Patents

Literature

30results about How to "High temperature conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

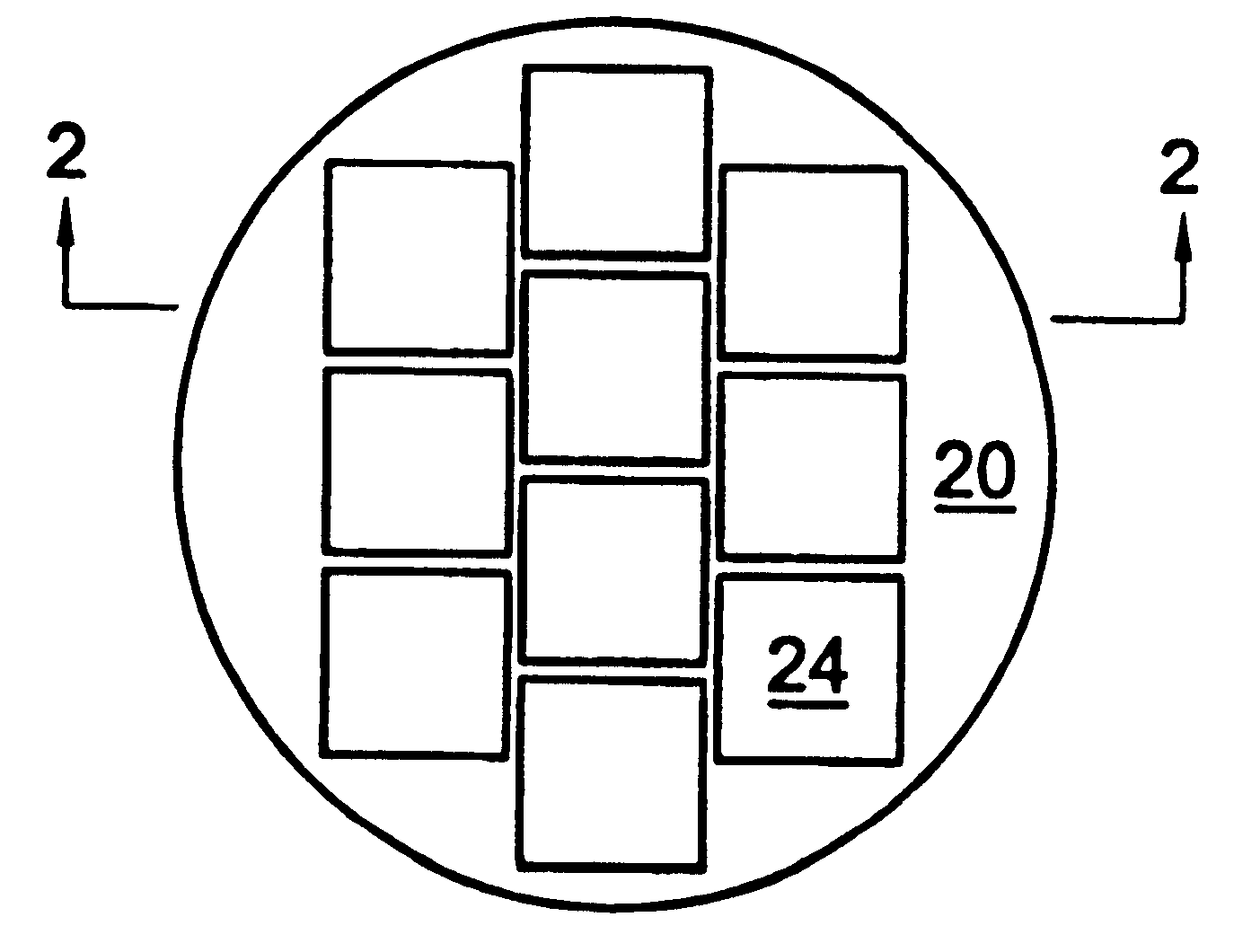

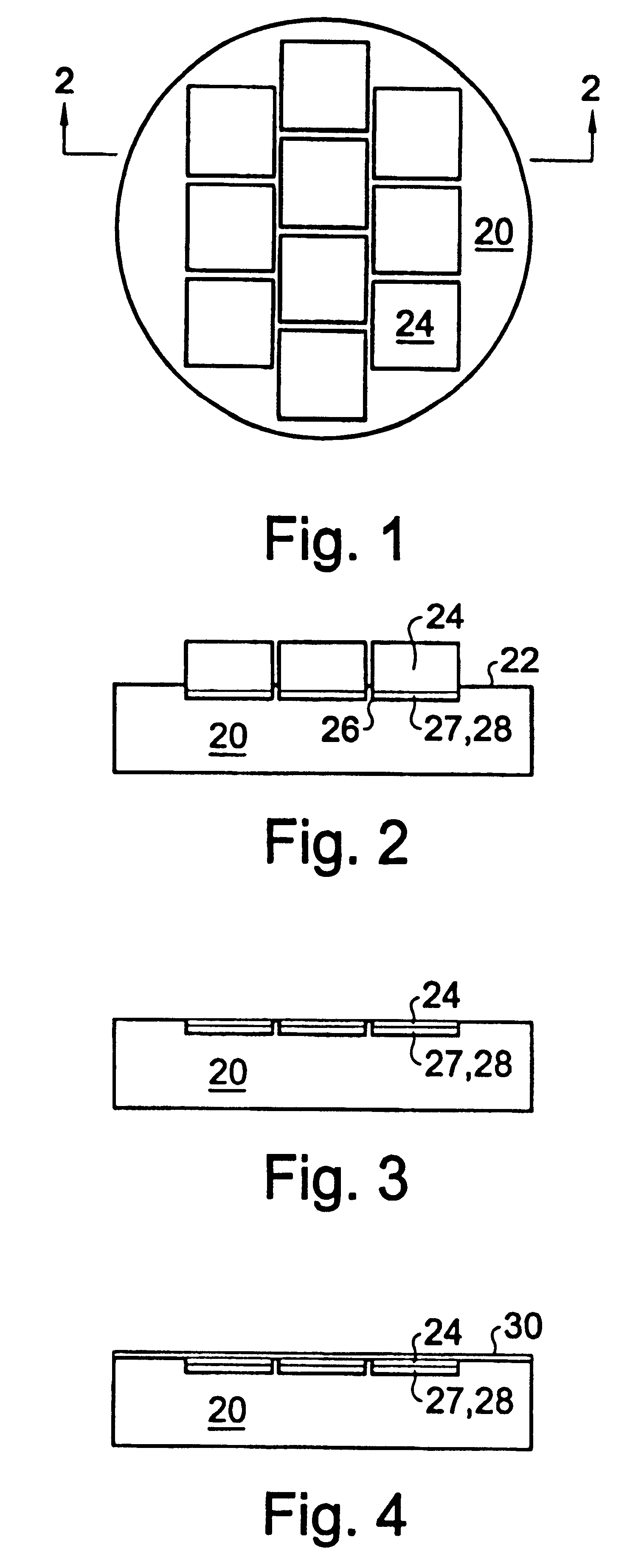

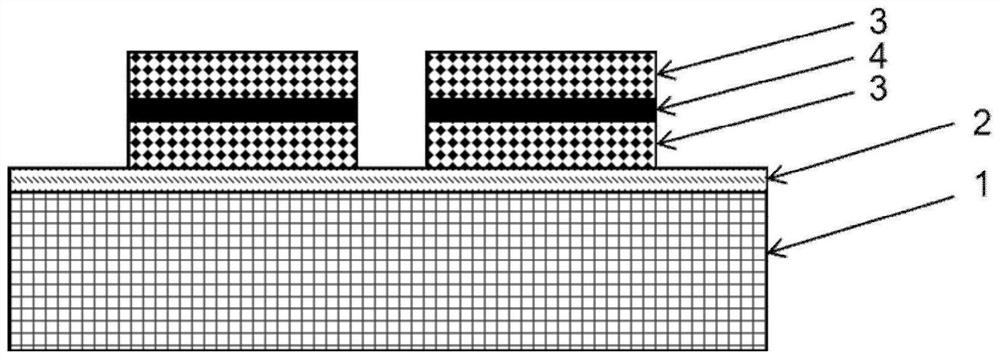

Discrete wafer array process

InactiveUS6248646B1High temperature resistanceGreat ruggednessSolid-state devicesSemiconductor/solid-state device manufacturingWaferingCompound (substance)

A method of preparing small wafers for compatibility with conventional large wafer fabrication equipment comprising the following steps: indenting a face of a large wafer to form an array of depressions thereon, each depression sized to matingly accept a lower portion of a small wafer; applying a bonding medium to an exterior side of the depressions on the indented face of the large wafer; matingly fitting the small wafers into the depressions so that the small wafers are positioned in an array on the large wafer; and, removing the top portion of the small wafers standing out of the depressions by chemical mechanical polishing so that the remaining portions of the small wafers then have a uniform thickness generally equal to the depth of the indentations in the large wafer. A preferred aspect of this invention provides for a method as above wherein the small wafer is SiC and the large wafer is made from an amorphous substance which comprises SiC or aluminum nitride.

