A kind of fly ash autoclaved aerated concrete block

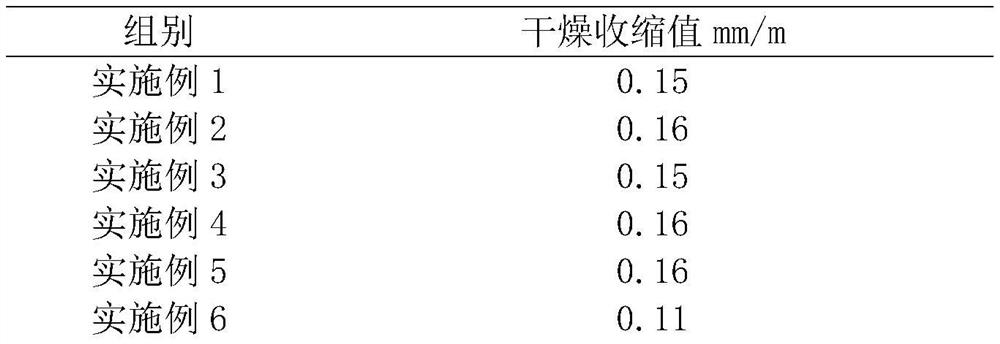

A concrete block, autoclaved gas filling technology, applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of decreased adhesion between mortar and block, difficulty in normal hydration, and wall cracking, etc., to achieve Not easy to crack and hollow, reduce the drying shrinkage value, the effect of small drying shrinkage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

