Carbonaceous material for negative electrodes of nonaqueous electrolyte secondary batteries, and method for producing same

A non-aqueous electrolyte and secondary battery technology, applied in non-aqueous electrolytes, secondary batteries, battery electrodes, etc., can solve the problems of large crystal expansion and shrinkage, low cycle characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

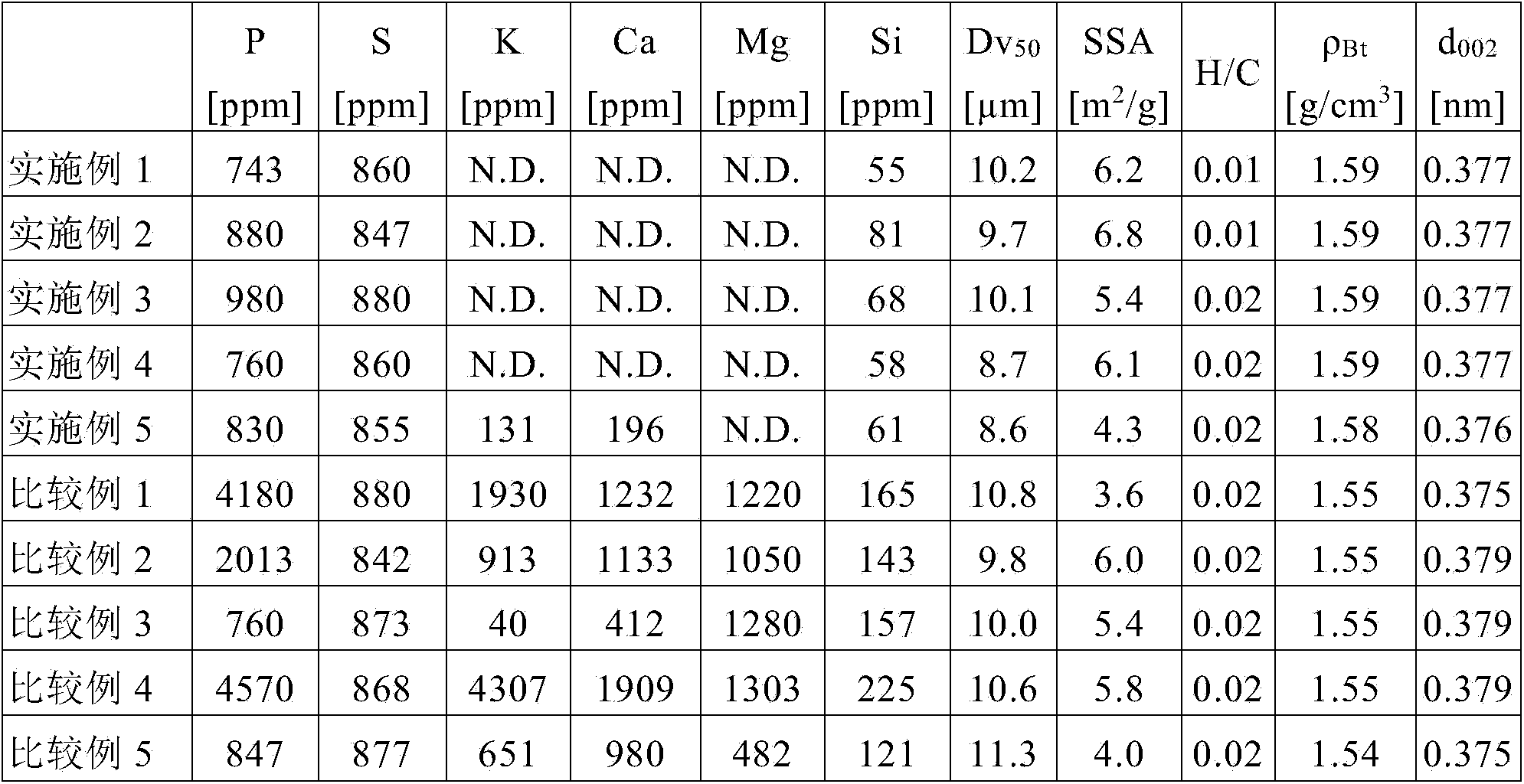

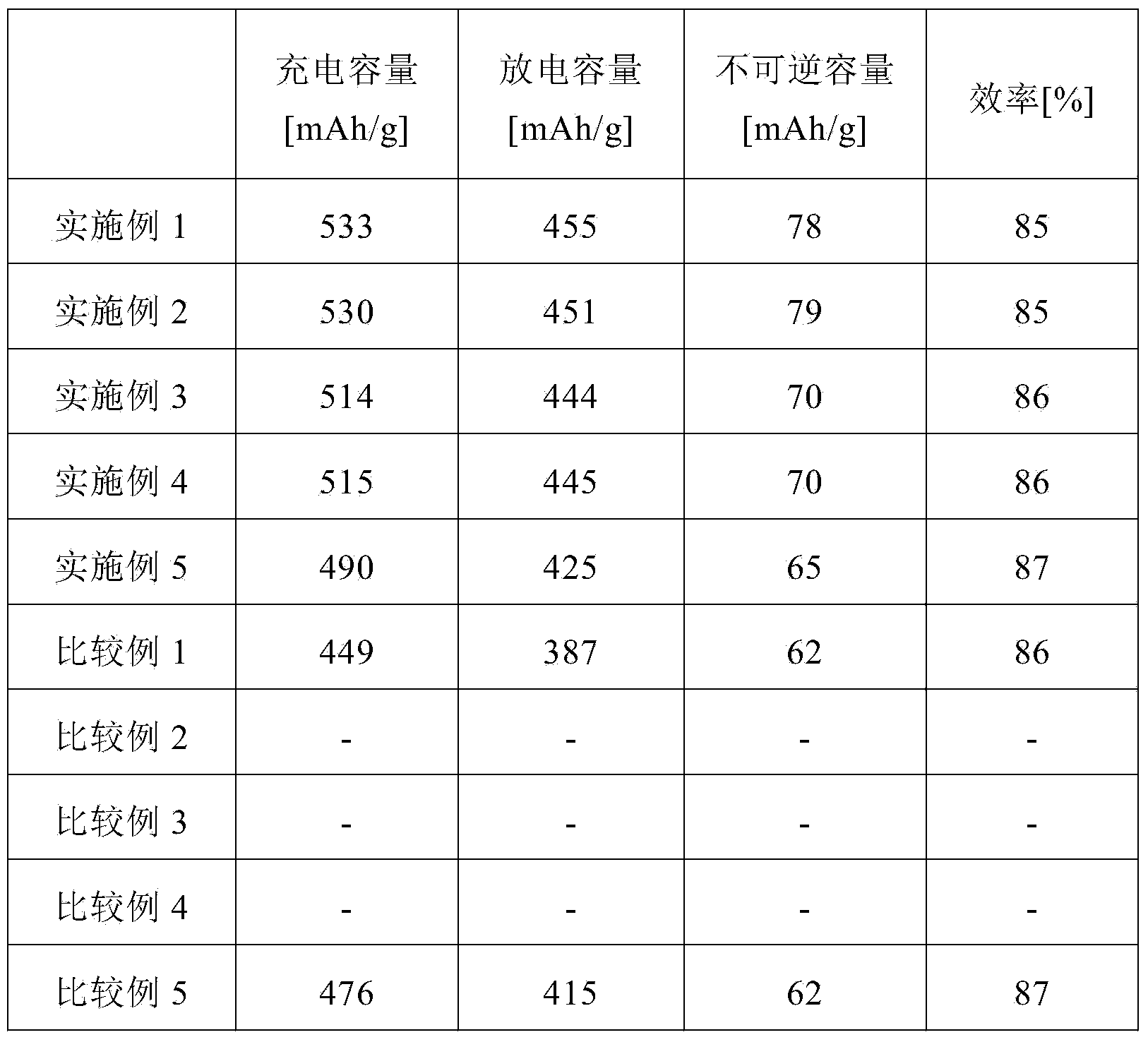

Embodiment 1

[0253] After adding 300 g of 1% hydrochloric acid to 100 g of extracted coffee grounds, the mixture was stirred at a temperature of 100° C. for 1 hour, and then filtered. Then, repeat the water washing operation three times, that is, add 300 g of boiling water, filter after stirring for 1 hour, and perform deashing treatment to obtain deashed coffee extraction residue. The obtained delimed coffee residue was dried under a nitrogen atmosphere, and then detarred at a temperature of 700° C. to obtain a carbonaceous precursor. It was pulverized using a rod mill to produce carbonaceous precursor particles. Then, the carbon precursor was mainly fired at 1250° C. for 1 hour to obtain a carbonaceous material 1 with an average particle diameter of 10 μm.

Embodiment 2

[0255] Carbonaceous material 2 was obtained in the same manner as in Example 1, except that the acid used for deliming was sulfuric acid.

Embodiment 3

[0257] Carbonaceous material 3 was obtained in the same manner as in Example 1, except that the acid used for deliming was citric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com