Composite isolation membrane and preparation method thereof

An isolation film and metal technology, applied in the field of composite isolation film and its preparation, can solve the problems of reducing the water absorption of the coated isolation film, peeling off of the surface coating of the isolation film, limited drying and water removal effect, etc. Low-demand, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

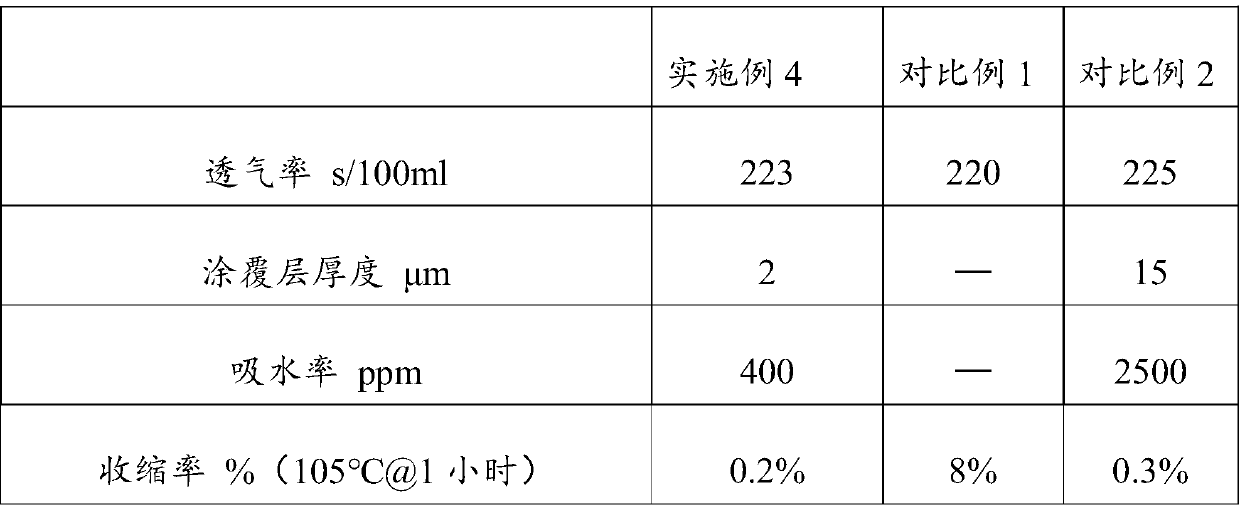

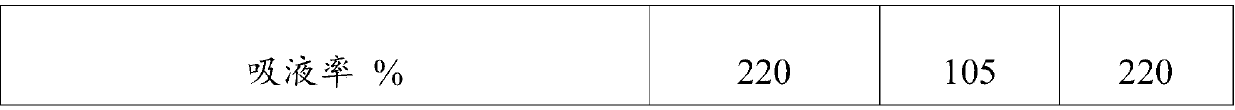

Examples

Embodiment 1

[0039] This embodiment provides the first kind of composite isolation membrane, and its specific preparation process is as follows:

[0040] S11. Selecting alumina with an average particle size (D50) of 0.5 μm and calcining in a high-temperature muffle furnace at 1400° C. for 12 hours, and cooling in the furnace after calcining to obtain pretreated alumina powder.

[0041] S12. Put the pretreated alumina powder and stearic acid into the ball mill at a mass ratio of 100:3, the number ratio of large balls (5-8mm in diameter) and small balls (2-4mm in diameter) in the ball mill 3:5, ball milled at room temperature for 12 hours, and sieved to obtain surface-hydrophobized alumina.

[0042] S13. Mix the binder, water and surface-hydrophobized alumina uniformly at room temperature, and stir for 12 hours to obtain a coating slurry, wherein the binder is prepared by mixing β-cyclodextrin with hydrogen peroxide React at 70°C for 24 hours, and obtain the binder after drying. The mass r...

Embodiment 2

[0046] This embodiment provides the second composite isolation membrane, and its specific preparation process is as follows:

[0047] S21. Selecting alumina with an average particle size (D50) of 1.5 μm and calcining at a high temperature muffle of 1700° C. for 48 hours, and cooling in the furnace after calcining to obtain pretreated alumina powder.

[0048] S22. Put the pretreated alumina powder and oleic acid into the ball mill together in a mass ratio of 100:12. The number ratio of large balls (5-8 mm in diameter) and small balls (2-4 mm in diameter) in the ball mill is 3:5, ball milled at room temperature for 24 hours, and sieved to obtain surface-hydrophobized alumina.

[0049] S23. Mix the binder, water and surface-hydrophobized alumina uniformly at room temperature, and stir for 12 hours to obtain a coating slurry, wherein the binder is prepared by mixing β-cyclodextrin with hydrogen peroxide React at 100°C for 48 hours, and obtain the binder after drying. The mass ra...

Embodiment 3

[0053] This embodiment provides the third kind of composite isolation membrane, and its specific preparation process is as follows:

[0054] S31, selecting alumina with an average particle size (D50) of 1 μm and calcining at a high temperature muffle of 1500° C. for 24 hours, and cooling in the furnace after calcining to obtain pretreated alumina powder.

[0055] S32. Add the pretreated alumina powder and zinc stearate into the ball mill at a mass ratio of 100:8, the number of large balls (5-8 mm in diameter) and small balls (2-4 mm in diameter) in the ball mill The ratio is 3:5, ball milling at room temperature for 48 hours, and the surface hydrophobized alumina is obtained after sieving.

[0056] S33. Mix the binder, water and surface-hydrophobized alumina uniformly at room temperature, and stir for 12 hours to obtain a coating slurry, wherein the binder is prepared by mixing β-cyclodextrin with hydrogen peroxide React at 90°C for 48 hours, and obtain the binder after dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com