Patents

Literature

82results about How to "Minimal waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

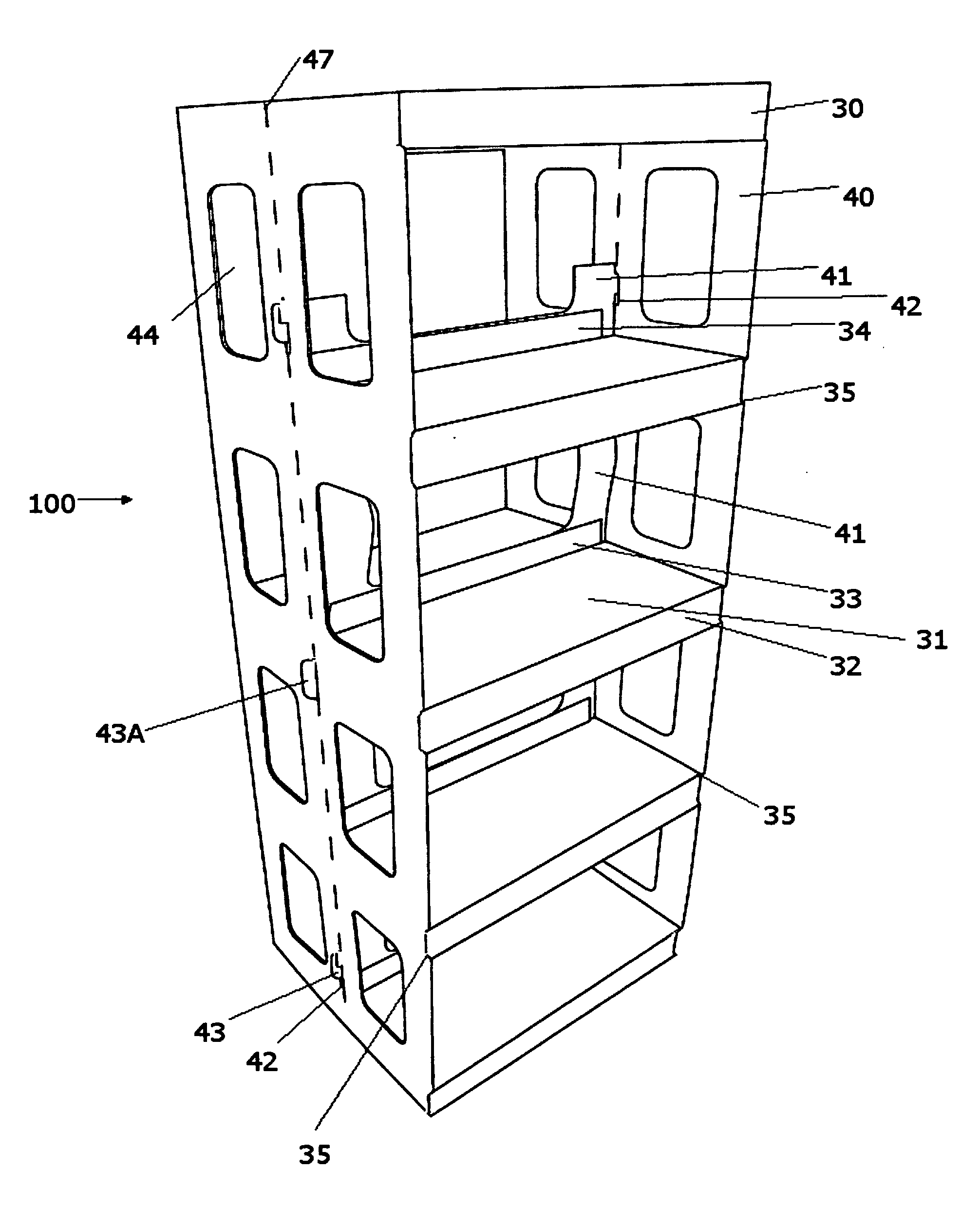

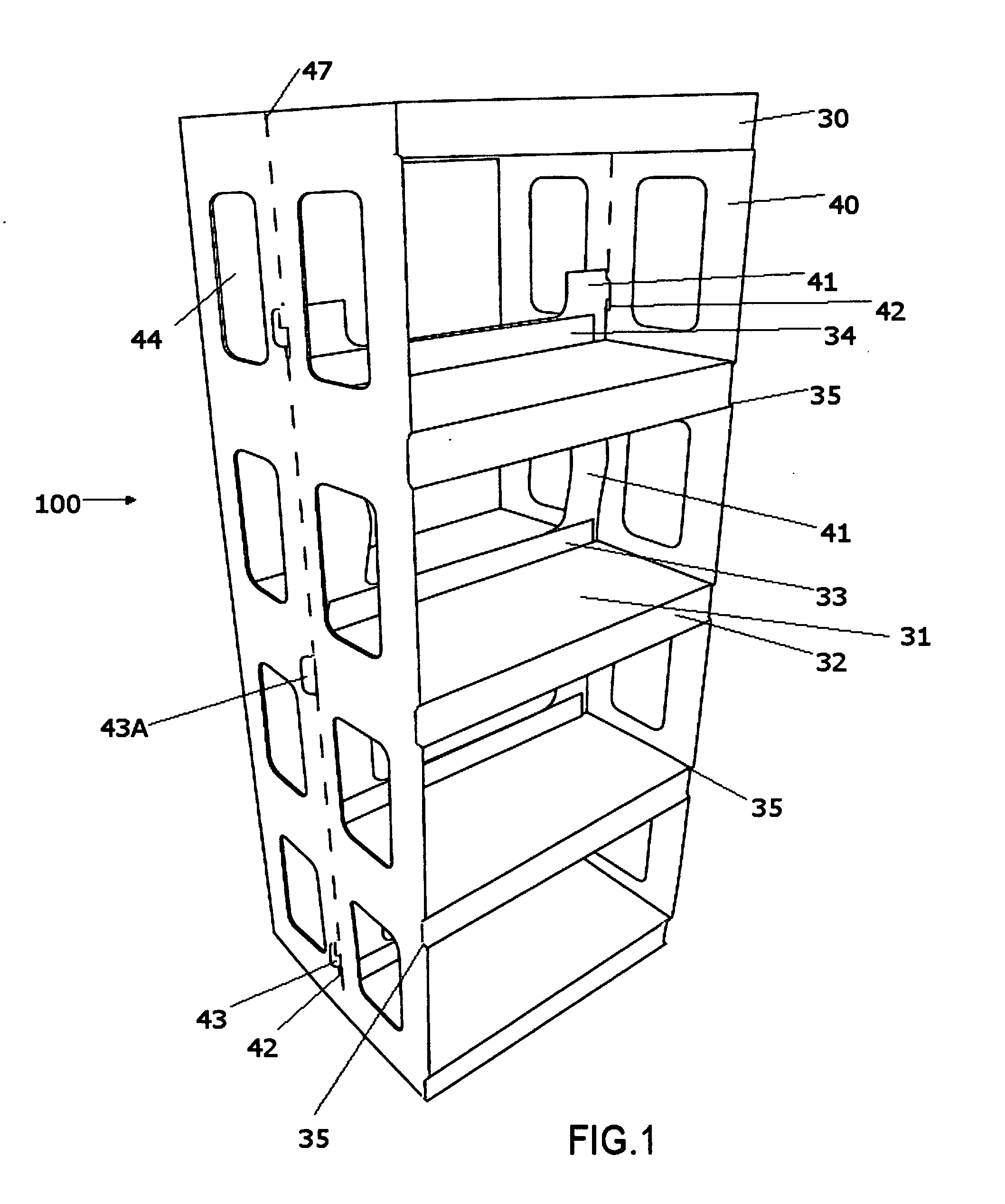

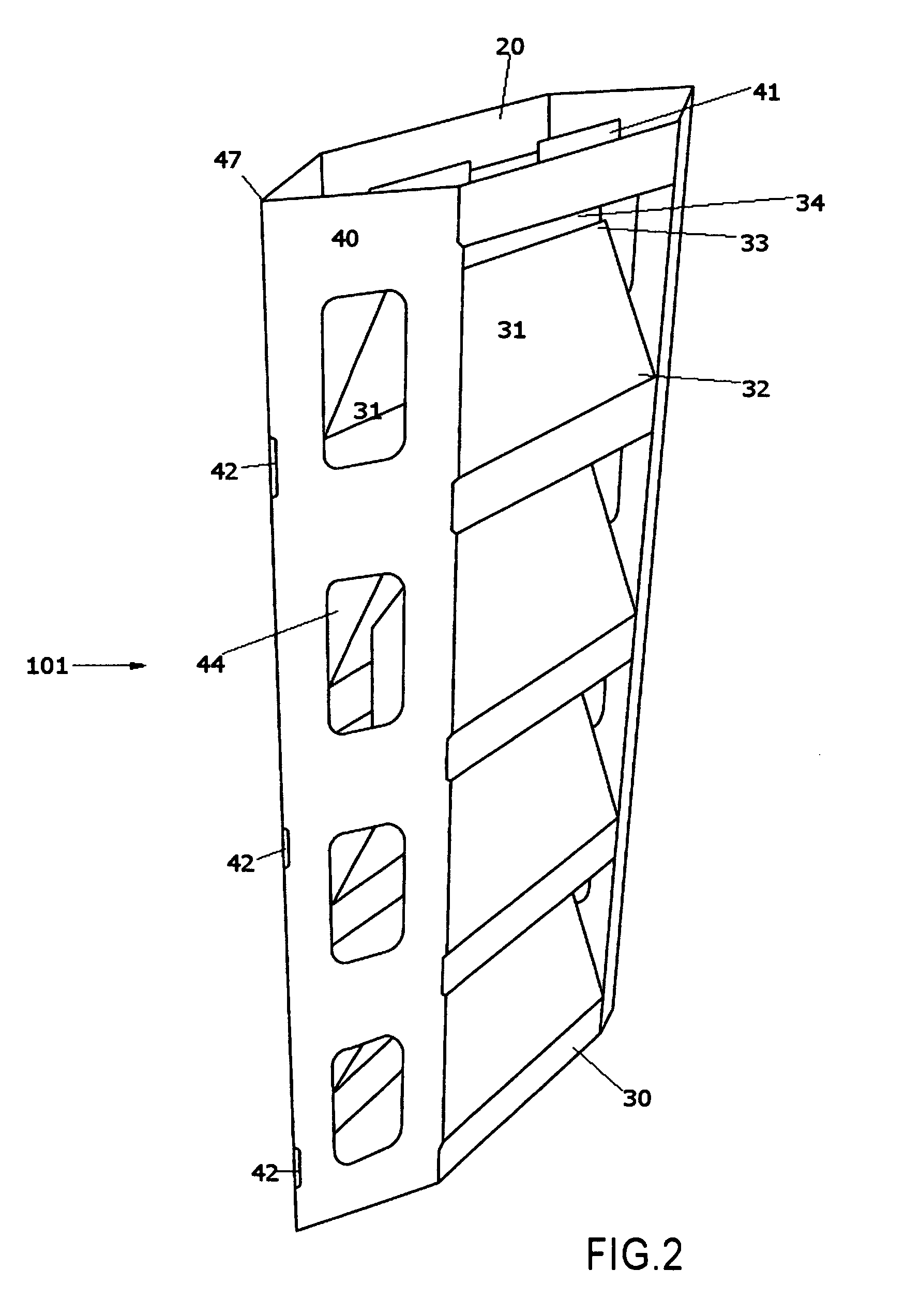

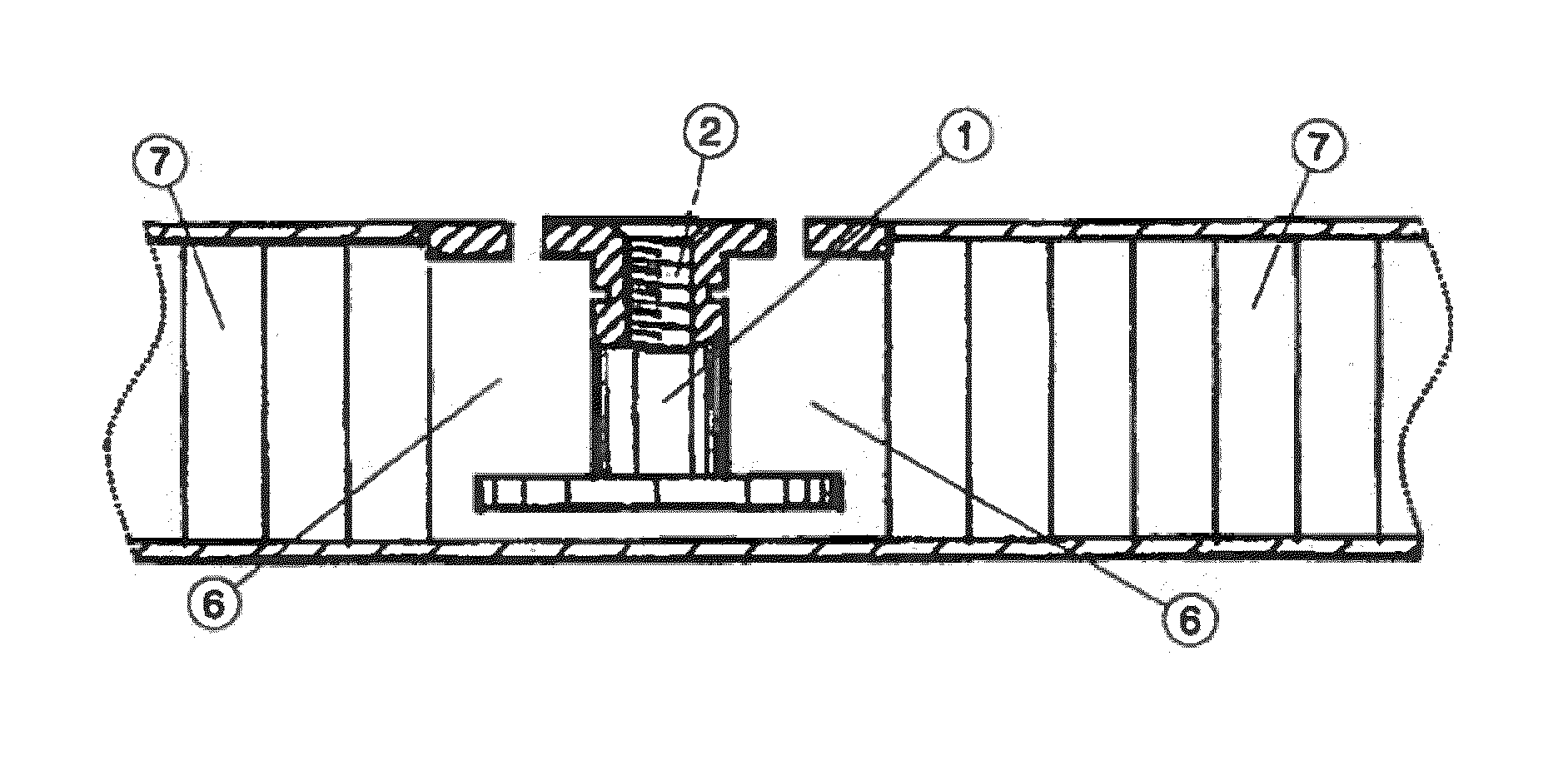

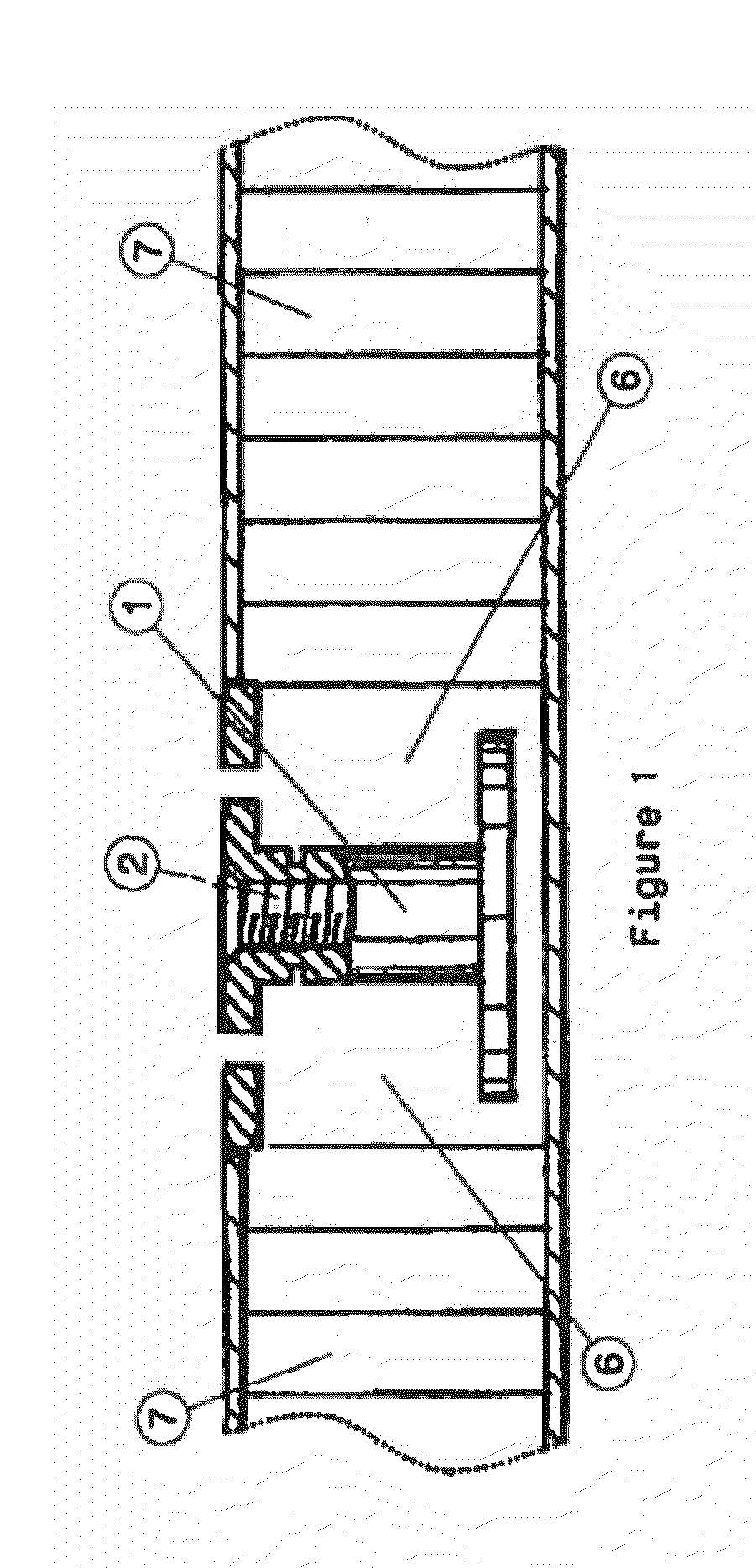

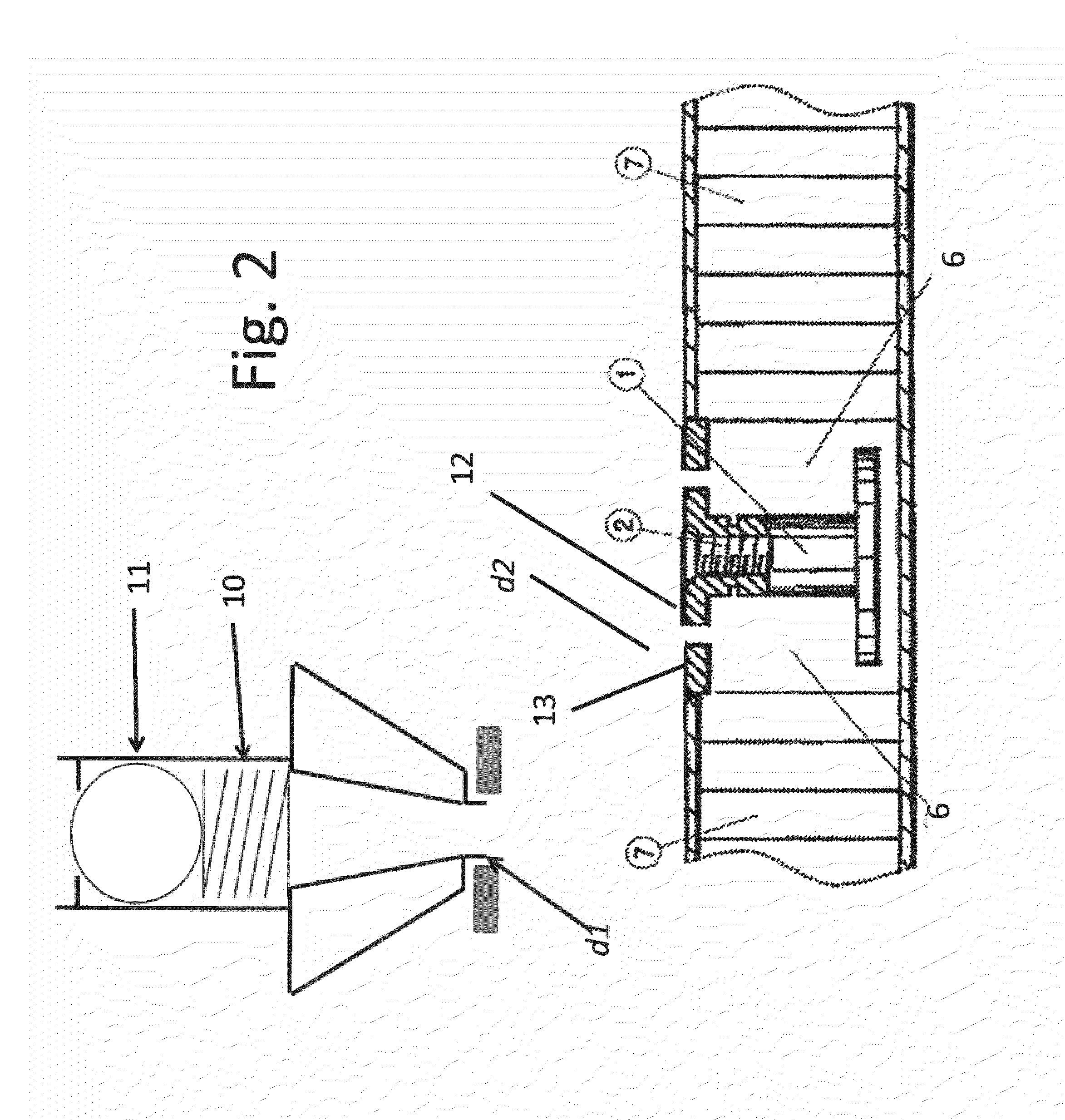

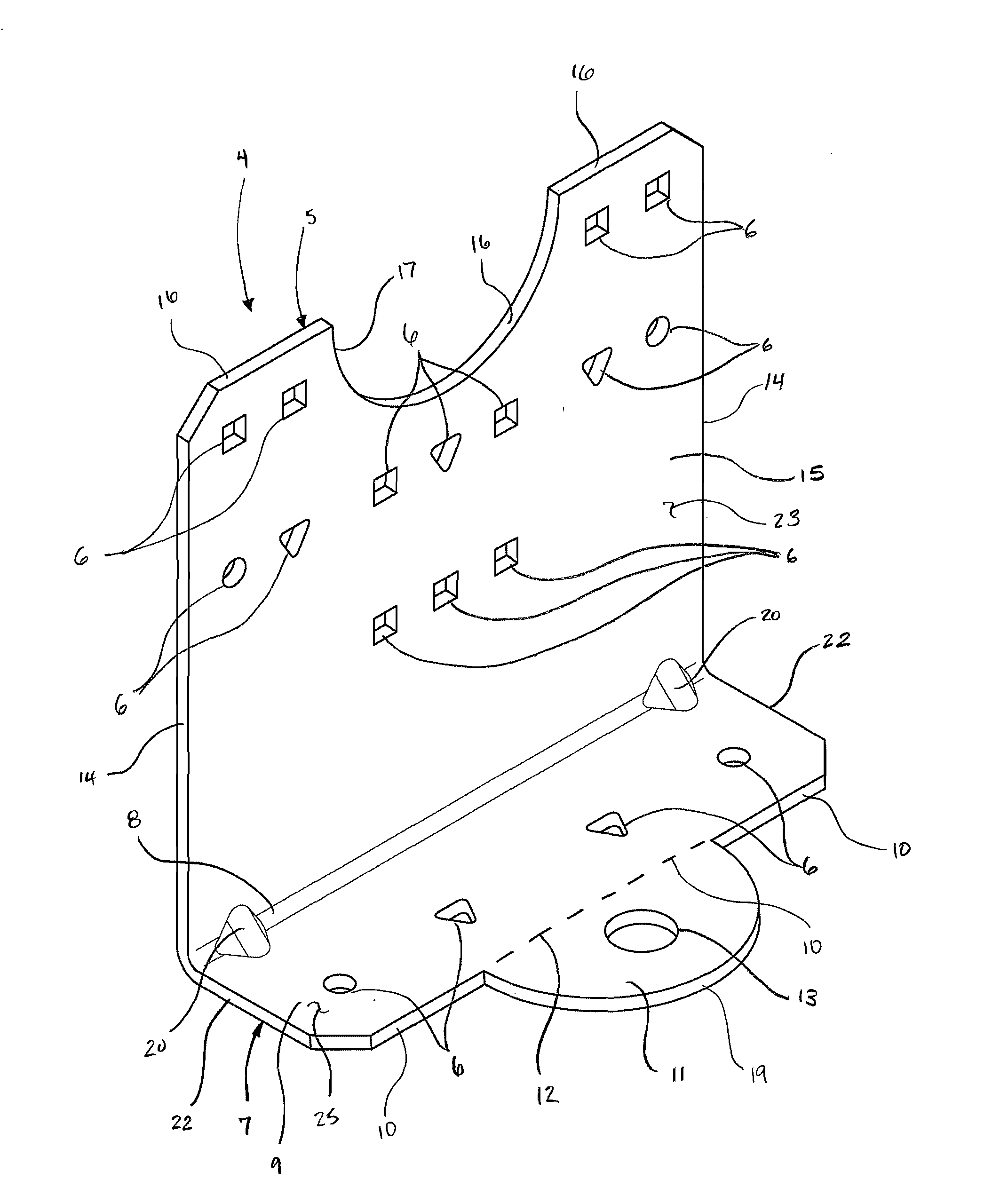

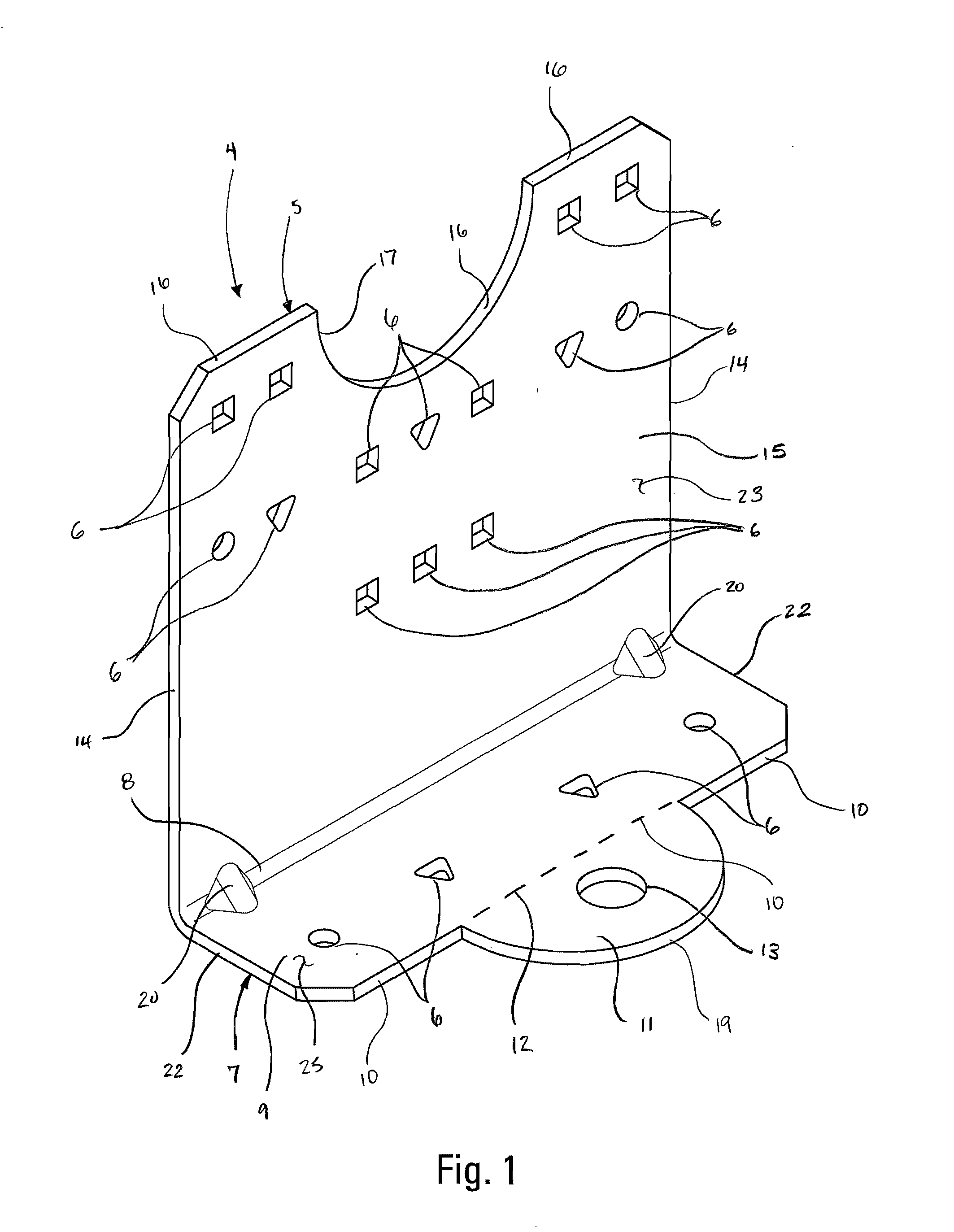

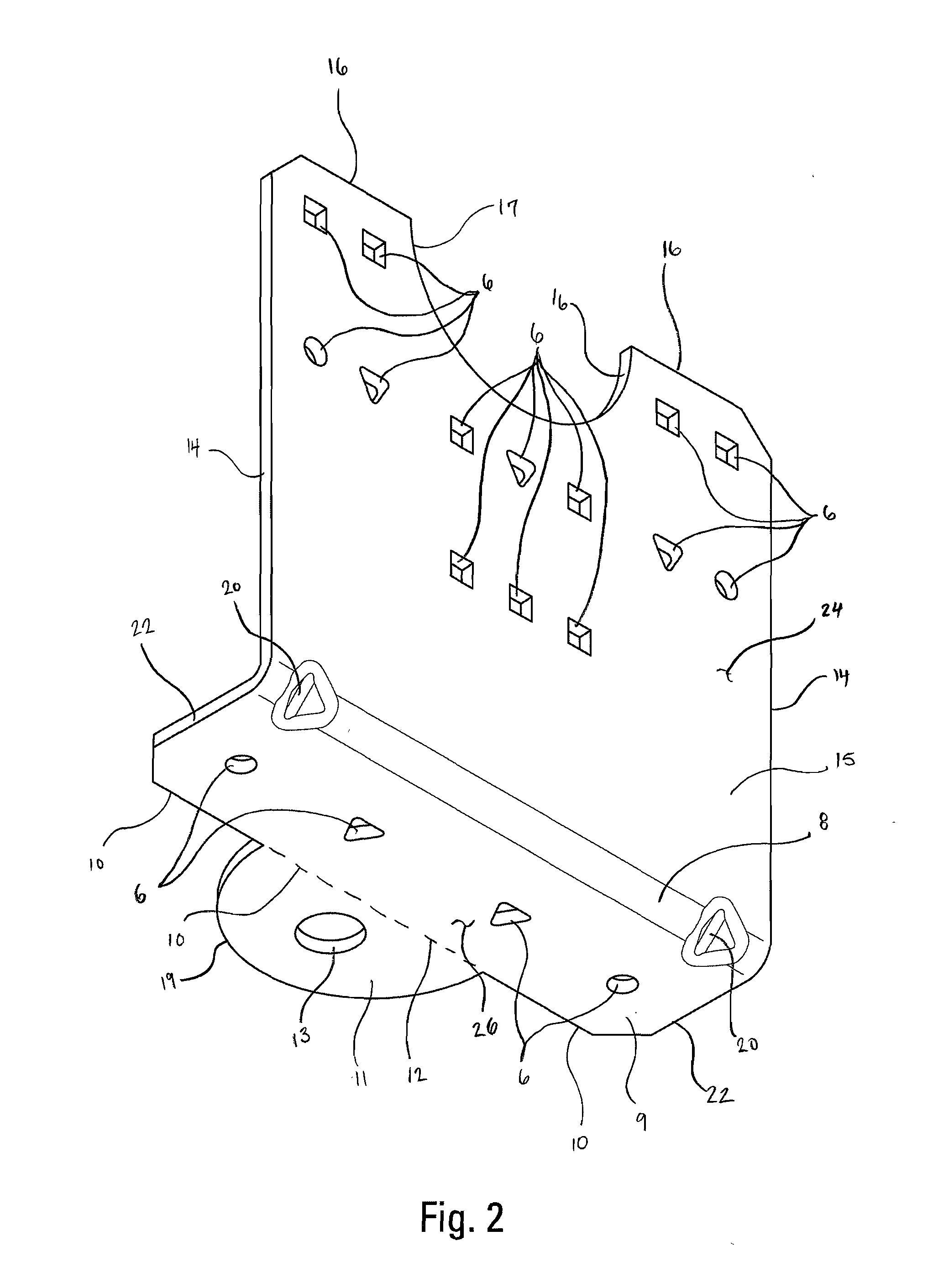

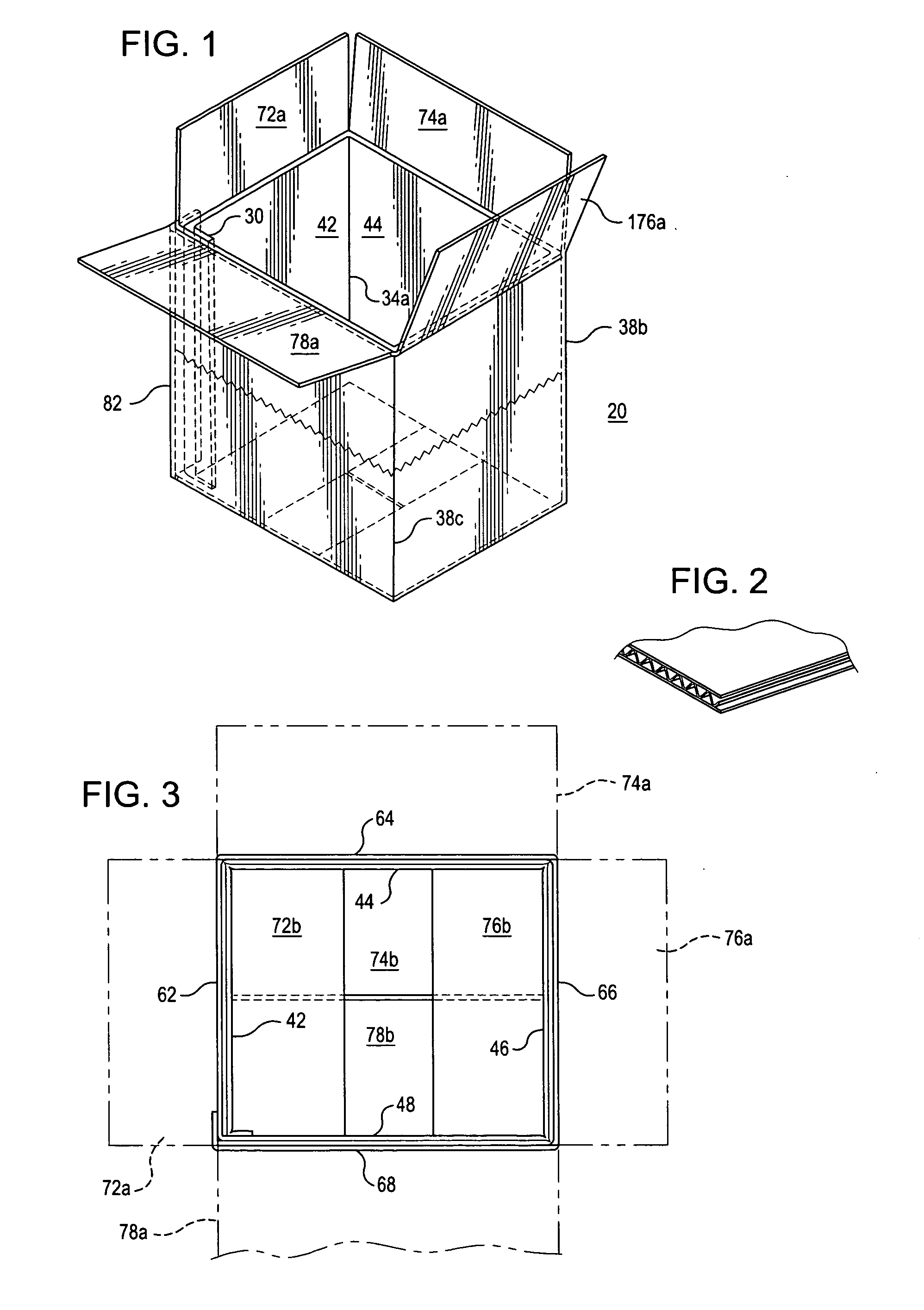

Collapsiable merchandising display

InactiveUS20100006529A1Easy to collapseEasy to set upFolding cabinetsDismountable cabinetsCardboardDisplay device

A one-piece, easily erected, collapsible cardboard display for merchandise. Shelves formed from the display's front panel are secured to a longitudinally displaceable sliding panel providing support for the device and facilitating assembly and disassembly thereof.

Owner:INTERSTATE CONTAINER READING