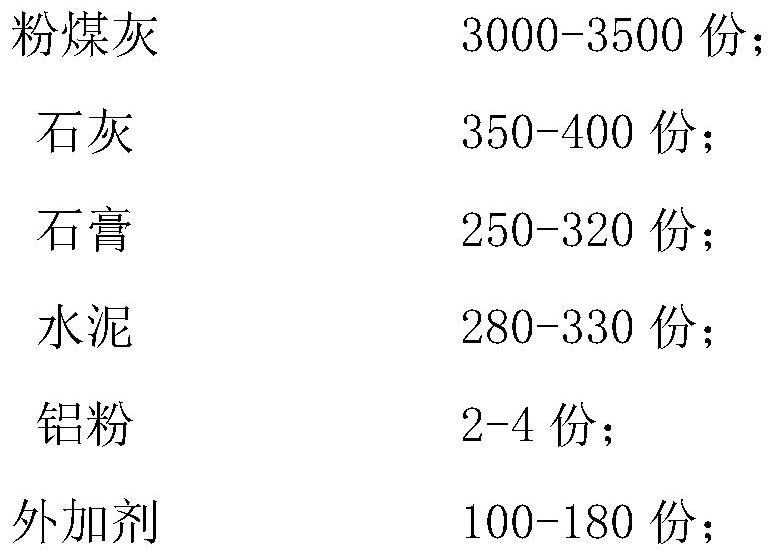

Method used

Image

Examples

Embodiment 1

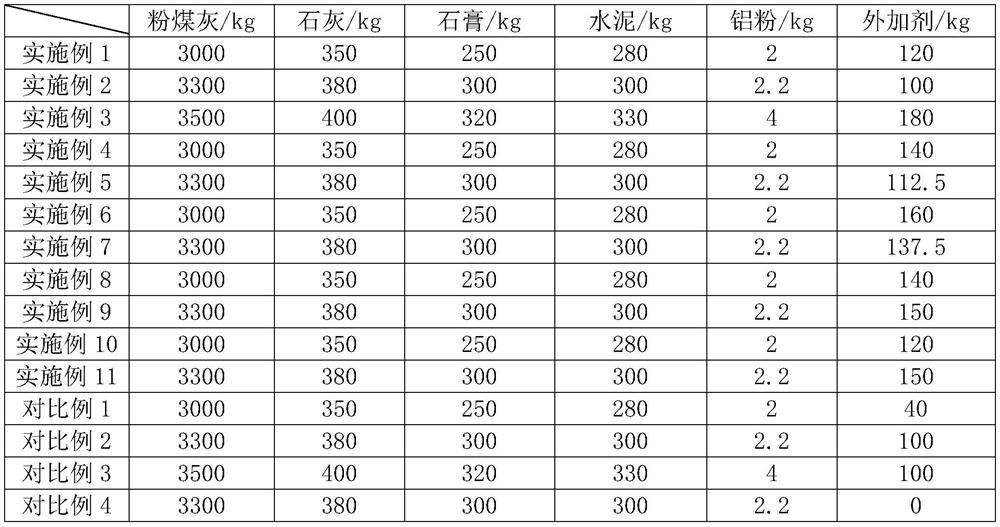

[0027]Example 1: A fly ash autoclaved aerated concrete block. The raw materials include water and materials, and the mass ratio of water and materials is 0.56:1. Each component and its content in the material are shown in Table 1, wherein the admixture includes 80kg acrylamide / butyl acrylate / vinyl acetate / 2-acrylamide-2-methylpropanesulfonic acid tetrapolymer, 20kg polyglycerol Ricinoleate and 20 kg calcium cyclamate.

[0028] The preparation method of acrylamide / butyl acrylate / vinyl acetate / 2-acrylamide-2-methylpropanesulfonic acid tetrapolymer is as follows: in parts by weight, get 180 parts of butyl acrylate and 180 parts of vinyl acetate , 150 parts of acrylamide, mixed to get reagent A; take 15 parts of 2-acrylamido-2-methylsulfonic acid, mix with 15 parts of water to get reagent B; take 2 parts of potassium persulfate and dissolve in 10 parts In water, get reagent C; take 4 parts of ethoxylated nonylphenol sulfosuccinic acid half ester disodium salt, 1 part of sodium st...

Embodiment 2

[0030] Example 2: A fly ash autoclaved aerated concrete block, the difference from Example 1 is that the mass ratio of water and material in the raw material is 0.55:1, and the components and contents of the material are shown in Table 1 , admixtures include 75kg acrylamide / butyl acrylate / vinyl acetate / 2-acrylamido-2-methylpropanesulfonic acid tetrapolymer, 12.5kg polyglycerol ricinoleate and 12.5kg cyclohexyl sulfamate Calcium acid.

[0031] The preparation method of acrylamide / butyl acrylate / vinyl acetate / 2-acrylamide-2-methylpropanesulfonic acid tetrapolymer is as follows: in parts by weight, 195 parts of butyl acrylate and 195 parts of vinyl acetate , 160 parts of acrylamide, mixed to get reagent A; take 20 parts of 2-acrylamido-2-methylsulfonic acid, mix with 15 parts of water to get reagent B; take 3 parts of potassium persulfate and dissolve in 10 parts In water, get reagent C; take 6 parts of ethoxylated nonylphenol sulfosuccinic acid half ester disodium salt, 2 parts...

Embodiment 3

[0032] Example 3: A fly ash autoclaved aerated concrete block, the difference from Example 1 is that the mass ratio of water and material in the raw material is 0.6:1. Each component and its content in the material are shown in Table 1, wherein the admixture includes 120kg acrylamide / butyl acrylate / vinyl acetate / 2-acrylamide-2-methylpropanesulfonic acid tetrapolymer, 30kg polyglycerol Ricinoleate and 30kg calcium cyclamate.

[0033] The production method of the fly ash autoclaved aerated concrete block comprises the following steps, step one, screening the fly ash, grinding the fly ash finely, after screening with a sieve, weighing the fly ash of formula quantity; step two, Slurry making, take fly ash and water with a formula quantity of 99%, and mix them evenly to obtain a slurry; Step 3, batching, weigh lime, gypsum, cement, and admixtures, and add them to the slurry; weigh aluminum powder and formula Measure 1% of water, mix evenly to obtain a mixed solution, add the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com