Owner:OKOJIE ROBERT S

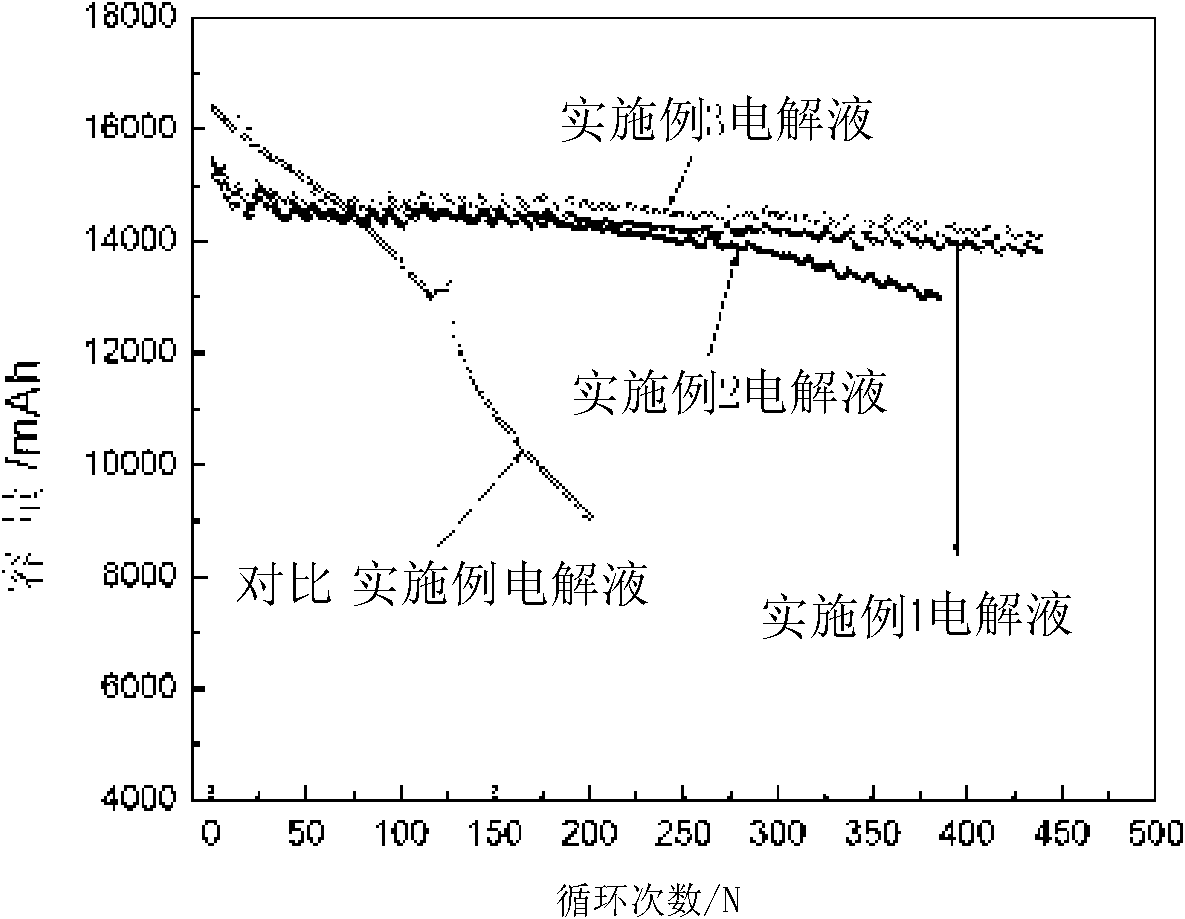

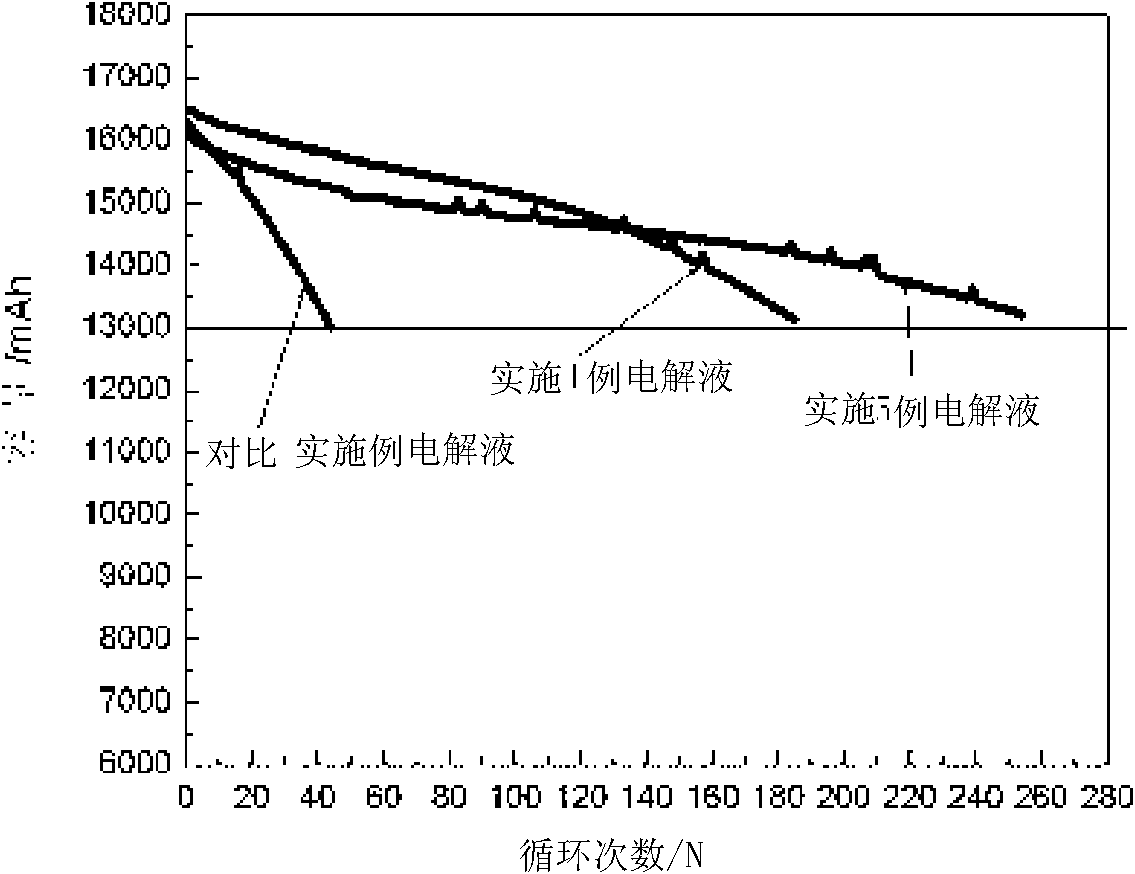

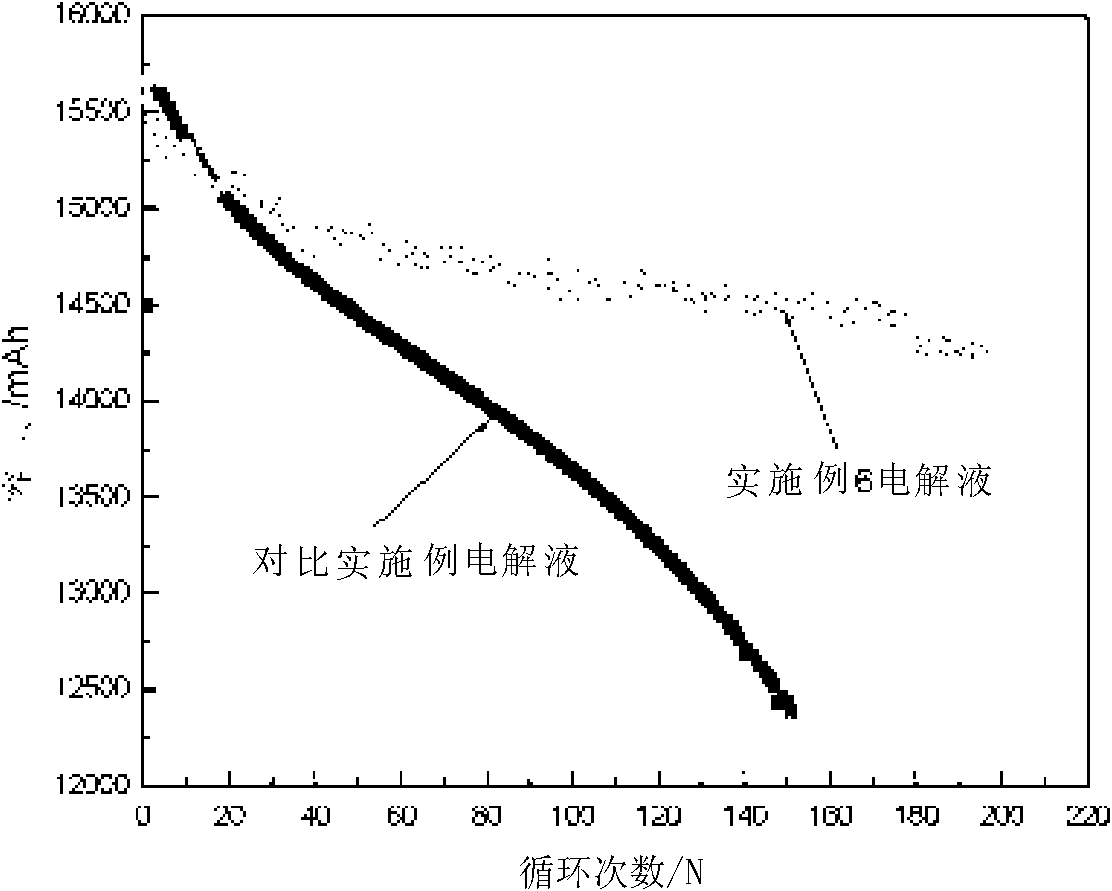

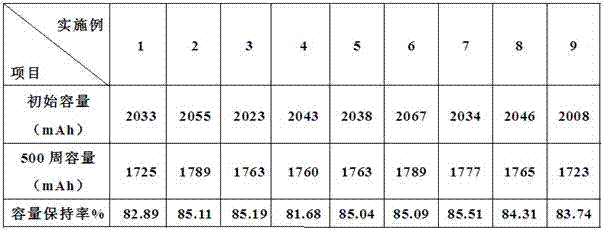

Electrolyte for lithium-ion power battery and preparation method thereof

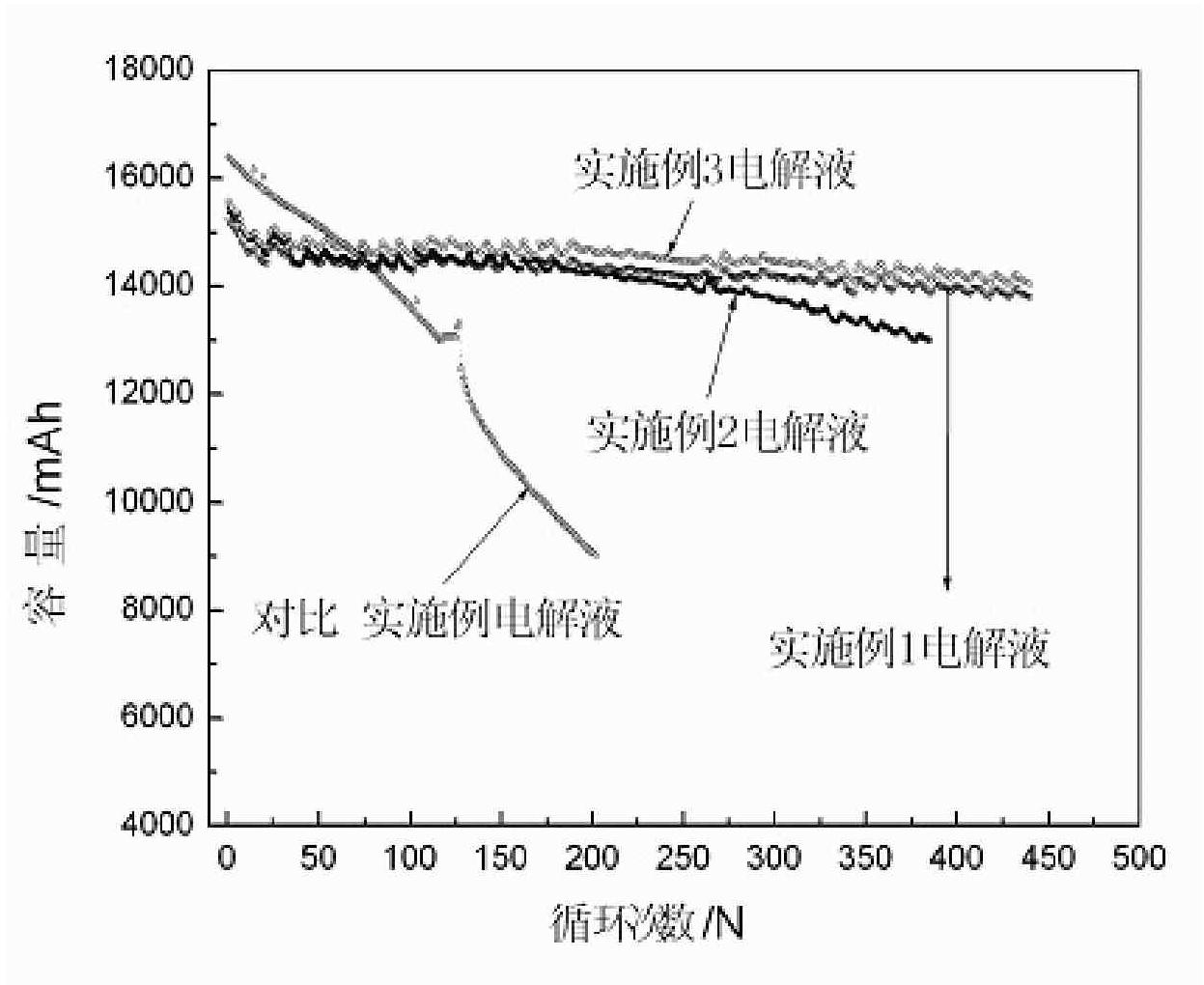

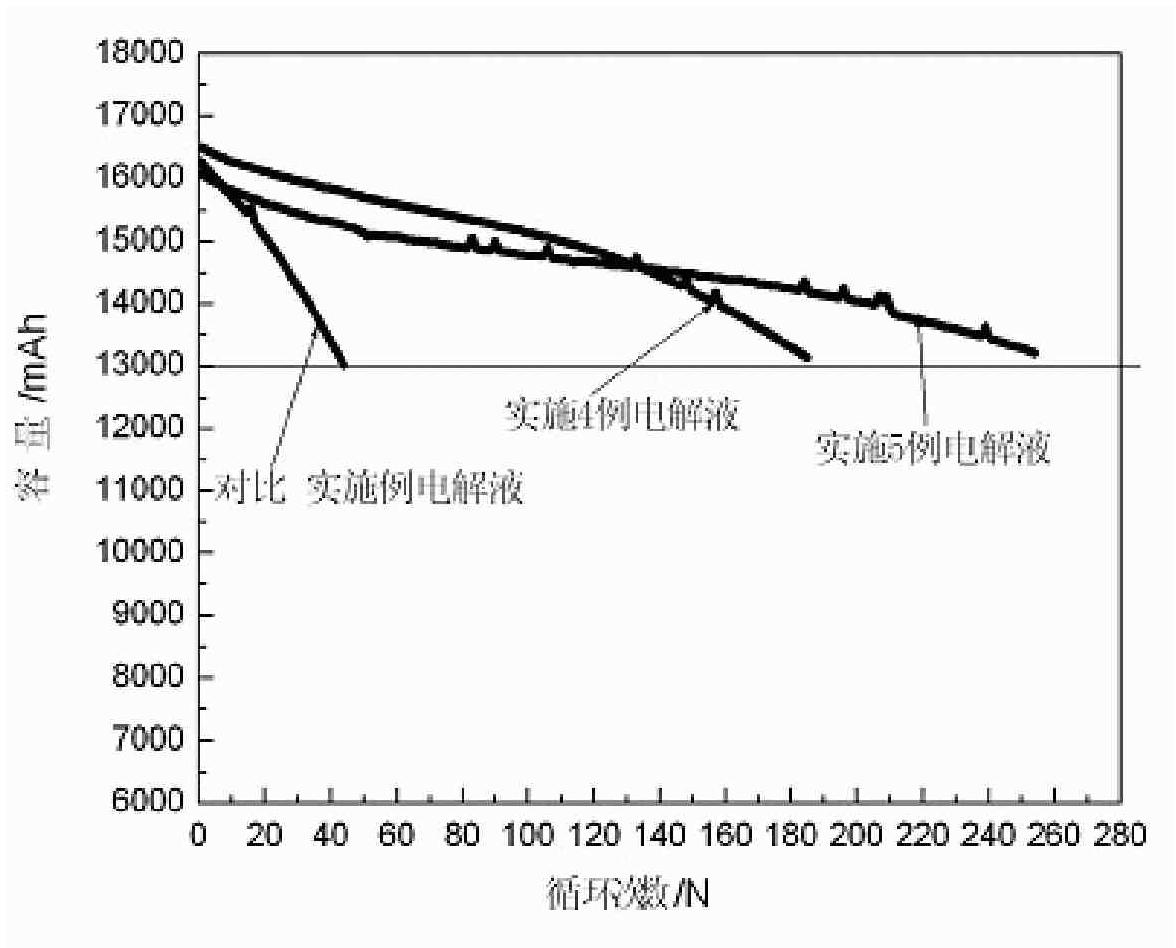

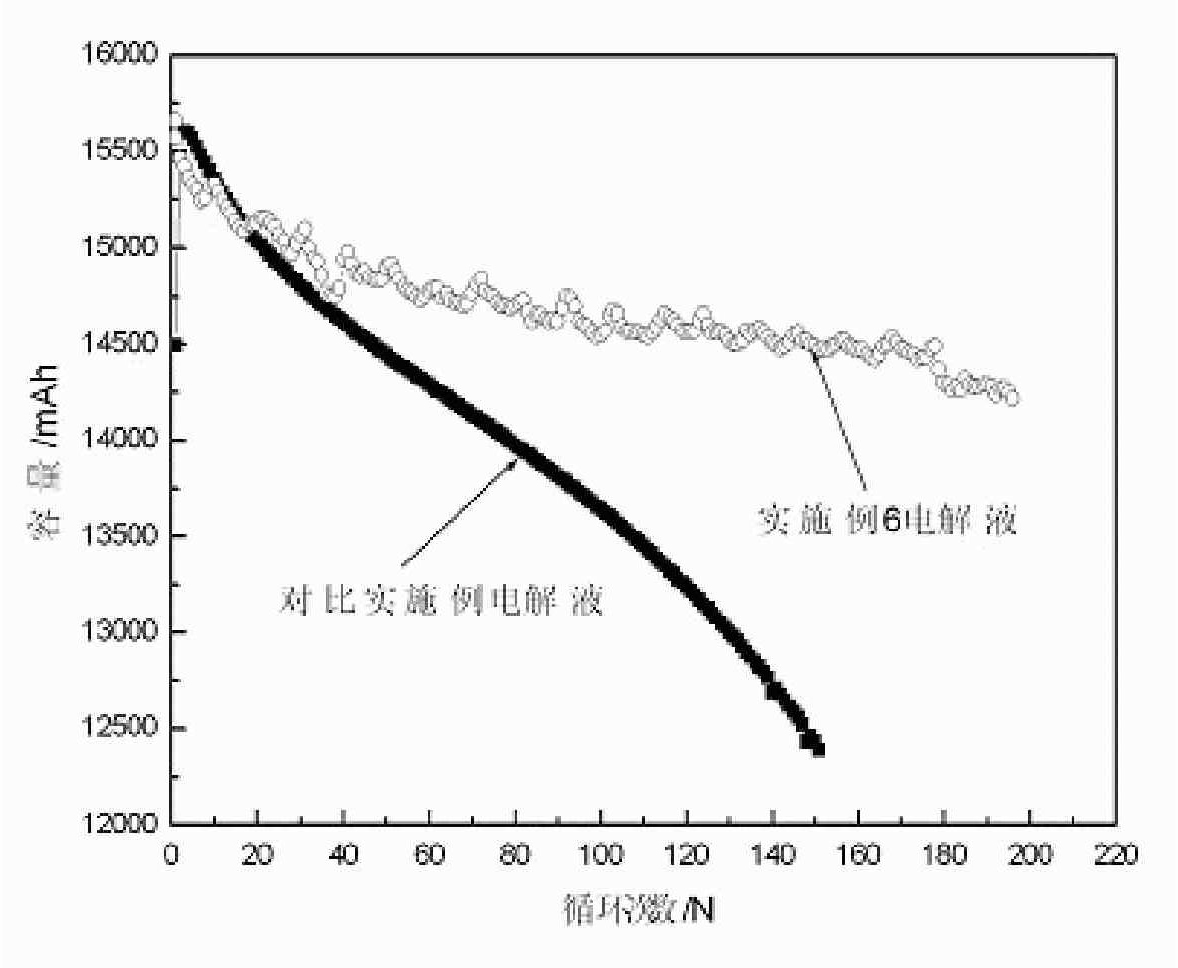

ActiveCN101635379AImprovement of poor capacity retention at high temperatureAvoid flatulenceFinal product manufactureSecondary cellsGas explosionDecomposition

The invention discloses an electrolyte for a lithium-ion power battery, which comprises lithium salts, organic solvents and additives, wherein the lithium salts comprise at least one of LiODFB, LiPF6, LiClO4, LiBF4, LiAsF6, LiCF3SO3, LiN(SO2CF3)2 and LiBOB; the invention also discloses a preparation of the electrolyte, which comprises the following steps: mixing the organic solvents after impurities and water are removed; (2) adding the lithium salts in the mixed organic solvents, evenly stirring till the solution is clear and has no sediments, and allowing the solution to stand for at least half an hour to obtain mixed solution; (3) adding the additives into the mixed solution, evenly stirring, and then allowing the mixed solution to stand to obtain the required electrolyte. The invention improves the cycle performance of the battery at the high temperature, prevents gas explosion caused by electrolyte decomposition, can remarkably promote the long-life function of the volume conservation rate of the lithium-ion power battery at the high temperature, and has simple preparation method and easy industrialization production simultaneously.