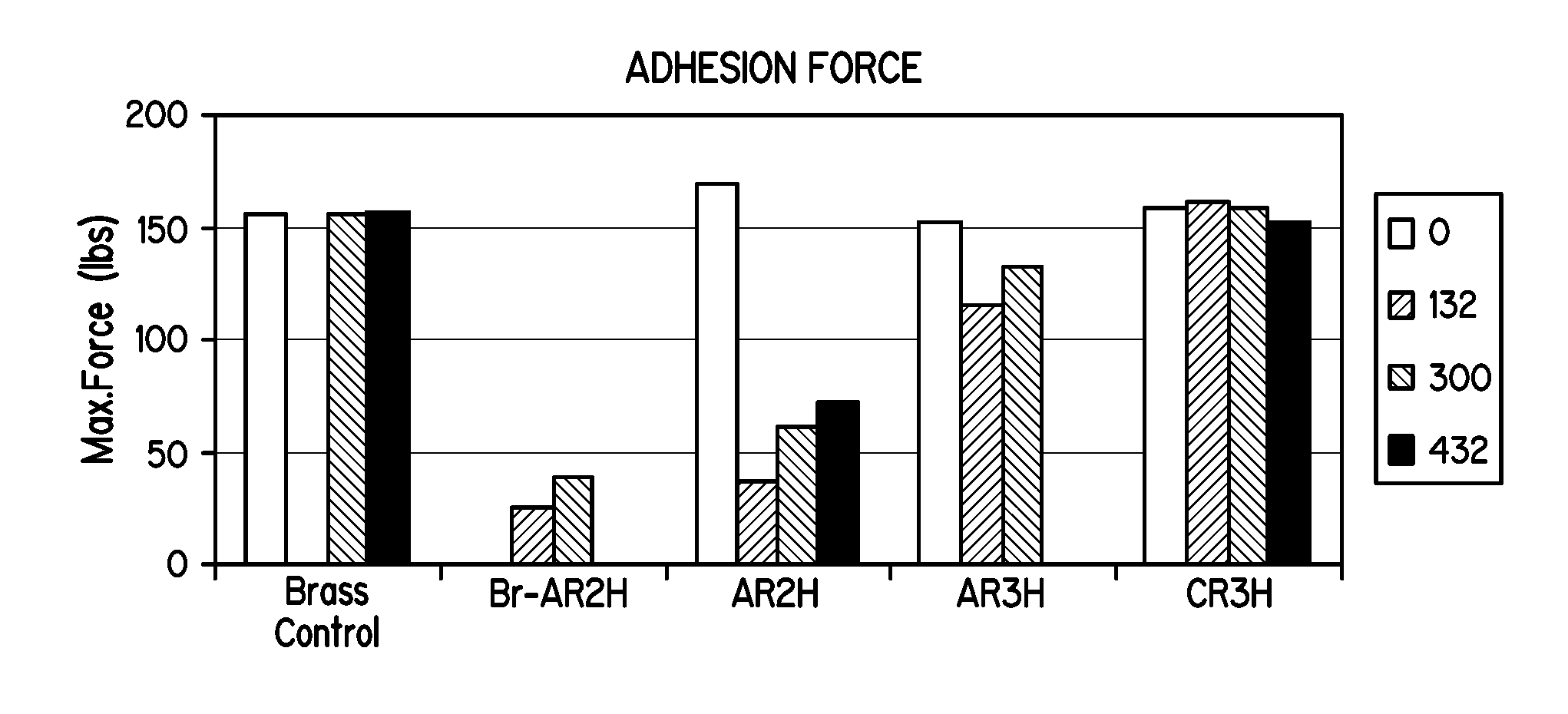

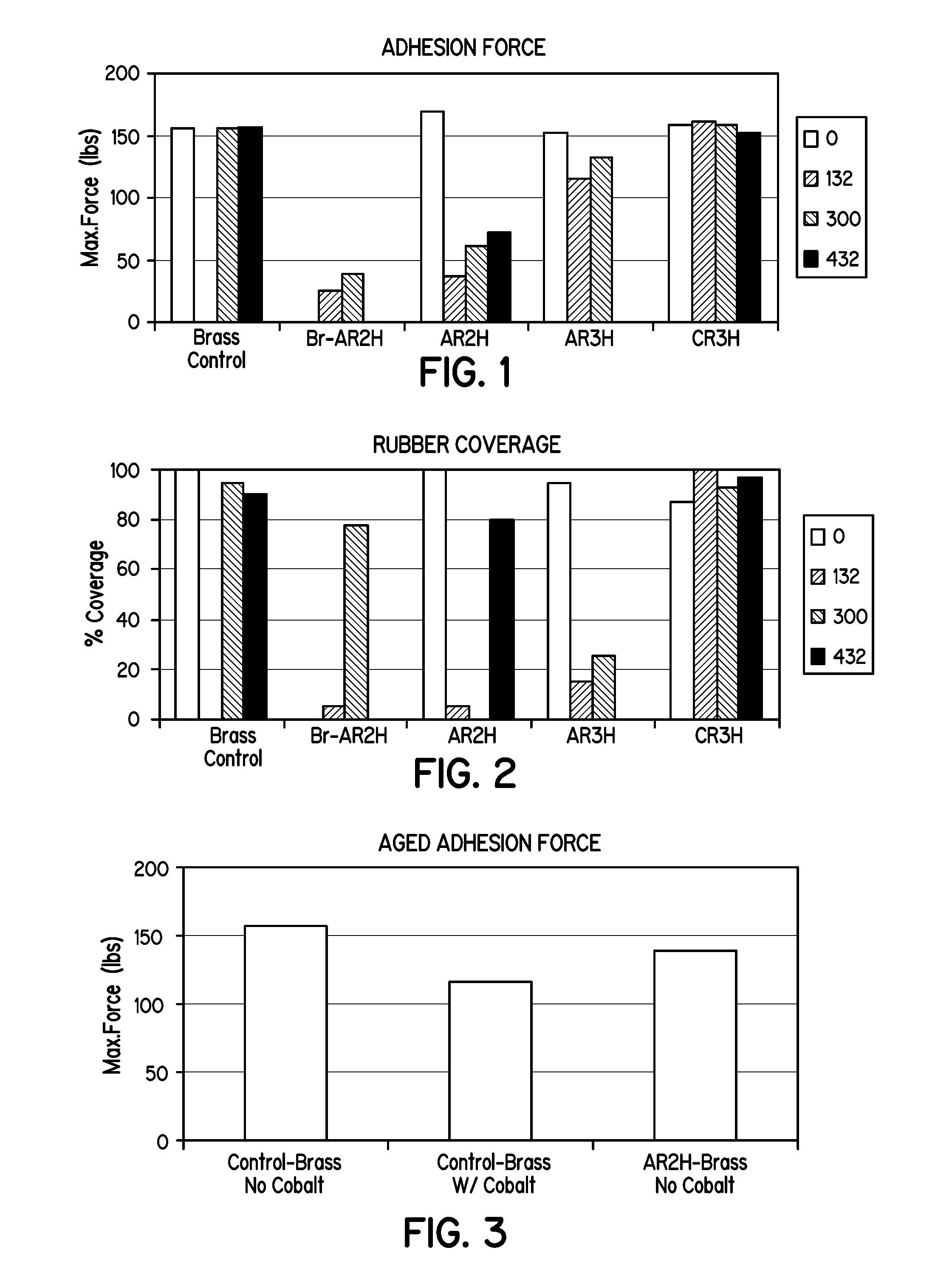

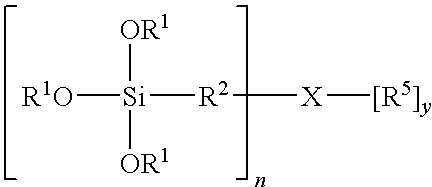

Silane Compositions and Methods for Bonding Rubber to Metals

InactiveUS20090181248A1Efficiently and economically adhereMinimal wasteAdhesive processes with surface pretreatmentSpecial tyresVulcanizationMetal substrate

Compositions and methods for treating metal substrates and / or bonding metal substrates to polymeric materials, such as rubber, are provided. The compositions include at least one substantially hydrolyzed amino silane and at least one substantially hydrolyzed sulfur-containing silane. Optionally, the compositions include a nano-size particulate material. The compositions provide coatings on metal substrates for protecting the metal from corrosion and for adhering rubber-like polymeric compositions to the metal with polymer-to-metal vulcanization conditions less dependent on the coating thickness, and with use of less coating materials.

