Aerated concrete block produced by dump-leached slags

A technology of aerated concrete and heap leaching slag, applied in the field of aerated concrete blocks and new wall materials, can solve the problems of easy formation of dust, landslides, land occupation, environmental threats, etc., and achieves low cost, reduced usage, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

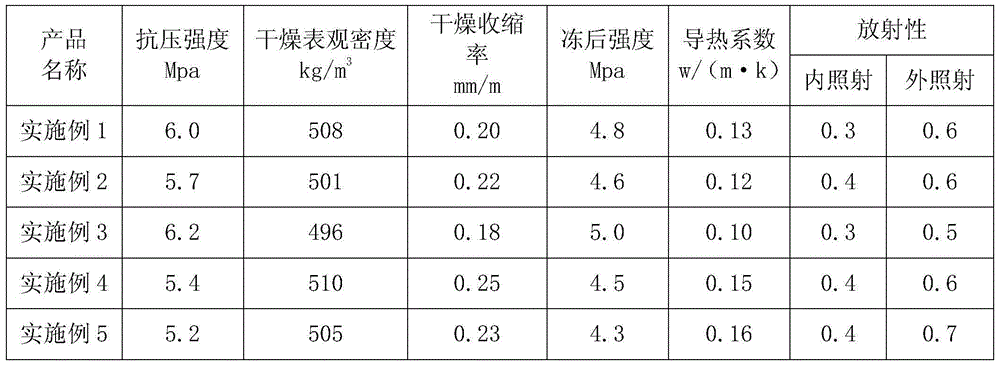

Examples

Embodiment 1

[0030] The manufacture method of the aerated concrete block produced by heap leaching slag comprises the following steps:

[0031] 1. Take lateritic nickel ore heap leaching slag, quicklime, and gypsum, and grind them into powders with a particle size of less than 0.08mm;

[0032] 2. Take raw materials respectively by following parts by weight: laterite nickel ore heap leaching residue 500kg, quicklime 150kg, cement 200kg, gypsum 10kg, aluminum powder 1.2kg, polycarboxylate superplasticizer 15kg;

[0033] 3. Add laterite nickel ore heap leaching slag and gypsum into the ball mill, add an appropriate amount of water for water milling, and grind until the particle size is less than 0.08mm, and control the fluidity of the slurry to 280mm;

[0034] 4. Put the slurry in the slurry mixer, add polycarboxylate high-efficiency water reducer, stir well, so that the fluidity of the slurry reaches 400mm; pour it into the pouring mixer, continue stirring for 1 minute, add cement, and stir ...

Embodiment 2

[0040] The manufacture method of the aerated concrete block produced by heap leaching slag comprises the following steps:

[0041] 1. Take lateritic nickel ore heap leaching slag, quicklime, and gypsum, and grind them into powders with a particle size of less than 0.08 mm;

[0042]2. Take the raw materials respectively by the following parts by weight: laterite nickel ore heap leaching residue 200kg, quicklime 80kg, cement 50kg, gypsum 3kg, aluminum powder 0.4kg, polycarboxylate superplasticizer 8kg;

[0043] 3. Add laterite nickel ore heap leaching slag and gypsum into the ball mill, add an appropriate amount of water for water milling, and grind until the particle size is less than 0.08mm, and control the fluidity of the slurry to 260mm;

[0044] 4. Put the slurry in the slurry mixer, add polycarboxylate high-efficiency water reducer, and stir well, so that the fluidity of the slurry reaches 370mm; pour it into the pouring mixer, continue stirring for 1 minute, add cement, a...

Embodiment 3

[0050] The manufacture method of the aerated concrete block produced by heap leaching slag comprises the following steps:

[0051] 1. Take lateritic nickel ore heap leaching slag, quicklime, and gypsum, and grind them into powders with a particle size of less than 0.08 mm;

[0052] 2. Take the raw materials respectively by the following parts by weight: laterite nickel ore heap leaching residue 400kg, quicklime 120kg, cement 100kg, gypsum 6kg, aluminum powder 0.7kg, polycarboxylate superplasticizer 12kg;

[0053] 3. Add lateritic nickel ore heap leaching slag and gypsum into the ball mill, add an appropriate amount of water for water milling, and grind until the particle size is less than 0.08mm, and control the fluidity of the slurry to 270mm;

[0054] 4. Put the slurry in the slurry mixer, add polycarboxylate high-efficiency water reducer, stir well, so that the fluidity of the slurry reaches 380mm; pour it into the pouring mixer, continue stirring for 1 minute, add cement, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com