Owner:WANXIANG 123 CO LTD

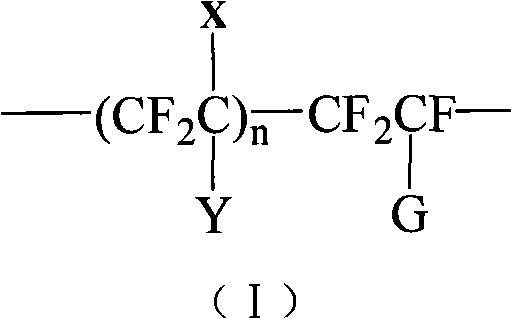

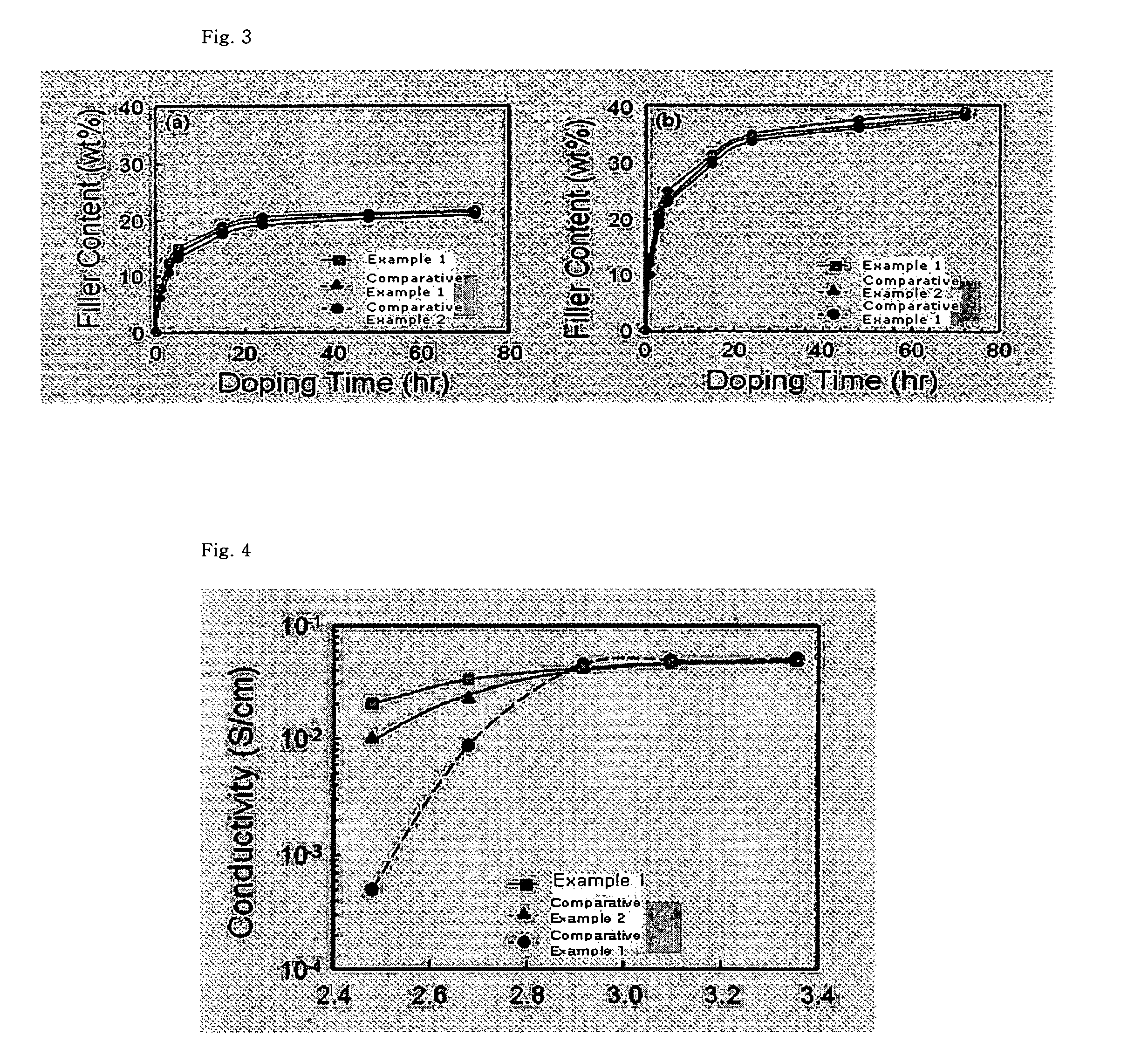

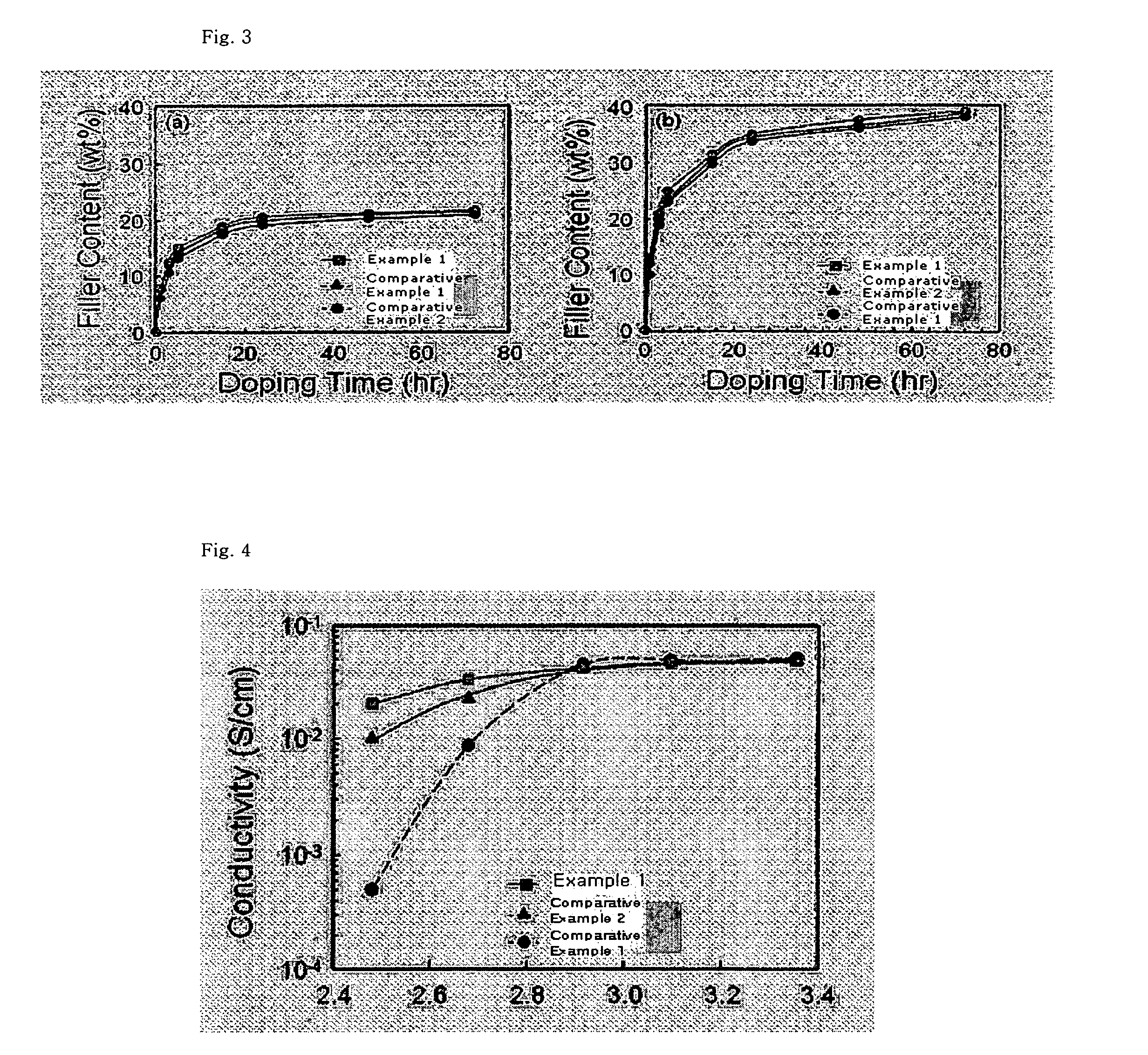

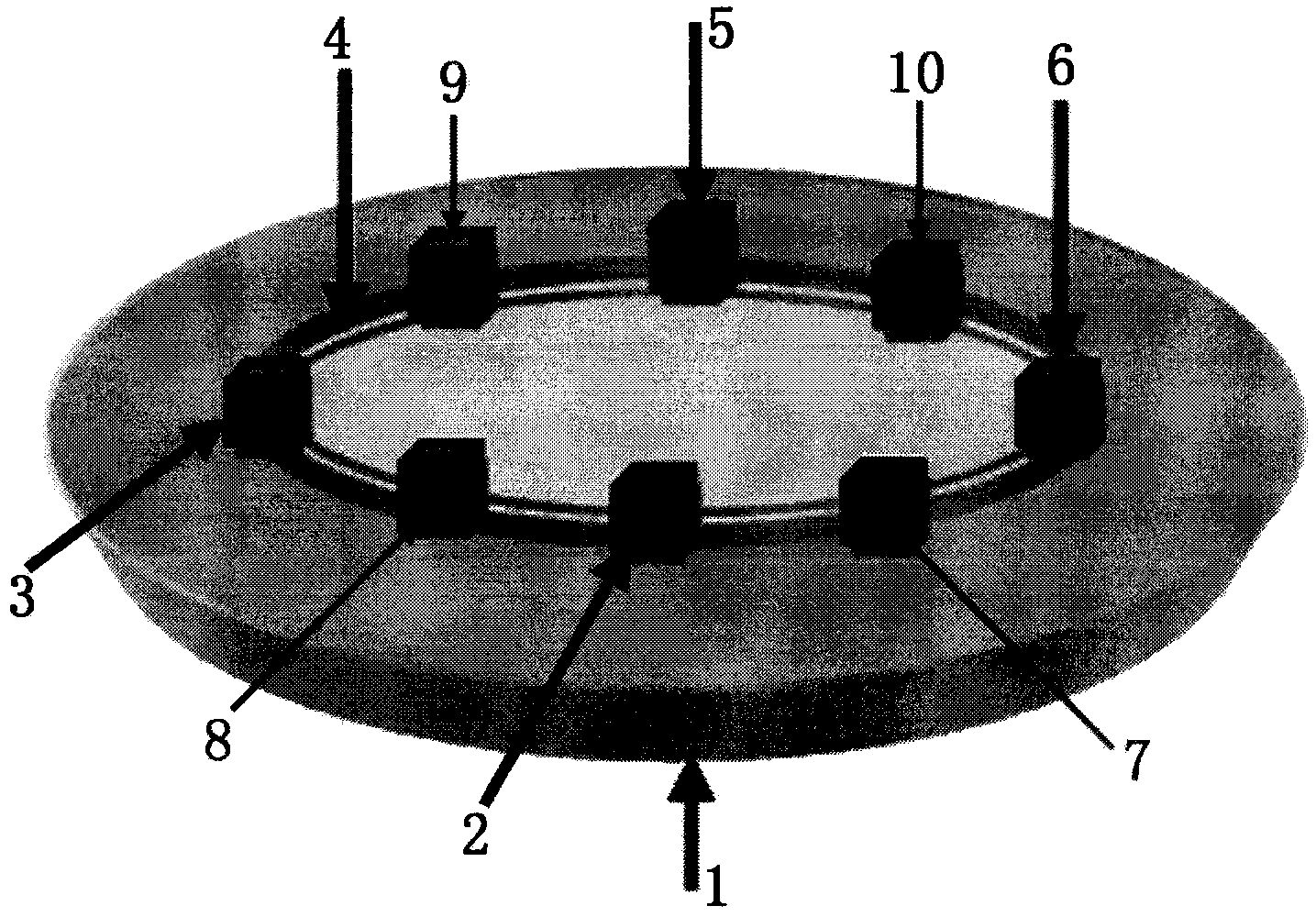

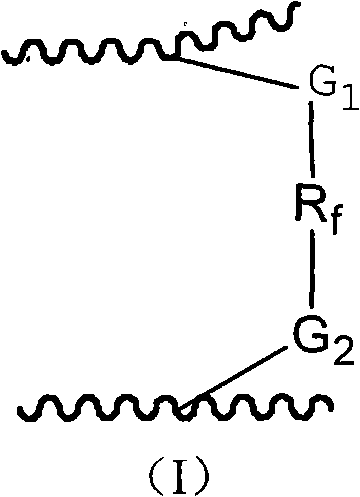

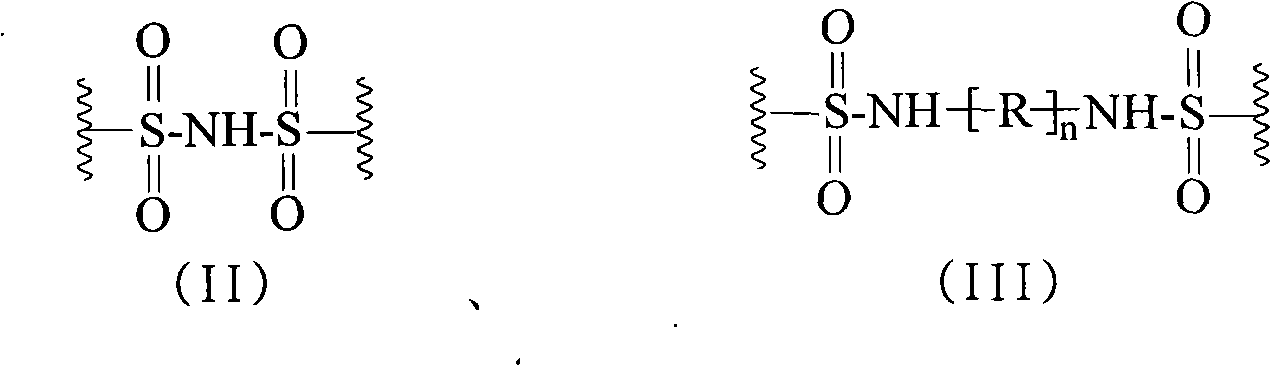

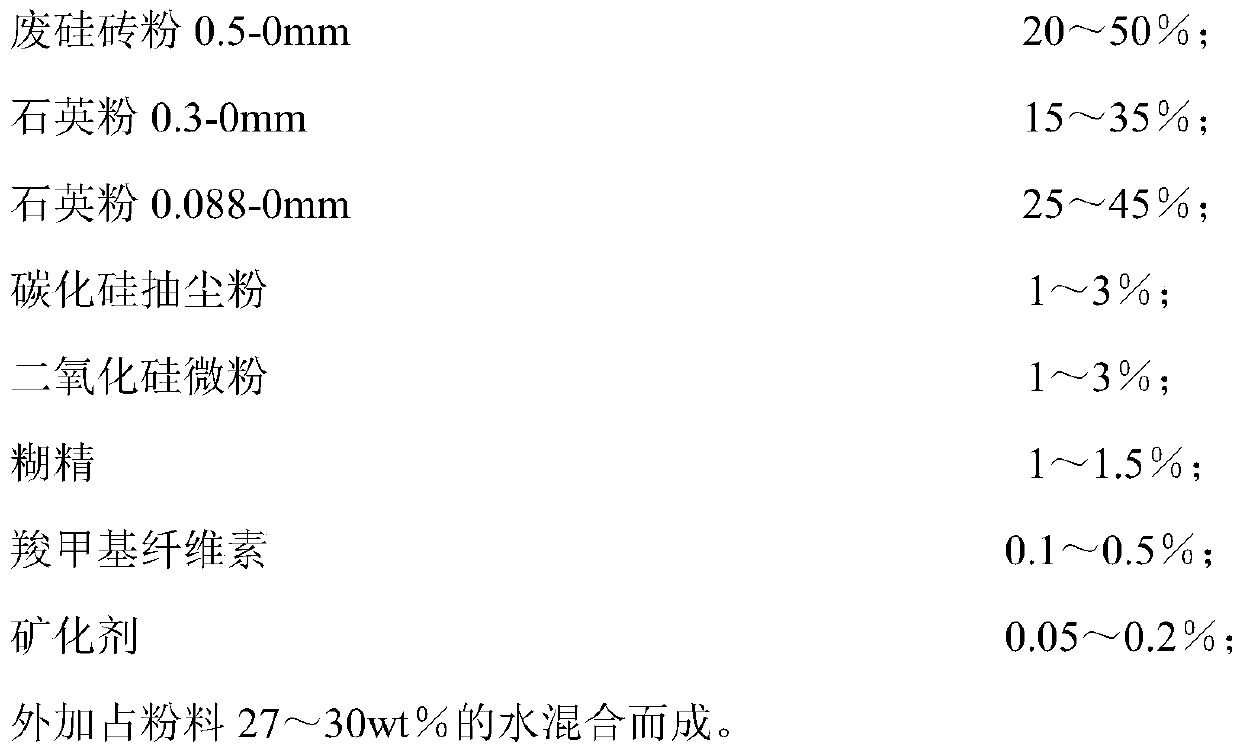

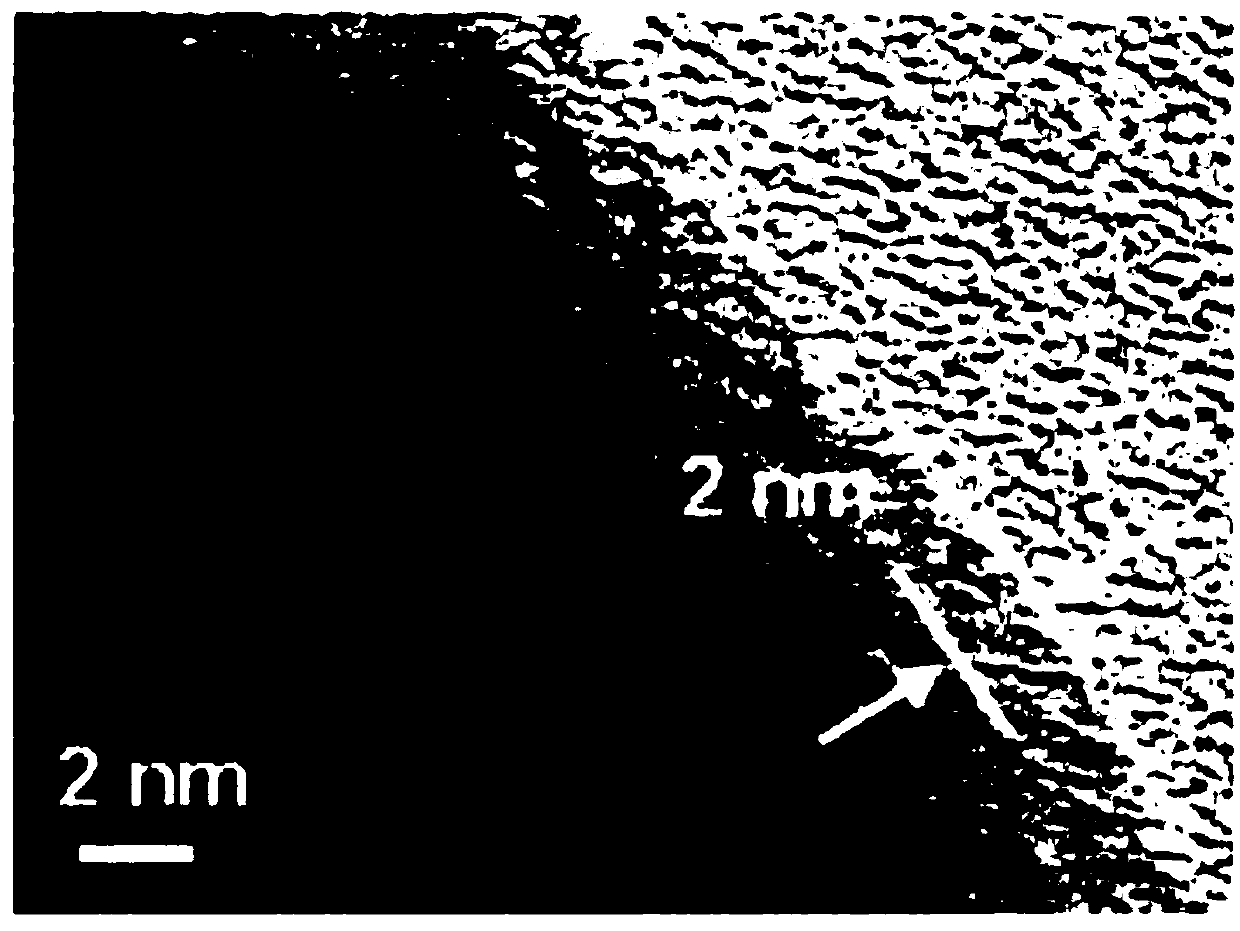

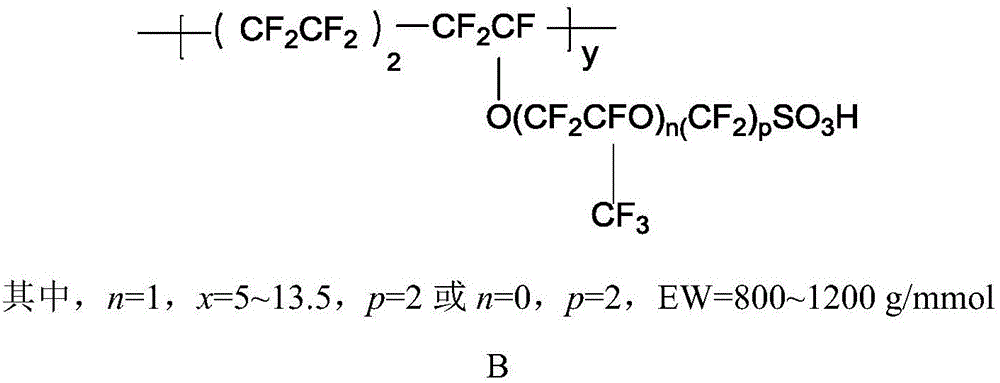

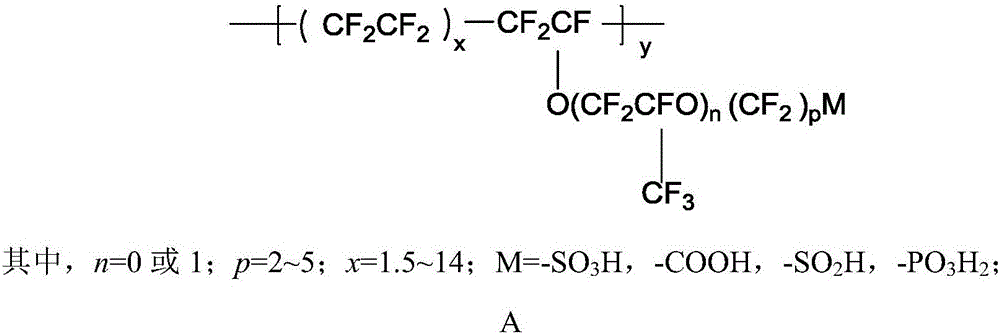

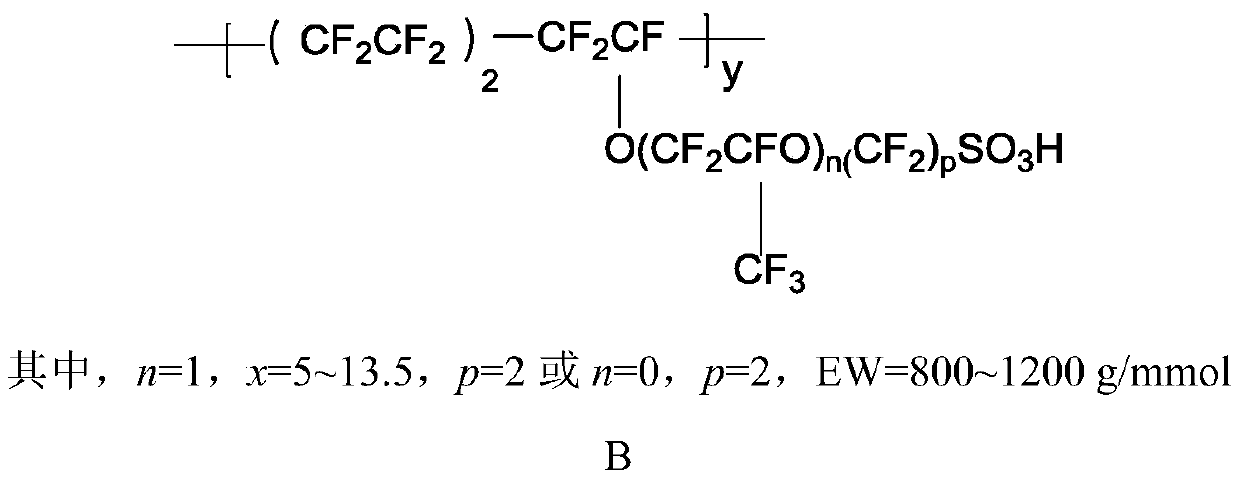

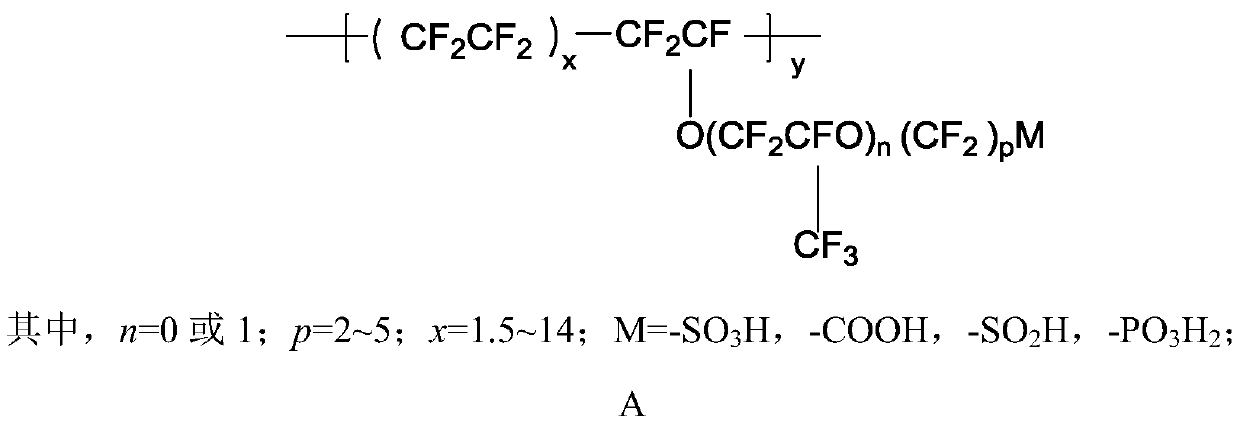

Doped crosslinking chemical stable ion exchange membrane and preparation method thereof

ActiveCN101745320AEasy to operateExtended service lifeSemi-permeable membranesCell component detailsPhysical chemistryCompound (substance)

The invention relates to a doped crosslinking chemical stable ion exchange membrane, which belongs to the field of functional polymer composite materials. The doped crosslinking chemical stable ion exchange membrane is a perfluorinated ion exchange membrane which is formed by taking perfluorinated ion exchange resin with crosslinking sites as film-forming resin and simultaneously doping an inorganic substance with a water holding function or a proton conduction assisting function and a substance with a function of eliminating free radicals into the film-forming resin, so the chemical stability of the improved ion exchange membrane is greatly improved.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Mineral-doped fluor-containing cross-linking ion exchanger membrane and method for preparing same

ActiveCN101333322AEasy to operateExtended service lifeFinal product manufactureSolid electrolyte fuel cellsCross-linkPhysical chemistry

The invention relates to an inorganically doped fluorin-containing ion exchange membrane and a preparation method thereof, belonging to the field of functional macromolecule composite material. The fluorin-containing ion exchange membrane takes fluorin-containing ion exchange resin which has crosslinking sites as the membrane forming resin and at the same time is doped with inorganic matter; under certain conditions, the materials have cross linking reaction to produce a meshwork doped fluorin-containing ion exchange. The ion exchange membrane prepared through the method of the invention is of high protonic conductivity and size stability.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

High-temperature lithium battery electrolyte

InactiveCN107230804AImprove conductivityIncrease capacitySecondary cellsOrganic electrolytesPhysical chemistrySolvent