Owner:UNIVERSITY OF CINCINNATI +1

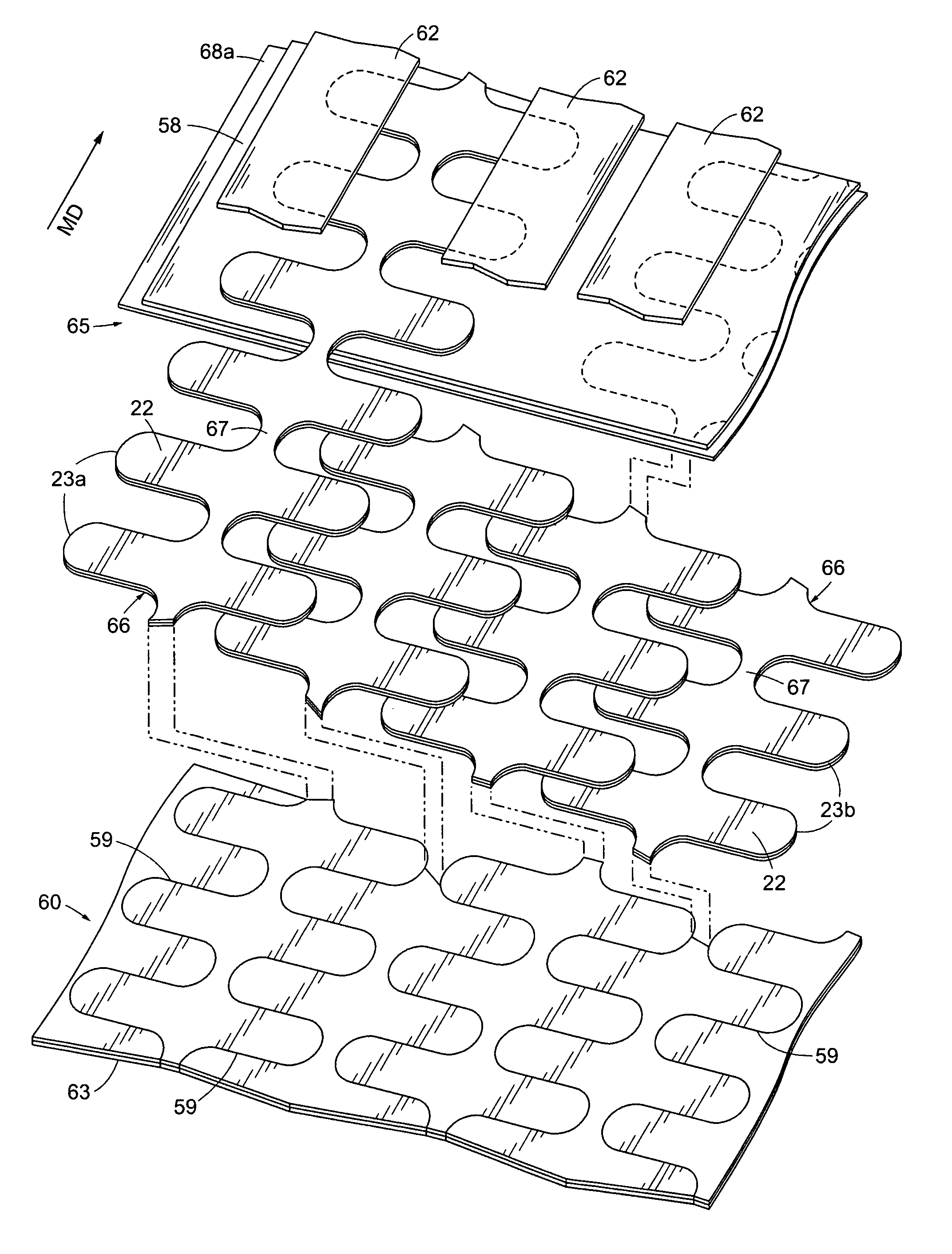

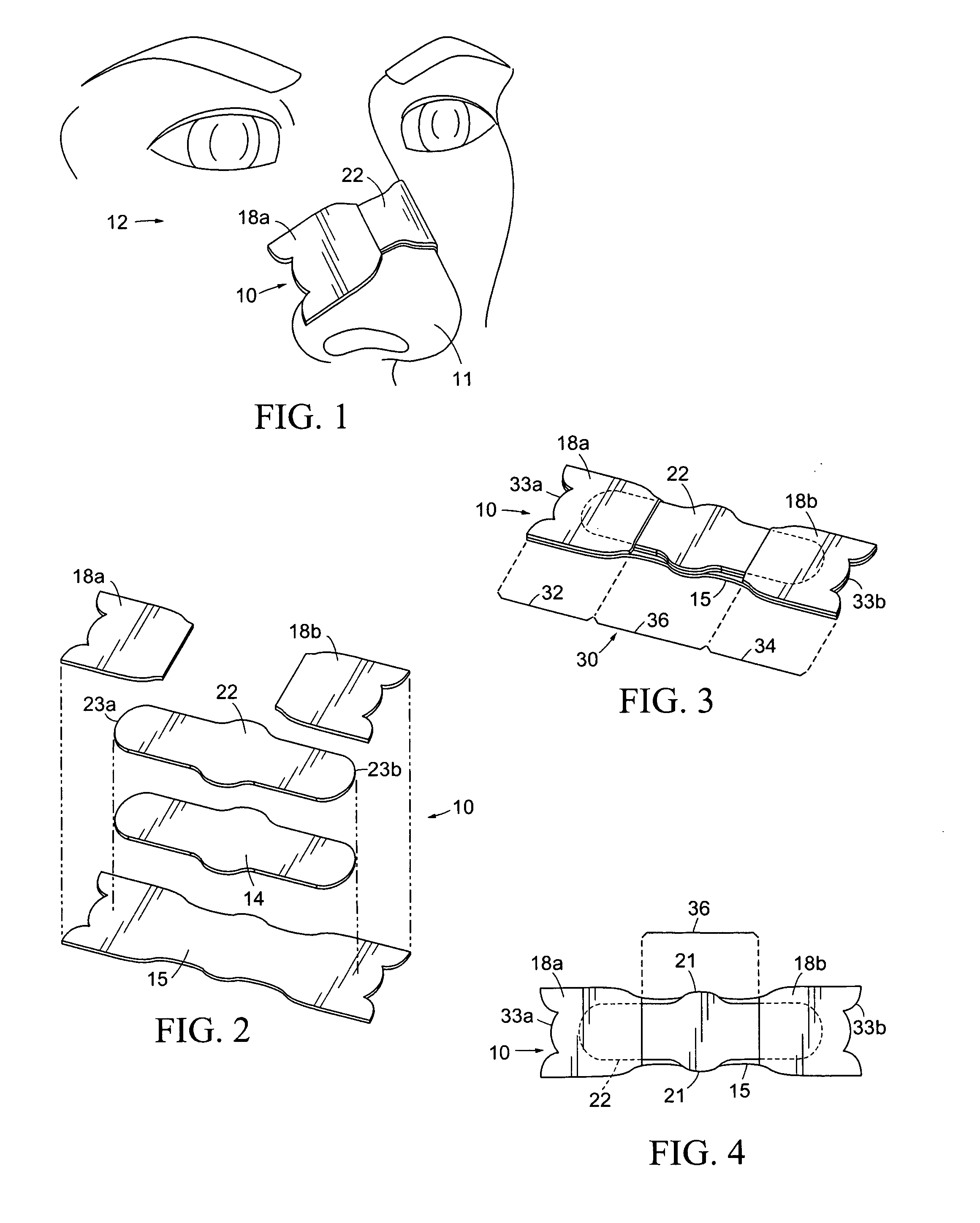

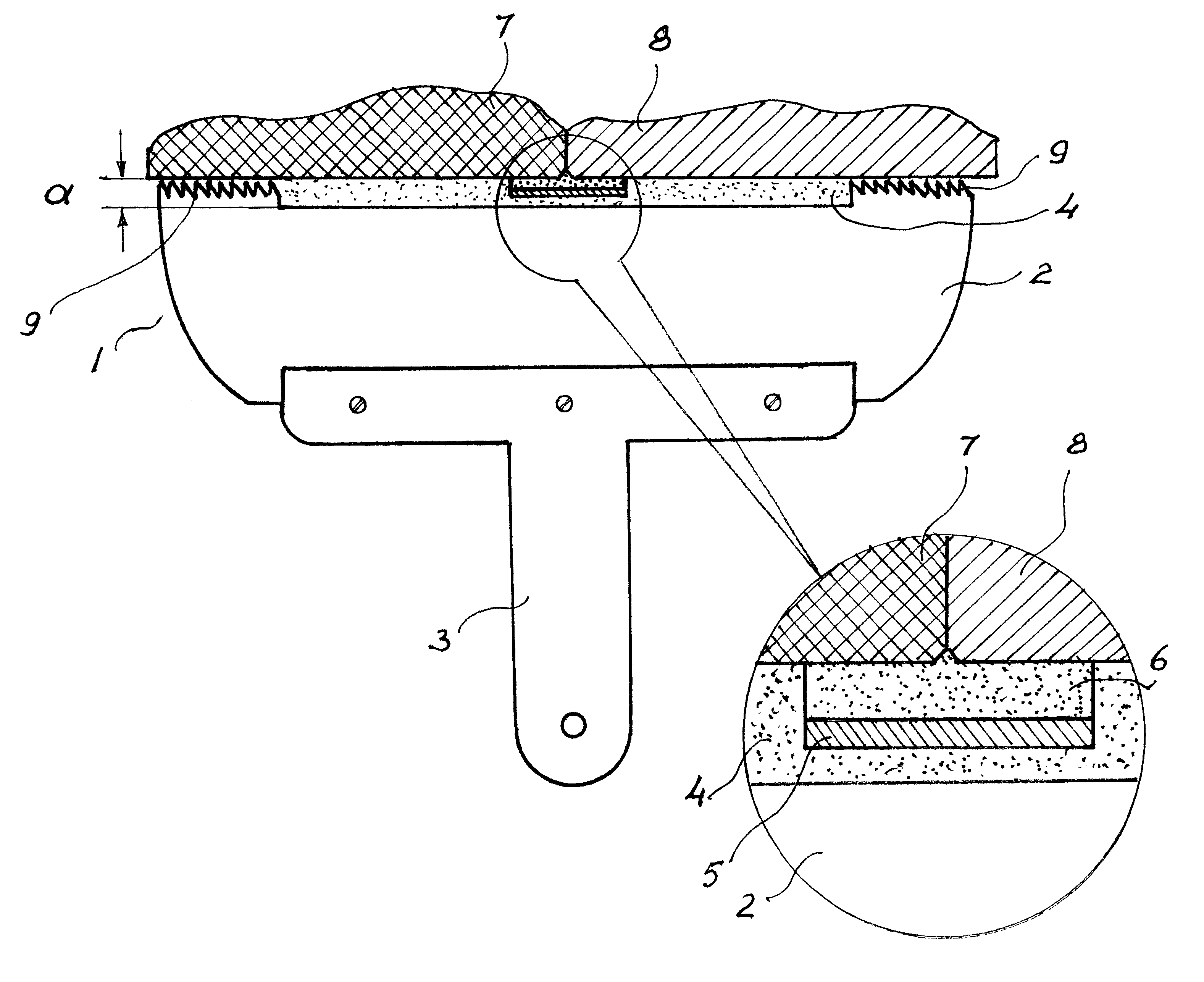

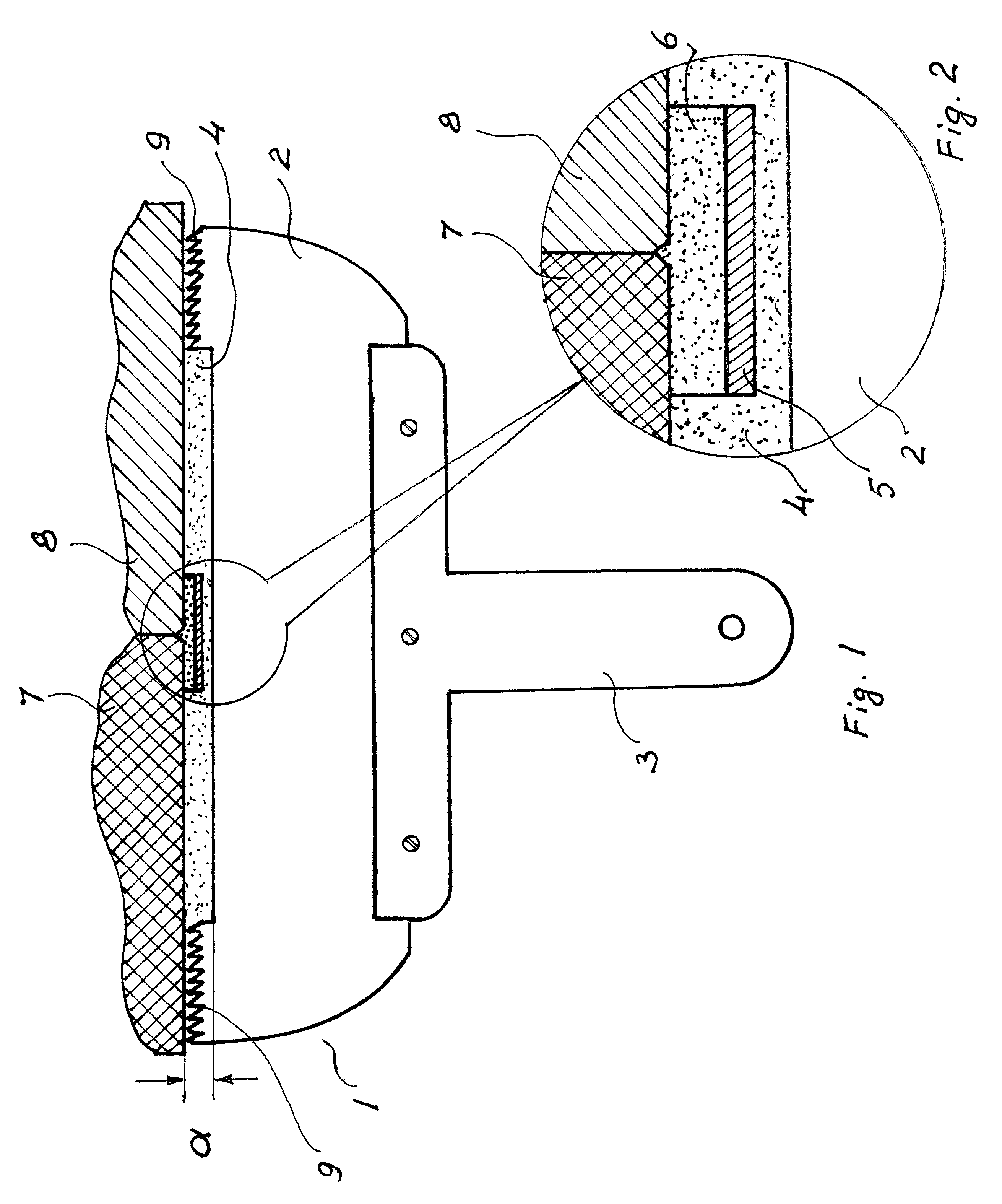

Nasal dilator and method of manufacture

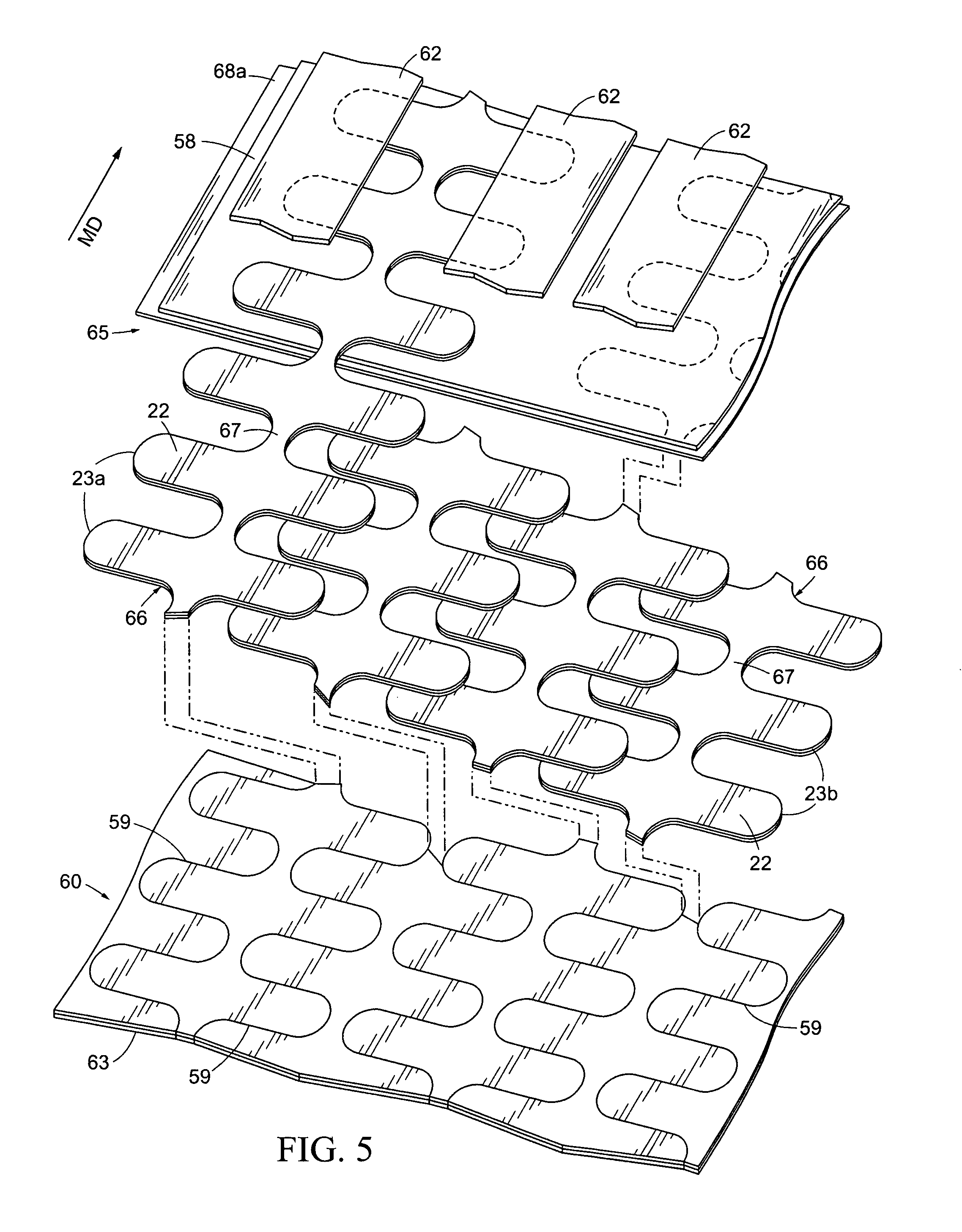

ActiveUS8858587B2Easy to disassembleAvoid high pressureLamination ancillary operationsSurgeryEngineeringWaste material

