Chromium oxide-aluminum doped zinc oxide anti-corrosion composite coating and preparation method thereof

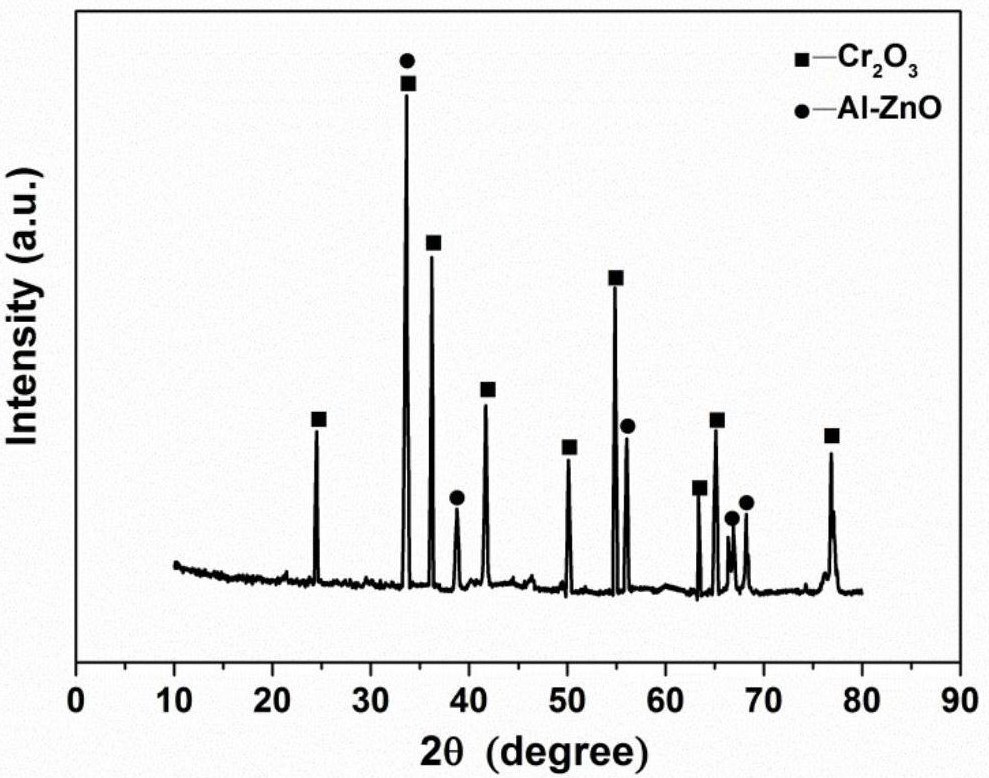

An aluminum-doped zinc oxide, composite coating technology, applied in the directions of chromium oxide/hydrate, chromium trioxide, chemical instruments and methods, etc., can solve the problems of uneven particle distribution, uneven thermal performance, poor bonding force, etc. , to achieve uniform composition, improve high temperature corrosion resistance, and high density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The volume of mixed solution in step 1 is 1000mL, wherein Cr(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 The mass fraction of O is 30wt.%, and the molar ratio of Cr 3+ : Zn 2+ 1:1, Zn 2+ :Al 3+ 40:1;

[0043] Step 2, gradually add excess ammonia water to the mixed solution in step 1 and keep stirring until the generated Cr(OH) 3 , Zn(OH) 2 and Al(OH) 3 The mixed white precipitate, the concentration of ammonia water is 30%.

[0044] Step 3, add a certain amount of PVA aqueous solution to the white precipitate obtained in step 2, the concentration of the PVA aqueous solution is 5%, and the addition amount is 150mL.

[0045] In step 4, the mixture in step 3 is placed on a roller ball mill for ball milling, the speed of the roller ball mill is 70r / min, and the working time is 24h.