The invention belongs to the technical field of lithium battery materials, and particularly relates to a high-temperature lithium battery electrolyte. The electrolyte is prepared from lithium salt, a compound solvent and a functional additive. The functional additive accounts for 1%-10% of the electrolyte. Compared with the traditional lithium battery electrolyte, the high-temperature lithium battery electrolyte is improved in ion conductivity, and enables batteries to be used at higher temperatures. Both a voltage platform and a discharge capacity are improved when the lithium ion battery containing the electrolyte discharges at high temperature, so that the high-temperature performance and cycle performance of the lithium battery are improved.

Owner:SHANDONG HIRONG POWER SUPPLY MATERIAL

Fiber reinforced inorganic doped proton exchange film containing fluorine

InactiveCN101290996AHigh temperature conductivityGuaranteed mechanical propertiesSemi-permeable membranesFinal product manufactureScreen printingThermal treatment

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

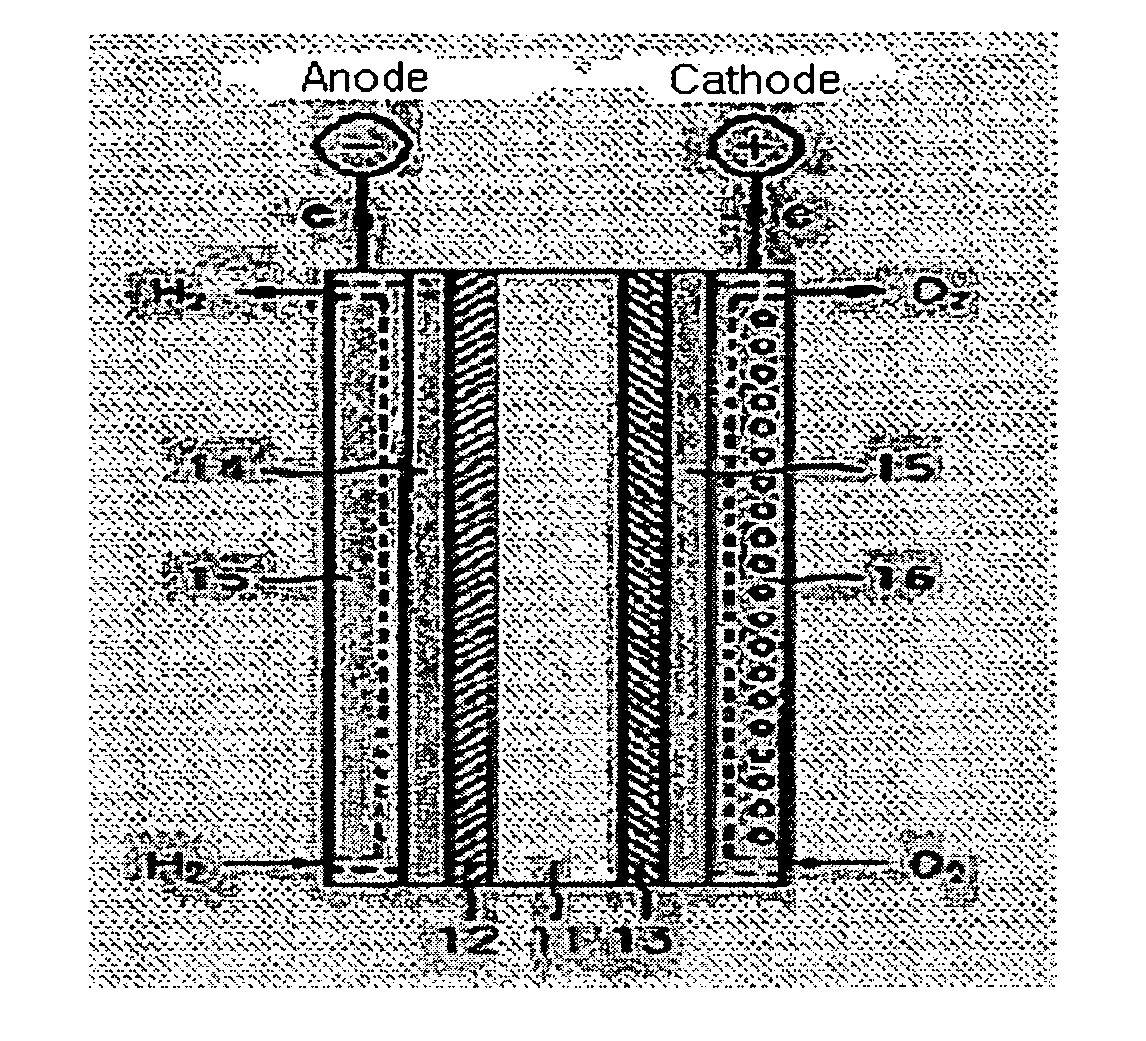

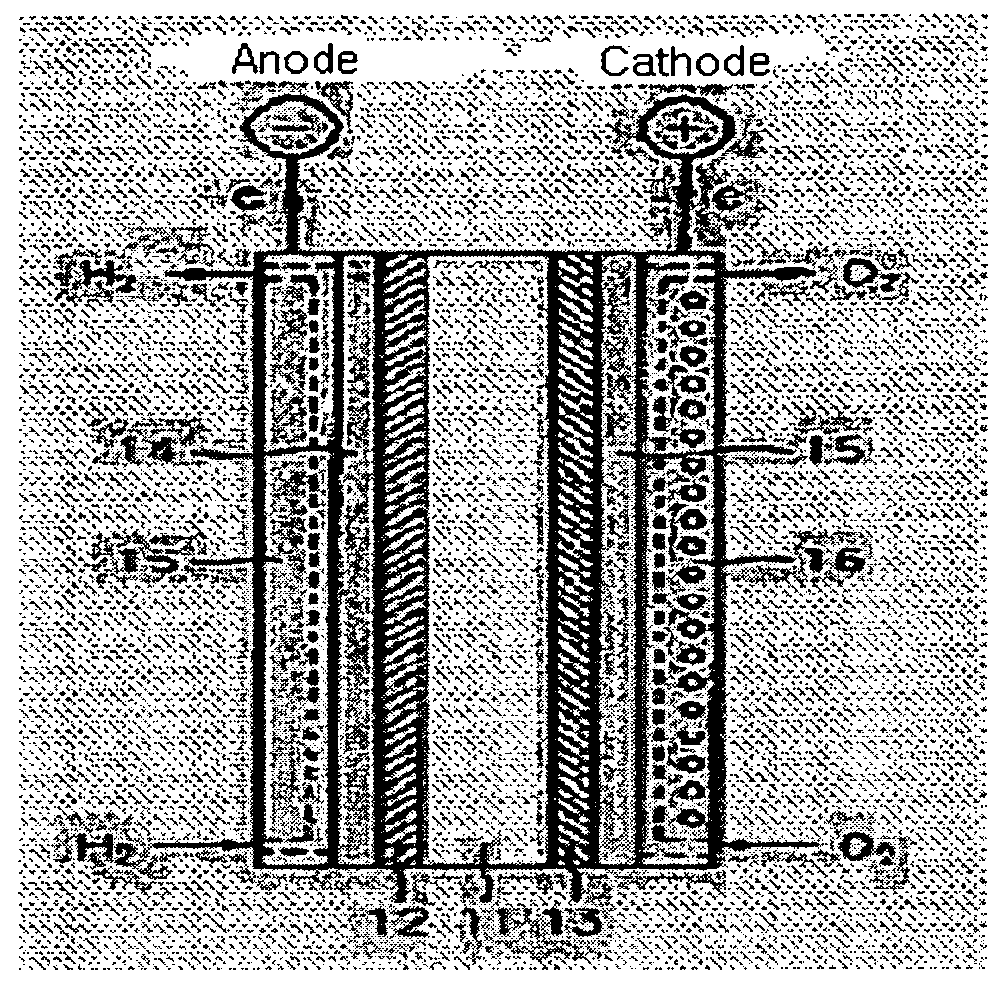

Composite ion-exchange membrane, fabrication method of the same, and membrane-electrode assembly, and polymer electrolyte fuel cell having the same

InactiveUS20050170229A1Improve electrochemical stabilityMinimal ohmic lossMaterial nanotechnologyFuel cells groupingFuel cellsIon-exchange membranes

The present invention relates to a composite ion-exchange membrane that can exhibit good conductivity at high temperatures, methods to produce the polymer membrane, membrane-electrode assemblies that comprise one or more of such polymers, and polymer electrolyte fuel cells that comprise one or more of such electrode assemblies.

Owner:HYUNDAI MOTOR CO LTD +1

Composite ion-exchange membrane, fabrication method of the same, and membrane-electrode assembly, and polymer electrolyte fuel cell having the same

InactiveUS7074510B2Improve performanceMaintain good propertiesMaterial nanotechnologyFuel cells groupingFuel cellsIon-exchange membranes

The present invention relates to a composite ion-exchange membrane that can exhibit good conductivity at high temperatures, methods to produce the polymer membrane, membrane-electrode assemblies that comprise one or more of such polymers, and polymer electrolyte fuel cells that comprise one or more of such electrode assemblies.

