A preparation method of composite-coated lithium titanate negative electrode material

A technology of coating lithium titanate and negative electrode materials, which is applied in the field of preparation of composite coated lithium titanate negative electrode materials, can solve the problems of increased electrode/electrolyte interface impedance, affecting the application of lithium titanate, and shortening battery life. Achieves the effect of improving the rate and cycle performance, facilitating the test, and suppressing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

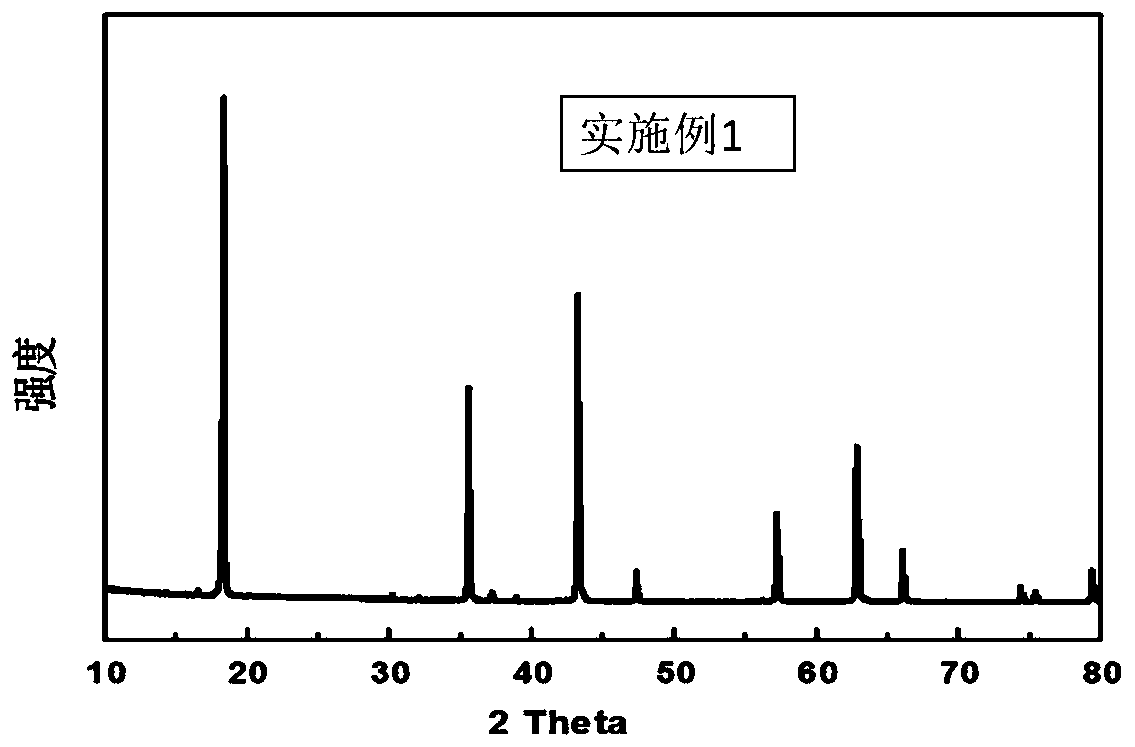

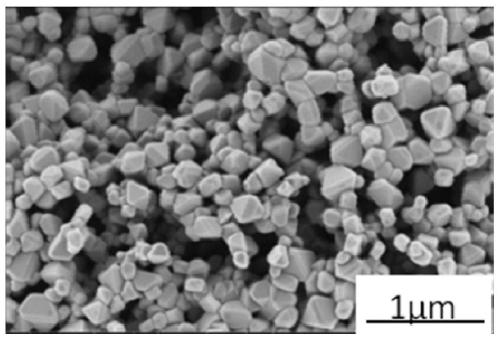

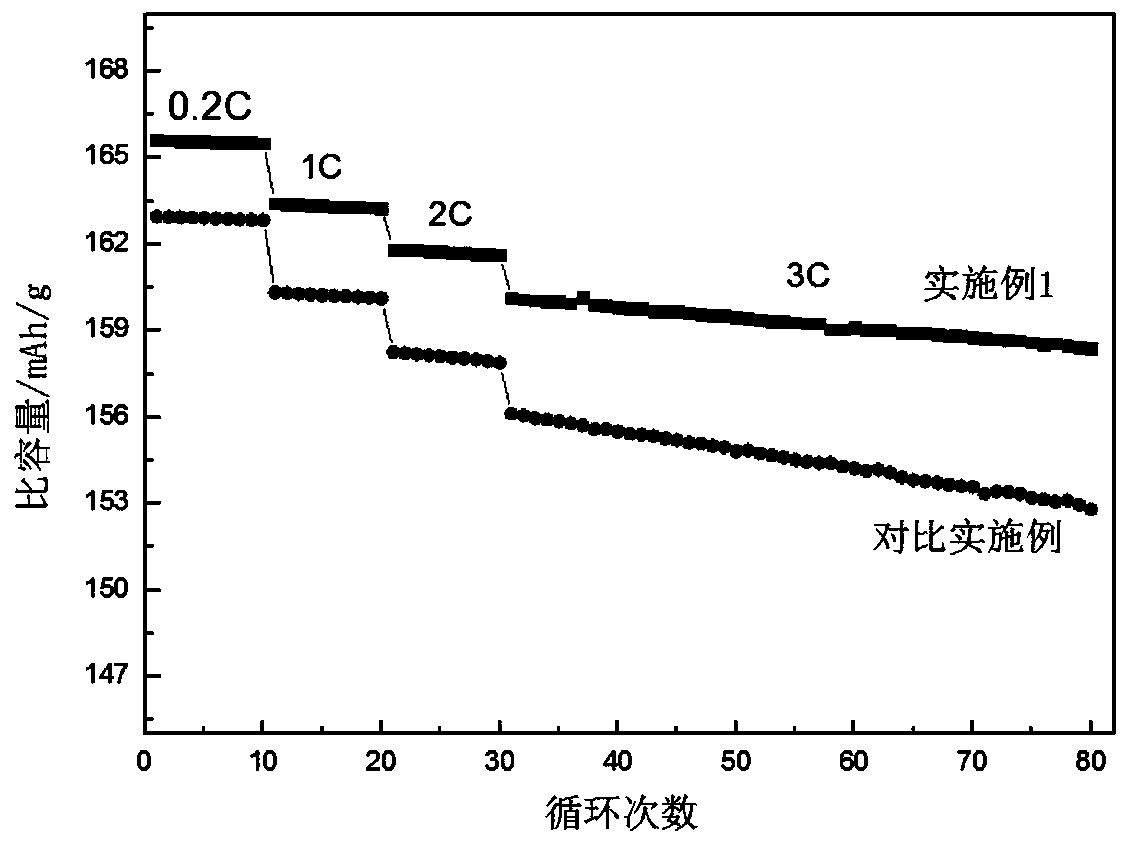

Embodiment 1

[0023] Zn 2 Te 3 o 8 0.5TiTe 3 o 8 The preparation of composite coated lithium titanate negative electrode material comprises the following steps:

[0024] (1) Preparation of pure-phase lithium titanate precursor: according to Li:Ti stoichiometric ratio of 4.1:5, accurately weigh lithium hydroxide and tetraisopropyl titanate, and add them to 5wt% citric acid absolute ethanol solution (the amount of citric acid added is 5% of the mass of theoretically synthesized pure-phase lithium titanate), and ultrasonic treatment was carried out for 1.6h, and then reacted at 80°C under stirring and reflux for 6h to form a gel, and the gel was heated at 110°C drying to form a xerogel; pre-calcining the xerogel at 500°C for 3 hours in an air atmosphere to obtain a pure-phase lithium titanate precursor;

[0025] (2) Press Zn 2 Te 3 o 8 : TiTe 3 o 8 =1:0.5 mass ratio to weigh Zn 2 Te 3 o 8 、TiTe 3 o 8 , mixed to form Zn 2 Te 3 o 8 0.5TiTe 3 o 8 Mixture, weigh Zn according to...

Embodiment 2

[0028] Zn 2 Te 3 o 8 0.1TiTe 3 o 8 The preparation of composite coated lithium titanate negative electrode material comprises the following steps:

