Desulfurization gypsum composition and preparation method, gypsum-based interior wall putty and application

A technology of interior wall putty and desulfurized gypsum, which is applied in the field of architectural coatings, can solve the problems of gypsum-based interior wall putty that cannot be used, is easily deformed by moisture, and has strong water absorption, and achieves excellent workability, fluidity, and water resistance and moisture resistance. Good, stable retarding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the preparation method of the desulfurized gypsum composition provided by the present invention, the moisture in the desulfurized gypsum powder is completely removed by calcination, and then aged in a closed space with a humidity of 20%-50%, so that the desulfurized gypsum powder is combined with the moisture in the air to form Different phases of desulfurized gypsum exist stably, thereby improving the stability of the desulfurized gypsum composition, inhibiting its hydrophilicity and absorption, improving water and moisture resistance, and helping to expand its application in high humidity environments. .

[0039] In addition, the preparation method of the desulfurized gypsum composition provided by the present invention is simple in process, convenient in operation, suitable for large-scale production, and improves production efficiency.

[0040] In a preferred solution of the present invention, when the desulfurized gypsum composition is prepared, when the desulfu...

Embodiment 1

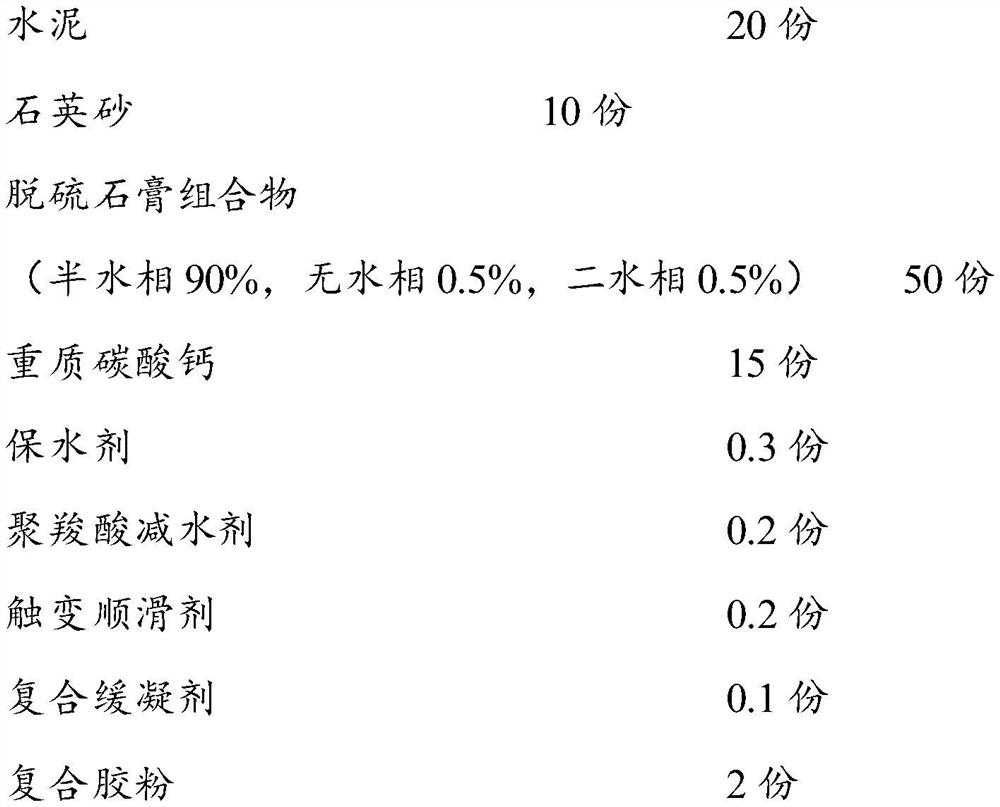

[0097] The present embodiment provides a gypsum-based interior wall putty, including the following raw materials in parts by mass:

[0098]

[0099]

[0100] Among them, the composite retarder is composed of citric acid, borax and tartaric acid according to the mass ratio of 0.09:1:0.01; the composite rubber powder is composed of styrene-acrylic rubber powder and EVA rubber powder according to the mass ratio of 1:2 The desulfurized gypsum composition is prepared according to the following steps: after the desulfurized gypsum powder is calcined at 175 ° C for 90 minutes, air-selected and aged at a speed of 10 m / s by a high-speed fan, and then aged in a closed room with a humidity of 35% 14 days.

Embodiment 2

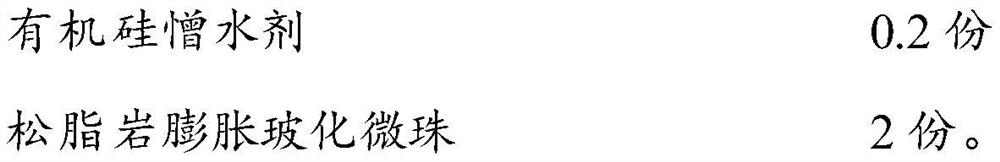

[0102] The present embodiment provides a gypsum-based interior wall putty, including the following raw materials in parts by mass:

[0103]

[0104] Wherein, the sulfur gypsum composition is prepared according to the following steps: after calcining the desulfurized gypsum powder at 180° C. for 110 min, air-selected and aged at a speed of 10 m / s by a high-speed fan, and then aged in a closed room with a humidity of 50% for 14 The composite retarder and the composite rubber powder are from the same batch as the composite retarder and the composite rubber powder used in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com