Owner:HYUNDAI MOTOR CO LTD +1

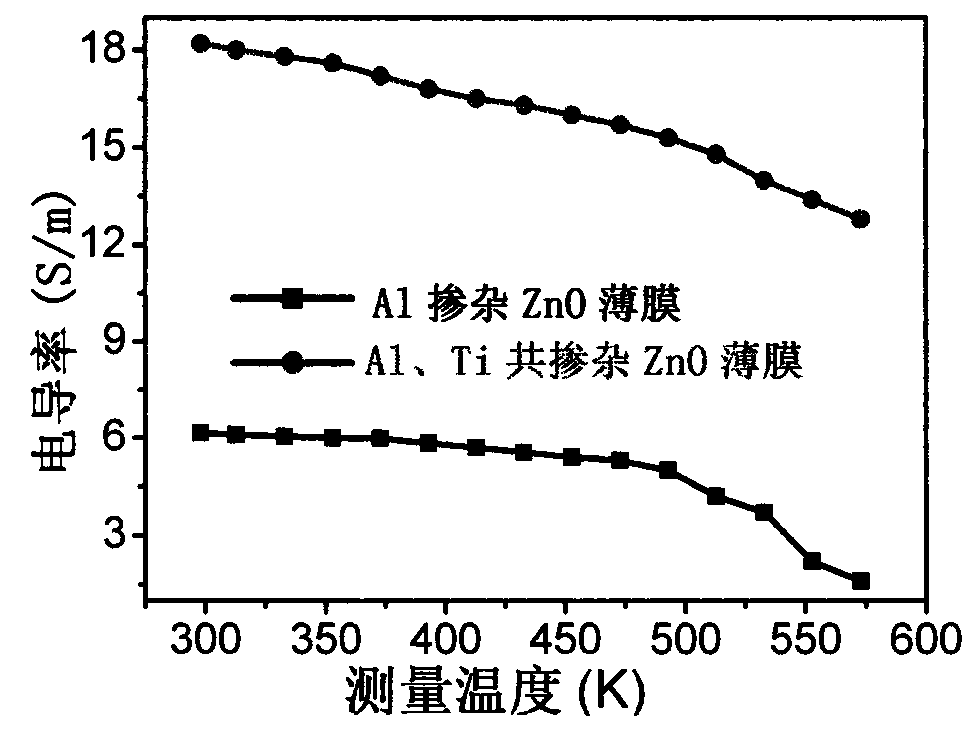

Novel ZnO-based thermoelectric thin film and preparation method thereof

InactiveCN104018118ASolving conductivitySolve the problem that the Seebeck coefficient cannot be improved at the same timeVacuum evaporation coatingSputtering coatingPower factorState density

The invention discloses a novel ZnO-based thermoelectric thin film and a preparation method thereof. The novel ZnO-based thermoelectric thin film is a ZnO thermoelectric thin film codoped by Al and Ti, the chemical formula of which is Zn(1-x-y)AlxTiyO (X is greater than or equal to 0.005 and less than or equal to 0.04 and y is greater than or equal to 0.005 and less than or equal to 0.04). Ti is introduced on the basis of the Al-doped ZnO thermoelectric thin film to be used as a second doping element. The conductivity of the thermoelectric thin film codoped by Al and Ti is remarkably improved. In addition, as Ti is introduced, the effective state density of the thermoelectric thin film is improved, so that the high temperature seebeck coefficient is also further improved. According to the invention solves, the problem that the conductivity and the seebeck coefficient of the thermoelectric thin film cannot be improved at the same time are solved. The novel Zn(1-x-y)AlxTiyO thermoelectric thin film both has great high temperature conductivity and seebeck coefficient, so that the thermoelectric thin film has a good power factor. The novel Zn(1-x-y)AlxTiyO thermoelectric thin film disclosed by the invention has an excellent thermoelectric performance and has a wide application prospect in the high temperature thermoelectric field.

Owner:SHENZHEN UNIV

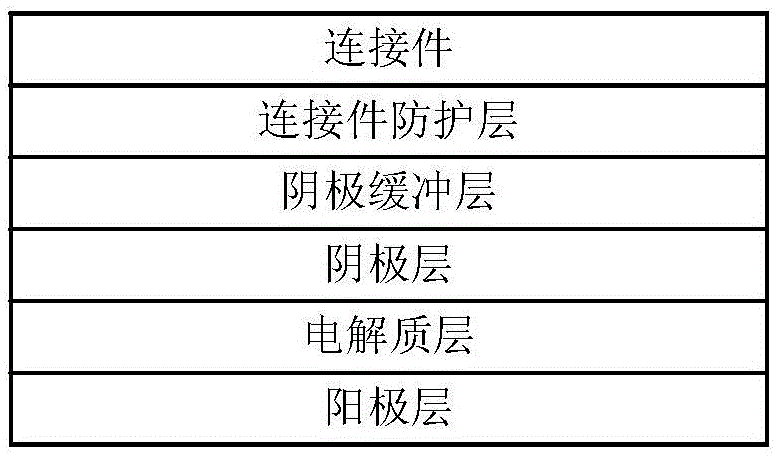

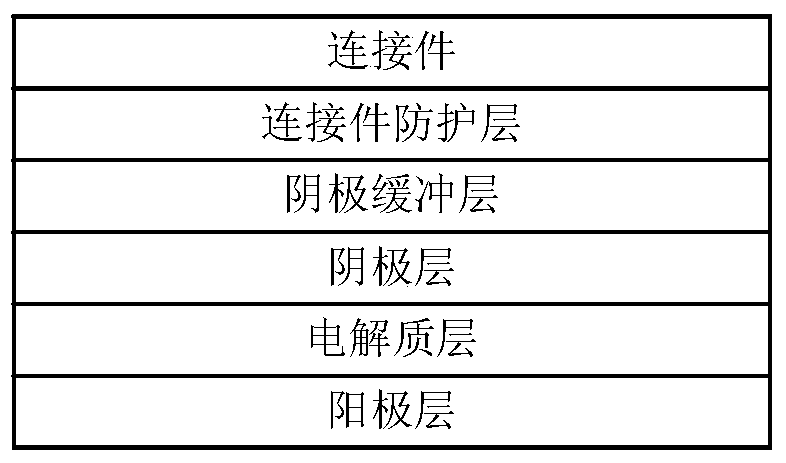

Anode of high-temperature solid-state fuel cell and cell stack unit

ActiveCN105161743AAddress performance degradationImprove stabilityFuel cells groupingCell electrodesFuel cellsNickel compounds

The invention provides an anode of a high-temperature solid-state fuel cell. The anode adopts the structure that nickel or / and a nickel compound is replaced by a ceramic high-temperature conductive material, on one hand, the ceramic high-temperature conductive material does not change structurally along with the oxidation-reduction reaction of the cell to avoid performance reduction caused by structural damage of the cell, on the other hand, the ceramic high-temperature conductive material can separate nickel particles microcosmically to inhibit growth of the nickel particles, so as to facilitate performance stability improvement of the cell, and prolong the service life of the cell. Besides, for a cell stack unit comprising the anode, the cathode active layer, the cathode buffer layer, and / or the connecting part protective layer of the cell stack unit also comprise(s) the ceramic high-temperature conductive material, so as to further improve the conductivity of the cell stack unit.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

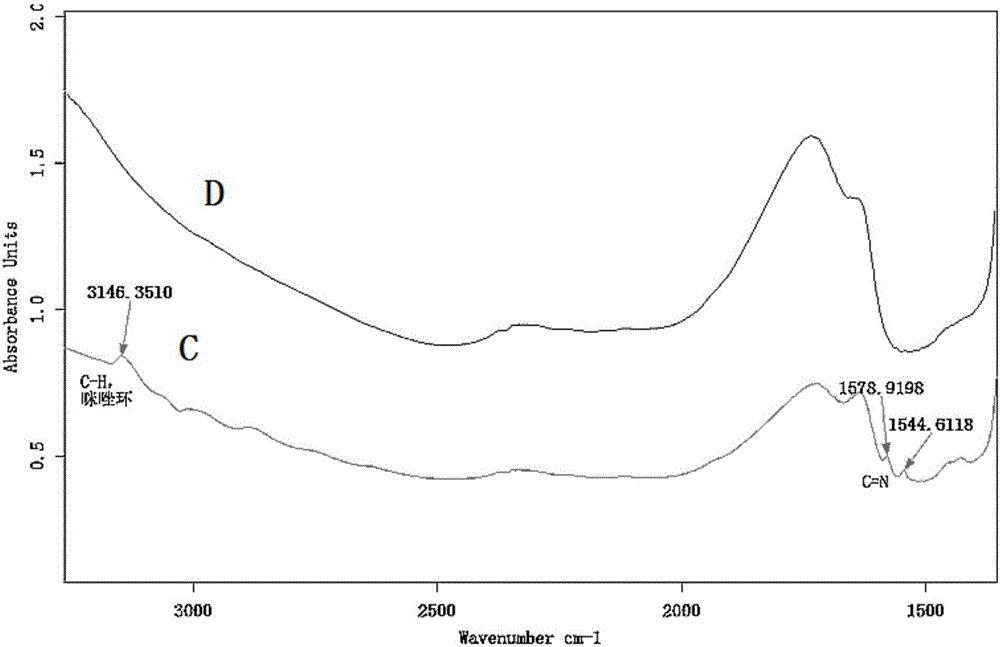

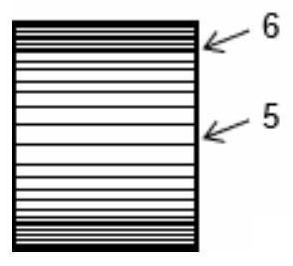

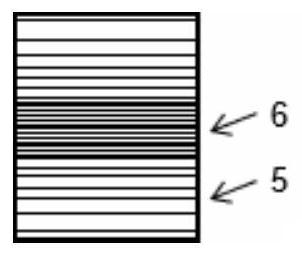

Doped and crosslinked multilayer perfluorinated ionic membrane and preparation method thereof

ActiveCN101797483AHigh temperature conductivityImprove mechanical propertiesSemi-permeable membranesCell component detailsNetwork structureProton

The invention relates to a doped and crosslinked multilayer perfluorinated ionic membrane and a preparation method thereof, and belongs to the field of functional polymer composite materials. The fluoride-containing ion exchange membrane has a multilayer structure. The fluoride-containing ion exchange resin serves as a membrane-forming resin; proton conduction assisting materials and highvalent metallic compounds are added therein at the same time to perform a crosslinking reaction under a certain condition so as to form the doped ion exchange membrane having a network structure. The ion exchange membrane prepared by the method of the invention has the advantages of higher proton conductivity, size stability, and chemical stability, particularly extremely excellent gas-permeation resistant performance.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

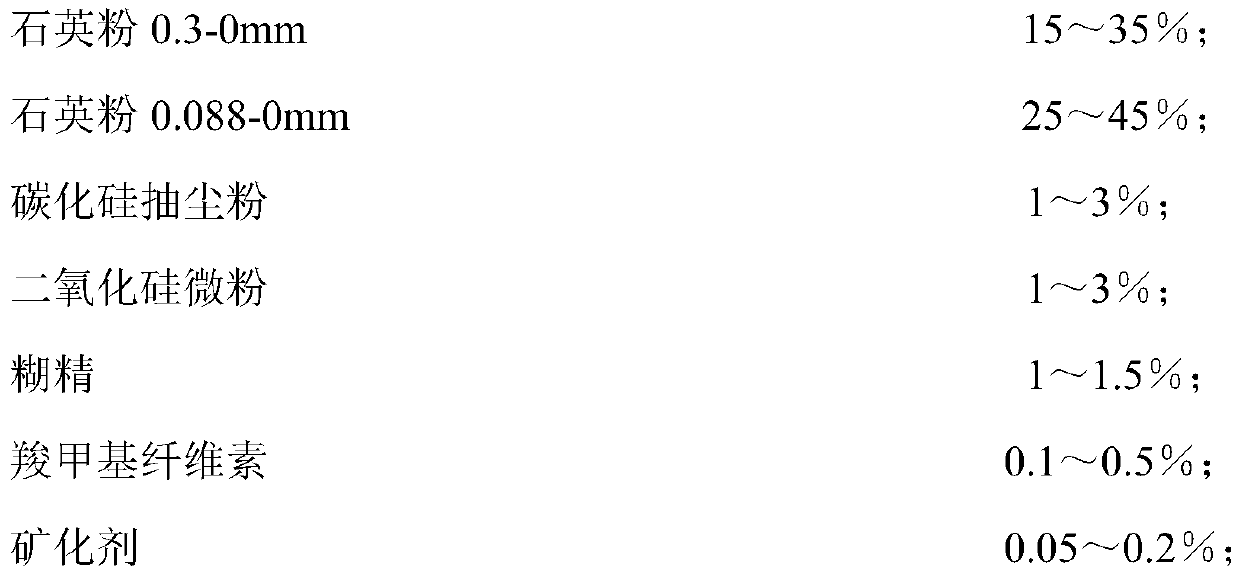

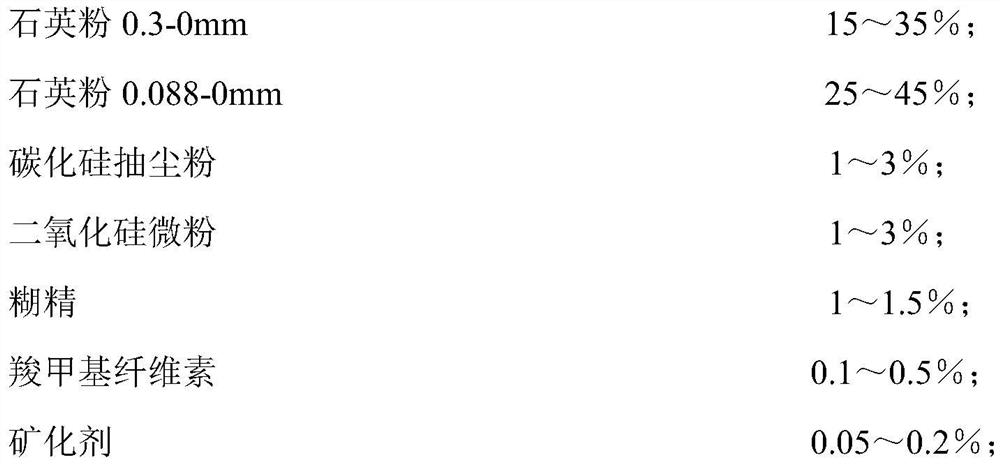

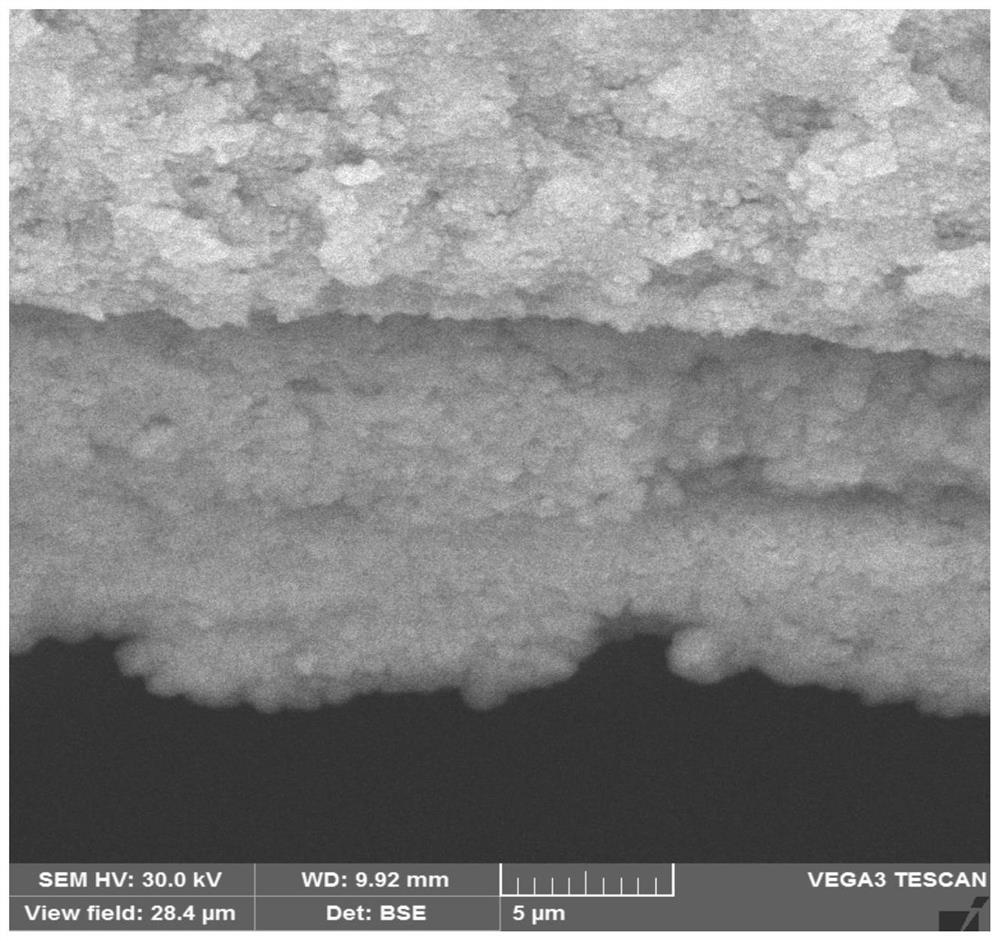

Siliceous refractory mortar with excellent high-temperature performance

ActiveCN111548171AComplete crystal transformationImprove volume stabilityCelluloseCarboxymethyl cellulose

The invention discloses siliceous refractory mortar with excellent high-temperature performance. Powder of the siliceous refractory mortar is prepared by mixing 20-50% of waste silicon brick powder with the particle size of 0.5-0 mm, 15-35% of quartz powder with the particle size of 0.3-0 mm, 25-45% of quartz powder with the particle size of 0.088-0 mm, 1-3% of silicon carbide dust extraction powder, 1-3% of silica micropowder, 1-1.5% of dextrin, 0.1-0.5% of carboxymethyl cellulose, 0.05%-0.2% of a mineralizing agent, and adding water accounting for 27-30 wt% of the powder by mass. The silicondioxide content of the siliceous refractory mortar provided by the invention is greater than or equal to 94%, raw clay, sodium bentonite and the like are not added, the content of aluminum oxide is low, the content of low melt is low, and the refractoriness under load is high. And meanwhile, the waste silicon brick powder is added, so that secondary utilization of resources is realized, and the waste silicon brick powder basically exists in a phosphorus quartz phase, is good in volume stability, is matched with the built silicon brick material, is good in adhesion in a high-temperature use environment, and does not fall off from the surface.

