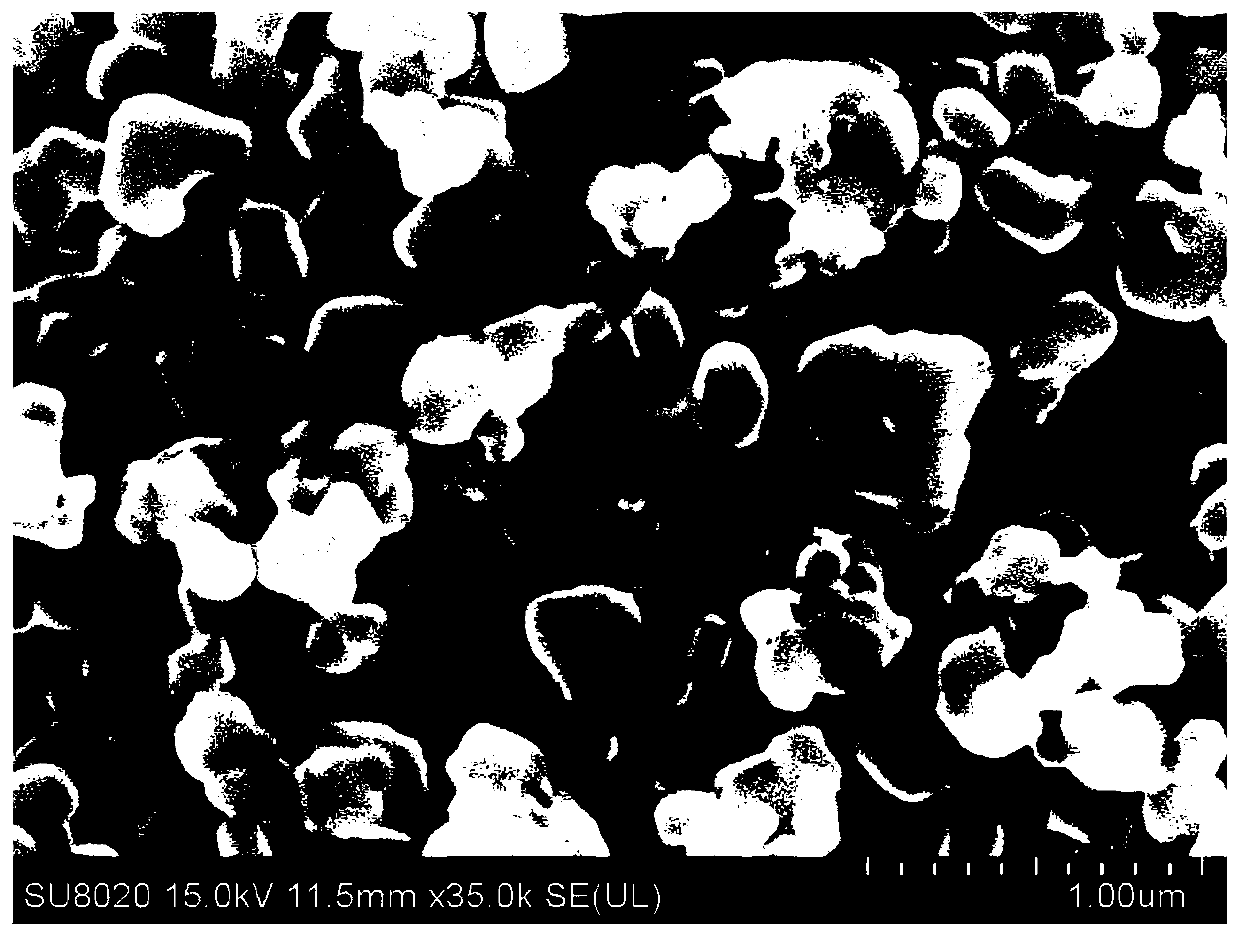

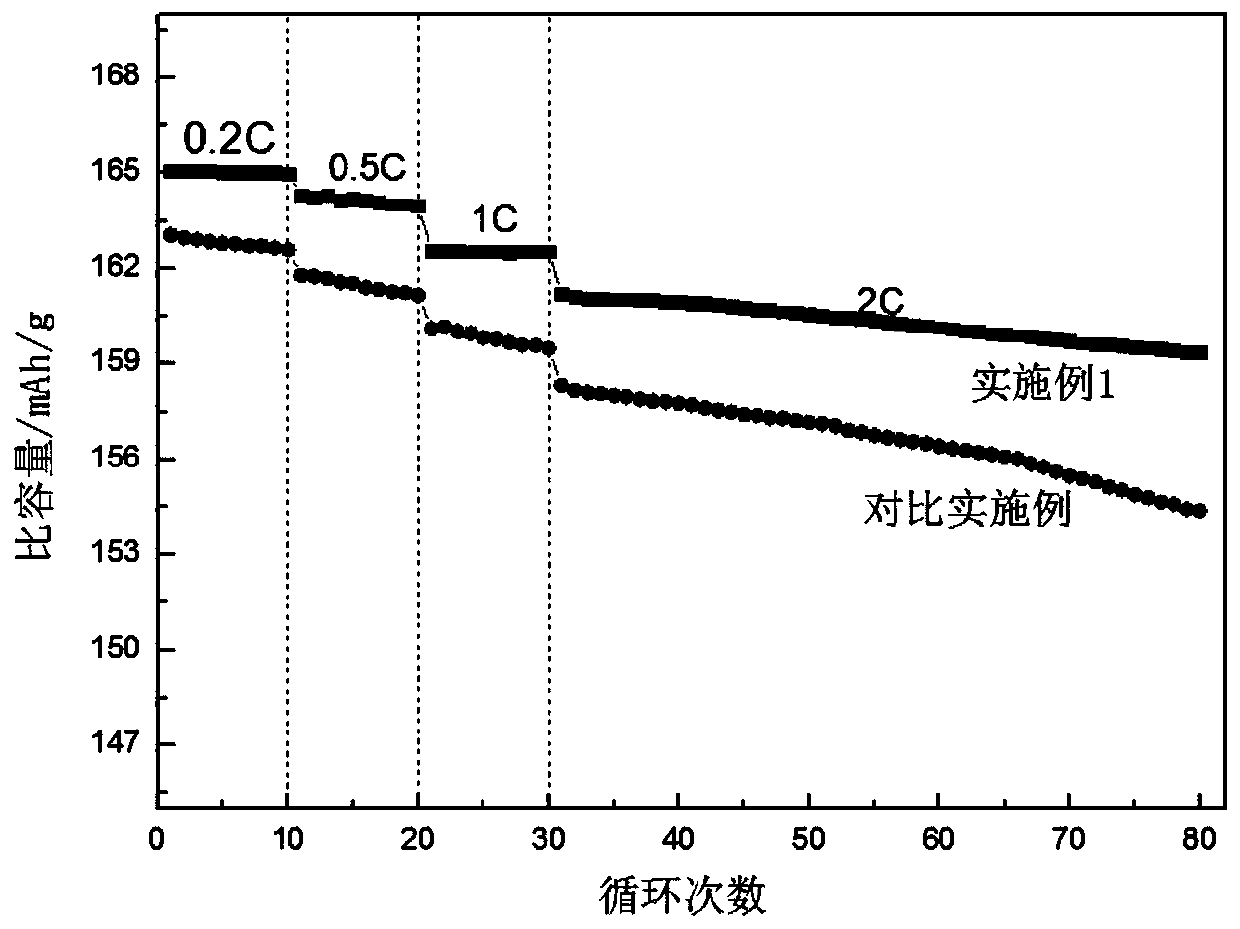

A kind of zirconium scandium composite oxide coated lithium titanate negative electrode material and preparation method thereof

ActiveCN107293720BLower pHInhibition of water absorptionCell electrodesSecondary cellsAlcoholHafnium