Owner:HORIZON IP TECH LLC

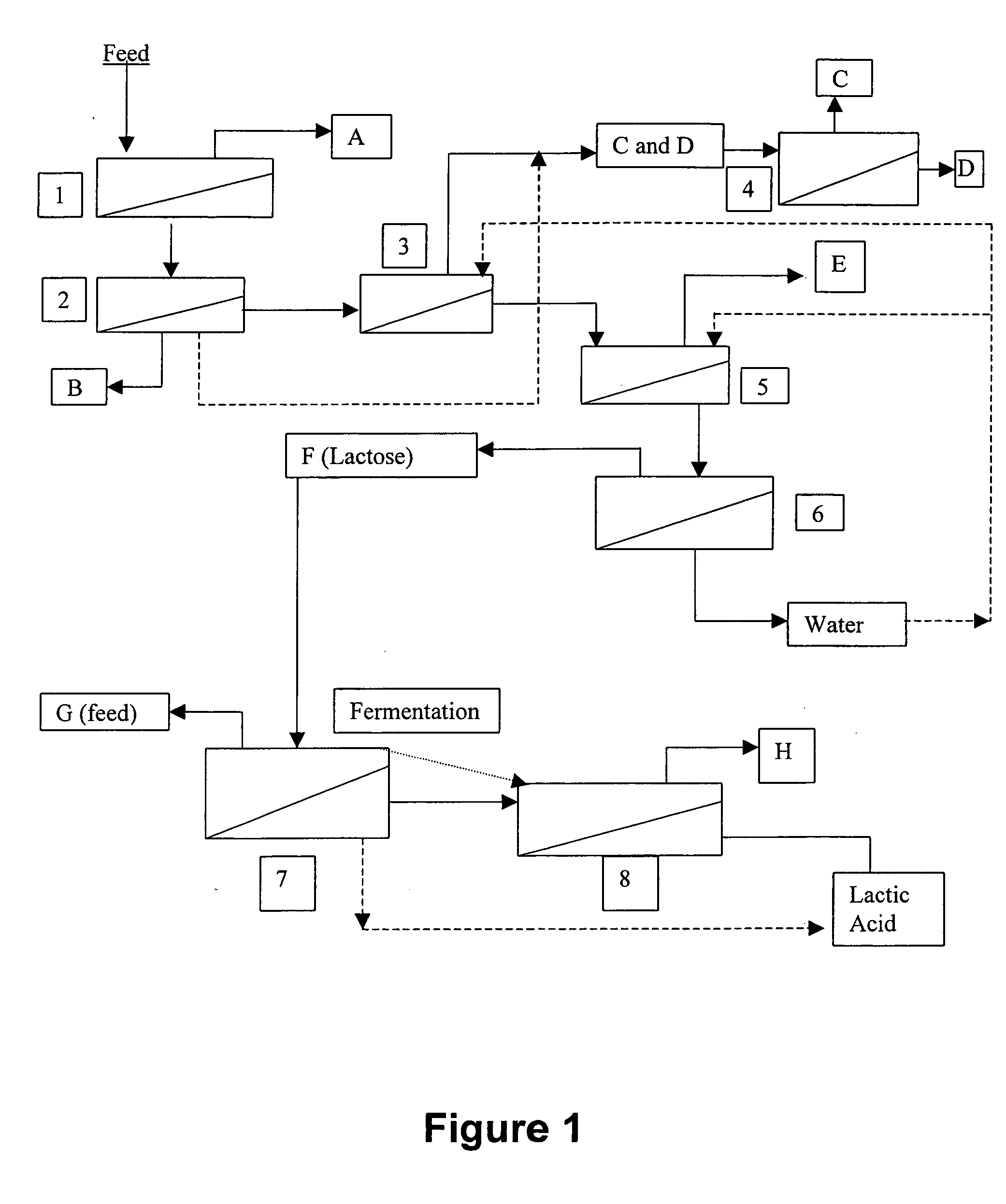

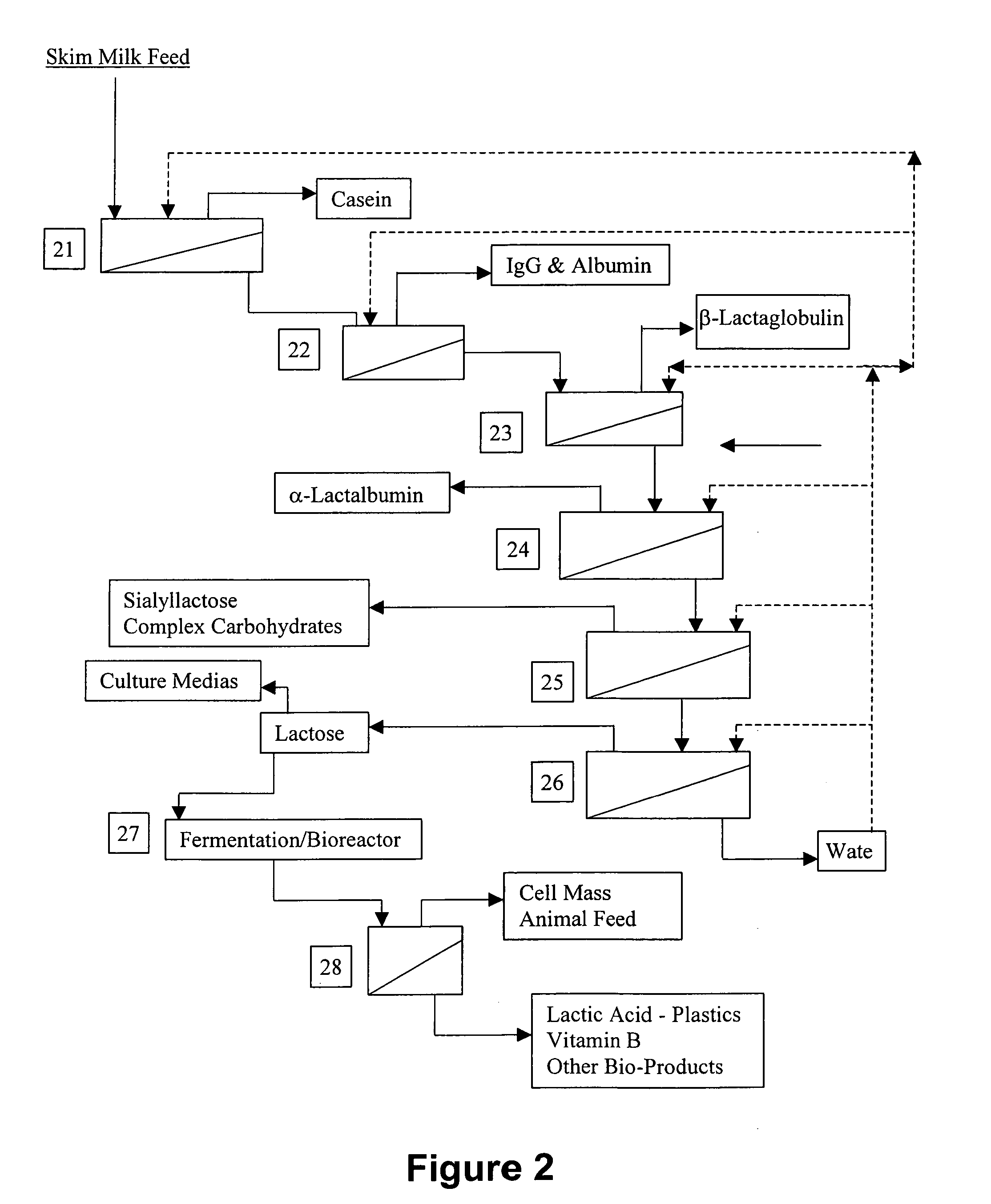

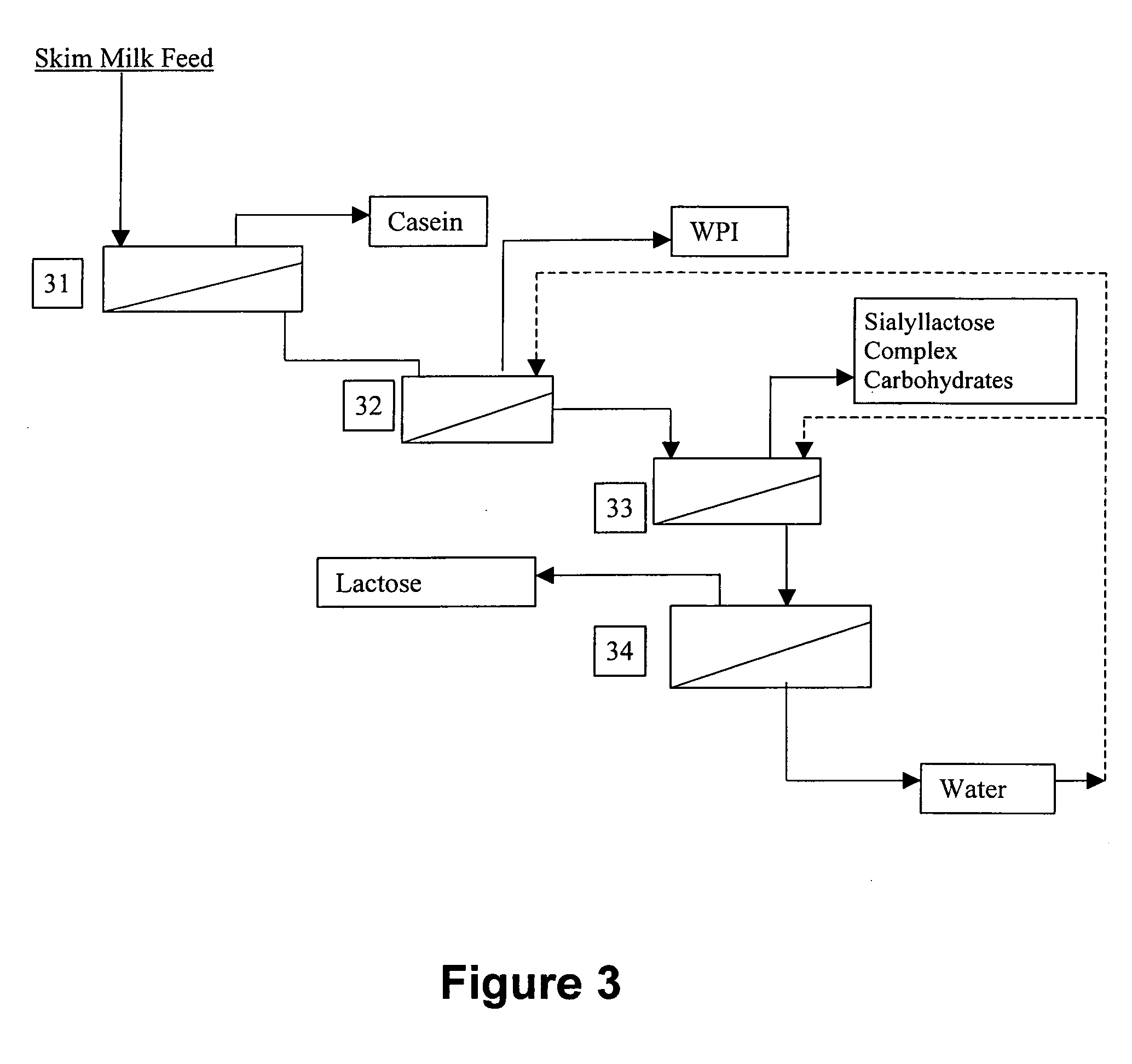

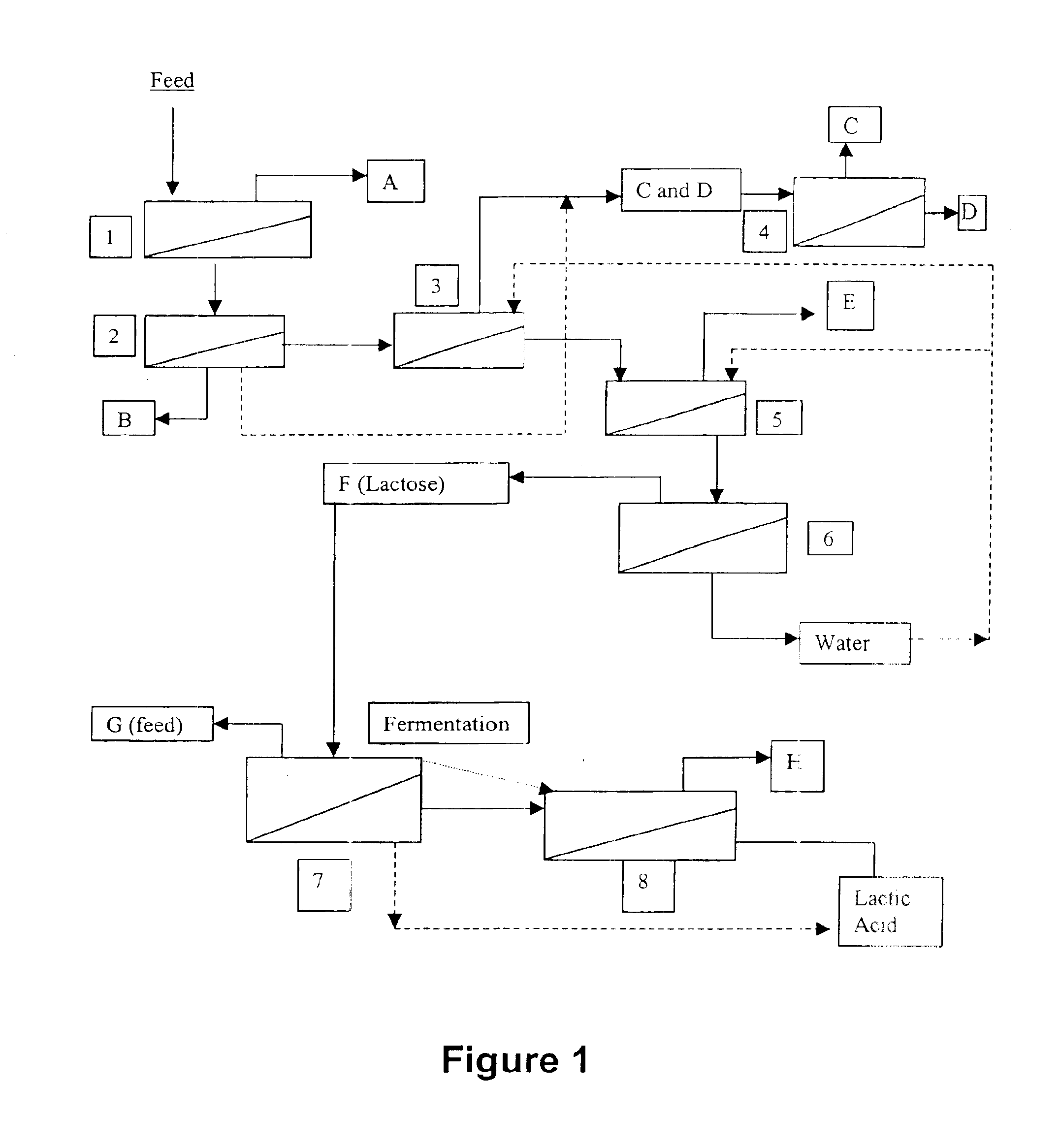

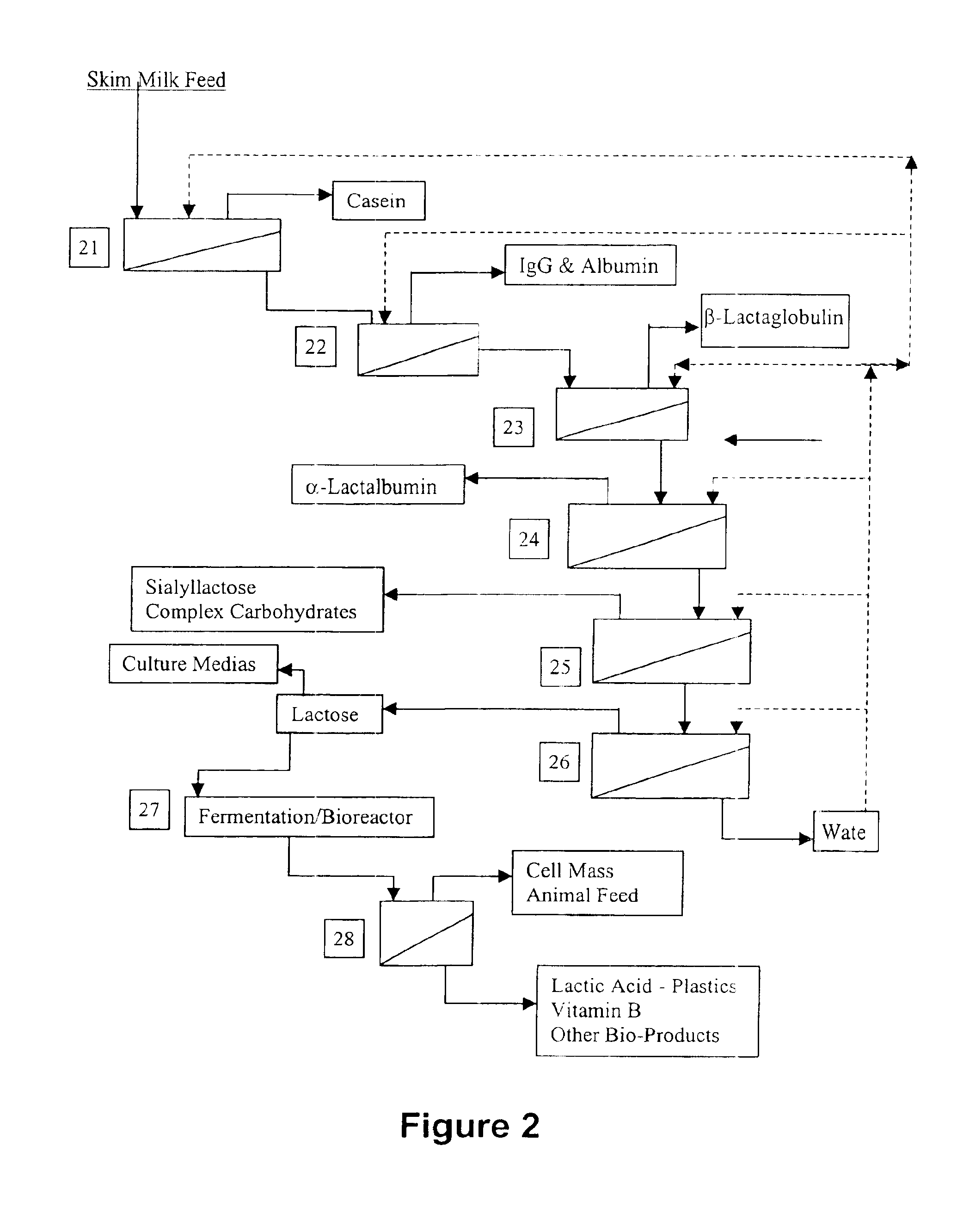

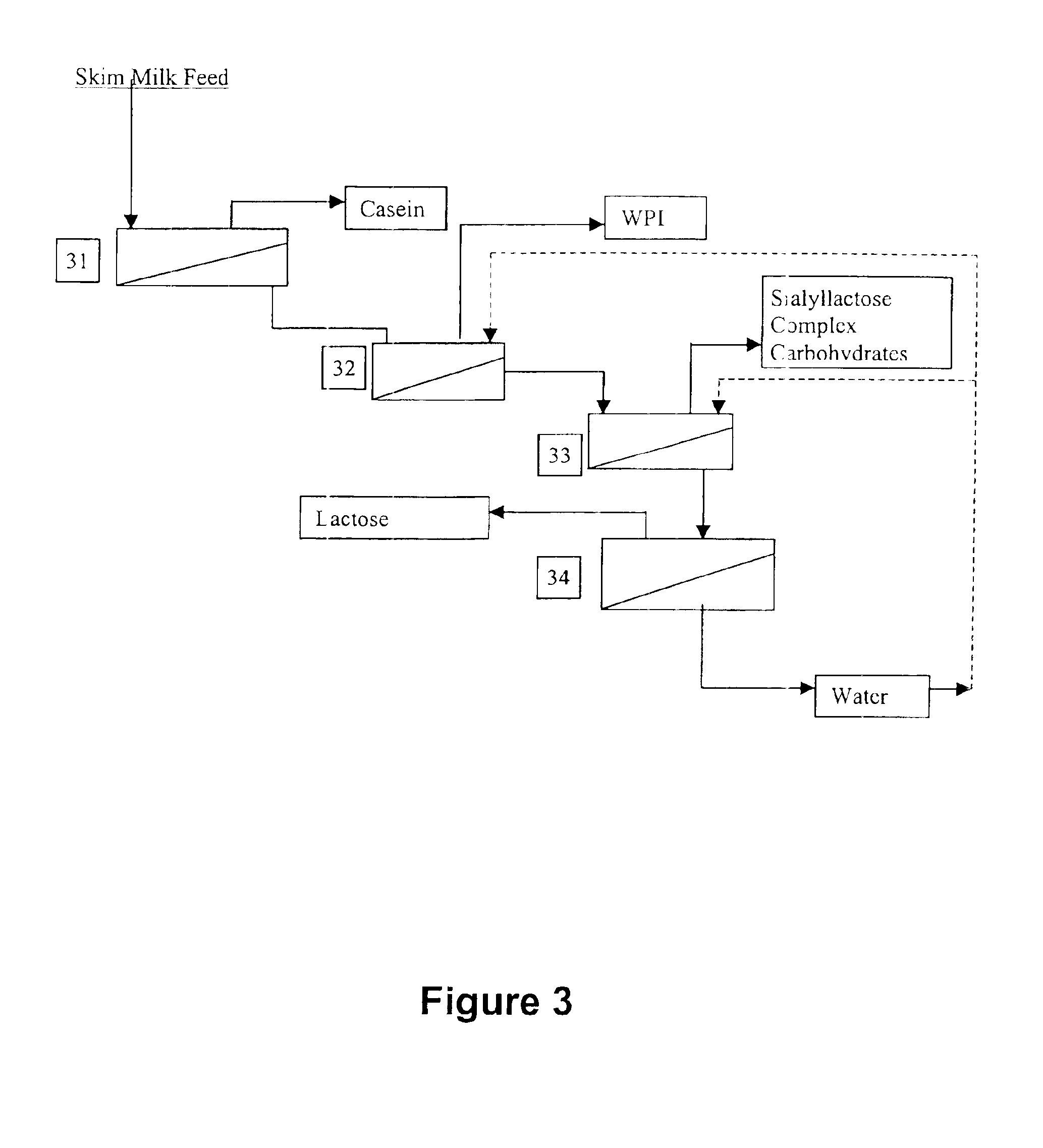

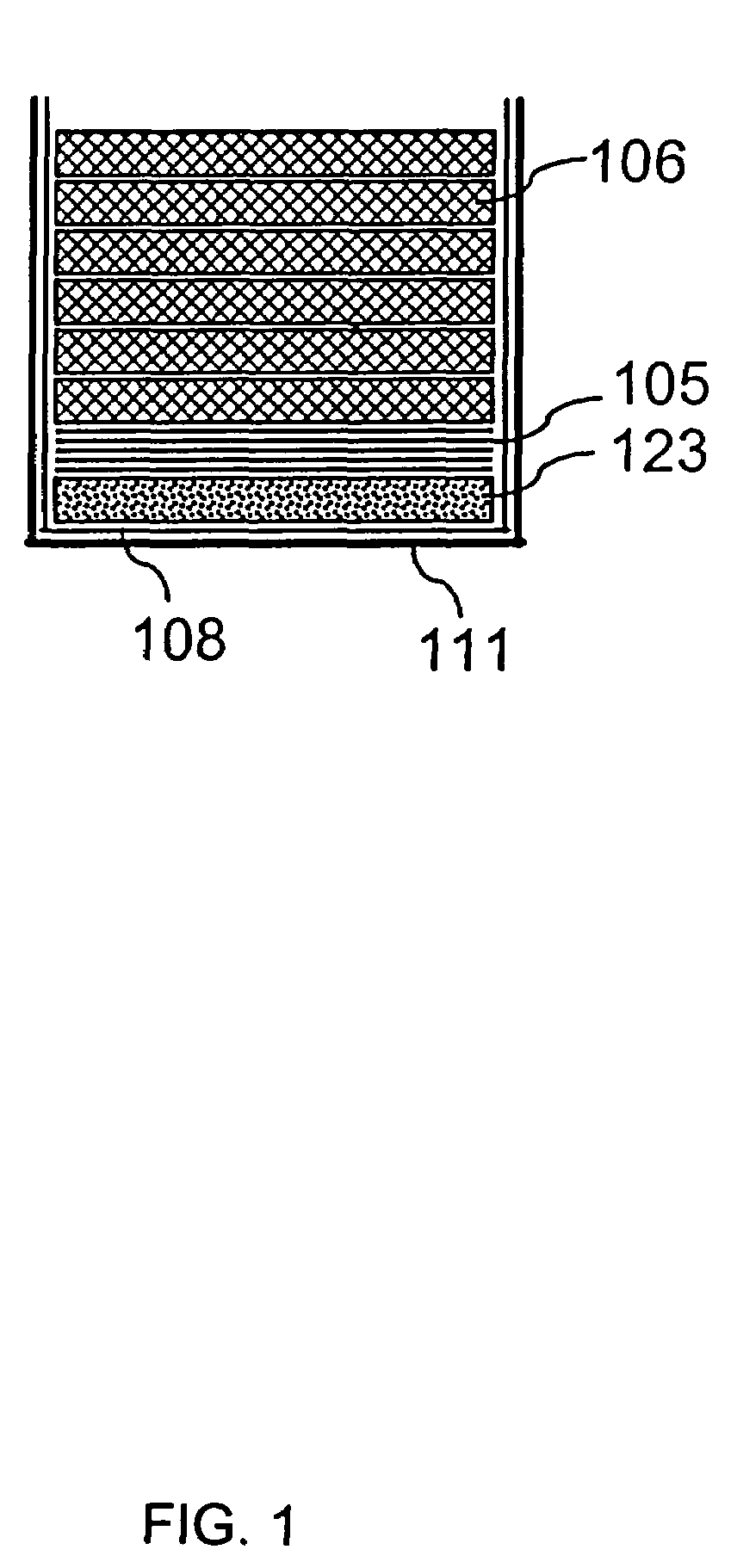

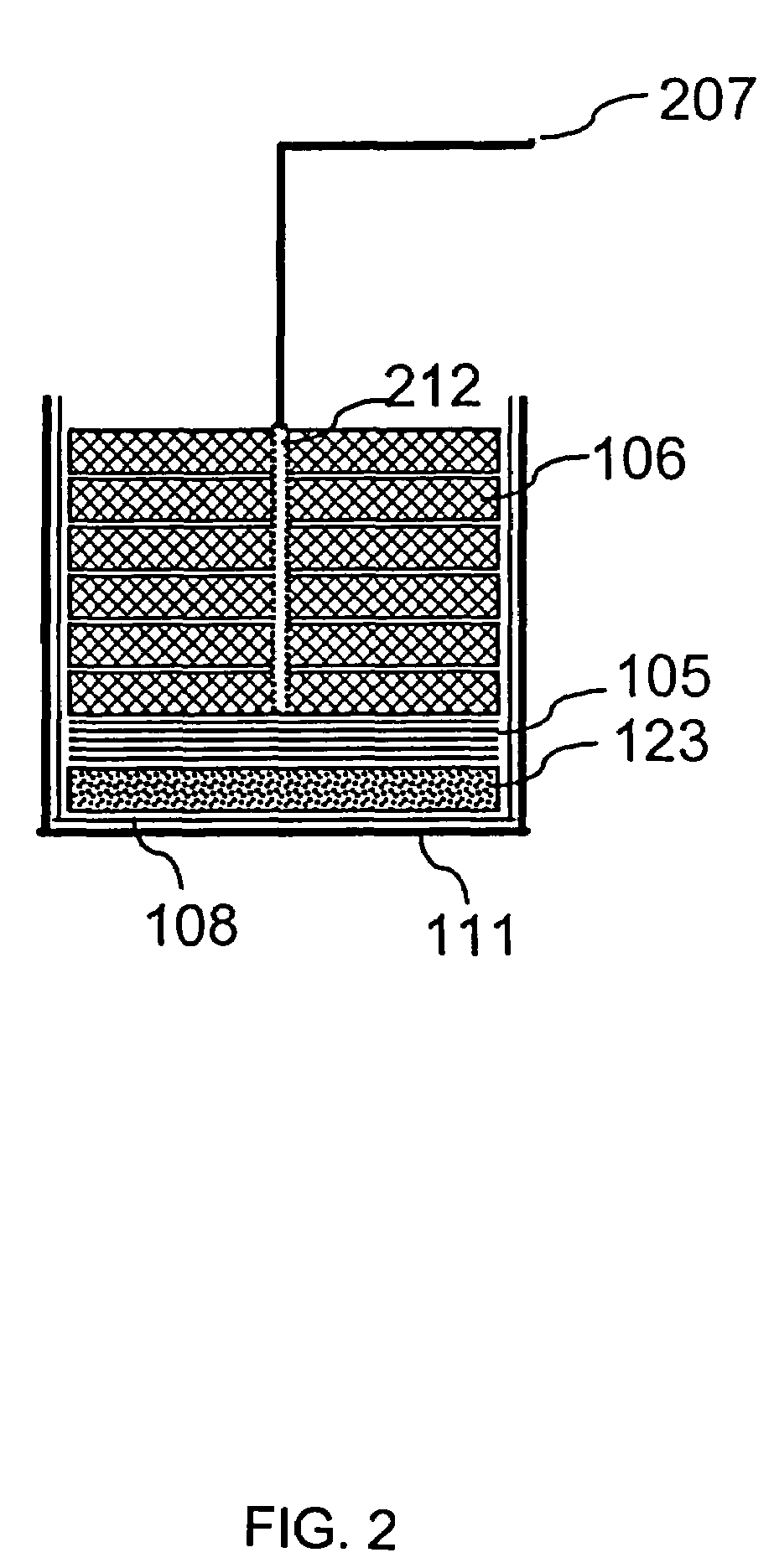

Method and apparatus for separation of milk, colostrum, and whey

InactiveUS20050053707A1Reduce quality and nutritional valueFacilitate efficient usMilk preparationMembranesMilk SerumDairy foods

Apparatus and method for separation of milk and milk products, e.g., involving sequential separation of milk, colostrum, and whey components by cross-flow filtration. The apparatus and method in a preferred aspect employ cross-flow filtration, chromatography and fermentation to separate and fully utilize the components of milk, colostrum, and whey to generate numerous individual components, minimize waste, lower adverse environmental issues and provide enhanced economic benefits to dairy producers. A wide variety of consumer and nutraceutical products can be produced from the fractions and / or sub-fractions of milk products obtained from such separation. The invention further contemplates a methodology for selecting optimum membrane, device, and operating conditions to achieve a desired separation.

