Boiler ash-cleaning and decoking agent and preparation method thereof

A decoking agent and ash cleaning technology, which is applied in fuel additives, petroleum industry, fuel and other directions, can solve the problems of aggravating the cost of decoking agent, lack of raw material sources, and insignificant effects, so as to alleviate the coking and wettability of flue gas. good, the effect of reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

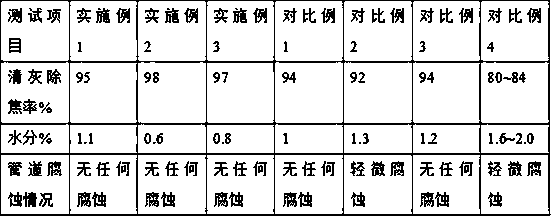

Examples

preparation example Construction

[0021] A preparation method for a boiler dust removal and decoking agent, comprising the steps of:

[0022] According to the number of parts by mass, take 10~16 parts of auxiliary agent A, 6~9 parts of auxiliary agent B, 5~9 parts of auxiliary agent C, 3~5 parts of borax, 2~3 parts of silicon dioxide, 3~5 parts of chlorine Sodium chloride is mixed to obtain boiler ash and coke removal agent.

Embodiment 1

[0024] Auxiliary A: Take corn stalks and crush them through a 100-mesh sieve, collect the sieved particles, and steam-explode them at 0.35MPa for 120s. Take the steam-exploded products and add 15% sodium hydroxide solution at a mass ratio of 1:20. Keep for 18 hours, adjust the pH to 7, filter, take the filter residue, and dry to obtain the dried product. Take sodium dodecylbenzenesulfonate and add polyoxyethylene octylphenol ether-10 and deionized water according to the mass ratio of 1:2:10. Mix to obtain mixture A. In terms of parts by mass, take 10 parts of mixture A, 4 parts of butyl acrylate, 3 parts of methyl methacrylate, and 2 parts of acrylamide, and stir and mix at 35°C for 20 minutes to obtain mixture B. Take the mixture Add sodium persulfate to B at a mass ratio of 10:50:1, keep at 70°C for 1 hour, and cool down to obtain additive A.

[0025]Auxiliary B: Take ethanolamine and add it to absolute ethanol at a mass ratio of 3:5 to mix, stir and mix at 20°C for 30 minut...

Embodiment 2

[0030] Auxiliary A: Take corn stalks and crush them through a 100-mesh sieve, collect the sieved particles, and steam-explode them at 0.35MPa for 130s. Take the steam-exploded products and add 15% sodium hydroxide solution at a mass ratio of 1:20. Keep it for 24 hours, adjust the pH to 7.2, filter, take the filter residue, and dry to obtain the dried product. Take sodium dodecylbenzenesulfonate and add polyoxyethylene octylphenol ether-10 and deionized water according to the mass ratio of 1:2:10. Mix to obtain mixture A. In terms of parts by mass, take 15 parts of mixture A, 6 parts of butyl acrylate, 5 parts of methyl methacrylate, and 4 parts of acrylamide, and stir and mix at 40°C for 30 minutes to obtain mixture B. Take the mixture Add sodium persulfate to B at a mass ratio of 10:50:1, keep at 75°C for 2 hours, and cool down to obtain additive A.

[0031] Auxiliary B: Take ethanolamine and add it to absolute ethanol at a mass ratio of 3:5 to mix, stir and mix at 25°C for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com