The invention provides a zirconium-scandium composite oxide-coated lithium titanate negative electrode material and a preparation method therefor. The zirconium-scandium composite oxide-coated lithium titanate negative electrode material is a Zr<5>Sc<2>O<13>-coated lithium titanate negative electrode material; the preparation method comprises the steps of weighing a lithium source, a titanium source, a zirconium source and a scandium source based on proportion and then adding into an absolute ethyl alcohol solution dissolved with citric acid, heating and stirring to perform a reaction to form gel, and then drying and grinding on the gel, and next, performing pre-sintering and then calcining to obtain the Zr<5>Sc<2>O<13>-coated lithium titanate negative electrode material. In the negative electrode mateirla, the surface of lithium titanate is uniformly coated with Zr<5>Sc<2>O<13> to suppress growth of lithium titanate particles and lower the pH value of the material; in addition, the coating layer on the surface of Zr<5>Sc<2>O<13> material is high in chemical stability, so that structural stability of lithium titanate is effectively maintained and the rate capacity and cycling performance of lithium titanate are improved in the repeated charging-discharging process; and meanwhile, the whole preparation process is simple and easy to test so that the preparation method has wide application prospect.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Nylon composite material filled with nano silicon nitride

The invention discloses a nylon composite material filled with nano silicon nitride, belonging to the technical field of high polymer materials. The nylon composite material comprises the raw materials in parts by weight: 180-210 parts of nylon 66 resin, 70-85 parts of nylon 6 resin, 1.5-2.4 parts of coupling reagent, 70-95 parts of fille, 20-26 parts of nano silicon nitride, 0.6-1.0 part of antioxygen, 103-126 parts of glass fibre and 0.3-0.7 part of oleamide. The nylon composite material has the advantages that the surface is improved by adopting the oleamide for preventing the glass fibre from escaping to the outside so as to greatly inhibit water absorbing quality; and according to the test results of mechanical and physical properties, tensile strength is more than 170MPa, bending strength is more than 250MPa, cantilever notch impact strength is more than 24.5kj / m<2>, and a melt index is more than 18g / 10min.

