Preparation process of polyurethane-based thermal insulation type multi-layer composite waterproof coiled material

A multi-layer composite and waterproof membrane technology, which is applied in the field of waterproof membrane preparation, can solve the problems of weakening the van der Waals force between polyvinyl chloride molecules, increasing the mobility of polyethylene molecular chains, and reducing the crystallinity of polymer molecular chains. Achieve the effects of enhanced flexibility, reduced viscosity, and reduced crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

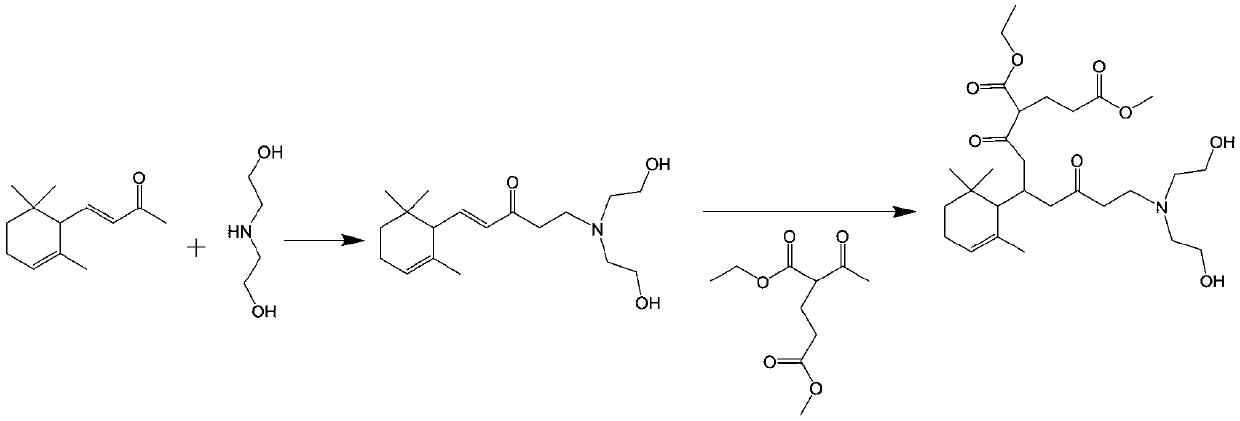

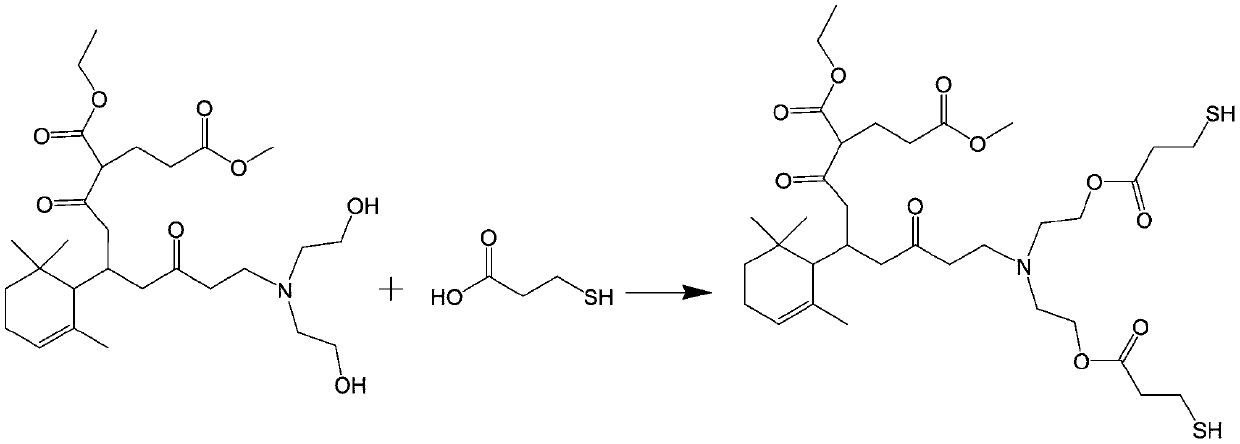

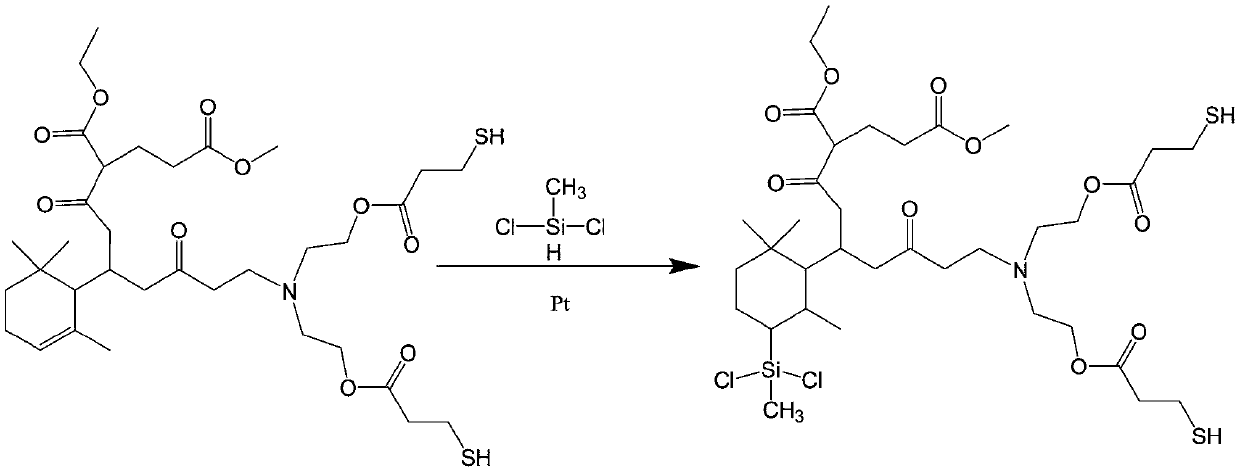

[0035] The concrete preparation process of toughening modifier is as follows:

[0036] Step 1, add 100g of α-ionone, 61g of diethanolamine, 17g of paraformaldehyde, 53g of concentrated hydrochloric acid and 400g of absolute ethanol into the reaction kettle at the same time, raise the temperature to 60°C and reflux for 3-4h, cool to room temperature and use sodium hydroxide Adjust the pH of the solution to 13, then add diethyl acetylglutarate dropwise therein, stir and react at room temperature for 6 hours, let stand overnight, filter, wash with deionized water for 4-5 times, and dry to obtain product A. The reaction structural formula is as follows, and the product A is identified by the infrared spectrometer at the same time, and the product A is at 1724cm -1 A new absorption peak appears at the place, which is the infrared absorption peak of -C=O in the ester group of diethyl acetylglutarate, so it can be seen that diethyl acetylglutarate is successfully grafted on α-ionone;...

Embodiment 2

[0052] The preparation process of the toughened polyvinyl chloride sheet is as follows:

