A method for modifying lithium titanate negative electrode material of lithium ion battery

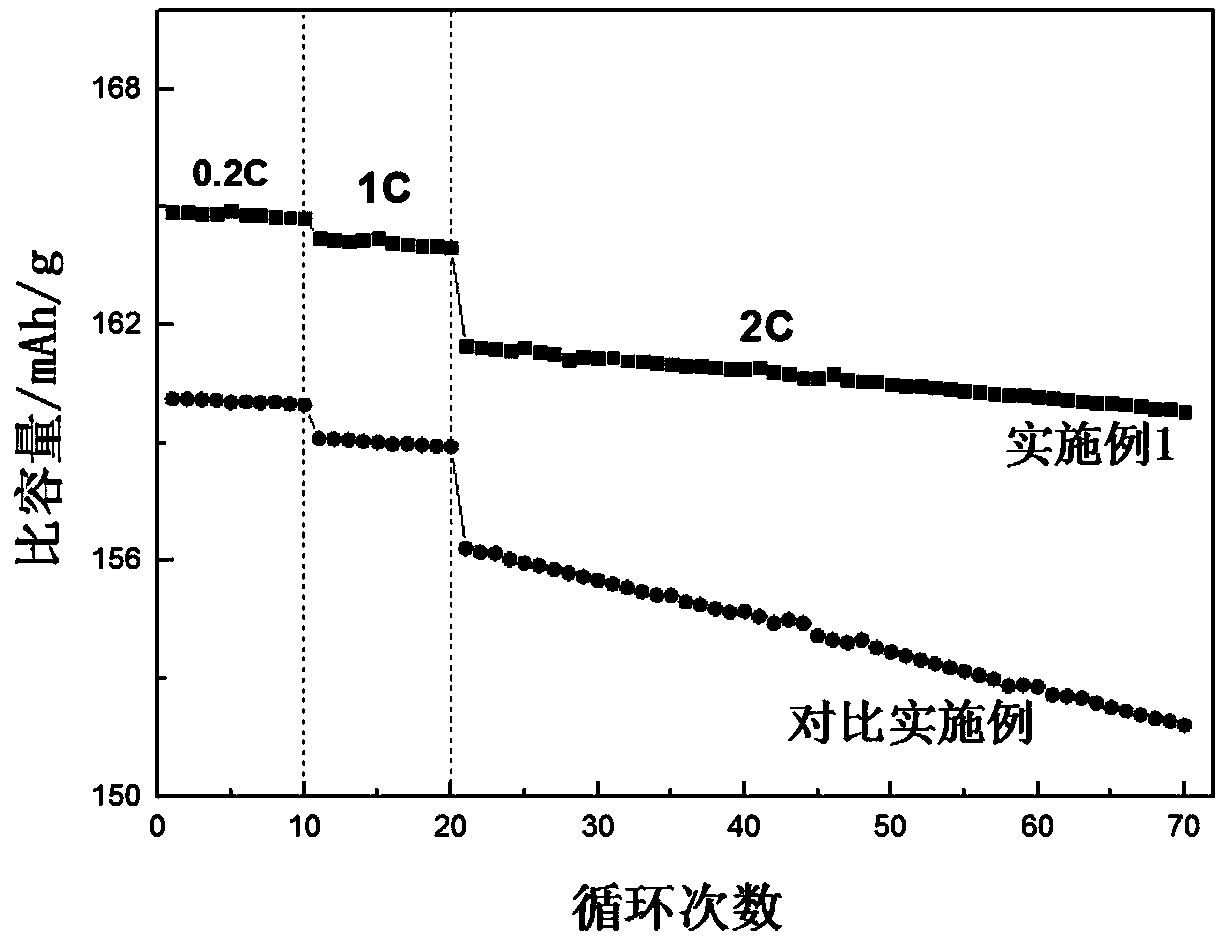

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of increasing electrode/electrolyte interface impedance, affecting the application of lithium titanate, and reducing cycle performance, and achieving reversible capacity and The effect of improving cycle performance, reducing charge transfer resistance, and reducing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