Owner:CHANGSHU CHIKUSHI MACHINERY

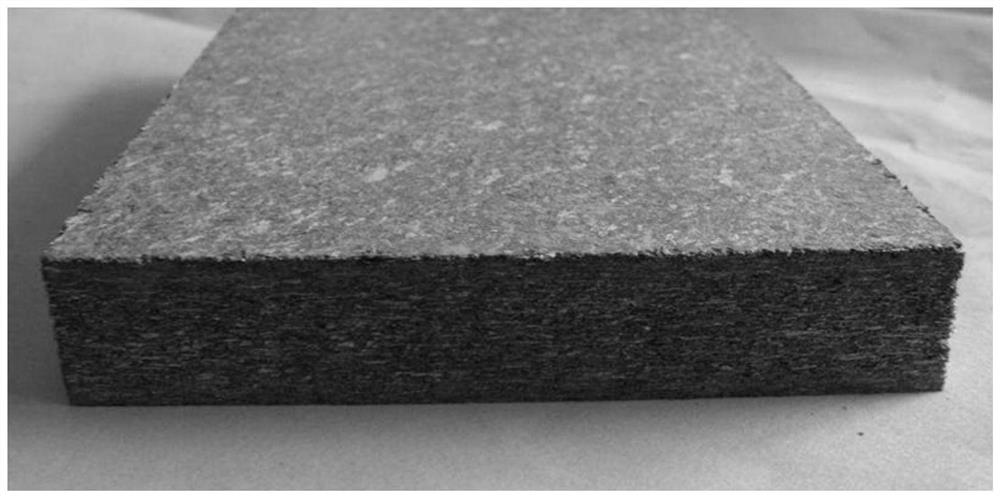

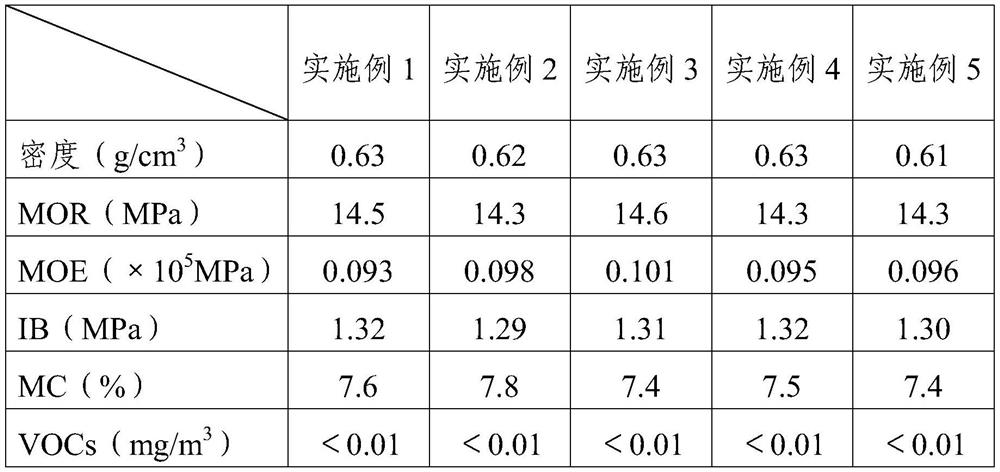

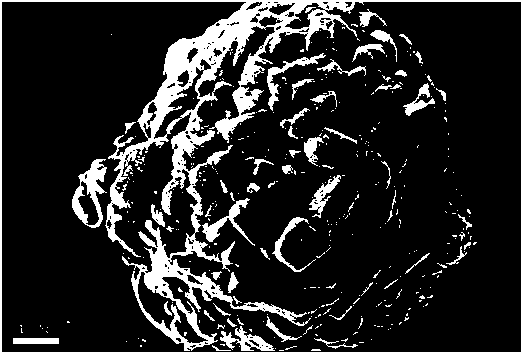

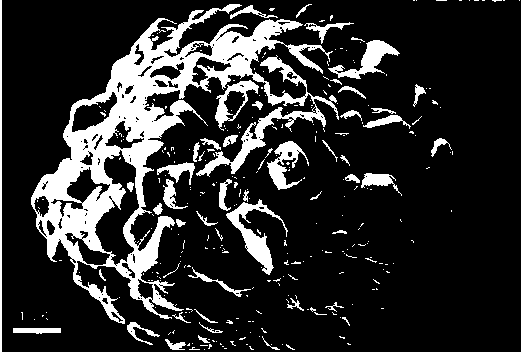

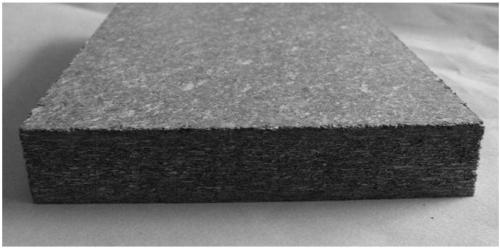

Method for manufacturing environment-friendly home improvement building material board by using chrysanthemum straw and birch shavings

InactiveCN109487633BEasy accessEasy to makeFibreboardNon-macromolecular adhesive additivesAdhesiveEthylic acid

The invention provides a method for manufacturing an environment-friendly household building material board by using yellow top chrysanthemum straws and birch shavings, and relates to the field of household building materials; the method comprises the following steps: (1) treating yellow top chrysanthemum straws with sodium hydroxide solution, taking out, draining, soaking in water vapor of 180-200 DEG C in acetic acid solution, pressurizing to 5-8 MPa, keeping the temperature and the pressure for 3 minutes, and then carrying out pressure relief blasting to obtain the yellow top chrysanthemumpowder body; (2) soaking the birch shavings in hydrogen peroxide solution at room temperature, and treating the birch shavings with steam at 160-180 DEG C for 5-20min to obtain birch fiber; (3) preparing an adhesive; (4) adding the yellow top chrysanthemum powder body and the birch fiber into a proper amount of deionized water to prepare paste, adding the paste into a mould, prepressing for 10-15sunder 1.5MPa to obtain prepressing plates, uniformly coating a layer of the adhesive between the two prepressing plates, prepressing for 10-20s under 2-5MPa, uniformly raising the temperature and pressurizing to 150-160 DEG C within 100s, 10-15MPa hot pressing for 200-250s, cooling to obtain a plate blank, finishing, curing and cutting to obtain a finished product. The method has the advantages of excellent performance, is green and environmentally friendly, and can be widely used in the market.

