Doped lithium nickel manganese oxide material, modified lithium nickel manganese oxide positive electrode material and preparation method thereof

A technology of lithium nickel manganese oxide and positive electrode materials, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve problems affecting electrochemical performance, etc., and achieve the effects of improving material interface stability, inhibiting dissolution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

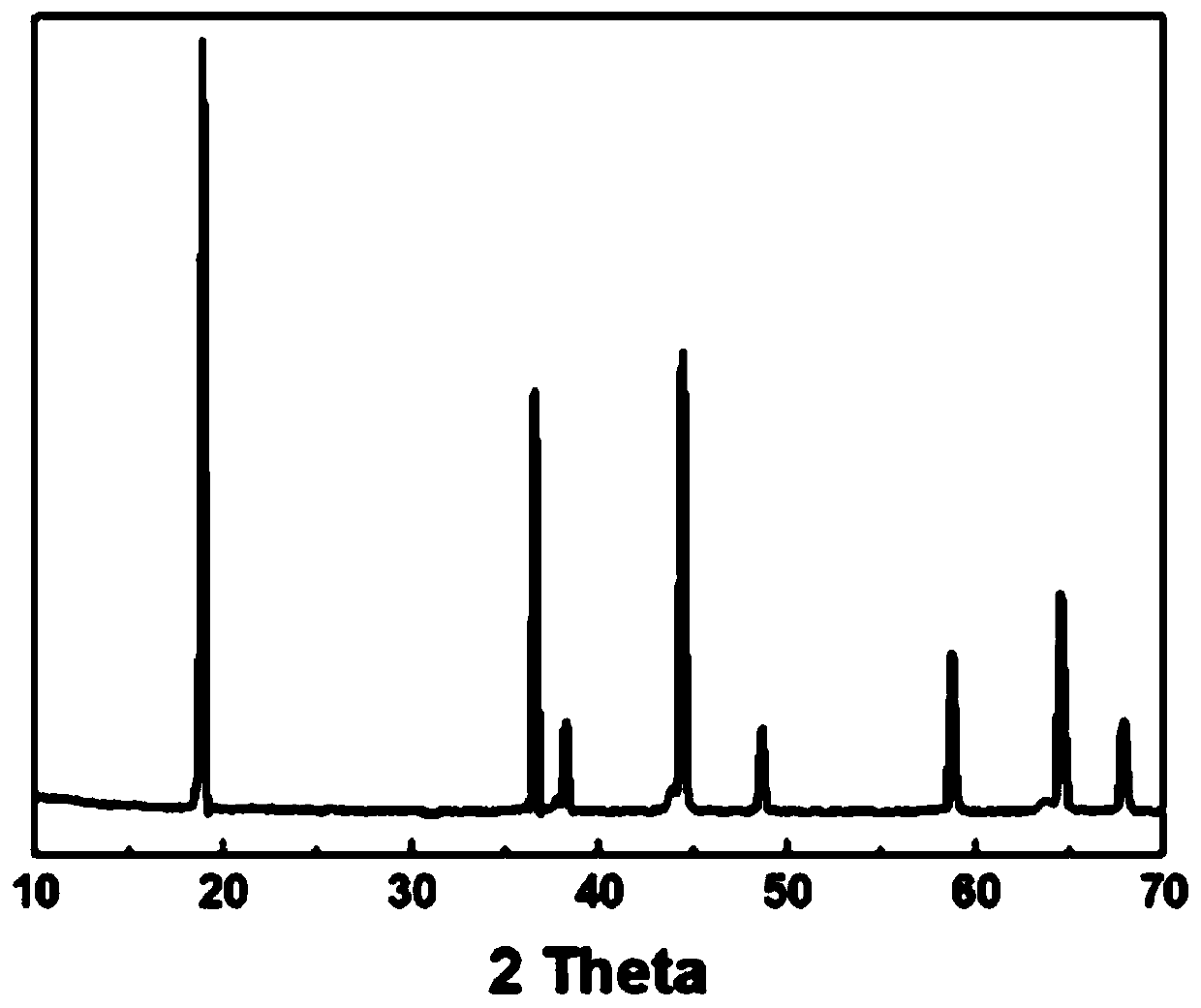

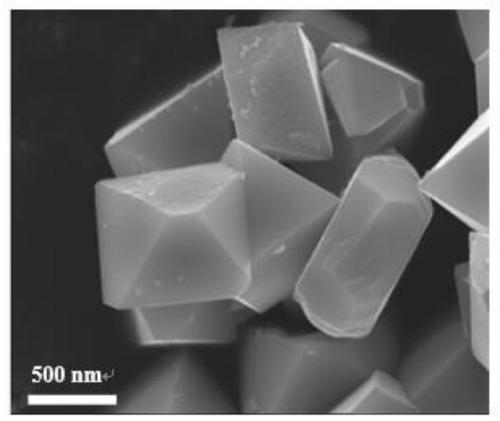

[0034] A preparation method for a doped lithium nickel manganese oxide material, comprising the steps of: dropwise adding lithium source aqueous solution, manganese source aqueous solution, nickel source aqueous solution, and yttrium source aqueous solution to an aqueous citric acid solution, stirring for 3.5 hours, adjusting the pH to 7.5, and raising the temperature Stir until a sol is formed, dry to obtain a xerogel; pre-calcine the xerogel, grind, and heat treat to obtain LiMn doped nickel manganese oxide material LiMn 1.485 Ni 0.485 Y 0.03 o 4 .

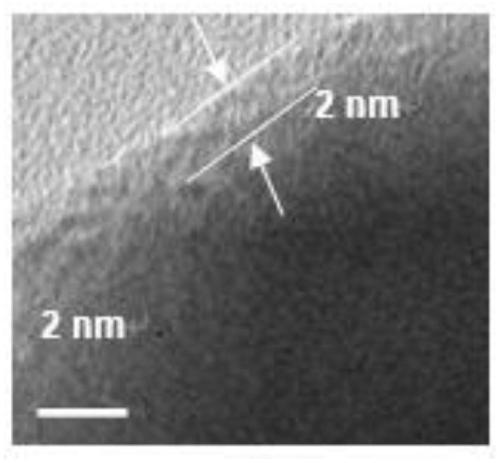

[0035] A preparation method of a modified lithium nickel manganese oxide positive electrode material, comprising the steps of: making Li 2 SnO 3 Add the above-mentioned doped lithium nickel manganese oxide material into water and mix evenly, stir to form a precipitate, take the precipitate for annealing treatment, wash, and dry to obtain a modified lithium nickel manganese oxide positive electrode material.

Embodiment 2

