Lithium battery fire-extinguishing filling material additive preparation method

A technology for preparation of additives and filling materials, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as flammable electrolyte leakage, and achieve excellent thermal stability, easy synthesis, and high flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take the PEO-based total fire extinguishing additive as an example:

[0019] An embodiment of the present invention provides a method for preparing a lithium battery fire extinguishing filling material additive, the method comprising the following steps:

[0020] 1) Prepare PEO (polyethylene oxide)-based fire extinguishing additive: accurately weigh PEG (polyethylene glycol) and silane coupling agent according to the mass ratio, the mass ratio of the PEG and silane coupling agent is 5:1, use mass Concentration is 20% THF (tetrahydrofuran) as a solvent to dissolve PEG and silane coupling agent, after the two are mixed, react under the protection of nitrogen, react in the reactor for 4 hours, the stirring speed is 70 rev / min, the reaction time For 4 hours, the reaction temperature was controlled at 60°C.

[0021] 2) Filter the product of step 1), remove the unreacted silane coupling agent, leave the product PEG-silane conjugate and react with nano-silica hydrosol under t...

Embodiment 2

[0029] The difference with embodiment one is: select physical doping dimethyl phosphate fire extinguishing additive as an example. The method includes:

[0030] 1) Accurately weigh PEG and silane coupling agent according to the mass ratio of 5:1, dissolve PEG and silane coupling agent with an appropriate amount of THF as a solvent, mix them and react under the protection of nitrogen. The product from the previous step is filtered and reacted with the nano-silica hydrosol under the protection of nitrogen, and the reaction product is centrifuged. Finally, react the product of the previous step with PPG, mix the obtained solution with dimethyl methyl phosphate (25%) and stir evenly, and pour it on a PTFE mold to obtain a physically doped dimethyl methyl phosphate polymer electrolyte.

