Self-compacting mortar and preparation method thereof

A self-compacting, mortar technology, applied in the field of building materials, can solve the problem of high tailings volume, and achieve the effect of improving performance, good economic benefits, and suppressing water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

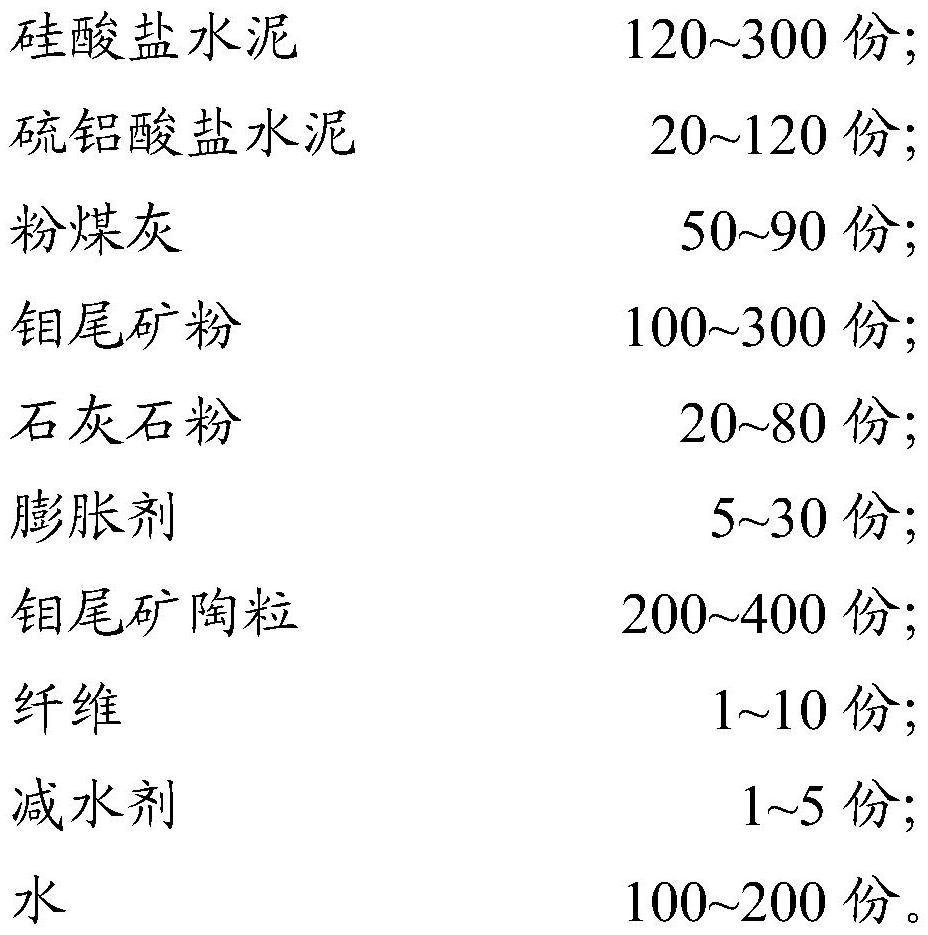

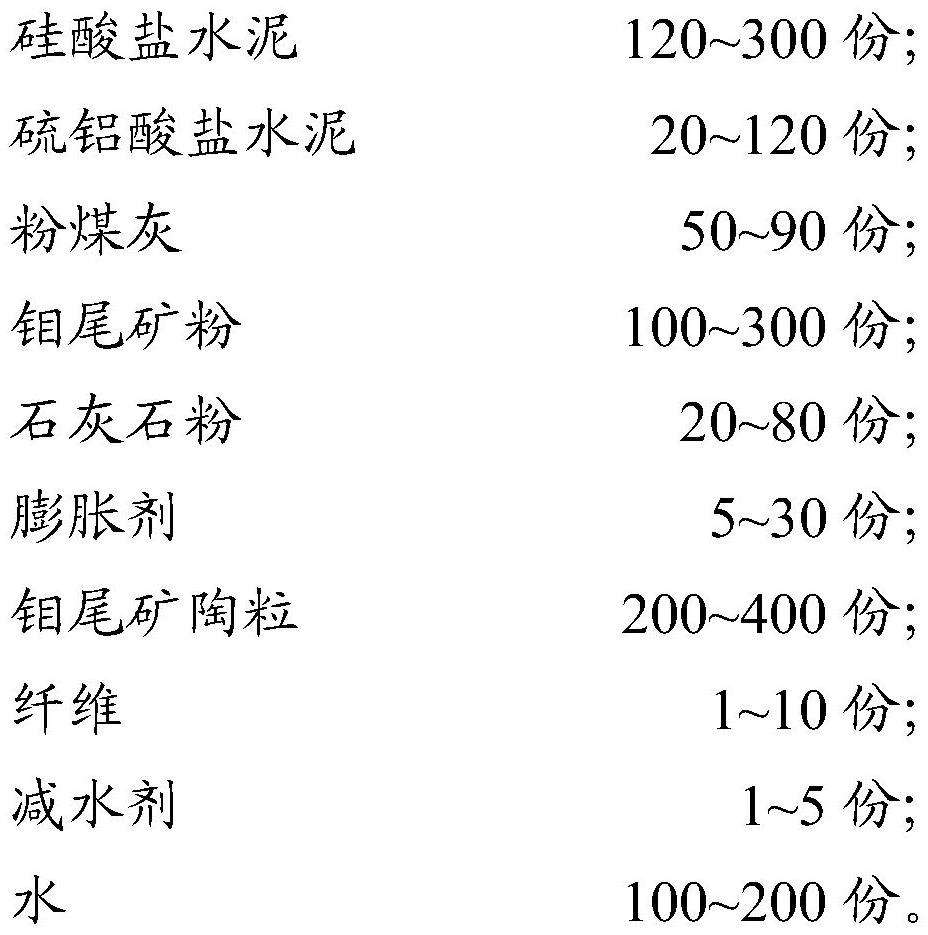

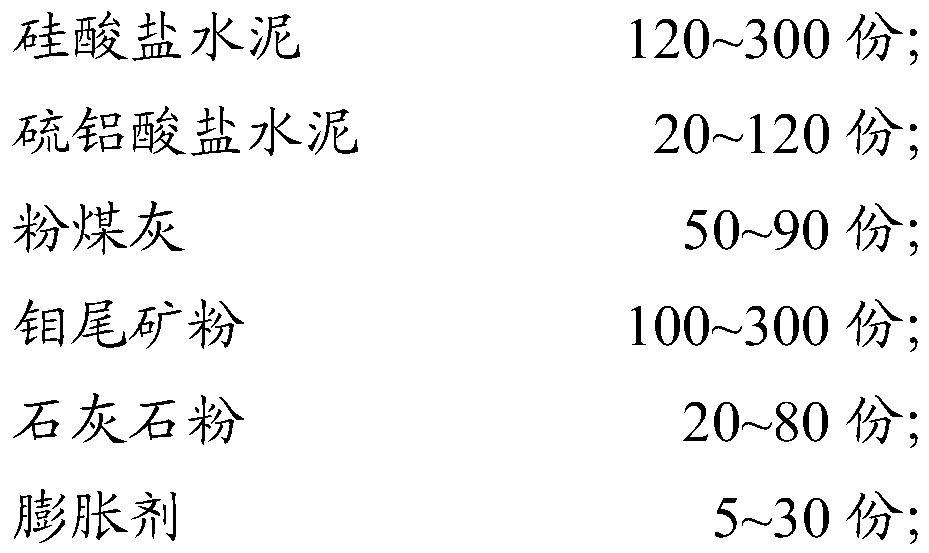

[0058] The present invention also provides a method for preparing the self-compacting mortar described in the above technical solution, comprising the following steps:

[0059] Portland cement, sulphoaluminate cement, fly ash, molybdenum tailings powder, limestone powder, expansion agent, molybdenum tailings ceramsite, fiber, water reducer and water are mixed to obtain self-compacting mortar.

[0060] In the preparation method provided by the present invention, Portland cement, sulphoaluminate cement, fly ash, molybdenum tailings powder, limestone powder, expansion agent, molybdenum tailings ceramsite, fiber, water reducer and water Mix uniformly in proportion to obtain the self-compacting mortar provided by the present invention; the specific mixing process preferably includes: first mix Portland cement, sulphoaluminate cement, fly ash, molybdenum tailings powder, limestone powder, expansion agent , molybdenum tailings ceramsite, water reducing agent and water are mixed, and ...