Owner:双建建设股份有限公司

Surface-coated ternary cathode material and preparation method thereof

ActiveCN106941162BImprove cycle retentionImprove Interface StabilityMaterial nanotechnologyCell electrodesAlkalinityNanoparticle

The invention discloses a surface-coated ternary positive electrode material and a preparation method thereof, belonging to the technical field of lithium ion battery positive electrode materials. The present invention includes molecular formula is LiNi x co 1‑x‑y mn y o 2 particles, the LiNi x co 1‑x‑y mn y o 2 The particle surface is covered with Li 2 MTiO 4 Nanoparticles, wherein M is at least one metal element in Ni, Co, and Mn. The present invention LiNi x co 1‑x‑y mn y o 2 The basic crystal phase structure of the battery is not destroyed, but a new phase of nanoparticles is coated on the surface to form surface protection, increase the interface stability between the surface of the positive electrode material and the electrolyte, and further improve the cycle retention rate of the material. Enhanced electrochemical performance. The surface alkalinity of the cathode material of the invention is reduced, the water absorption is suppressed, and the processing performance is improved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

A modification method of lithium titanate negative electrode material for lithium ion battery

ActiveCN109065856BEnsure structural stabilityHigh magnificationCell electrodesSecondary cellsCharge dischargeLithium electrode

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A method of manufacturing a semiconductor planarization layer

ActiveCN104658906BAvoid surface hardeningEnsure consistencyPhotomechanical apparatusSemiconductor/solid-state device manufacturingPhotoresistSemiconductor

The invention provides a manufacturing method of a semiconductor planarization layer. The manufacturing method comprises the following steps: a coating, baking and drying step, that is, a photoresist for forming a planarization layer is coated on a lower layer film and then the baking treatment and drying treatment are performed; an exposure and development step, that is, the exposure treatment and the development treatment are performed on the planarization layer after the coating, baking and drying step; the manufacturing method is characterized in that the coating, baking and drying step is carried out in at least twice according to the required coating thickness of the planarization layer to be manufactured; the exposure and development step is carried out for at least once. The manufacturing method can improve the taper angle of the planarization layer, reduce the undercut phenomenon of the planarization layer, and prevent the breakage of an upper layer film of the planarization layer, so as to improve the reliability of products.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

A preparation method of composite-coated lithium titanate negative electrode material

ActiveCN107293726BInhibit growthInhibition of water absorptionCell electrodesSecondary cellsAir atmosphereLithium

A method for preparing a lithium titanate anode material coated with a composite is disclosed. The lithium titanate anode material is coated with the composite that is Zn2Te3O8.xTiTe3O8 (with the x being 0-1). The method includes preparing a pure-phase lithium titanate precursor by adopting a sol-gel process, subjecting the precursor and a Zn2Te3O8.xTiTe3O8 mixture in a certain ratio to solid-phase grinding, and performing calcination in an air atmosphere to obtain the lithium titanate anode material coated with the composite that is the Zn2Te3O8.xTiTe3O8. In the anode material, the lithium titanate is evenly coated with the Zn2Te3O8.xTiTe3O8, and therefore growth of lithium titanate particles is inhibited, the pH value of the anode material is reduced, and a Zn2Te3O8.xTiTe3O8 surface coating is good in chemical stability, structure stability of the lithium titanate is effectively maintained in repeated charging and discharging processes, and the rate and cyclic performance of the lithium titanate are increased. In addition, a whole preparing process is simple and easy to test. The method has a wide application prospect.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for manufacturing environment-friendly household building material board by using yellow top chrysanthemum straws and birch shavings

ActiveCN109487633AEasy accessEasy to makeFibreboardNon-macromolecular adhesive additivesFiberWood shavings