Owner:中冶武汉冶金建筑研究院有限公司

Electrolyte for lithium-ion power battery and preparation method thereof

ActiveCN101635379BImprove the disadvantage of poor capacity retention at high temperatureEfficient formationFinal product manufactureSecondary cellsLithiumPower battery

The invention discloses an electrolyte for a lithium-ion power battery, which comprises lithium salts, organic solvents and additives, wherein the lithium salts comprise at least one of LiODFB, LiPF6, LiClO4, LiBF4, LiAsF6, LiCF3SO3, LiN(SO2CF3)2 and LiBOB; the invention also discloses a preparation of the electrolyte, which comprises the following steps: mixing the organic solvents after impurities and water are removed; (2) adding the lithium salts in the mixed organic solvents, evenly stirring till the solution is clear and has no sediments, and allowing the solution to stand for at least half an hour to obtain mixed solution; (3) adding the additives into the mixed solution, evenly stirring, and then allowing the mixed solution to stand to obtain the required electrolyte. The invention improves the cycle performance of the battery at the high temperature, prevents gas explosion caused by electrolyte decomposition, can remarkably promote the long-life function of the volume conservation rate of the lithium-ion power battery at the high temperature, and has simple preparation method and easy industrialization production simultaneously.

Owner:WANXIANG 123 CO LTD

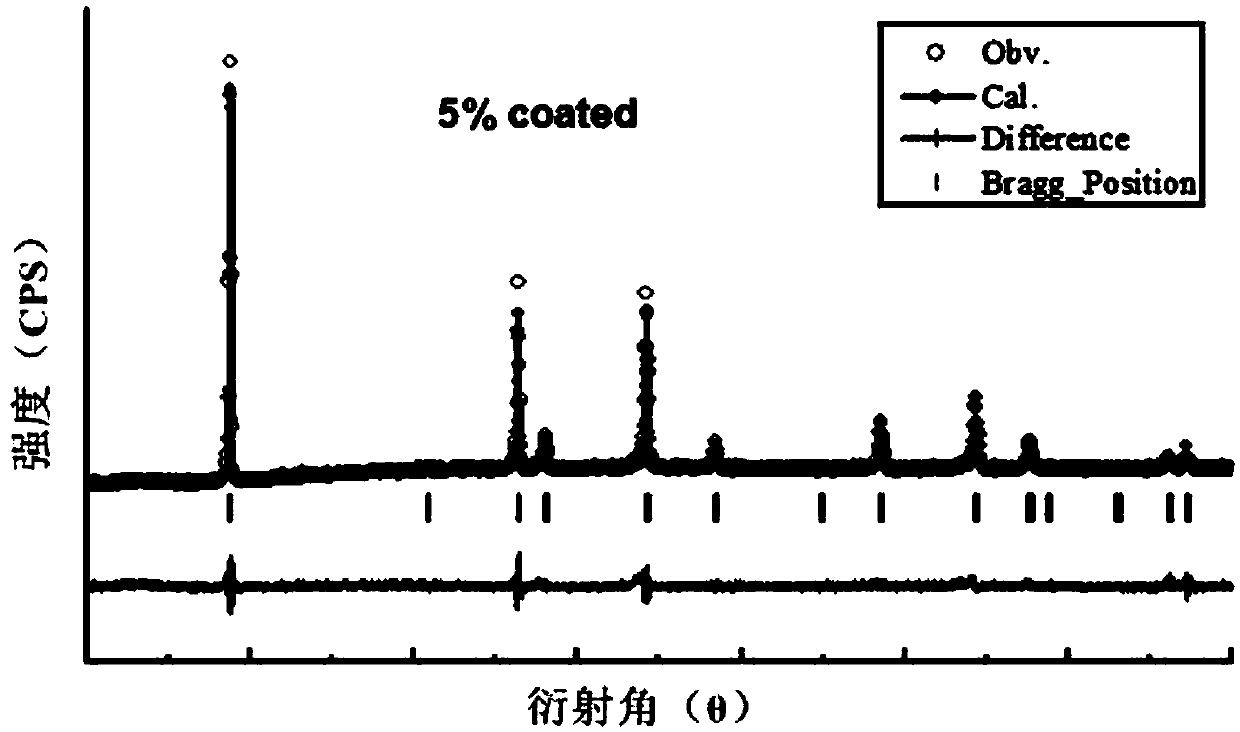

Surface modification method for composite lithium nickel manganese oxide positive electrode material

InactiveCN107681146AImprove structural stabilityHigh temperature conductivitySecondary cellsPositive electrodesDissolutionManganese oxide

The invention discloses a surface modification method for a composite lithium nickel manganese oxide positive electrode material. The method comprises the following steps of dissolving a lithium source, a manganese source, a nickel source and a yttrium source into deionized water to form solutions separately, dropwise adding various solutions into a citric acid solution separately, stirring to form a mixed solution, adjusting the pH value and carrying out heating to form dried gel; pre-sintering and grinding the dried gel and carrying out thermal treatment to form a yttrium-doped lithium nickel manganese oxide material; and dispersing [Y<1-x>Mg<x>][Cr<1-x-y>Sn<y>Ga<z>]O3 and the yttrium-doped lithium nickel manganese oxide material into the deionized water at a mass ratio of 0.05:1, stirring to form a mixture and carrying out washing, filtering and annealing treatment to obtain the coated yttrium-doped lithium nickel manganese oxide positive electrode material. The structure stability,the high-temperature conductivity and the cycle performance of the material are improved, side reaction of the material and an electrolyte and dissolution of metal ions can be suppressed, and the interface stability of the material is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

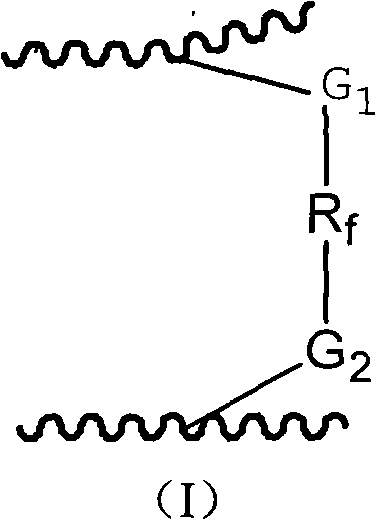

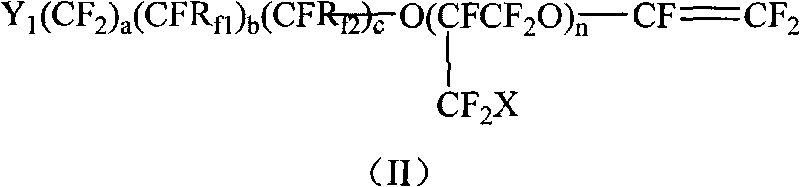

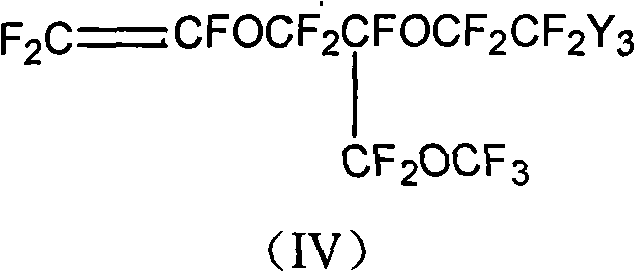

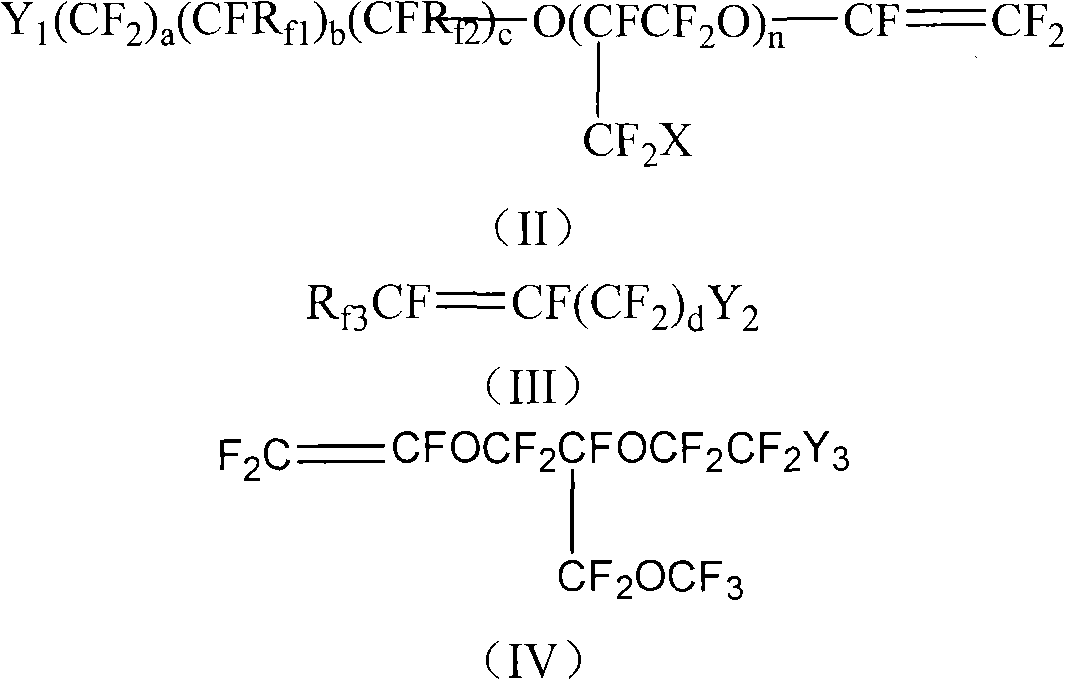

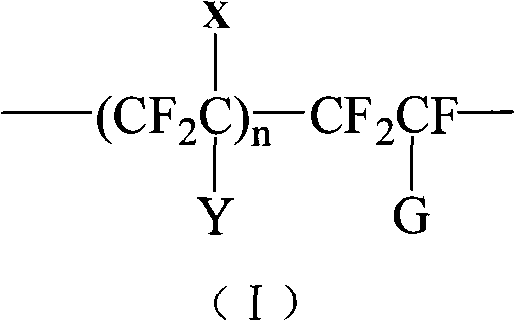

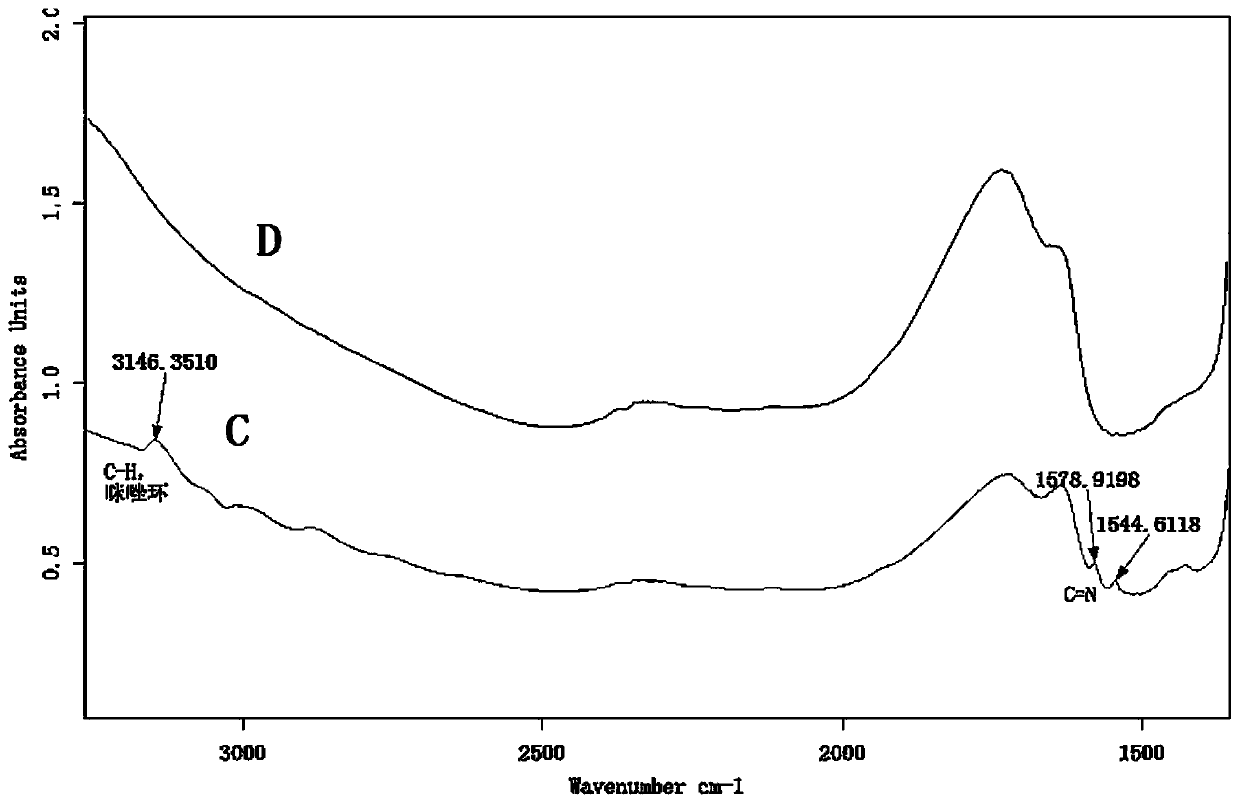

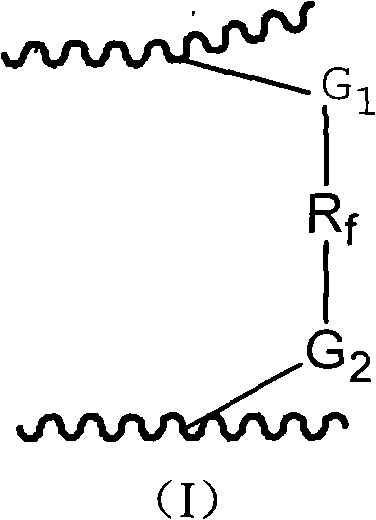

Fluorine-containing ion exchange membrane for fuel cell and preparation method of fluorine-containing ion exchange membrane

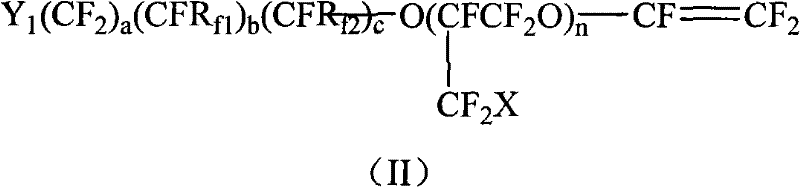

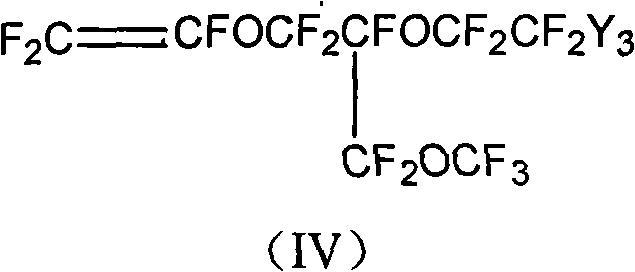

ActiveCN106654328AReduce combustion transmittanceHigh temperature conductivityFuel cellsSide chainChemistry

The invention belongs to the field of functional polymer composite materials and particularly relates to a fluorine-containing ion exchange membrane for a fuel cell and a preparation method of the fluorine-containing ion exchange membrane. According to the fluorine-containing ion exchange membrane for the fuel cell, film-forming resin of the membrane has a perfluorinated main chain; a side chain contains multiple functional groups, wherein at least one functional group has an ion exchange function; the membrane contains transition metal elements with a free radical elimination effect; and the transition metal elements and the functional groups on the side chain form a complex bond. Through a hydrogen bond and electrostatic interaction among the functional groups on the side chain of the film-forming resin, the high-temperature conductivity and the elasticity modulus of a proton exchange membrane are improved and the H2 transmittance is reduced. In addition, the functional groups have complexing action, and functional groups and transition metal ions with the free radical elimination effect form a complex, thereby preventing losses of these functional materials in the whole process.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