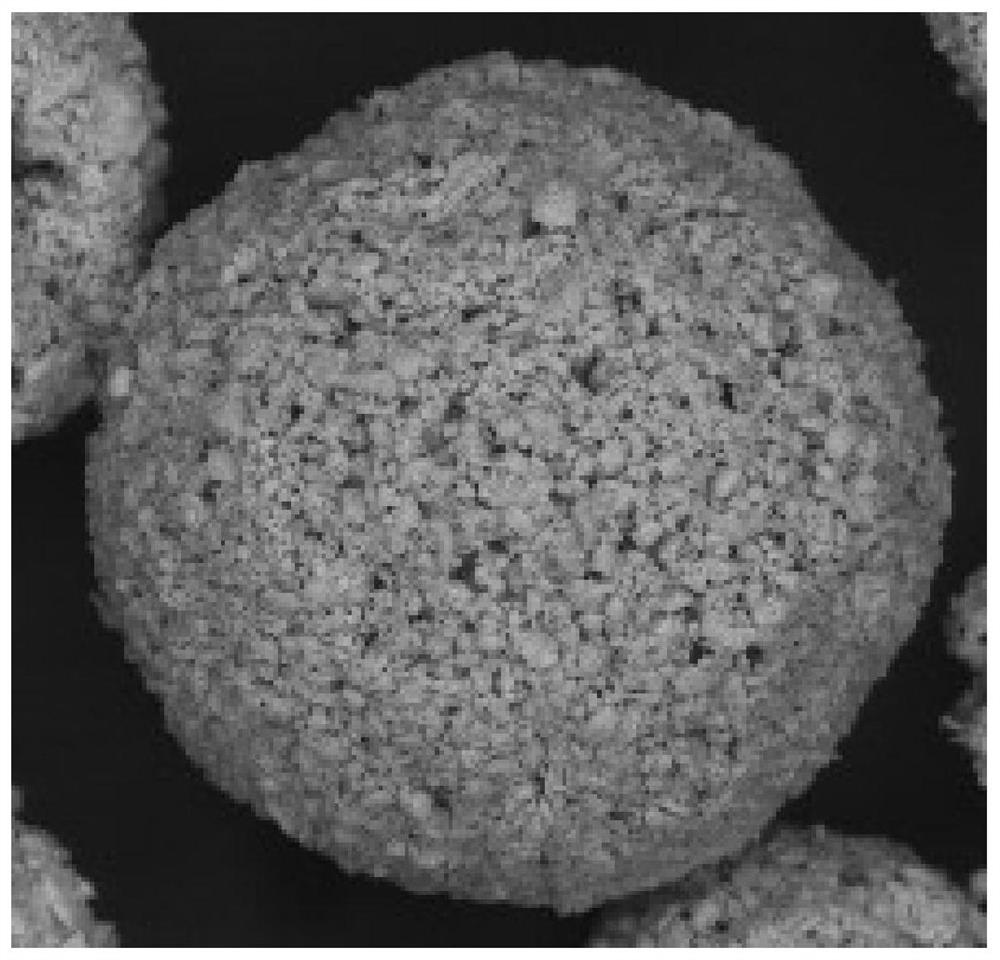

[0046] Step 5, granulate the ball-milled slurry in step 4 on a spray granulator, and obtain dry Cr(OH) after removing moisture 3 , Zn(OH) 2 and Al(OH) 3 The sphe...

Embodiment 2

[0050] The volume of mixed solution in step 1 is 1000mL, wherein Cr(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 The mass fraction of O is 20wt.%%, and the molar ratio of Cr 3+ : Zn 2+ 1:4, Zn 2+ :Al 3+ 25:1;

[0051] Step 2, gradually add excess ammonia water to the mixed solution in step 1 and keep stirring until the generated Cr(OH) 3 , Zn(OH) 2 and Al(OH) 3 The mixed white precipitate, the concentration of ammonia water is 50%.

[0052] Step 3, add a certain amount of PVA aqueous solution to the white precipitate obtained in step 2, the concentration of the PVA aqueous solution is 8%, and the addition amount is 200mL.

[0053] In step 4, the mixture in step 3 is placed on a roller ball mill for ball milling, the speed of the roller ball mill is 80r / min, and the working time is 24h.

[0054] Step 5, granulate the ball-milled slurry in step 4 on a spray granulator, and obtain dry Cr(OH) after removing moisture 3 , Zn(OH) 2 and Al(OH) 3 The sph...

Embodiment 3

[0058] The volume of mixed solution in step 1 is 1000mL, wherein Cr(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 The mass fraction of O is 20wt.%~50wt.%, and the molar ratio of Cr 3+ : Zn 2+ 1:3, Zn 2+ :Al 3+ 19:1;

[0059] Step 2, gradually add excess ammonia water to the mixed solution in step 1 and keep stirring until the generated Cr(OH) 3 , Zn(OH) 2 and Al(OH) 3 The mixed white precipitate, the concentration of ammonia water is 35%.

[0060] Step 3, add a certain amount of PVA aqueous solution to the white precipitate obtained in step 2, the concentration of the PVA aqueous solution is 5-8%, and the addition amount is 200mL.

[0061] In step 4, the mixture in step 3 is placed on a roller ball mill for ball milling, the speed of the roller ball mill is 60r / min, and the working time is 24-36h.

[0062] Step 5, granulate the ball-milled slurry in step 4 on a spray granulator, and obtain dry Cr(OH) after removing moisture 3 , Zn(OH) 2 and Al(OH)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com