Owner:SMARTFLOW TECH

Method and apparatus for separation of milk, colostrum, and whey

InactiveUS6852352B2Reduce quality and nutritional valueFacilitate efficient usMilk immunoglobulinsUltrafiltrationMilk SerumCross-flow filtration

Apparatus and method for separation of milk and milk products, e.g., involving sequential separation of milk, clostrum, and whey components by cross-flow filtration. The apparatus and method in a preferred aspect employ cross-flow filtration, chromatography and fermentation to separate and fully utilize the components of milk, clostrum, and whey to generate numerous individual components, minimize waste, lower adverse environmental issues and provide enhanced economic benefits to dairy producers. A wide variety of consumer and nutraceutical products can be produced from the fractions and / or sub-fractions of milk products obtained from such separation. The invention further contemplates a methodology for selecting optimum membrane, device, and operating conditions to achieve a desired separation.

Owner:SMARTFLOW TECH

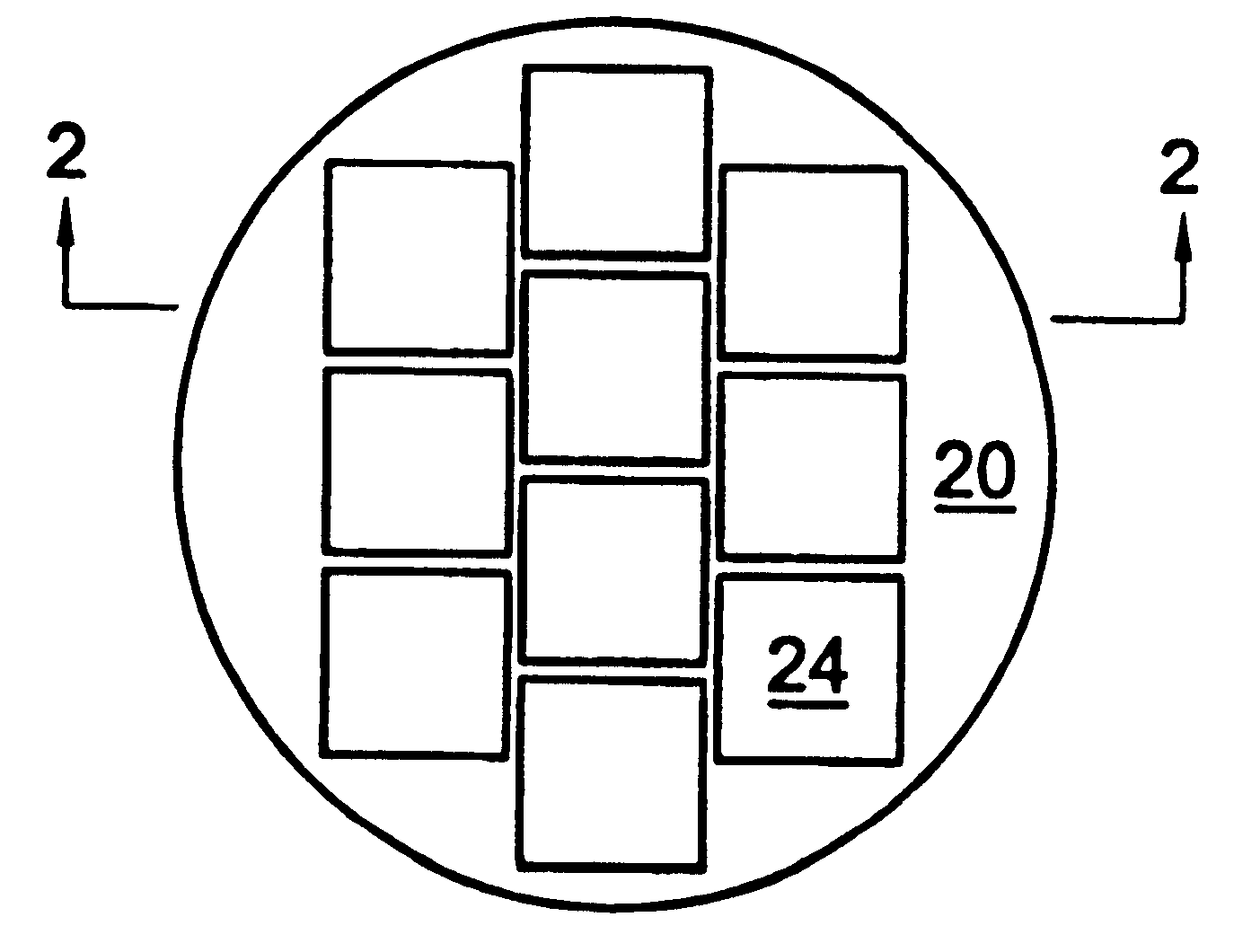

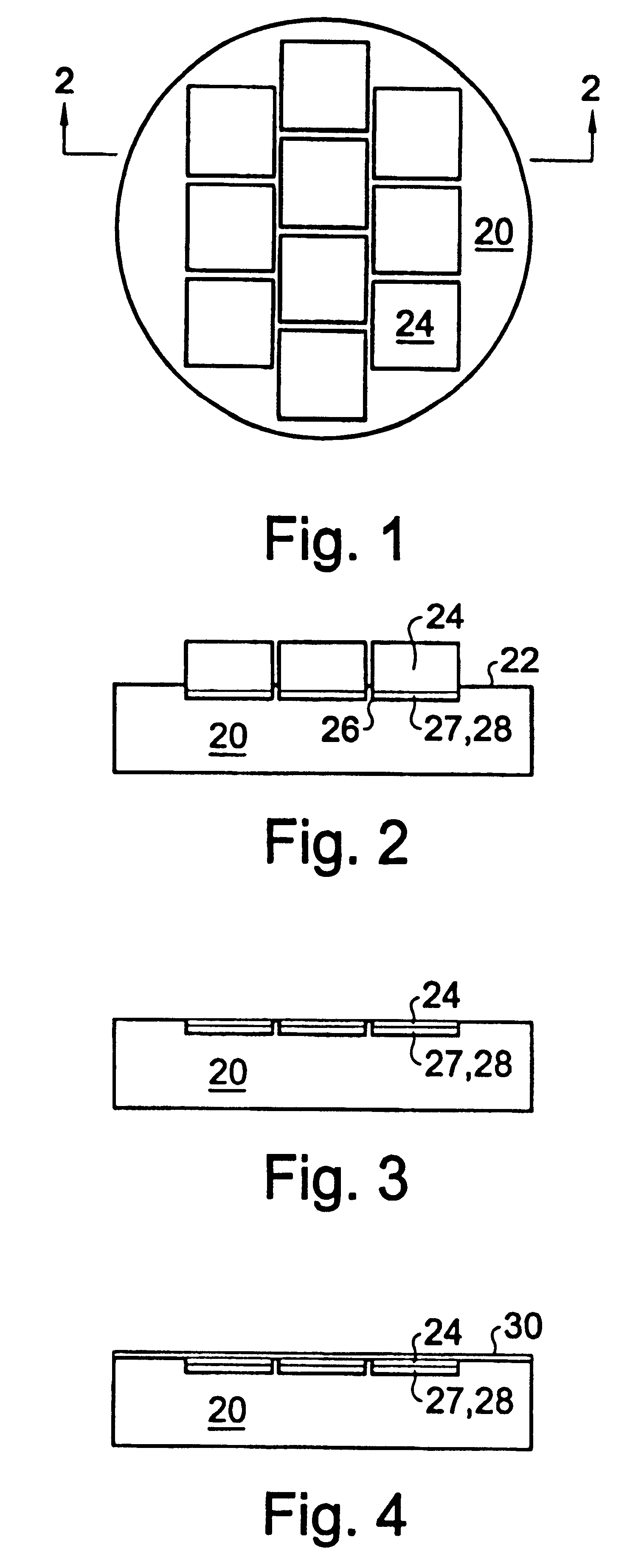

Discrete wafer array process

InactiveUS6248646B1High temperature resistanceGreat ruggednessSolid-state devicesSemiconductor/solid-state device manufacturingWaferingCompound (substance)

A method of preparing small wafers for compatibility with conventional large wafer fabrication equipment comprising the following steps: indenting a face of a large wafer to form an array of depressions thereon, each depression sized to matingly accept a lower portion of a small wafer; applying a bonding medium to an exterior side of the depressions on the indented face of the large wafer; matingly fitting the small wafers into the depressions so that the small wafers are positioned in an array on the large wafer; and, removing the top portion of the small wafers standing out of the depressions by chemical mechanical polishing so that the remaining portions of the small wafers then have a uniform thickness generally equal to the depth of the indentations in the large wafer. A preferred aspect of this invention provides for a method as above wherein the small wafer is SiC and the large wafer is made from an amorphous substance which comprises SiC or aluminum nitride.