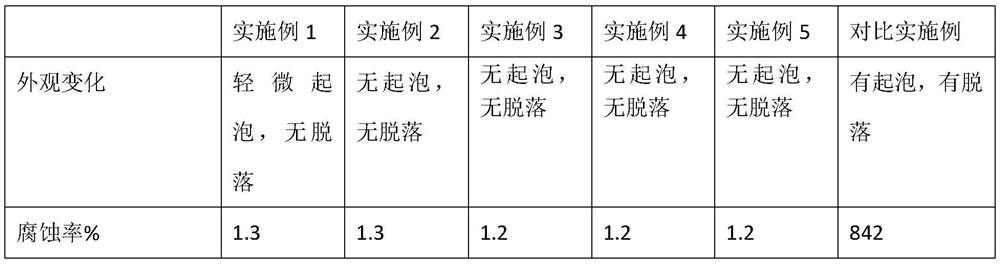

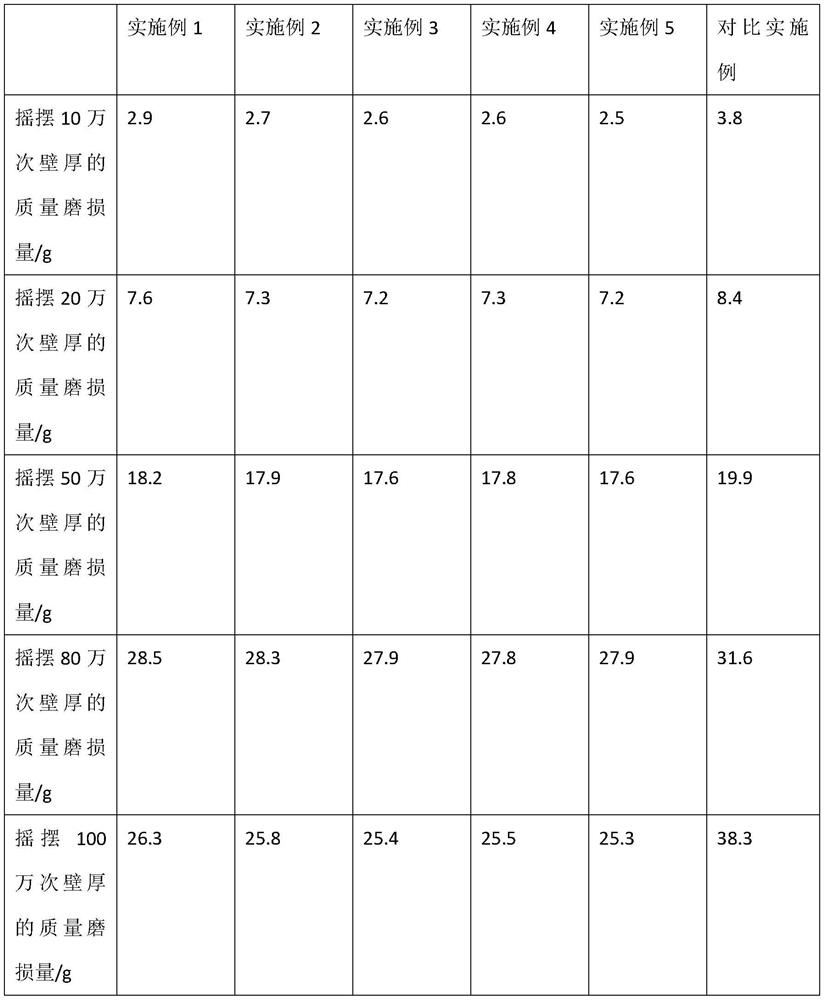

Corrosion-resistant heat-tracing sampling composite pipe and preparation method thereof

InactiveCN112815157AIncrease contact areaReduce lossThermal insulationPipe heating/coolingInsulation layerThermal insulation

The invention belongs to the technical field of industrial equipment, and relates to a composite pipe, in particular to a corrosion-resistant heat-tracing sampling composite pipe and a preparation method thereof. The corrosion-resistant heat-tracing sampling composite pipe is technically characterized by comprising a sampling pipe, a heat tracing band, a thermal insulation layer, a reinforcing layer and a protective layer. A heat tracing groove is cut in the outer part of the sampling pipe and is used for winding the heat tracing band on the sampling pipe; the heat tracing band is a constant-power heat tracing band; the outer layer of the heat tracing band is made of a basalt fiber / carbon fiber composite material; and the thermal insulation layer is arranged outside the sampling pipe, the reinforcing layer is wound outside the thermal insulation layer, and the protective layer is arranged outside the thermal insulation layer. According to the corrosion-resistant heat-tracing sampling composite pipe and the preparation method thereof, by adopting the heat tracing groove, the contact area of the heat tracing band and the sampling pipe is increased, the temperature conduction capacity is improved, the heat loss of the heat tracing band is reduced, on the other hand, the sampling pipe can be protected through the heat tracing band, and the high temperature resistance and the corrosion resistance of the sampling pipe are improved.

Owner:镇江长盈电气科技有限公司

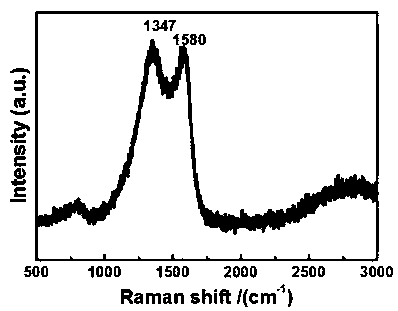

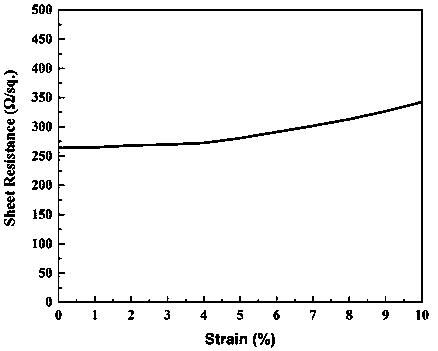

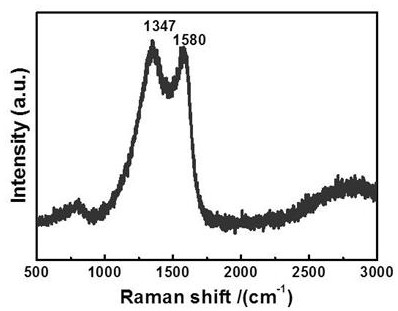

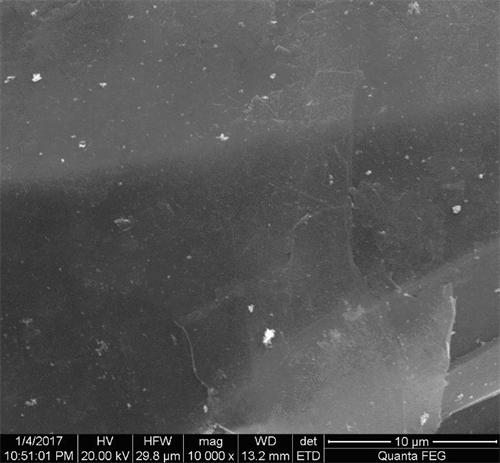

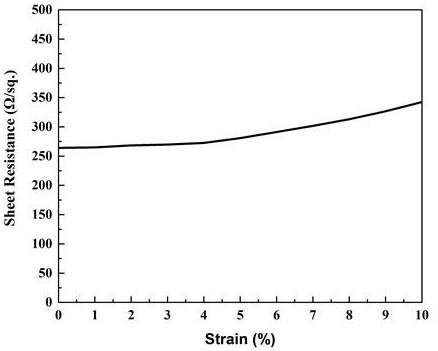

Method of achieving electric conduction on high-temperature rubber by using vapor deposition graphene

The invention relates to a method of achieving electric conduction on high-temperature rubber by using vapor deposition graphene and belongs to the field of application of graphene composite electricconductive materials. In the technical scheme, by means of plasma enhanced chemical vapor deposition (PECVD), a graphene film is deposited on the most upper layer of the high-temperature rubber, so that by means of the electric conductivity, flexibility and ductility of the graphene and through tight combination between the graphene and the high-temperature rubber, synchronous strain of the graphene and the high-temperature rubber during tensioning or twisting is achieved. The rubber has electric conductivity in all forms, thus changing the functional characters in aspects of electricity, stability and the like; in addition, the electric conductivity is stable in all forms or at all temperature. The method has significant effect and is simple in process.

Owner:广州理文能源科技有限公司

An anode and a battery stack unit of a high-temperature solid-state fuel cell

ActiveCN105161743BInhibit growthKeep aliveFuel cells groupingCell electrodesFuel cellsNickel compounds

The invention provides an anode of a high-temperature solid-state fuel cell. The anode adopts the structure that nickel or / and a nickel compound is replaced by a ceramic high-temperature conductive material, on one hand, the ceramic high-temperature conductive material does not change structurally along with the oxidation-reduction reaction of the cell to avoid performance reduction caused by structural damage of the cell, on the other hand, the ceramic high-temperature conductive material can separate nickel particles microcosmically to inhibit growth of the nickel particles, so as to facilitate performance stability improvement of the cell, and prolong the service life of the cell. Besides, for a cell stack unit comprising the anode, the cathode active layer, the cathode buffer layer, and / or the connecting part protective layer of the cell stack unit also comprise(s) the ceramic high-temperature conductive material, so as to further improve the conductivity of the cell stack unit.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of fluorine-containing ion exchange membrane for fuel cell and preparation method thereof

ActiveCN106654328BReduce combustion transmittanceHigh temperature conductivityFuel cellsFuel cellsBackbone chain

The invention belongs to the field of functional polymer composite materials, and in particular relates to a fluorine-containing ion exchange membrane for a fuel cell and a preparation method thereof. A fluorine-containing ion exchange membrane for a fuel cell, the film-forming resin of the membrane has a perfluorinated main chain, and the side chain contains a plurality of functional groups, at least one of which has an ion exchange function; the membrane contains free radicals The transition metal element that eliminates the effect, the transition metal element forms a complex bond with the functional group on the side chain. The functional groups on the side chains of the film-forming resin of the present invention improve the high-temperature conductivity and elastic modulus of the proton exchange membrane and reduce the H2 transmittance through hydrogen bonds and electrostatic interactions between the functional groups; in addition, the functional groups have a complexing effect , form complexes with transition metal ions that have the effect of eliminating free radicals, so as to ensure that these functional materials do not lose during the entire process.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

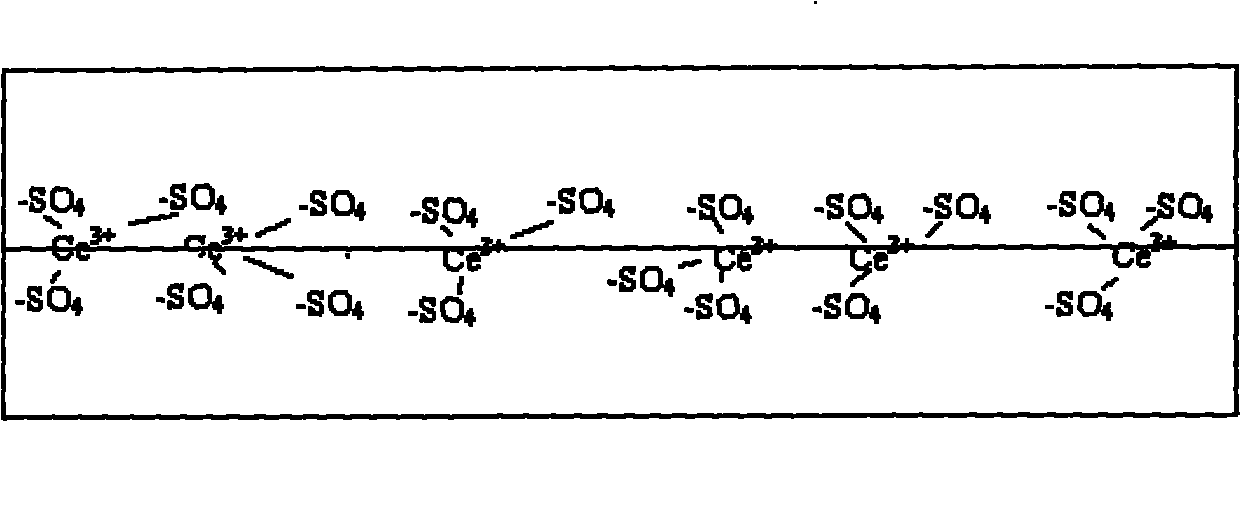

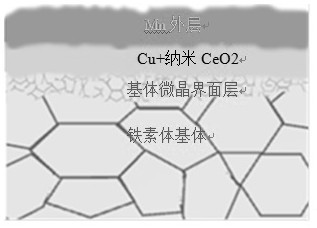

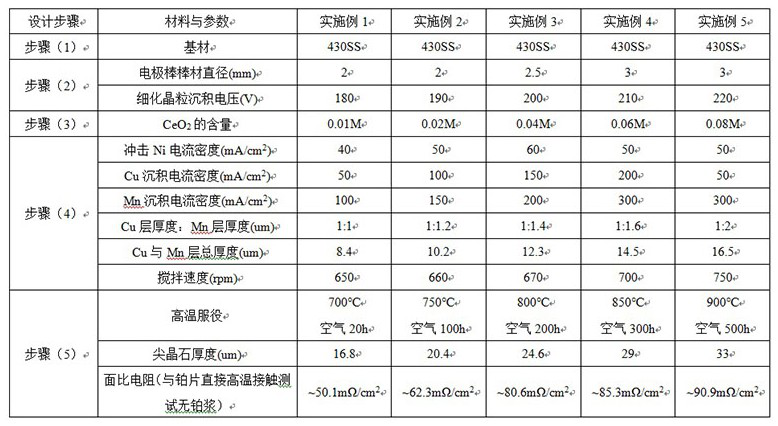

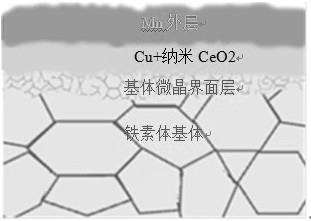

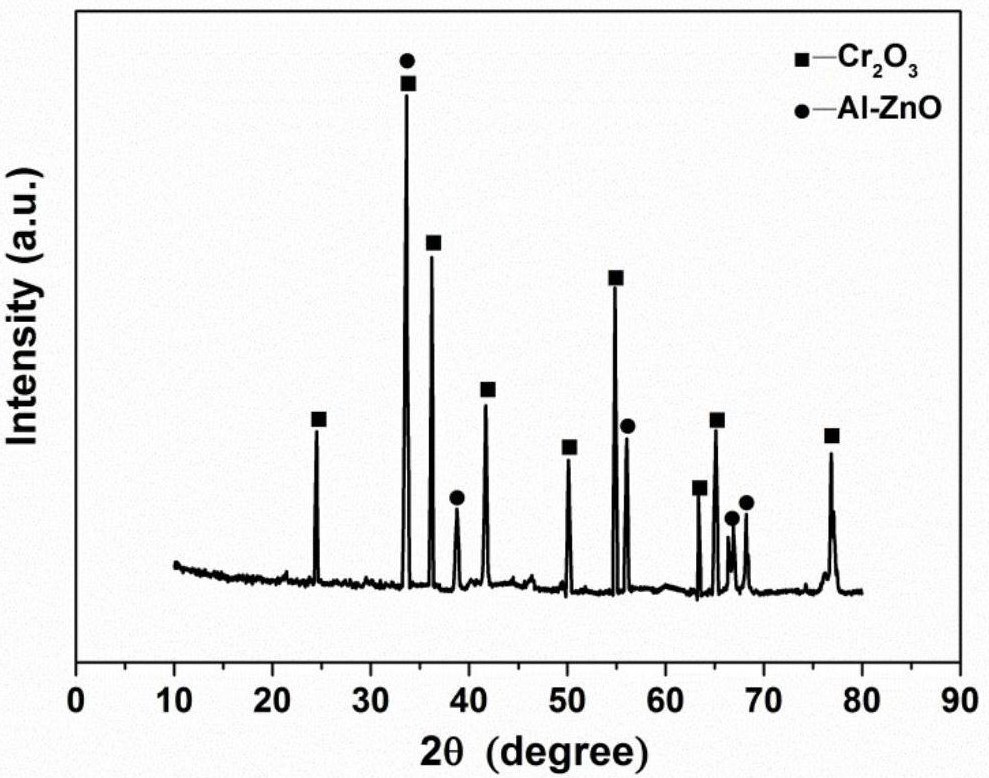

a kind of ceo 2 Doped cu/mn composite film/microcrystalline interface layer and metal matrix composite connector and preparation method thereof

ActiveCN112609210BGrow fastHigh temperature conductivityElectrolytic coatingsFinal product manufactureOxidation resistantElectrochemistry

The invention discloses a CeO2-doped Cu / Mn composite film / microcrystalline interface layer and a metal-based composite connector and a preparation method thereof, and relates to the field of metal connector composite materials for solid oxide fuel cells. Firstly, it is deposited by high-energy micro-arc alloy technology The microcrystalline transition layer of the matrix material; and then use the electrochemical deposition method to composite metal-plated Cu combined with nano-scale CeO 2 Composite film of particles; then electrochemically deposited metal Mn as the outer layer of the whole composite. Among them, a certain amount of nano-scale CeO added during electrodeposition of Cu coating 2 To refine the coating grains, improve the high-temperature diffusion of elements and the high-temperature oxidation resistance of the composite layer. The beneficial effects are: the prepared microcrystalline interface layer and the metal-based composite connector have strong electrical conductivity and excellent high-temperature oxidation resistance, and can effectively prevent the out-diffusion of Cr elements in the metal substrate to improve the performance of solid oxide fuel cells. The life and working efficiency of metal connectors.

Owner:JIANGSU UNIV OF SCI & TECH

CeO2-doped Cu/Mn composite film/microcrystalline interface layer and metal matrix composite connector and preparation method thereof

ActiveCN112609210AGrow fastHigh temperature conductivityElectrolytic coatingsFinal product manufactureFuel cellsInterface layer

The invention discloses a CeO2-doped Cu / Mn composite film / microcrystalline interface layer and metal matrix composite connector and a preparation method thereof, and relates to the field of solid oxide fuel cell metal connector composite materials. Firstly, a microcrystalline transition layer of a matrix material is deposed through a high-energy micro-arc alloy technology; then, a composite film plated with metal Cu and combined with nanoscale CeO2 particles is compounded through an electrochemical deposition method; and then metal Mn is electrochemically deposited to serve as an outer layer of the whole composite material, wherein a certain amount of nanoscale CeO2 is added during electrodeposition of a Cu plating layer to refine grains of the plating layer, so that the high-temperature diffusivity of elements and the high-temperature oxidation resistance of a composite layer are improved. The CeO2-doped Cu / Mn composite film / microcrystalline interface layer and metal matrix composite connector and the preparation method thereof have the beneficial effects that the prepared microcrystalline interface layer and metal matrix composite connector is high in conductivity and excellent in high-temperature oxidation resistance, and can effectively prevent the Cr element in the metal base material from diffusing outwards, so that the service life of the solid oxide fuel cell metal connector is prolonged, and the working efficiency of the solid oxide fuel cell metal connector is improved.