[0029] (1) Preparation of the pure-phase lithium titanate precursor: according to the Li:Ti stoichiometric ratio of 4.05:5, accurately weigh lithium acetate and tetraethyl titanate, and add them to 2wt% citric acid absolute ethanol solution ( The amount of citric acid added is 3% of the mass of theoretically synthesized pure-phase lithium titanate), and ultrasonic treatment is carried out for 1.2h, and then reacted at 90°C under stirring and reflux for 4h to form a gel, which is dried at 105°C to form Dry gel; pre-calcine the dry gel at 450°C for 4 hours in an air atmosphere to obtain a pure-phase lithium titanate precursor;

[0030] (2) Press Zn 2 Te 3 o 8 : TiTe 3 o 8 =1:0.1 mass ratio to weigh Zn 2 Te 3 o 8 、TiTe 3 o 8 , mixed to form Zn 2 Te 3 o 8 0.1TiTe 3 o 8 Mixture, weigh Zn according to 3% of the mass ...

Embodiment 3

[0033] Zn 2 Te 3 o 8 0.3TiTe 3 o 8 The preparation of composite coated lithium titanate negative electrode material comprises the following steps:

[0034] (1) Preparation of pure-phase lithium titanate precursor: according to the Li:Ti stoichiometric ratio of 4.1:5, accurately weigh lithium nitrate and tetraisopropyl titanate, and add them to 3wt% citric acid absolute ethanol solution (The amount of citric acid added is 4% of the mass of theoretically synthesized pure-phase lithium titanate), and ultrasonic treatment was carried out for 1.5h, and then reacted at 70°C under stirring and reflux for 5h to form a gel, which was dried at 110°C Forming a xerogel; pre-calcining the xerogel at 500°C for 4.5 hours in an air atmosphere to obtain a pure-phase lithium titanate precursor;

[0035] (2)(2) Press Zn 2 Te 3 o 8 : TiTe 3 o 8 =1:0.3 mass ratio to weigh Zn 2 Te 3 o 8 、TiTe 3 o 8 , mixed to form Zn 2 Te 3 o 8 0.3TiTe 3 o 8 Mixture, weigh Zn according to 5% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com