Owner:OKOJIE ROBERT S

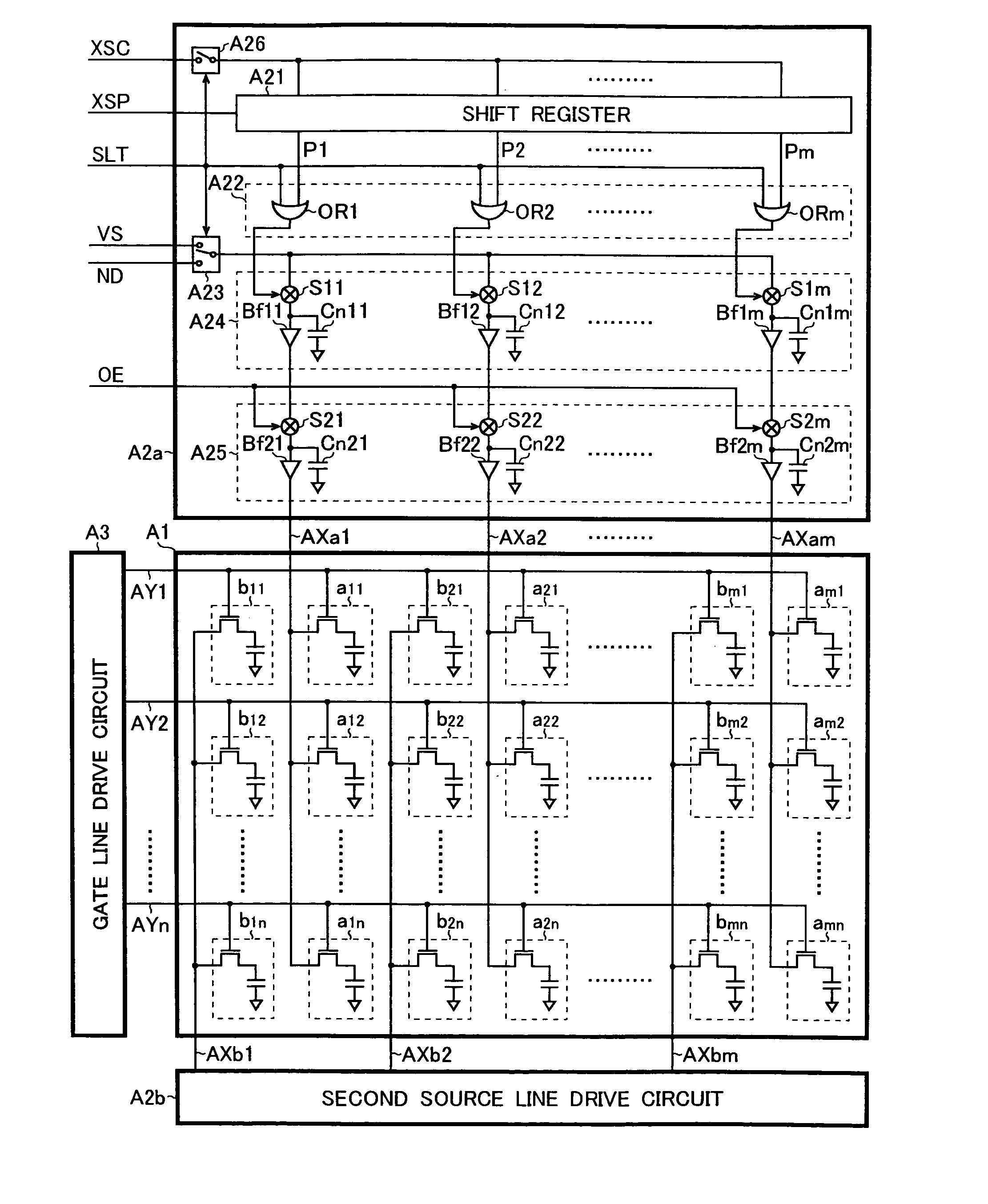

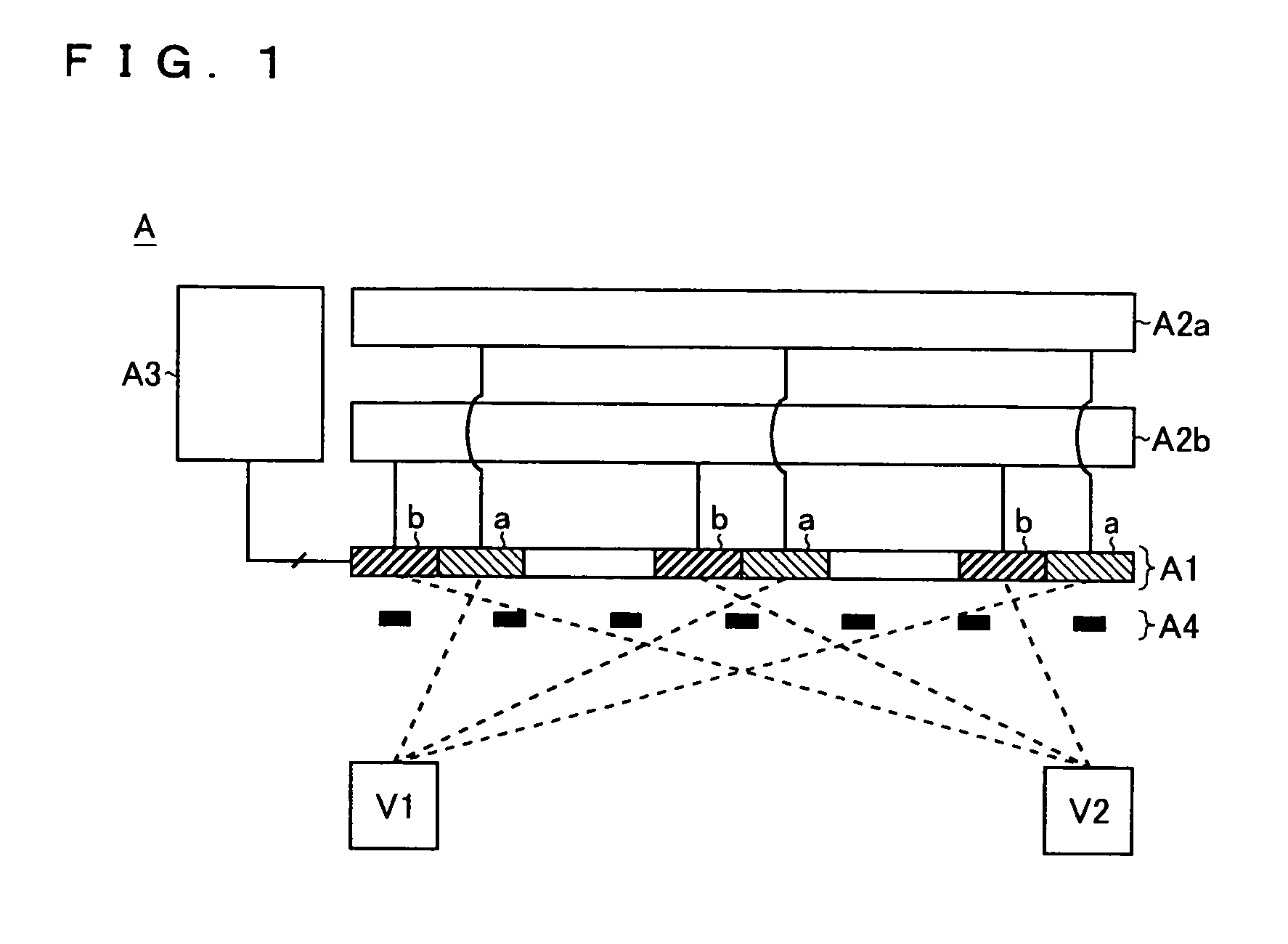

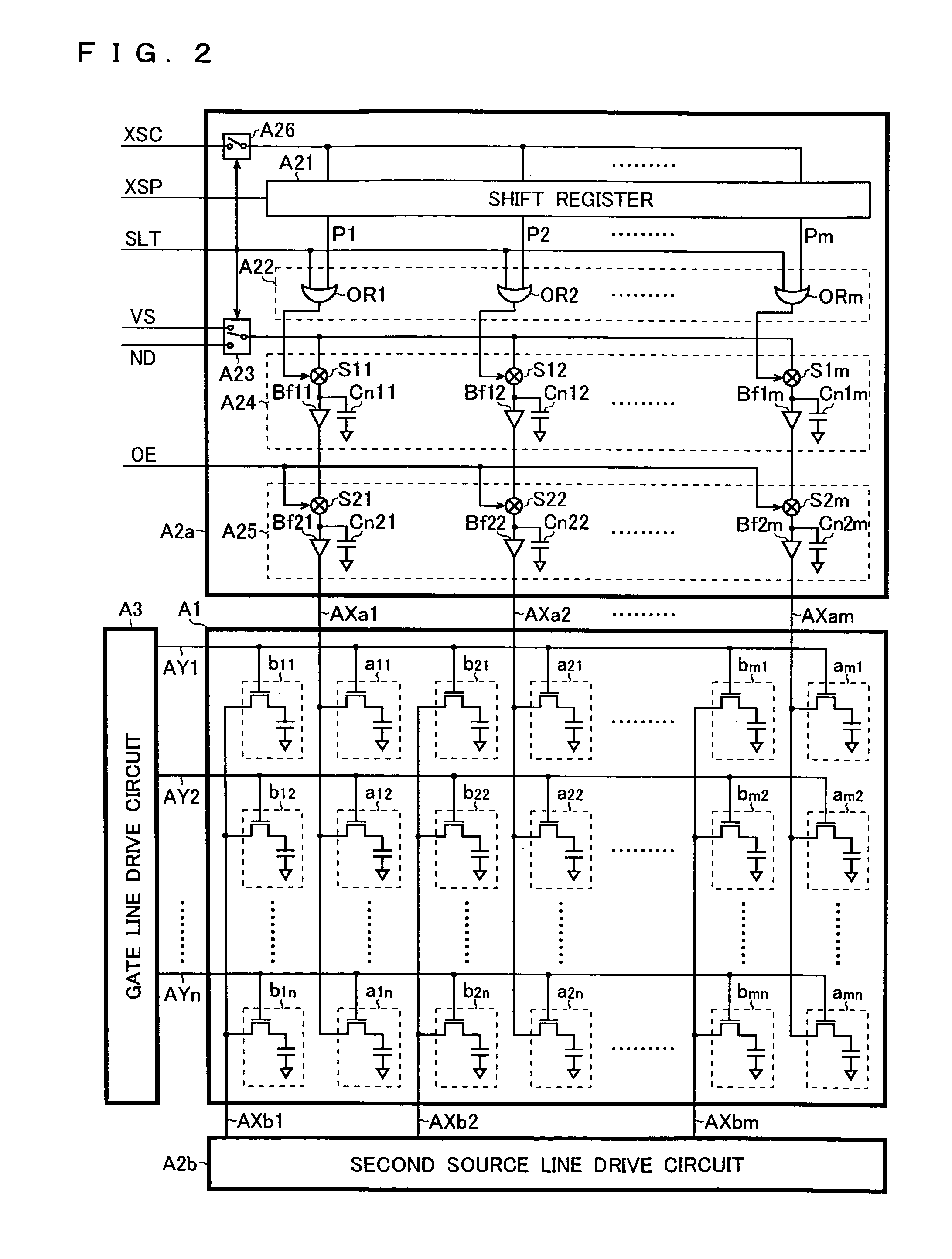

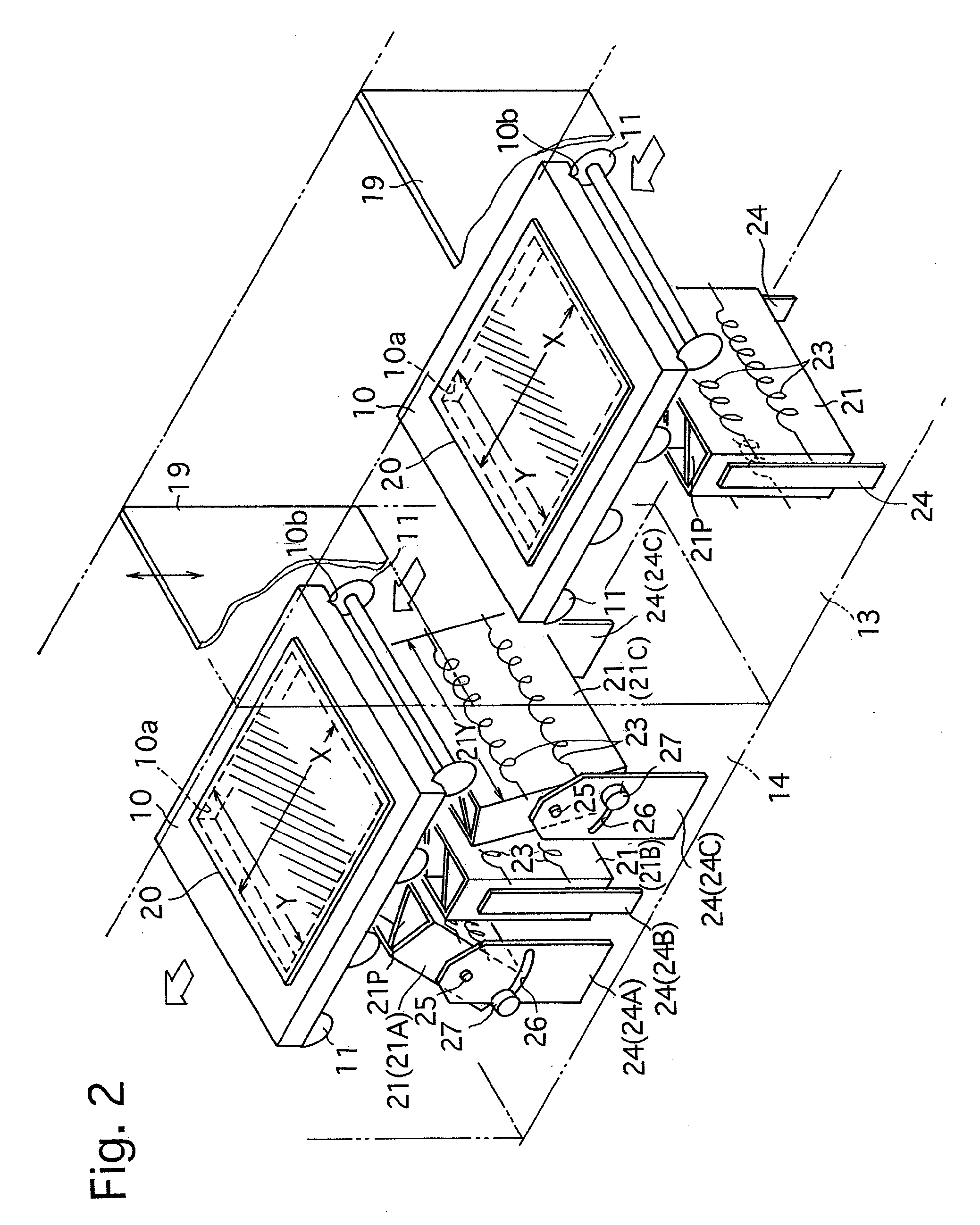

Display panel and display device

InactiveUS20050195150A1Minimal distortionMinimal wasteStatic indicating devicesSynchronismSampling circuits

In a display device, at least one of a first drive circuit that feeds source signals to first pixels to be viewed from a first viewing direction and a second drive circuit that feeds source signals to second pixels to be viewed from a second viewing direction includes a shift register that generates a sampling pulse by shifting a start pulse in synchronism with a clock signal, a sampling circuit that samples an image signal according to the sampling pulse, and a switch that controls according to a switch signal whether or not to feed the clock signal to the shift register or whether or not to feed the start pulse to the shift register. The first and second pixels are driven by the use of the output signal of the sampling circuit. With this configuration, a plurality of viewers can be presented with different images simultaneously with minimum waste of electric power.

Owner:SHARP KK

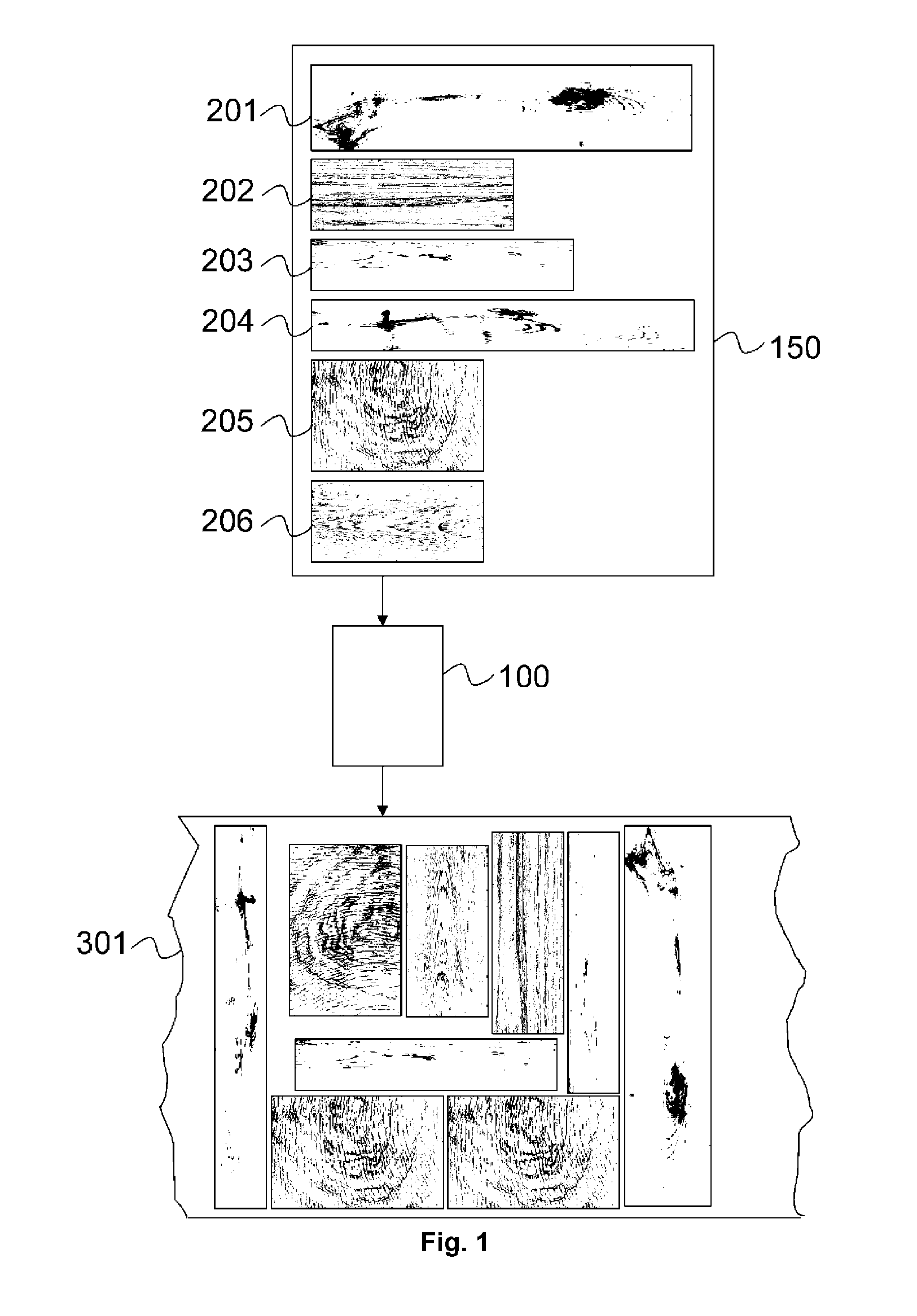

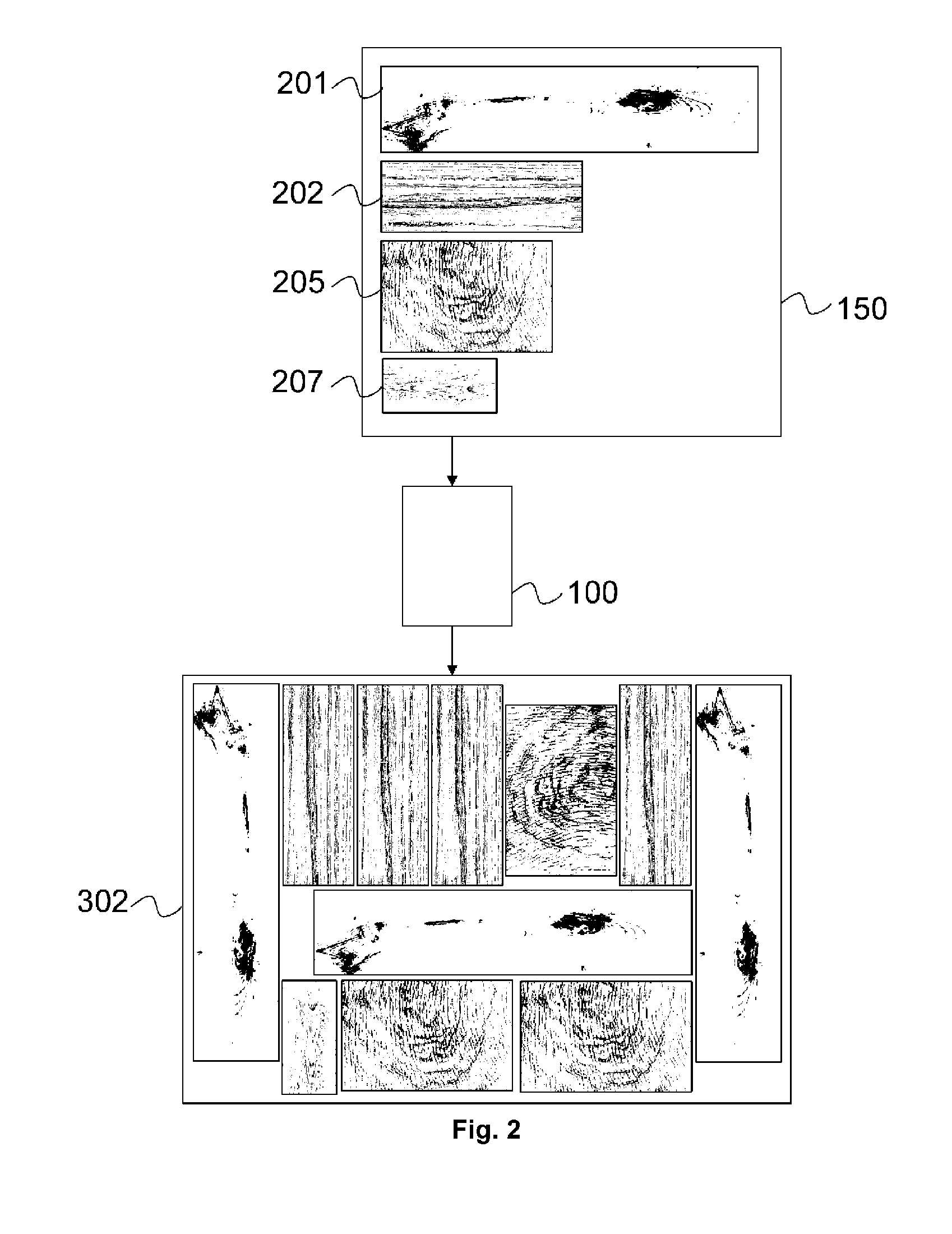

Manufacturing of decorative workpieces by inkjet

ActiveUS20160347085A1Quick responseFast preparationSpecial ornamental structuresTypewritersEngineeringFailure zone

A method for manufacturing decorative workpieces includes the step of nesting a set of decorative patterns digitally printed on a decoration layer to reduce the waste of decoration layer. To perform a corresponding relief for the nested decorative patterns on a nested decorative workpiece, the relief provided by a digital relief apparatus is in a correct match with the nested decorative workpiece. If the printing zone of the digital printer has a failure zone, the nesting method prevents arranging of the decorative patterns in this failure zone.

Owner:AGFA NV +1

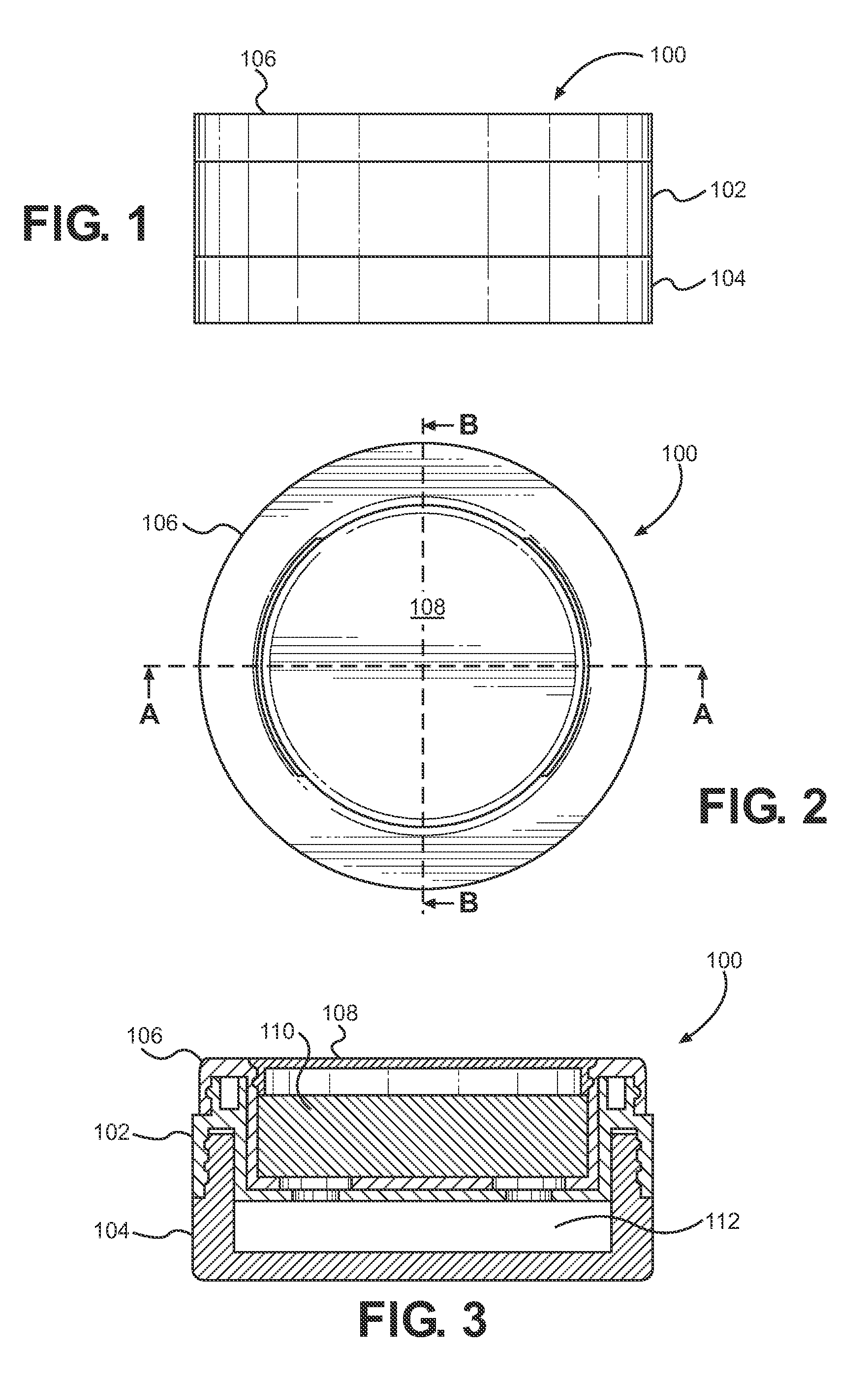

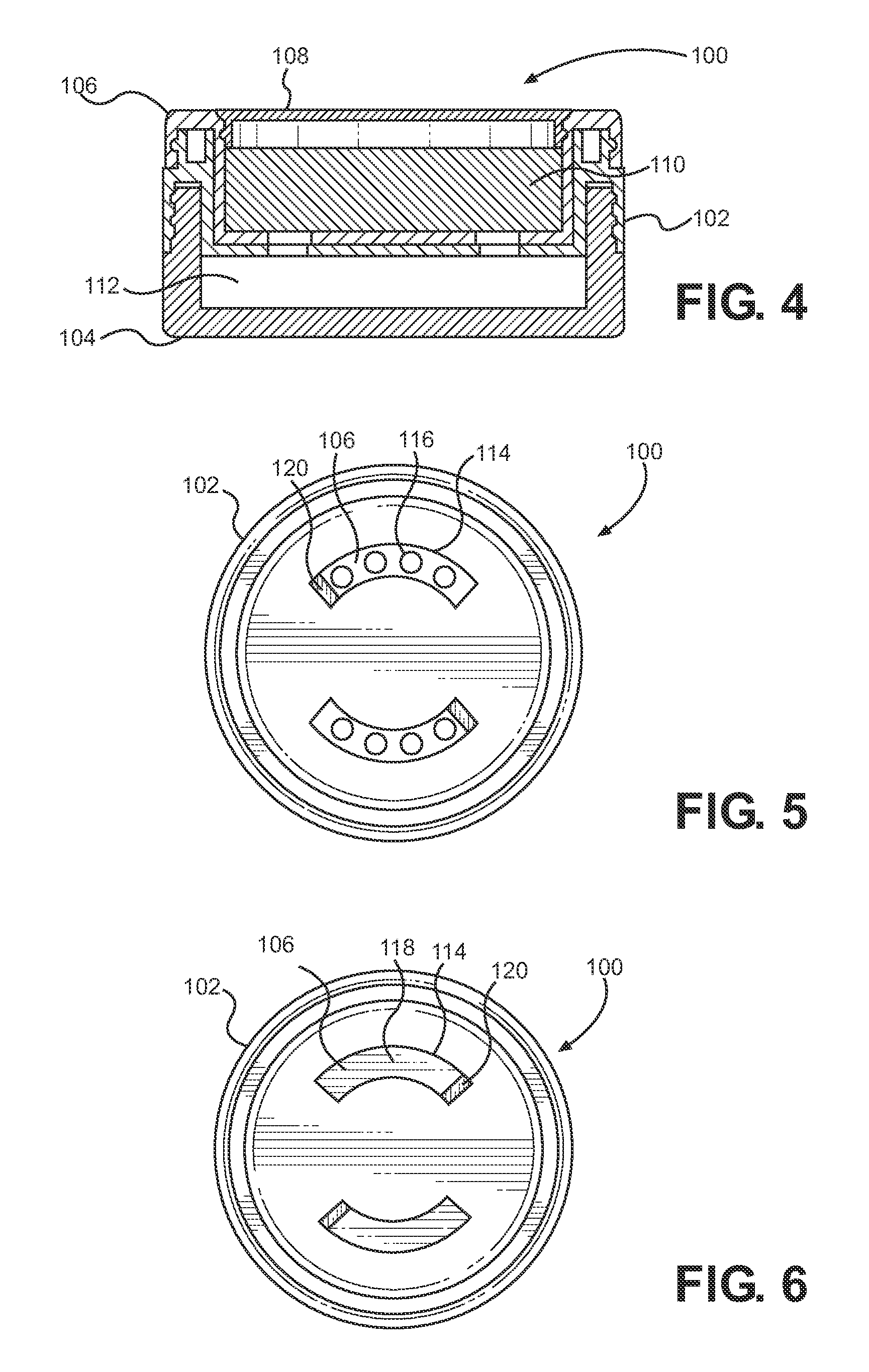

Rotationally controlled cosmetic powder dose dispenser

ActiveUS8839803B2Level of predictabilityMessiness can be reducedClosuresLiquid flow controllersDose dispenser

A rotationally controlled cosmetic powder dose dispenser with a sifter cup pivotally retained by a sifter housing. Opposed arcuate slots are disposed in the bottom wall of the sifter housing and first and second series of apertures are disposed in opposed arcuate configurations in the bottom wall of the sifter cup. The series of apertures and the arcuate slots can be selectively aligned to dispense a volume of cosmetic powder into a sifter jar that is removably coupled to the sifter housing. The sifter housing has a rim received between an outer cylindrical wall and a peripheral wall of the sifter cup, and the sifter jar has a rim received between an outer cylindrical wall and a peripheral wall of the sifter housing in a threaded engagement.