Owner:JIANGSU UNIV OF SCI & TECH

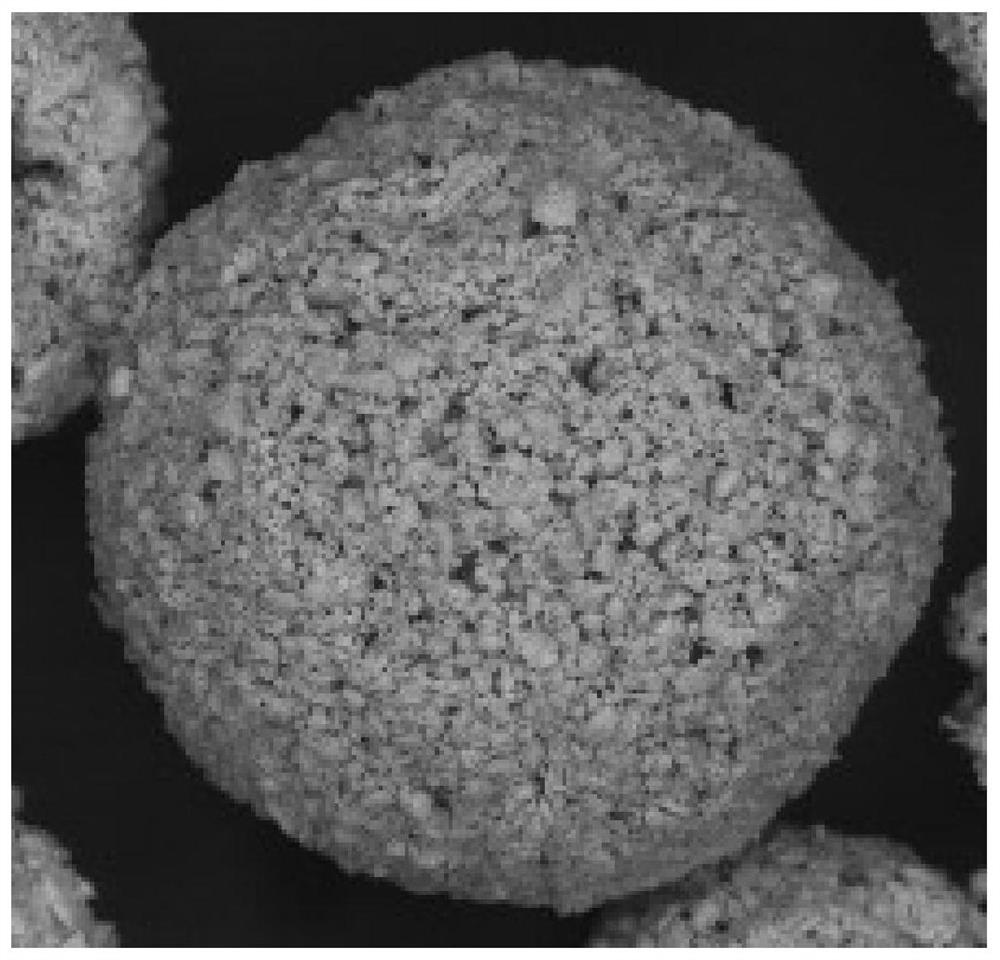

Chromium oxide-aluminum doped zinc oxide anti-corrosion composite coating and preparation method thereof

PendingCN113981360AUniform compositionHigh densityMolten spray coatingChromium trioxideAluminiumPolyvinyl alcohol

The invention discloses a chromium oxide-aluminum doped zinc oxide anti-corrosion composite coating and a preparation method thereof. The preparation method comprises the following steps of: 1, preparing a mixed solution according to a set proportion; 2, dropwise adding excessive ammonia water into the mixed solution step by step, and continuously stirring until a mixed white precipitate is generated; 3, adding a PVA (Polyvinyl Alcohol) aqueous solution into the obtained white precipitate; 4, putting the mixture on a roller type ball mill for ball milling; 5, granulating the ball-milled slurry on a spray granulator, and removing moisture to obtain spherical mixed powder; 6, calcining the obtained spherical mixed powder in a vacuum high-temperature environment, and decomposing to obtain spherical feed of Cr2O3 and AZO; and 7, putting the prepared spherical feed in a powder feeder, and preparing a Cr2O3 / AZO anti-corrosion composite coating on a metal plate in an atmosphere plasma spraying mode. The conductivity of the ZnO material is improved in an Al doping manner, so that the corrosion resistance of the coating is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

High-temperature-resistant electrode with doped oxide metal gradient layer and preparation method of high-temperature-resistant electrode

ActiveCN113178516AImprove high temperature conductivityHigh melting pointPiezoelectric/electrostrictive device manufacture/assemblyVacuum evaporation coatingThin membraneDoped oxide

The invention discloses a high-temperature-resistant electrode with an oxide-doped metal gradient layer and a preparation method of the high-temperature-resistant electrode. The existing interdigital electrode is easy to agglomerate and degrade at high temperature. The method comprises the following steps: a high-temperature-resistant oxide layer is deposited on a substrate; n doped oxide metal gradient layers are deposited on the high-temperature-resistant oxide layer at intervals; a plurality of thin film layer groups are deposited on each doped oxide metal gradient layer; if the number of the thin film layer groups is greater than 1, the thin film layer groups are stacked up and down; the thin film layer group consists of a doped oxide metal gradient layer and a thin film layer which are arranged from top to bottom; and the material of the oxide-doped metal gradient layer is oxide-doped metal. According to the invention, the high-temperature-resistant oxide layer is added in the electrode layer, so that the melting and fracture of the electrode at high temperature can be effectively prevented; the oxide is doped in the electrode layer, so that recrystallization and grain growth at high temperature can be effectively prevented, and the electrode has enough conductivity and is applied to a high-temperature surface acoustic wave device.

Owner:HANGZHOU DIANZI UNIV

Doped crosslinking chemical stable ion exchange membrane and preparation method thereof

ActiveCN101745320BEasy to operateExtended service lifeSemi-permeable membranesCell component detailsPhysical chemistryCompound (substance)

The invention relates to a doped crosslinking chemical stable ion exchange membrane, which belongs to the field of functional polymer composite materials. The doped crosslinking chemical stable ion exchange membrane is a perfluorinated ion exchange membrane which is formed by taking perfluorinated ion exchange resin with crosslinking sites as film-forming resin and simultaneously doping an inorganic substance with a water holding function or a proton conduction assisting function and a substance with a function of eliminating free radicals into the film-forming resin, so the chemical stability of the improved ion exchange membrane is greatly improved.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

A kind of siliceous refractory mud with excellent high temperature performance

The invention discloses a siliceous refractory mud with excellent high-temperature performance. The powder composition is as follows in terms of mass percentage: waste silica brick powder 0.5-0mm, 20-50%; quartz powder 0.3-0mm, 15-35%; quartz powder 0.088-0mm, 25-45%; silicon carbide dusting powder 1-3%; silica micropowder 1-3%; dextrin 1-1.5%; carboxymethyl cellulose 0.1-0.5%; ~0.2%; mixed with water accounting for 27~30wt% of the powder. The siliceous refractory mud provided by the invention has a silicon dioxide content greater than or equal to 94%, does not add raw clay, sodium bentonite, etc., has low alumina content, low low melt content, and a high load softening temperature point. At the same time, the addition of waste silica brick powder realizes the secondary utilization of resources, and the waste silica brick powder basically exists in the phosphorous quartz phase, which has good volume stability and matches the material of the silica bricks. noodle.

Owner:中冶武汉冶金建筑研究院有限公司

Adhesive layer slurry preparation material, preparation method and gas sensor

ActiveCN112242210BImprove the level ofGood adhesionMaterial analysis by electric/magnetic meansNon-conductive material with dispersed conductive materialDibutyl sebacatePolyvinyl alcohol

Owner:SUNLORD (SHANGHAI) ELECTRONICS CO

Automobile exhaust gas and resident coal burning waste gas purification system

PendingCN110354667ASimplified Exhaust SystemReduce manufacturing costGas treatmentExhaust apparatusEngineeringGuide tube

The invention discloses an automobile exhaust gas and resident coal / carbon burning waste gas purification system. The system comprises a gas cleaning device and a pollution exhaust gas discharge-freequicklime production process method, wherein the gas cleaning device comprises an air guiding tube, a pipeline supercharger, an exhaust gas / waste gas cleaning tank, a stirrer, a cleaning liquid, a sensor and a control circuit. The exhaust gas cleaning device is mounted on the top of an automobile or on the roof of a residential building, one end of the gas guiding tube is connected with the exhaust tube of the automobile or the chimney of the residential building, the other end of the gas guiding tube is connected with the cleaning tank, a plurality of cleaning tubes are arranged in the cleaning tank, and the automobile exhaust gas or the waste gas is conveyed to the bottom of the cleaning tank through the cleaning tubes overcoming the pressure of the cleaning liquid in order to complete the cleaning of the automobile exhaust waste and the waste gas, so the system achieves the effect of automobile emission reduction and provides a long-acting treatment method for urban air treatment.

Owner:王钟琴

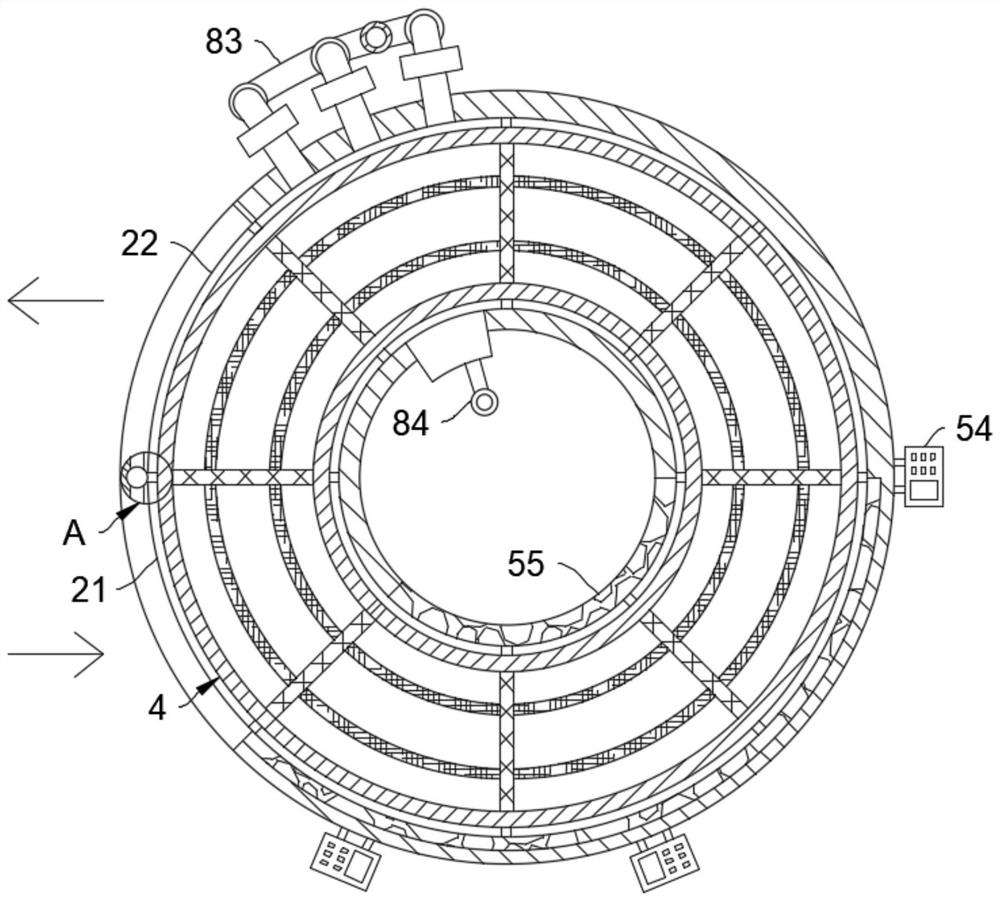

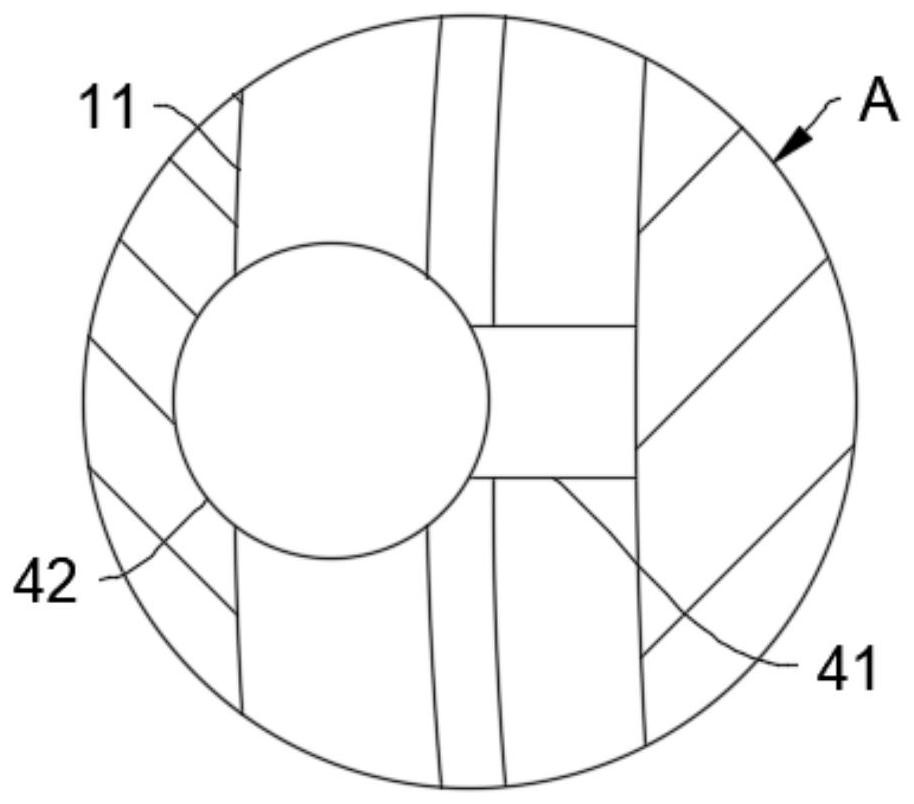

Horizontal continuous annealing device for tempered glass

InactiveCN113307479AImprove annealing efficiencyFacilitate temperature conductionCooling chamberElectric machinery

The invention belongs to the field of tempered glass production equipment, and particularly relates to a horizontal continuous annealing device for tempered glass. The device comprises a sealing chamber, the sealing chamber is provided with an opening, the opening is used for feeding and discharging tempered glass, the sealing chamber is rotationally connected with a supporting plate through a motor, and the supporting plate is slidably connected with the sealing chamber; the sealing chamber is provided with a temperature chamber with the temperature gradually increased from the opening, the end, away from the opening, of the temperature chamber is communicated with an annealing chamber, and the annealing chamber is communicated with a cooling chamber. The rotary horizontal continuous annealing device is arranged for tempered glass, so that the equipment directly carries out feeding and discharging work on the glass at the same position in annealing of the tempered glass, manpower resource utilization is improved, meanwhile, the annular annealing device effectively reduces the occupied space of the equipment, the distance between adjacent temperature chambers is shortened, temperature conduction in the tempered glass heating process is facilitated, and the heat transfer efficiency in the annealing process of the device is improved.

Owner:HUZHOU YUEBIN INTELLIGENT TECH CO LTD

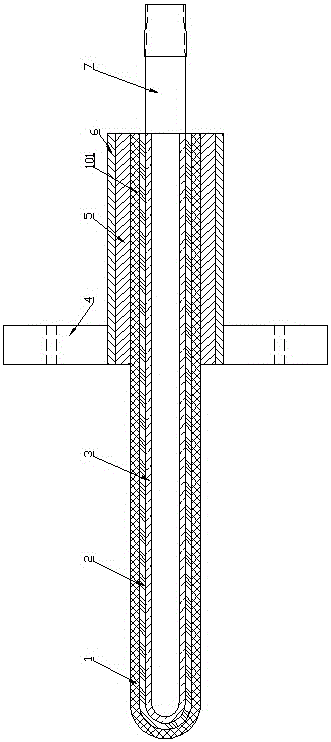

A thermocouple protection sleeve and its manufacturing method

ActiveCN103940524BExtended service lifeGuaranteed use strengthThermometers using electric/magnetic elementsUsing electrical meansMining engineeringPipe

A thermocouple protection casing, including corundum outer casing, titanium dioxide bonding layer, white steel inner casing, connecting flange, asbestos rope, connecting pipe and wire head. The method is: (1), mix and stir the titanium dioxide and sodium silicate aqueous solution evenly to obtain a titanium dioxide paste; (2), pour the prepared titanium dioxide paste into the corundum outer tube and fill it; (3), put After the asbestos rope is dipped in the titanium dioxide paste, it is wound around the back of the corundum outer casing and inserted into the connecting pipe; (4) insert the white steel inner casing into the corundum outer casing filled with titanium dioxide paste, and drain the overflowing titanium dioxide (5) After standing at room temperature for 18h to 24h, weld the connecting flange to the front end of the connecting pipe, and weld the wire head to the open end of the white steel inner sleeve to make a thermocouple protection sleeve. The advantage is that the thermocouple protection sleeve is suitable for normal operation under high temperature, high pressure, corrosion and wear titanium dioxide production conditions, and can prolong the service life of the thermocouple protection sleeve.

Owner:中信钛业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com