[0037] A preparation method for doped lithium nickel manganese oxide material, comprising the steps of: dropwise adding lithium hydroxide aqueous solution, manganese nitrate aqueous solution, nickel nitrate aqueous solution, and yttrium nitrate aqueous solution to citric acid aqueous solution, stirring for 2 hours, and adjusting pH=7 with ammonia water , heat up to 80°C, stir until a sol is formed, heat up to 100°C, and dry for 12 hours to obtain dry gel; heat up to 350°C, pre-calcine the dry gel for 6 hours, grind, heat up to 800°C, and keep warm for 5 hours to obtain doped nickel-manganese Lithium acid material LiMn 1.495 Ni 0.495 Y 0.01 o 4 , wherein the molar ratio of lithium, manganese, nickel, and yttrium elements is 1:1.495:0.495:0.01, and the amount of citric acid is 1% of the theoretically generated weight of the doped lithium nickel manganese oxide material.

[0038] A preparation method of a modified lithium nickel manganese oxide positive electrode material, com...

Embodiment 3

[0040]A preparation method for doped lithium nickel manganese oxide material, comprising the steps of: dropwise adding lithium acetate aqueous solution, manganese sulfate aqueous solution, nickel sulfate aqueous solution, and yttrium sulfate aqueous solution to citric acid aqueous solution, stirring for 3 hours, adjusting pH=7 with ammonia water, Heat up to 80°C, stir until a sol is formed, heat up to 110°C, and dry for 15 hours to obtain dry gel; heat up to 400°C, pre-calcine the dry gel for 7 hours, grind, heat up to 800°C, and keep warm for 7 hours to obtain doped nickel manganese acid Lithium material LiMn 1.475 Ni 0.475 Y 0.05 o 4 , wherein the molar ratio of lithium, manganese, nickel, and yttrium is 1:1.475:0.475:0.05, and the amount of citric acid is 10% of the theoretically generated weight of the doped lithium nickel manganese oxide material.

[0041] A preparation method of a modified lithium nickel manganese oxide positive electrode material, comprising the step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com