The invention provides a method for manufacturing an environment-friendly household building material board by using yellow top chrysanthemum straws and birch shavings, and relates to the field of household building materials; the method comprises the following steps: (1) treating yellow top chrysanthemum straws with sodium hydroxide solution, taking out, draining, soaking in water vapor of 180-200 DEG C in acetic acid solution, pressurizing to 5-8 MPa, keeping the temperature and the pressure for 3 minutes, and then carrying out pressure relief blasting to obtain the yellow top chrysanthemumpowder body; (2) soaking the birch shavings in hydrogen peroxide solution at room temperature, and treating the birch shavings with steam at 160-180 DEG C for 5-20min to obtain birch fiber; (3) preparing an adhesive; (4) adding the yellow top chrysanthemum powder body and the birch fiber into a proper amount of deionized water to prepare paste, adding the paste into a mould, prepressing for 10-15sunder 1.5MPa to obtain prepressing plates, uniformly coating a layer of the adhesive between the two prepressing plates, prepressing for 10-20s under 2-5MPa, uniformly raising the temperature and pressurizing to 150-160 DEG C within 100s, 10-15MPa hot pressing for 200-250s, cooling to obtain a plate blank, finishing, curing and cutting to obtain a finished product. The method has the advantages of excellent performance, is green and environmentally friendly, and can be widely used in the market.

Owner:双建建设股份有限公司

A method for modifying lithium titanate negative electrode material of lithium ion battery

ActiveCN109065856AEnsure structural stabilityHigh magnificationCell electrodesSecondary cellsChemical stabilityCalcination

The invention discloses a modification method of lithium titanate negative electrode material of lithium ion battery, wherein, pure titanium sheet is placed in an acidic solution and calcined to obtain titanium dioxide thin film, the titanium dioxide thin film is immersed in lithium source sol, the lithium titanate precursor thin film is obtained after extraction and pre-firing, and the lithium titanate precursor thin film is taken as a substrate and coated by plasma spraying. Ytterbium silicate coating was prepared by physical vapor deposition (PVD) on the substrate surface, and the cathode material of Ytterbium silicate coated lithium titanate thin film was obtained after calcination. The modified ytterbium silicate coated lithium titanate thin film negative electrode material can not only inhibit the growth of lithium titanate particles, but also inhibit the water absorption of the material, and can effectively maintain the structural stability of lithium titanate, improve the ratioof lithium titanate, cycle and chemical stability in the repeated charging and discharging process.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of preparation method of lithium titanate coated with hydroxyapatite

ActiveCN105185975BInhibit growthInhibition of water absorptionNegative electrodesPhysical chemistryEngineering

The invention discloses a preparation method of hydroxyapatite-coated lithium titanate. The method comprises the following steps: respectively preparing a lithium source solution of a certain concentration and a titanium source solution of a certain concentration; adding the lithium source solution and the titanium source solution to sol with a certain ratio of hydroxyapatite, and carrying out water bath and magnetic stirring to form gel; drying the gel to prepare a precursor; and grinding, crushing and calcining the precursor to obtain a hydroxyapatite-coated lithium titanate anode material. According to the preparation method of the hydroxyapatite-coated lithium titanate, the hydroxyapatite can effectively coat the surface of the lithium titanate, inhibits growth of particles, and shows relatively high electrochemical activity. The pH value of the material can be lowered; and the hygroscopic property of the material is inhibited. According to the preparation method, the required raw materials are low in price; the operation is simple and feasible; and the prepared lithium titanate anode material has excellent electrochemical properties.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Doped lithium nickel manganese oxide material, modified lithium nickel manganese oxide positive electrode material and preparation method thereof

ActiveCN107946551BUniform particle sizeLower pHCell electrodesSecondary cellsChemical compositionManganate

The invention discloses a doped lithium nickel manganate material having the chemical composition of LiMn<1.5-x>Ni<0.5-x>Y<2x>O<4>. The invention discloses a modified lithium nickel manganate positiveelectrode material. The invention also discloses a preparation method the doped lithium nickel manganate material and a preparation of the modified lithium nickel manganate positive electrode material. A sol-gel method is adopted to prepare the doped lithium nickel manganate material with uniform grain diameter; the surface of the doped lithium nickel manganate material is uniformly coated with Li<2>SnO<3> to obtain the modified lithium nickel manganate positive electrode material which has high structural stability, cycle performance and thermal stability; and the preparation methods are simple in operation.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com