Owner:HCP PACKAGING USA

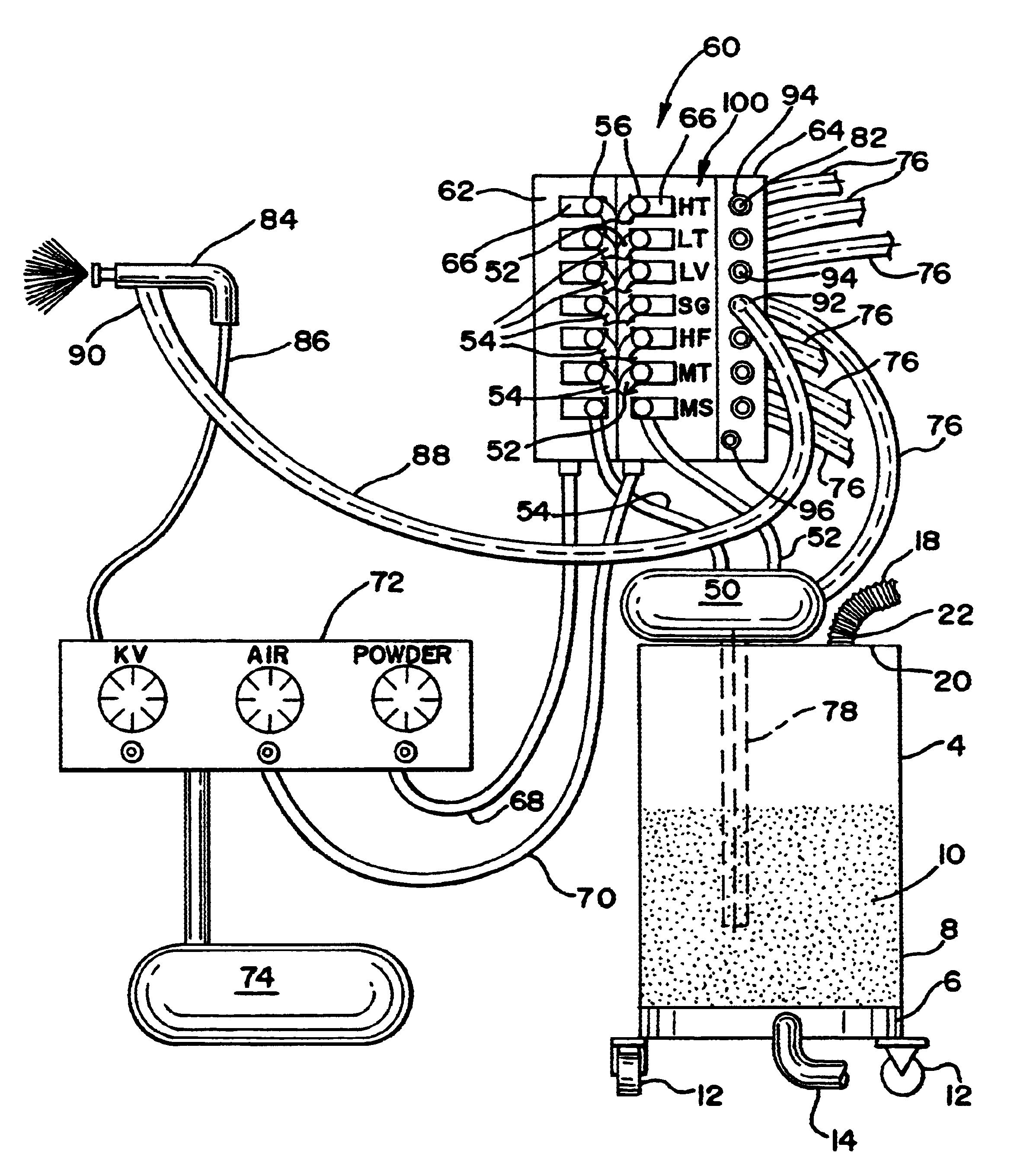

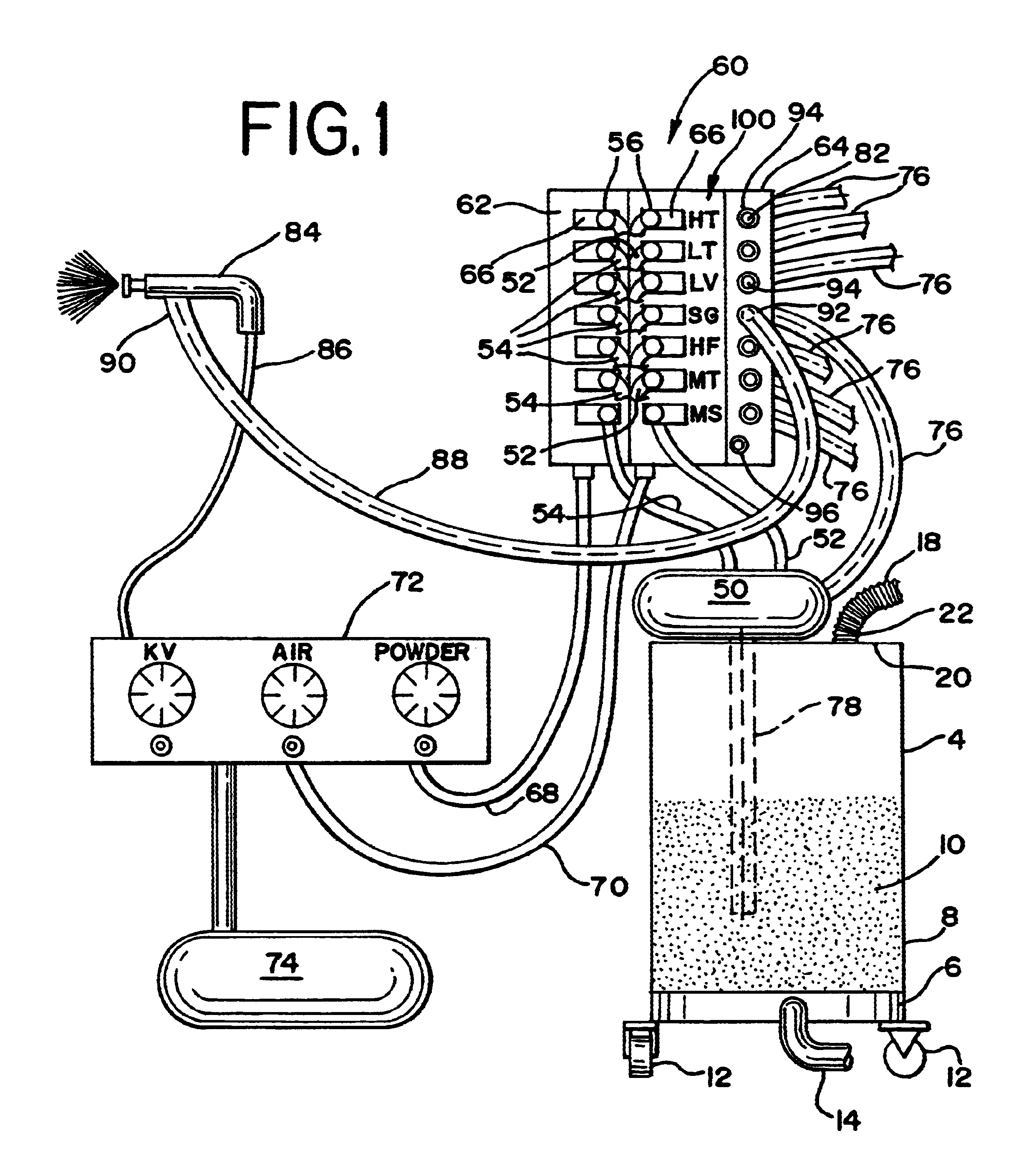

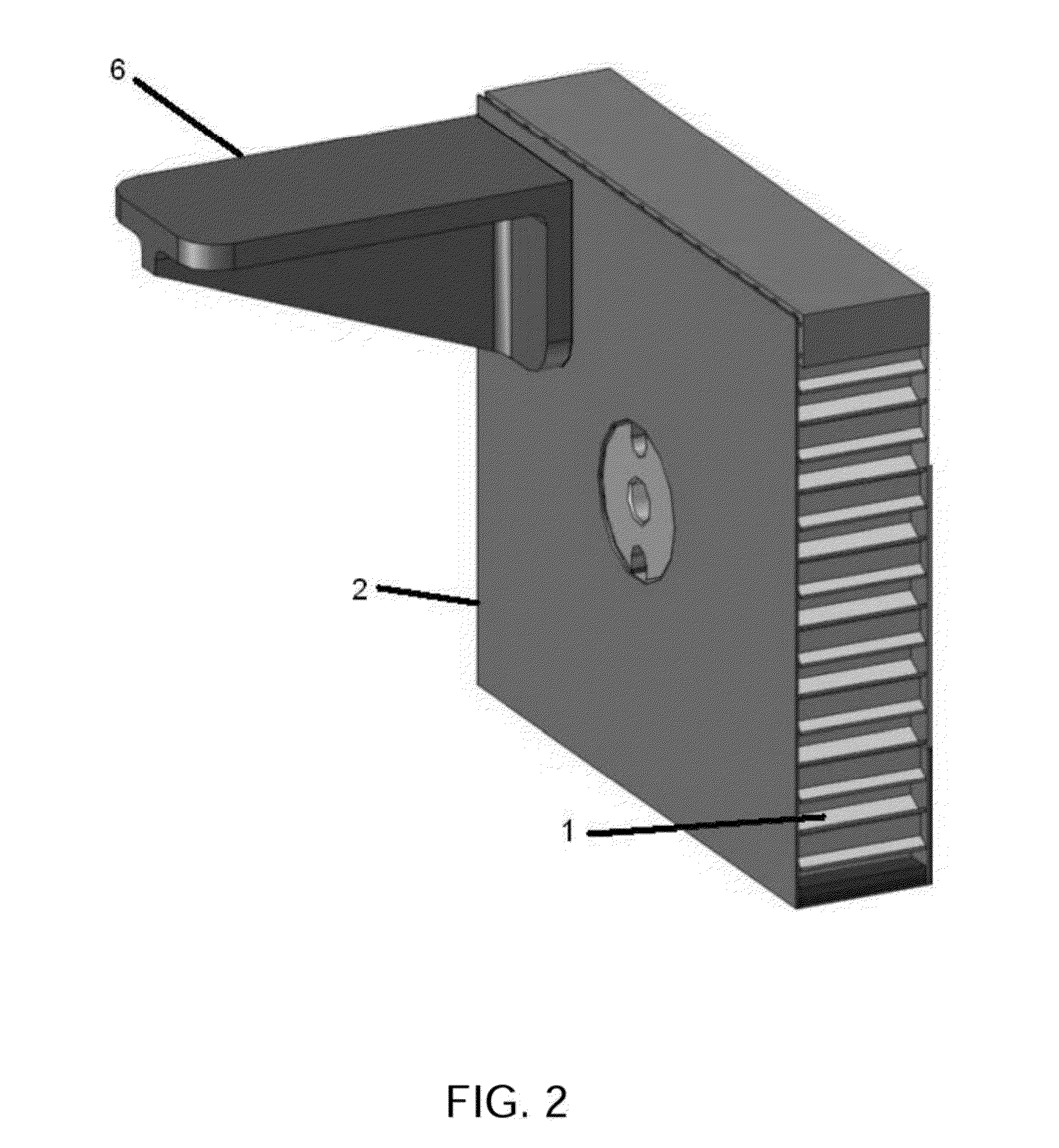

Powder spray coating system

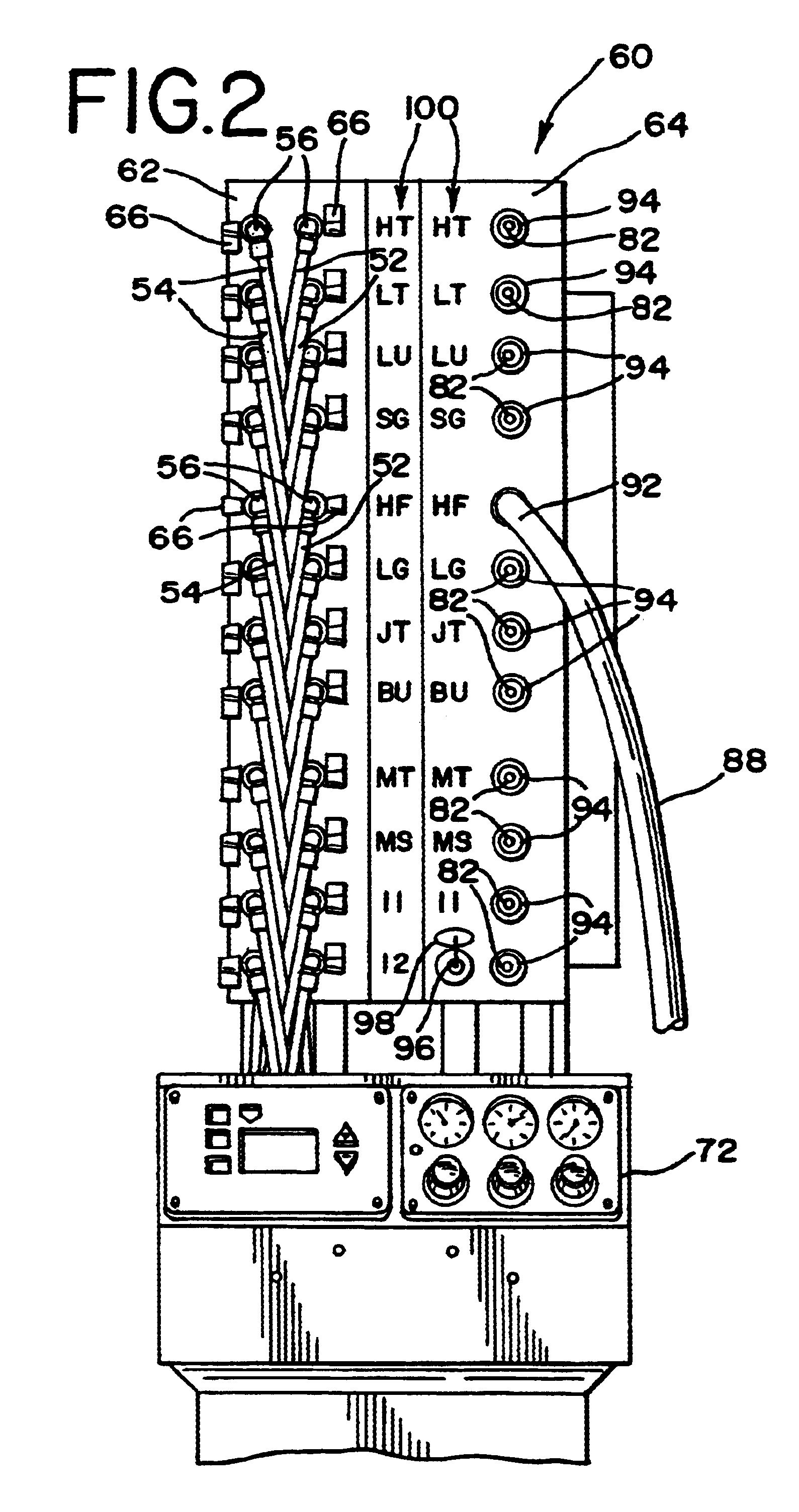

InactiveUS6695220B2Quickly and easily turned to isolate any particular hopperEasy to removeBurnersLiquid supply arrangementsCoating systemEngineering