[0053] S1: Weigh 1 kg of PVC powder and add it to 8 L of cyclohexanone and stir to dissolve it, then add 340 g of the toughening modifier prepared in Example 1 and 380 g of sodium carbonate to it, heat up to 80°C for reflux reaction for 32 hours, and recover the solvent by rotary evaporation , washing the obtained solid product with water for 4-5 times to obtain modified polyvinyl chloride powder;

[0054] S2: Add 1kg of toughened polyvinyl chloride powder and 96g of calcium carbonate into the open mill at the same time to melt and plasticize the sheet, then preheat the sheet in a vulcanizer at 170°C for 15 minutes, then pressurize, exhaust and re- The pressure was kept for 7 minutes, and then shaped by a cold press to obtain a polyvinyl chloride sheet.

Embodiment 3

[0066] A preparation process of polyurethane-based thermal insulation multi-layer composite waterproof membrane, the specific preparation process is as follows:

[0067] In the first step, 1kg of phosphorous trichloride, 1.21kg of ethanolamine and 860g of acetone were added to the reaction kettle at the same time, stirred and reacted for 3 hours at room temperature, then 350g of sodium carbonate was added to it, stirred and reacted for 2 hours, and then 2.86kg of ethylene glycol disulfide was added. Glycerol ether, heated to 82°C, refluxed and stirred for 4 hours to obtain a light yellow polymer solution, washed the polymer solution with ionic water for 5-6 times, and then subjected to vacuum distillation to obtain polyphosphoryloxypolyamine;

[0068] In the second step, 1 kg of polyphosphoryl oxypolyamine, dibutylene dilaurate, diisopropanolamine and water are simultaneously added to the stirring tank and stirred and mixed for 5 minutes, then triphenylmethane triisocyanate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com