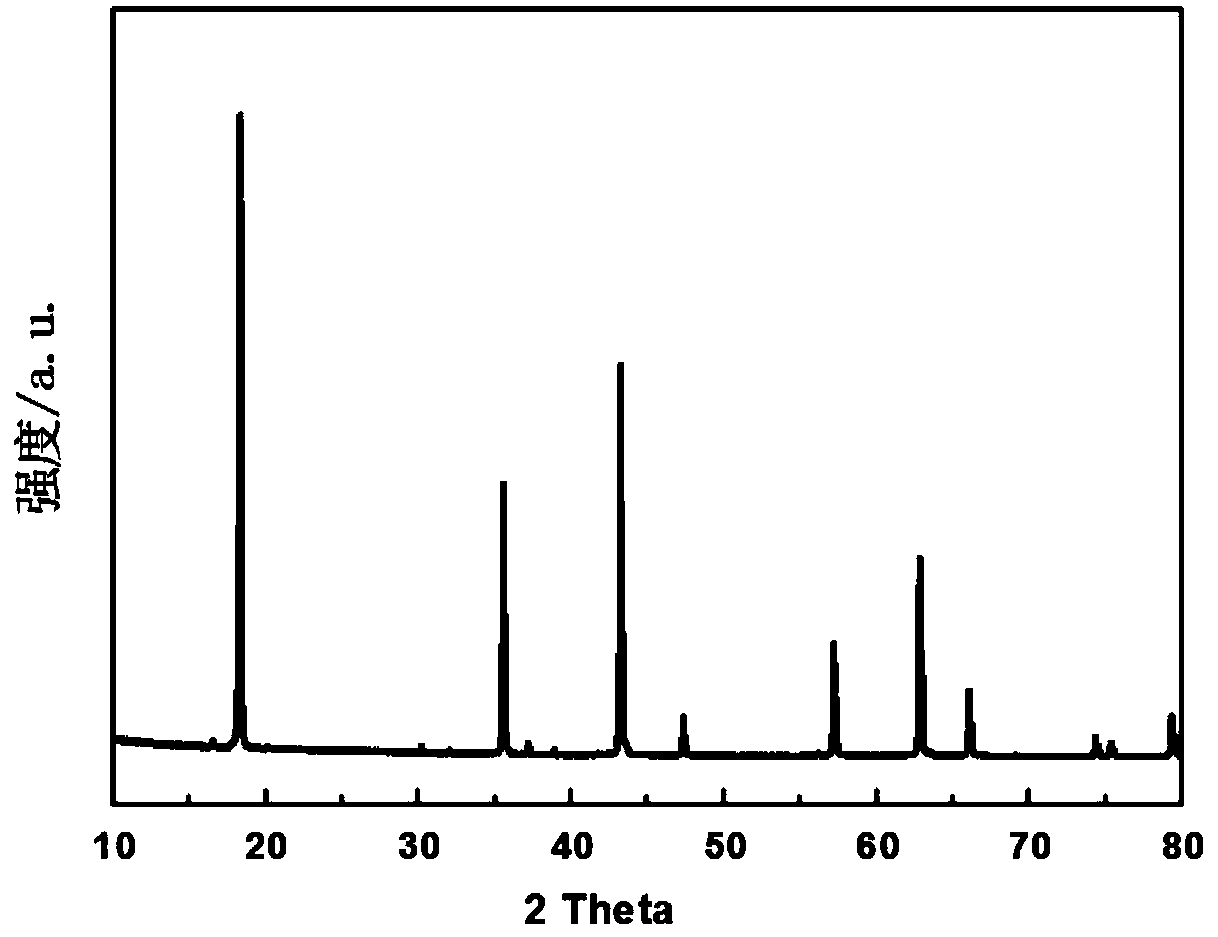

[0030] A method for modifying a lithium titanate negative electrode material for a lithium ion battery, specifically comprising the following steps:

[0031] (1) After smoothing the pure titanium sheet with sandpaper, ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and then soak it in HCL solution with a molar concentration of 6mol / L at normal temperature and pressure for 10h Then take it out, wash it with deionized water until the pH value is 6, put it into a drying oven, dry it at 80°C for 1 hour, and calcinate it at 350°C for 3 hours to obtain a titanium dioxide film;

[0032] (2) Add an ethylenediaminetetraacetic acid chelating agent to an absolute ethanol solution containing lithium hydroxide, and stir in a water bath at 60°C for 2 hours to obtain a sol; wherein, the molar concentration of lithium hydroxide is 0.1mol / L, B The mass concentration of diamine tetraacetic acid is 1%;

[0033] (3) Immerse the titanium dioxide film obtained...

Embodiment 2

[0039] A method for modifying a lithium titanate negative electrode material for a lithium ion battery, specifically comprising the following steps:

[0040] (1) After smoothing the pure titanium sheet with sandpaper, ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and then soak it in HCL solution with a molar concentration of 8mol / L at normal temperature and pressure for 15h Then take it out, then wash it with deionized water until the pH value is 7, and finally put it in a drying oven at 90°C for 5 hours, and then calcinate at 450°C for 4 hours to obtain a titanium dioxide film;

[0041] (2) Add an oxalic acid chelating agent to an absolute ethanol solution containing lithium acetate, and stir in a water bath at 70°C for 6 hours to obtain a sol; wherein, the molar concentration of lithium acetate is 1.5mol / L, and the mass concentration of oxalic acid is 5%. ;

[0042] (3) Immerse the titanium dioxide film obtained in step (1) into the...

Embodiment 3

[0048] A method for modifying a lithium titanate negative electrode material for a lithium ion battery, specifically comprising the following steps:

[0049] (1) After smoothing the pure titanium sheet with sandpaper, ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and then soak it in HCL solution with a molar concentration of 10mol / L at normal temperature and pressure for 25 hours Then take it out, wash it with deionized water until the pH value is 7.5, put it in a drying oven, dry it at 100°C for 8 hours, and calcinate it at 600°C for 4 hours to obtain a titanium dioxide film;

[0050] (2) Add a citric acid chelating agent to an absolute ethanol solution containing lithium nitrate, and stir in a water bath at 80°C for 12 hours to obtain a sol; wherein, the molar concentration of lithium nitrate is 3mol / L, and the mass concentration of citric acid is 15 %;

[0051] (3) Immerse the titanium dioxide film obtained in step (1) into the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com