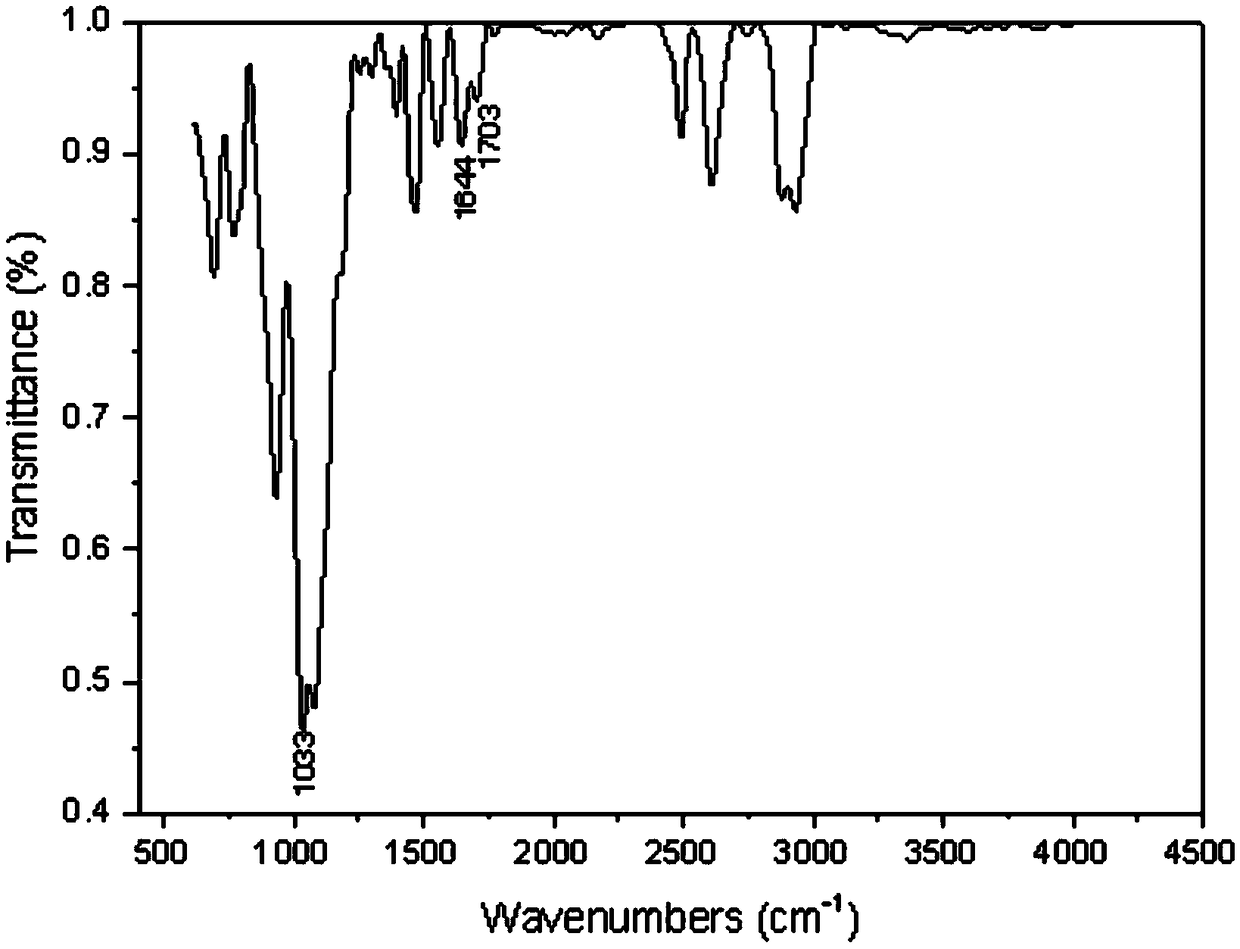

[0031] 2) Performance test: put the product on the workstation for infrared absorption characteristic test, see the results figure 1 , it can be seen that the infrared absorption characteristic pe...

Embodiment 3

[0033] The difference with Embodiment 1 and 2 is that:

[0034] Using the new dimethyl phosphate fire extinguishing additive, the method includes:

[0035] 1) Accurately weigh dimethyl methyl phosphate and PPG according to the mass ratio of 2:1, dissolve dimethyl methyl phosphate and PPG with an appropriate amount of chloroform as a solvent and add an appropriate amount of catalyst, mix the two under the protection of nitrogen reaction. Mix the product from the previous step with PEG, add an appropriate amount of catalyst and react under the protection of nitrogen. Finally, the product of the previous step is reacted with silanized PEG, and the resulting solution is poured on a PTFE mold to obtain a phosphate ester composite electrolyte.

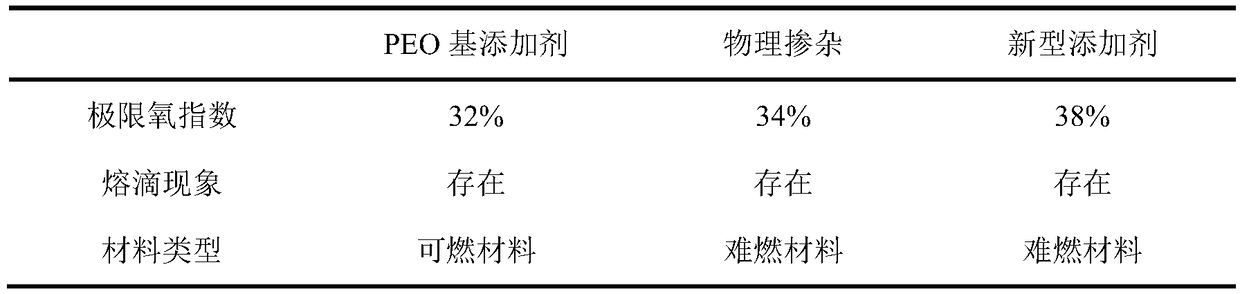

[0036] 2) Performance test: put the product on the workstation to test the combustion characteristics such as the limiting oxygen index, the results are shown in Table 1, it can be seen that the limiting oxygen index and flame retardancy o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com