Embodiment 1

[0118] Preparation of molybdenum tailings ceramsite:

[0119] 1) Raw material composition:

[0120] Element Dosage Molybdenum tailings powder 50 parts by weight Ceramic polishing waste powder 8 parts by weight fly ash 15 parts by weight limestone powder 10 parts by weight Portland cement 10 parts by weight plaster 3 parts by weight base activator 4 parts by weight water 15 parts by weight grinding aid 500g / t of the total mass of gypsum and alkali activator

[0121] 2) Preparation of molybdenum tailings ceramsite:

[0122] First, in the presence of grinding aids, mix and grind the alkali activator and gypsum to less than 0.075mm to obtain a prefabricated material; then mix the prefabricated material with ceramic polishing waste powder, molybdenum tailings powder, cement, stone powder, fly ash and Mix the water evenly to obtain a mixture; then put the mixture into a ball-forming tray to form pellets t...

Embodiment 2

[0126] Modification of molybdenum tailings ceramsite:

[0127] 1) Raw material composition:

[0128]

[0129]

[0130] 2) Preparation of modified molybdenum tailings ceramsite:

[0131] Mix molybdenum tailings ceramsite prepared in Example 1 with cement, polysiloxane, starch ether, cellulose, rubber powder, water reducer, air-entraining agent and defoamer to obtain modified molybdenum tailings ceramsite .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com