Environmentally friendly heat-insulation fireproof mortar and preparation method thereof

An environmentally friendly, mortar technology, applied in the field of building thermal insulation materials, can solve the problems of residents' personal and property safety threats, easy combustion, poor fire resistance, etc., and achieve the effect of satisfying environmental sustainable development, small bulk density, and enhanced construction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

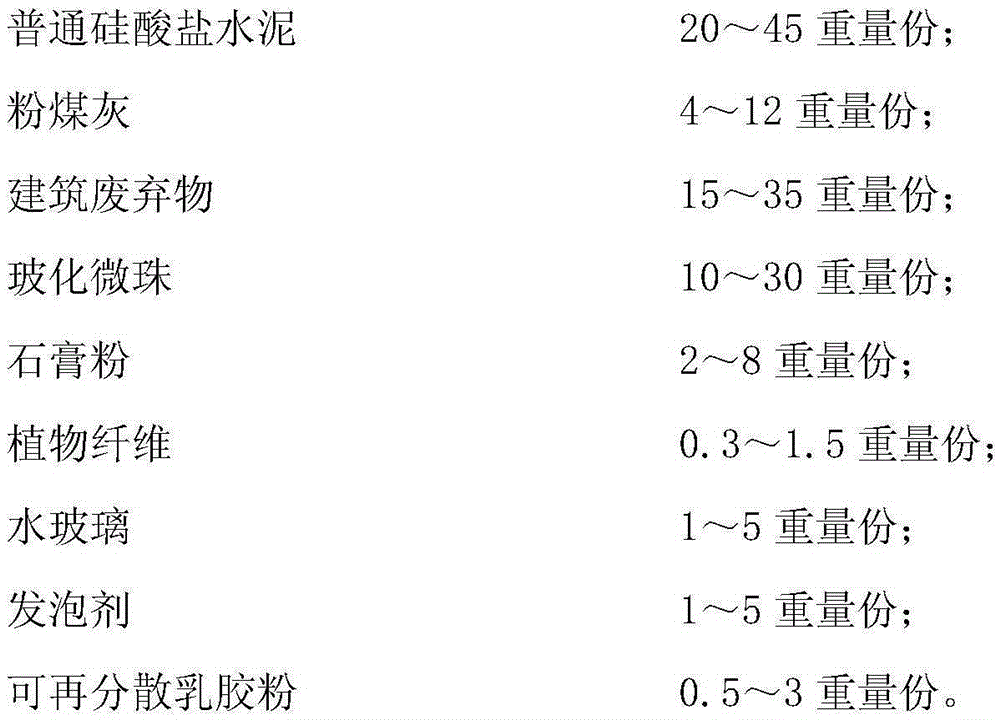

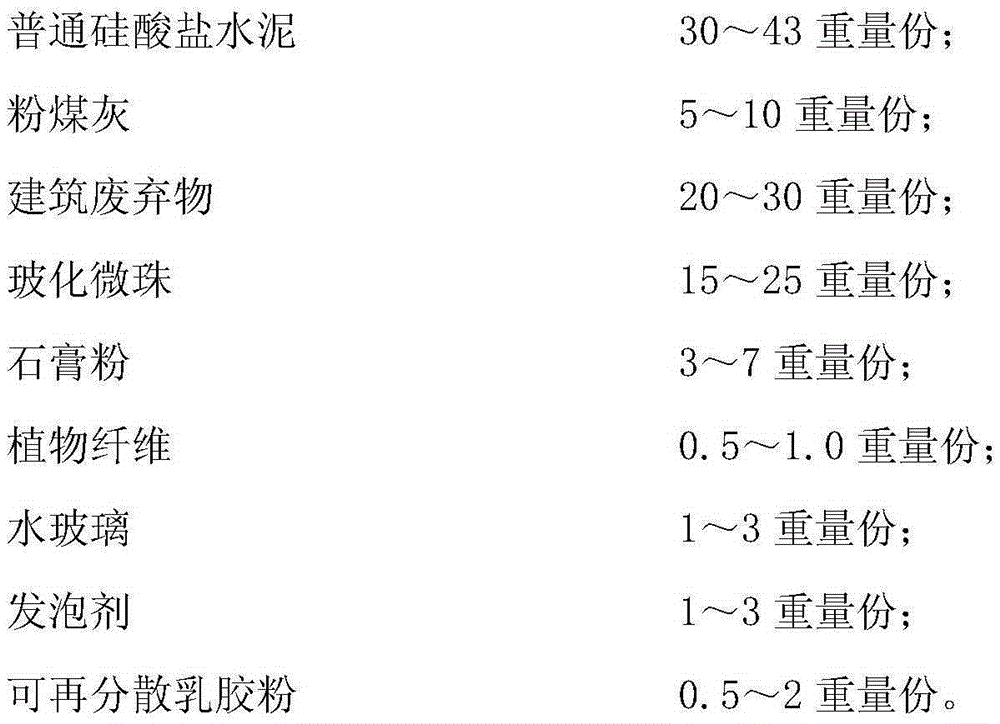

Examples

preparation example Construction

[0040] The preparation method of the above-mentioned environment-friendly thermal insulation fireproof mortar comprises the following steps:

[0041] Weigh the weight of each raw material according to the ratio of raw materials; first mix cement, fly ash, gypsum powder, and redispersible latex powder in a gravity-free mixer, and then put construction waste particles, vitrified microbeads, and plant fibers into the In the non-gravity mixer, fully mix and stir to form a raw material mixture, and put the raw material mixture into a packaging bag for standby; use a plastic packaging bag to pack the water glass weighed according to the ratio of raw materials, and put the packaged water glass in the packaging bag; construction When in use, the raw material mixture is mixed with water, the ratio of the raw material mixture to water is 1:1-1.5, and the water glass in the plastic packaging bag is added at the same time, and it is used after being fully stirred.

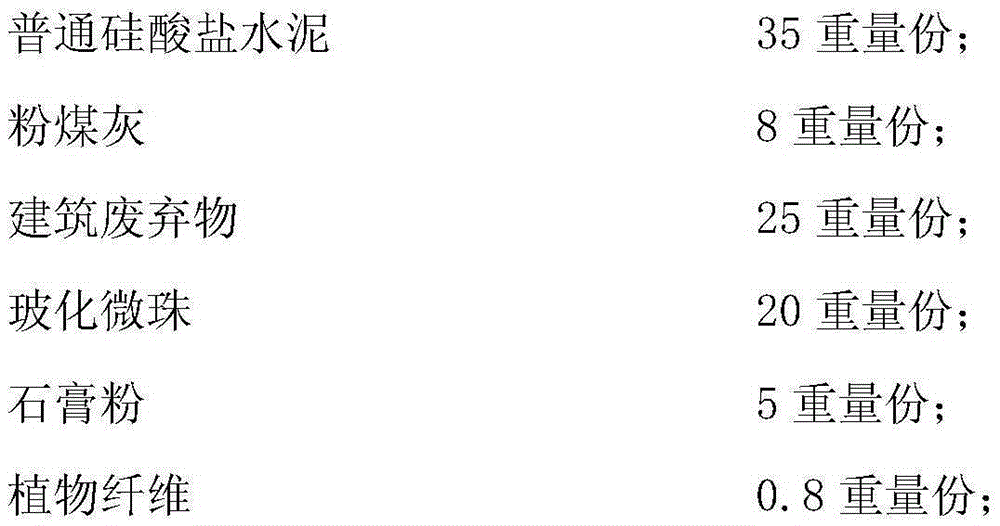

Embodiment 1

[0053] The environment-friendly thermal insulation fireproof mortar of the present embodiment is made up of the raw material of following weight:

[0054] Ordinary Portland Cement

[0055] Foaming agent

[0056]The preparation method of the above-mentioned environment-friendly thermal insulation and fireproof mortar comprises the following steps: weighing each raw material according to the ratio of raw materials; first mixing cement, fly ash, gypsum powder, and redispersible latex powder in a gravity-free mixer, and then Put construction waste particles, vitrified microbeads, and plant fibers into a gravity-free mixer for full mixing and stirring to form a raw material mixture, and put the raw material mixture into packaging bags for later use; use plastic packaging bags to pack water glass weighed according to the ratio of raw materials , put the packaged water glass in the packaging bag; during construction and use, mix the raw material mixture with water...

Embodiment 2

[0058] The environment-friendly thermal insulation fireproof mortar of the present embodiment is made up of the raw material of following weight:

[0059] Ordinary Portland Cement

[0060] The preparation method of the above-mentioned environment-friendly thermal insulation and fireproof mortar is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com