Owner:MILLERKNOLL INC

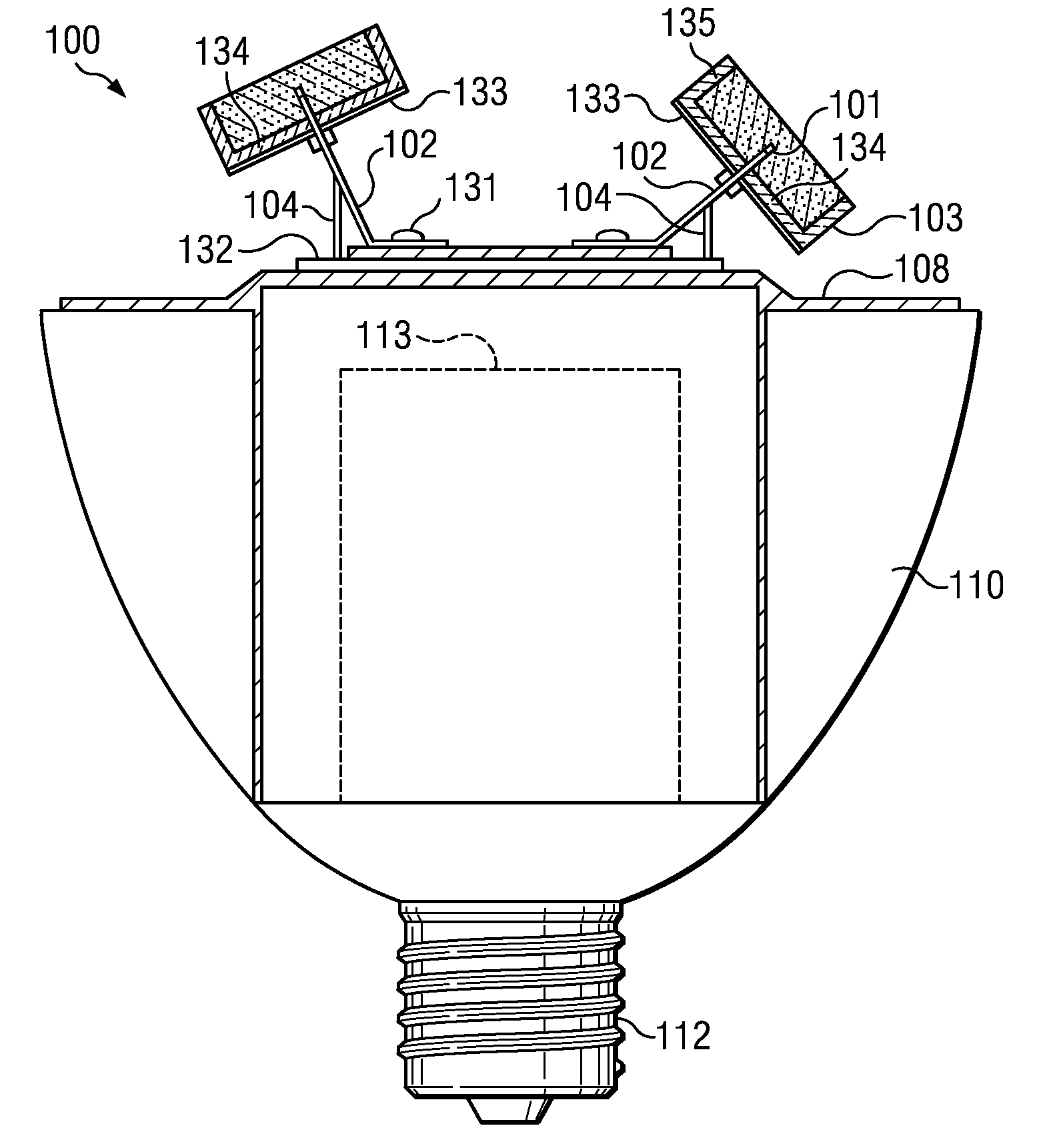

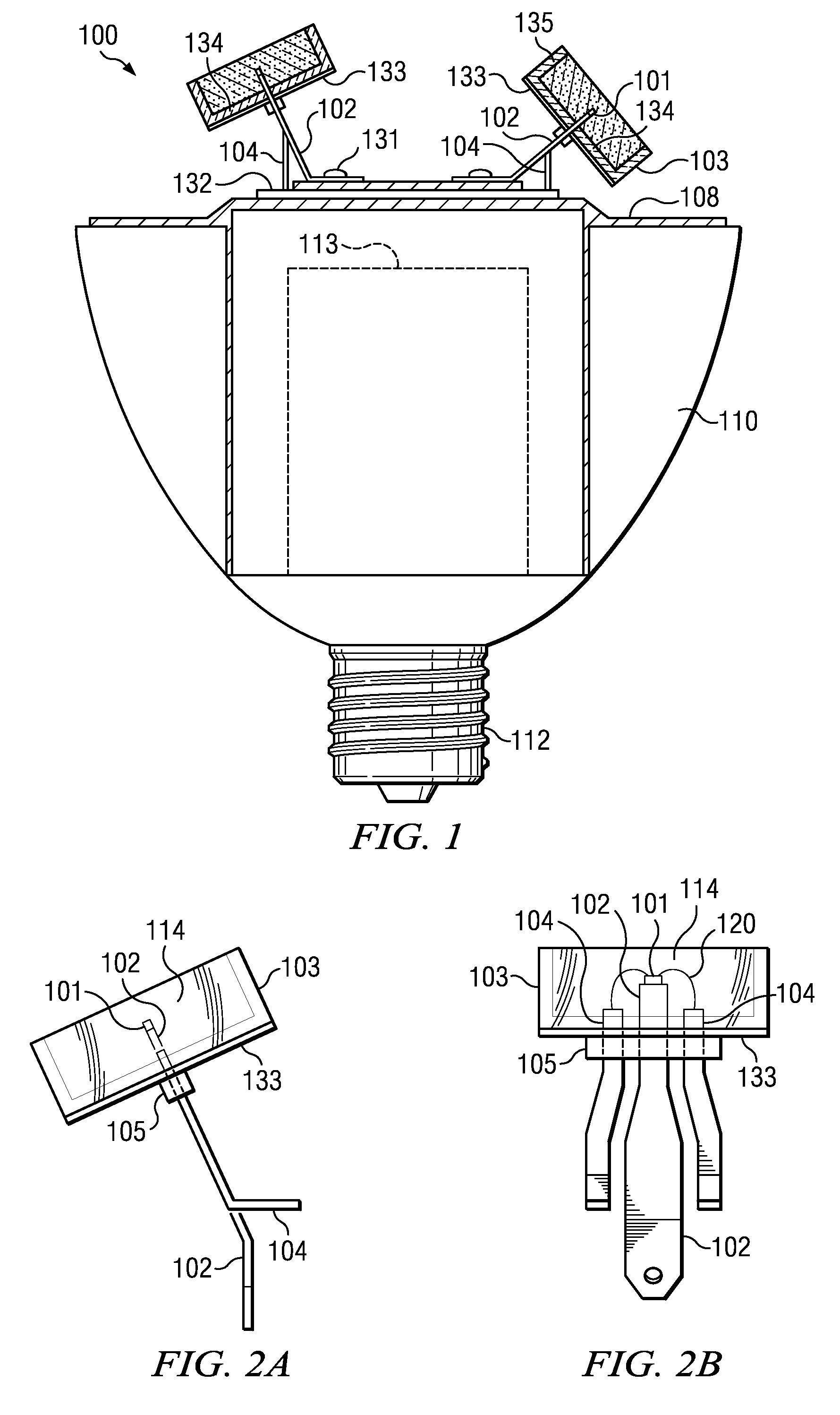

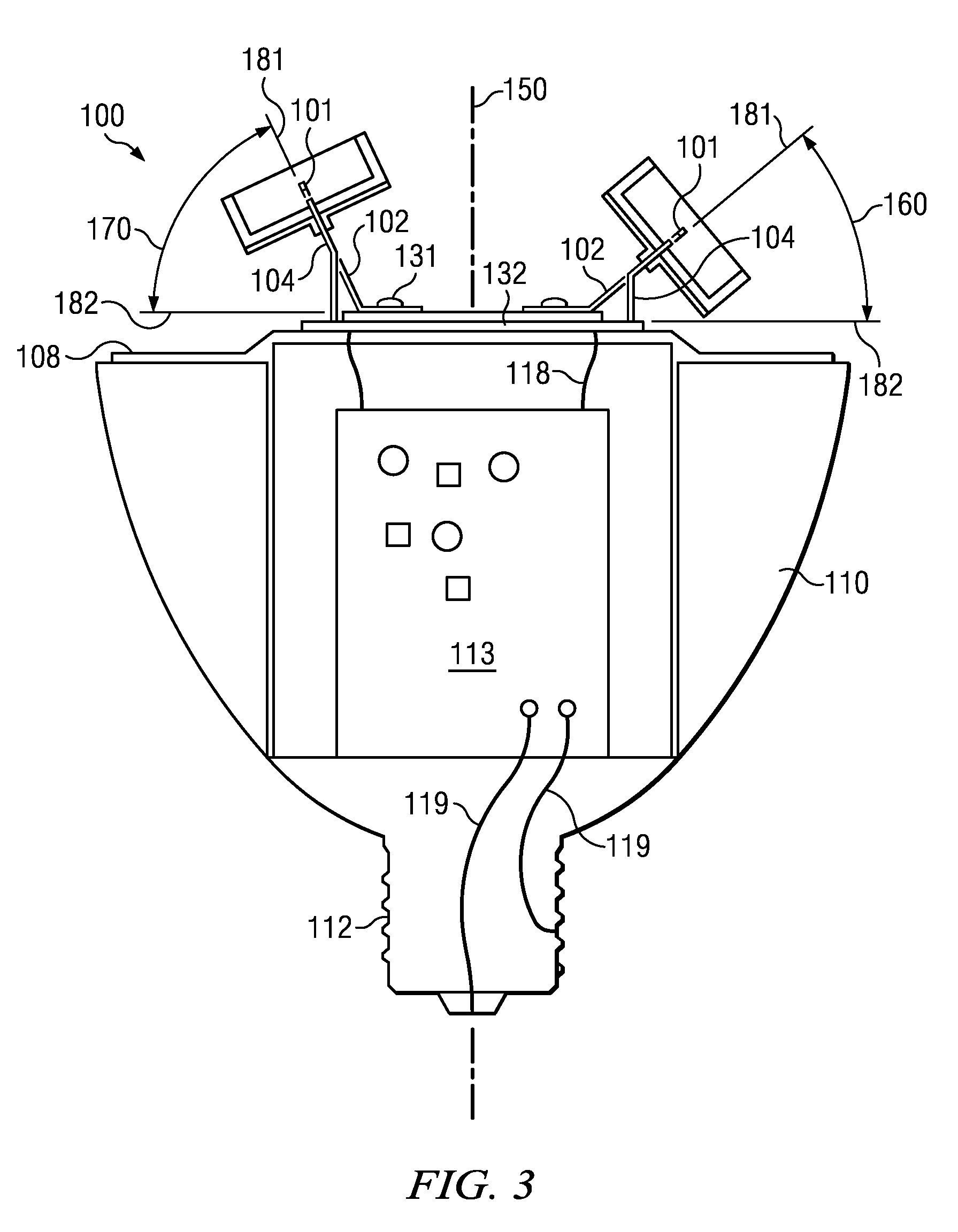

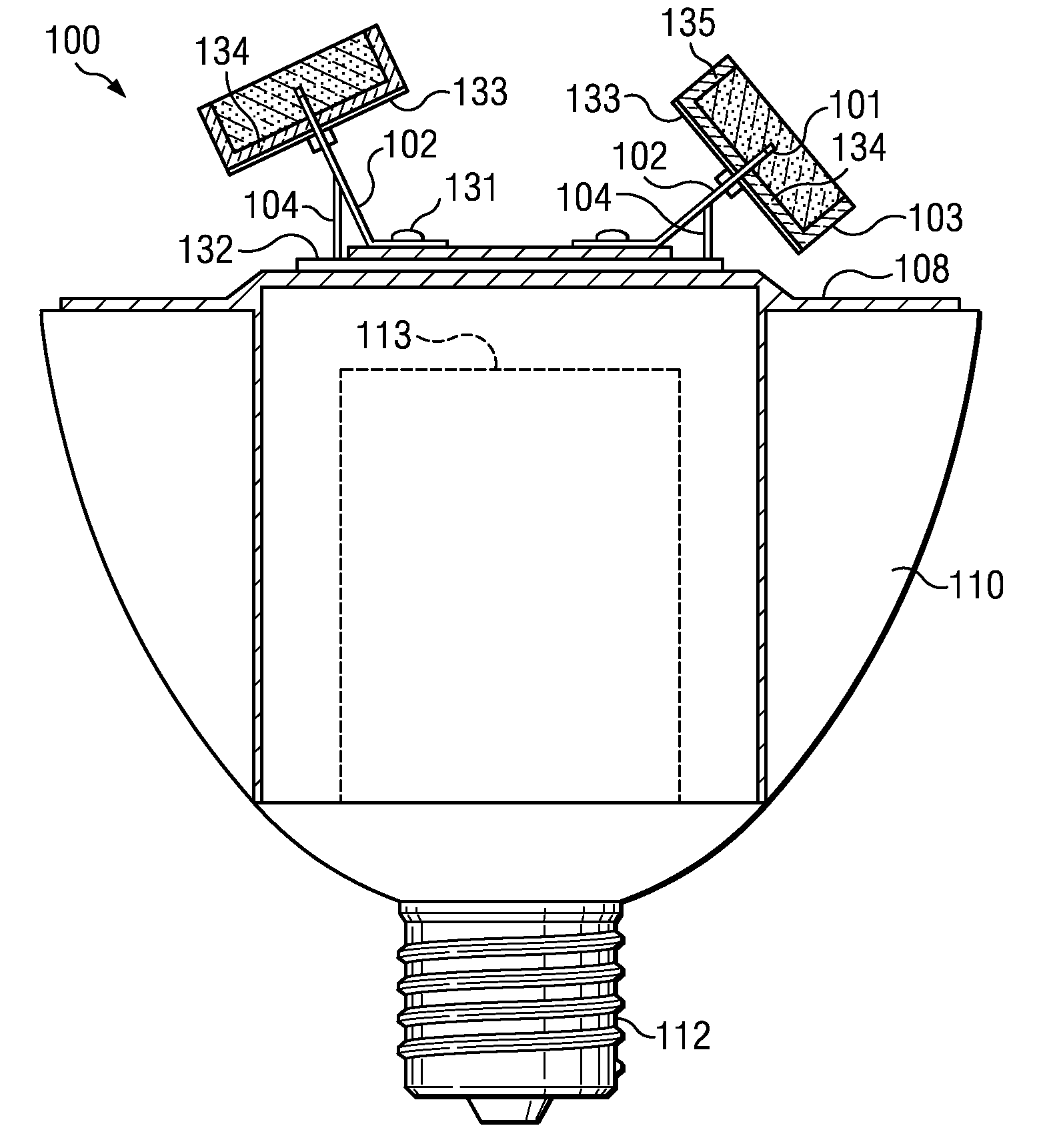

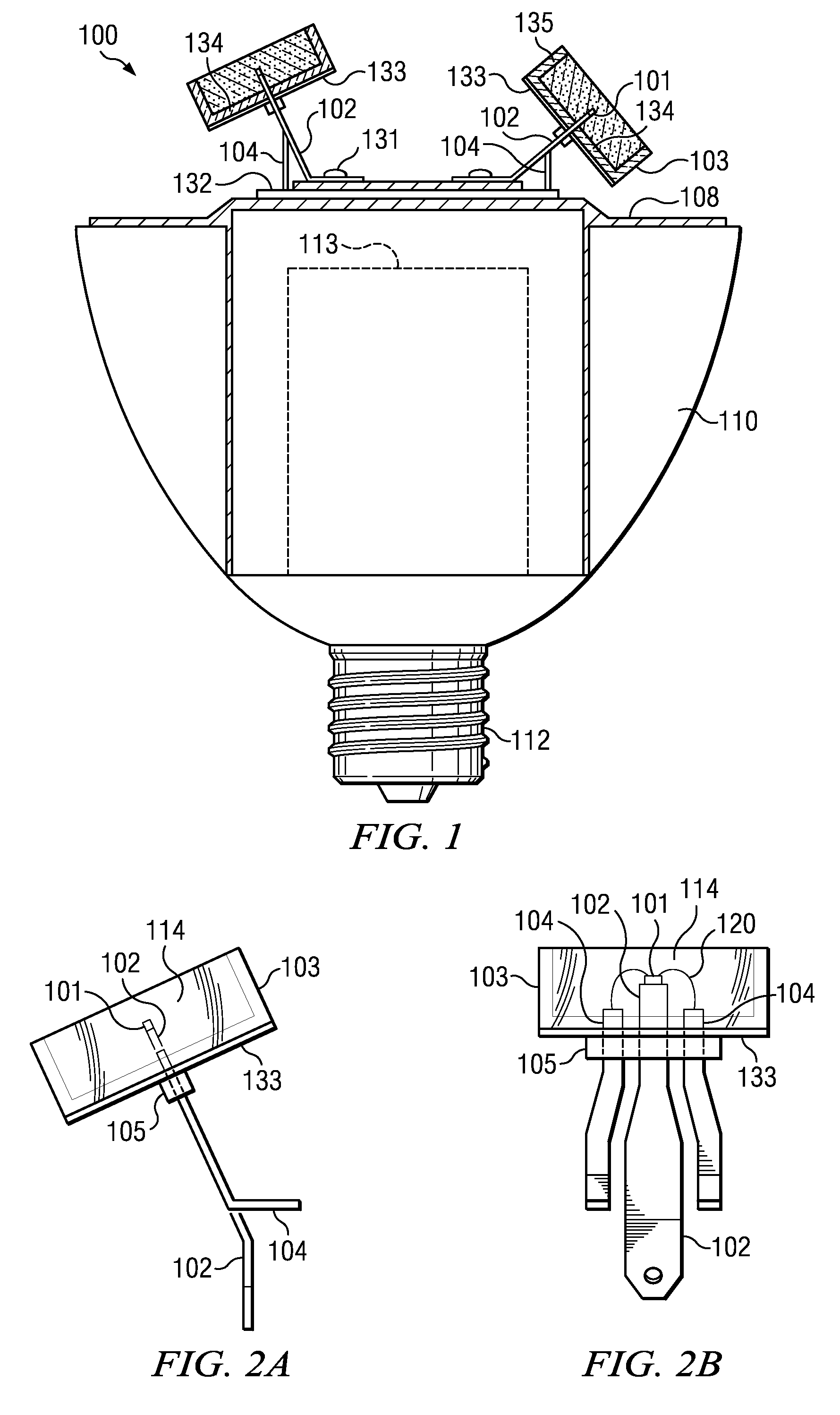

LED lighting lamp

InactiveUS20100254133A1Solve the lack of heat dissipation efficiencyWide illumination beam angleNon-electric lightingPoint-like light sourceBeam angleEffect light

Owner:CHENG YUNG PUN

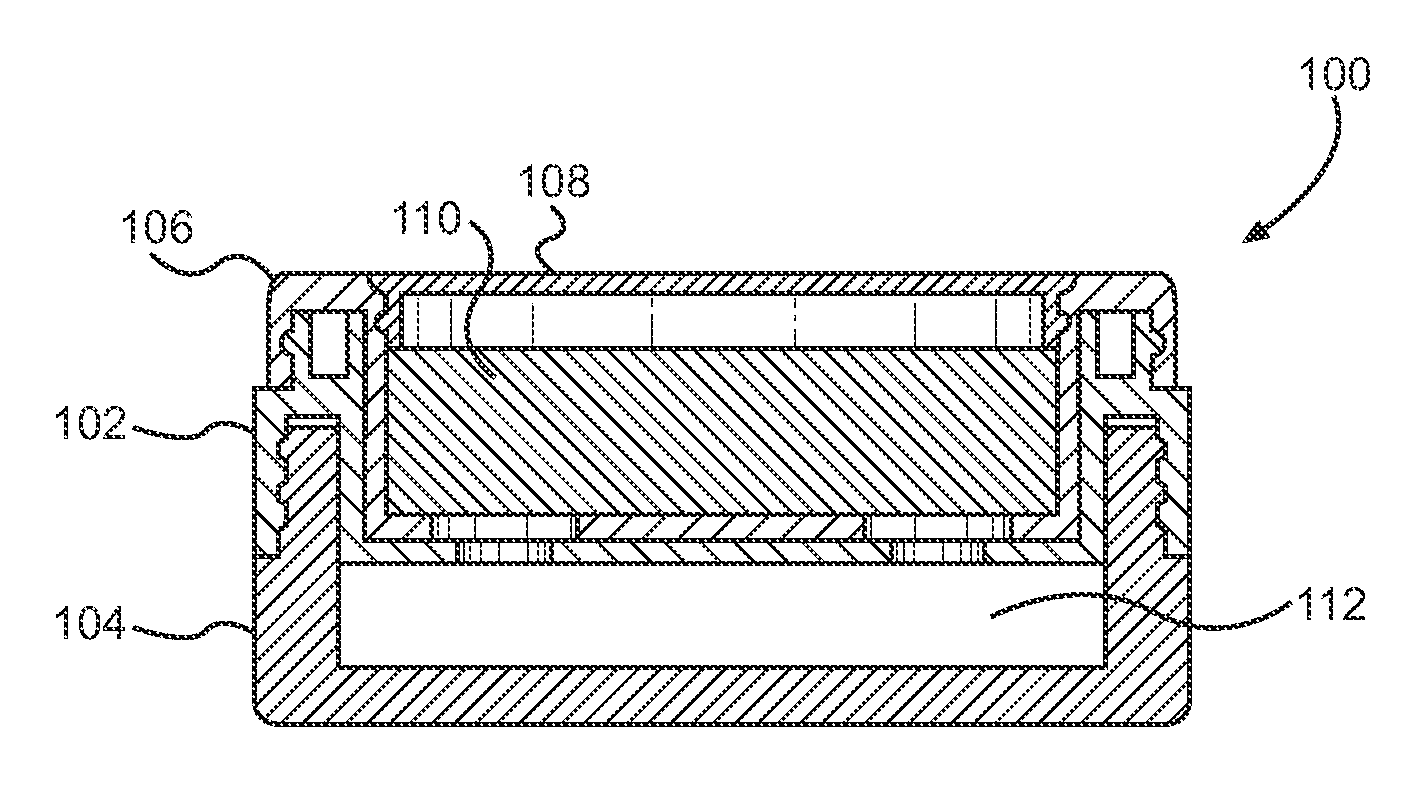

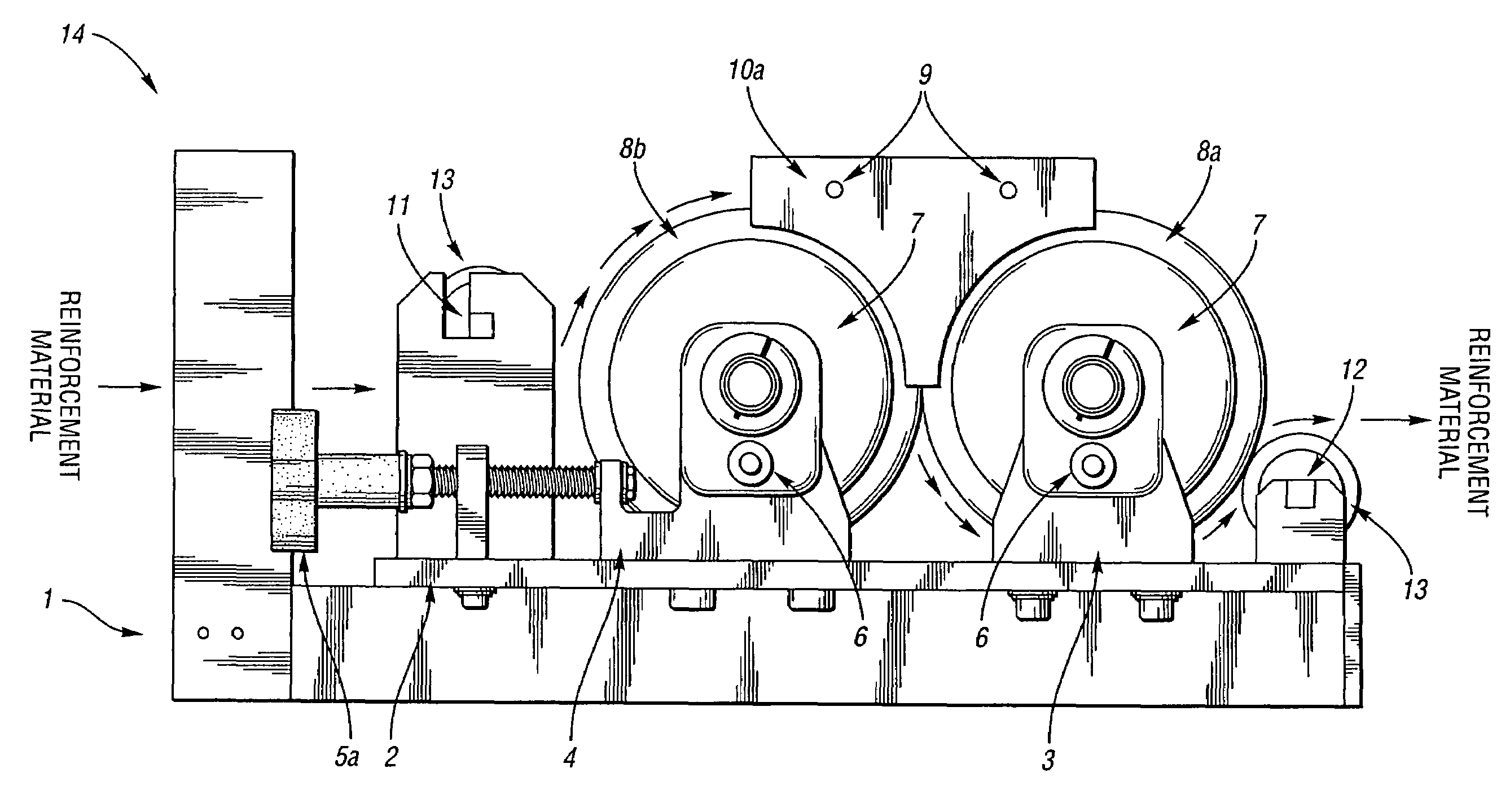

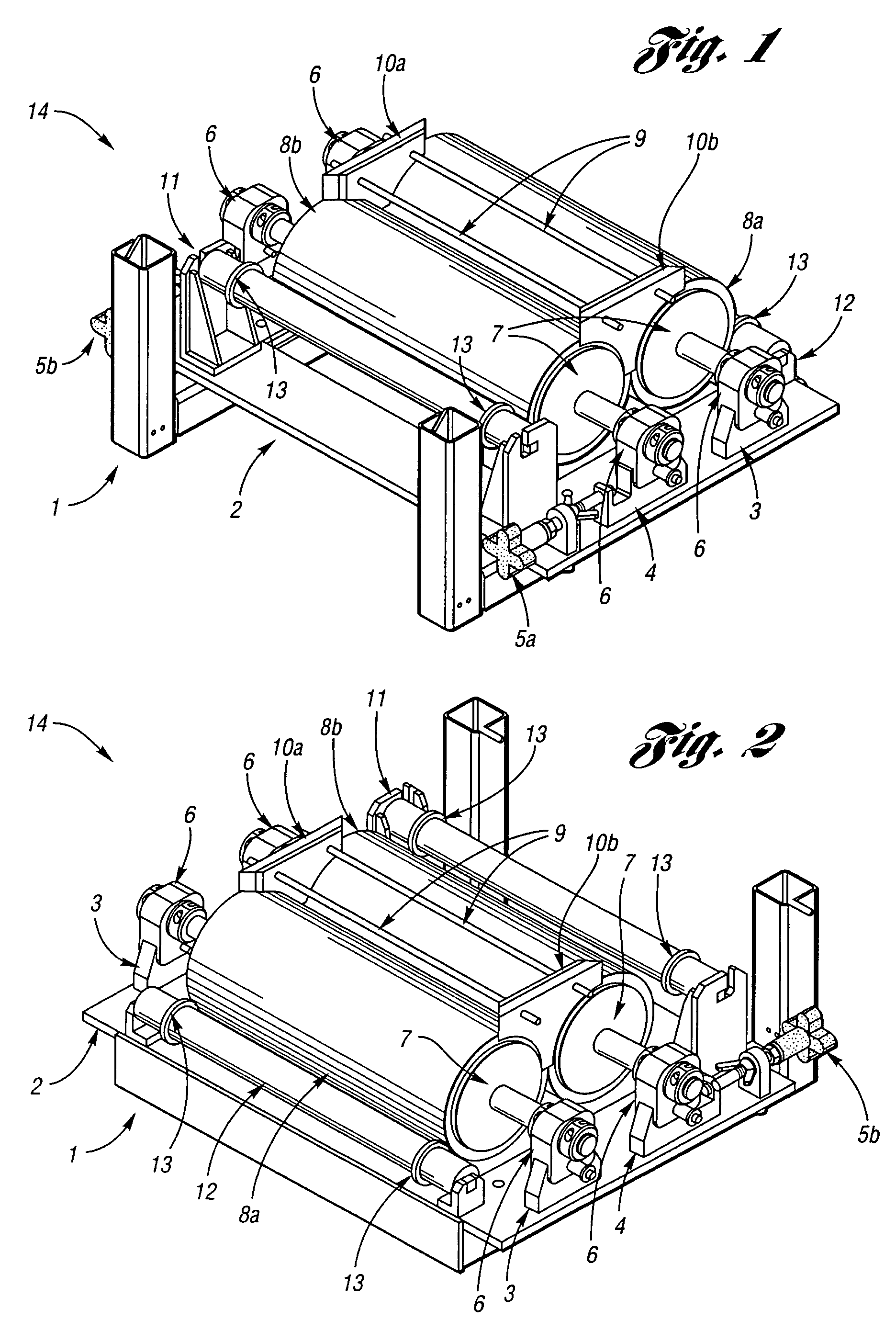

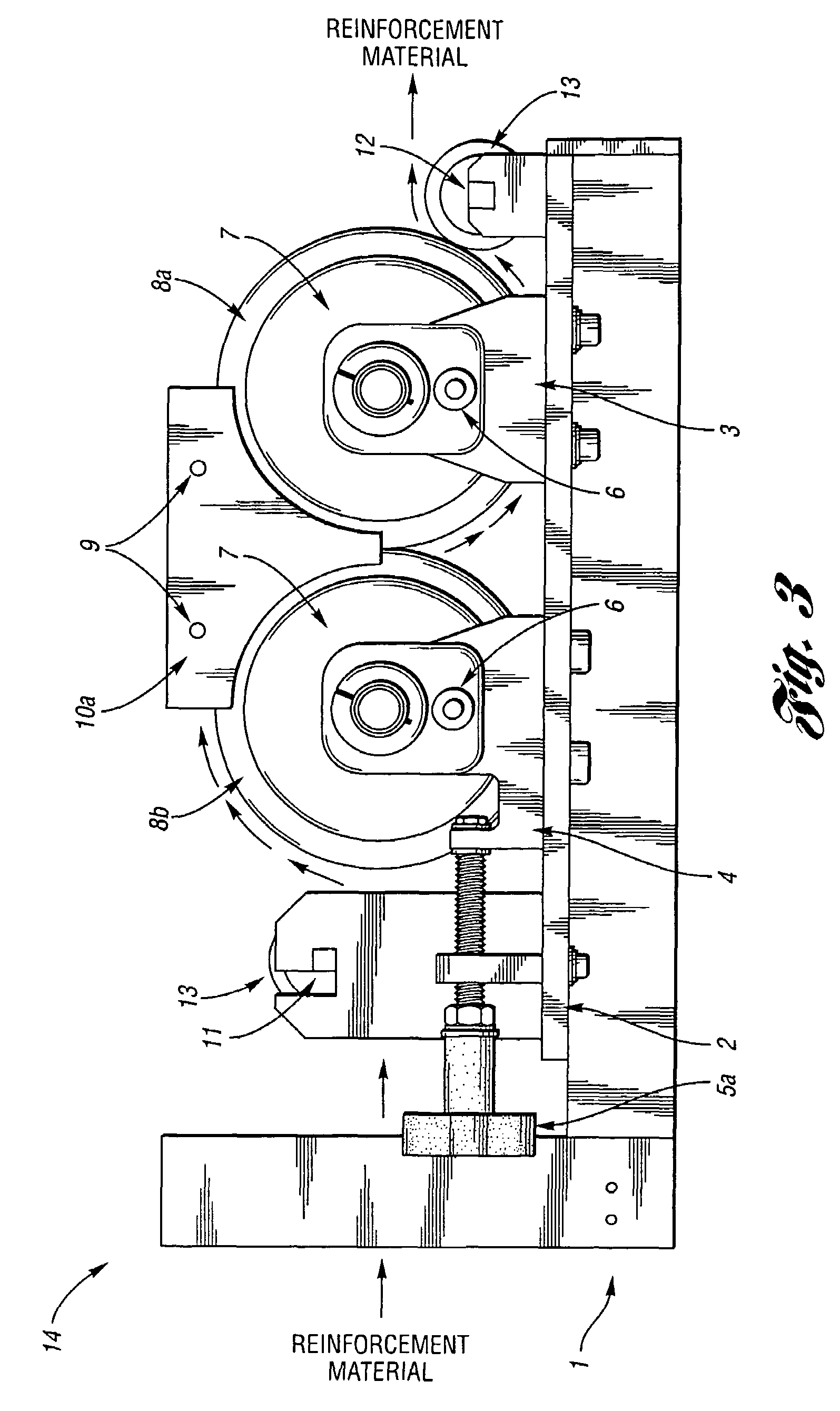

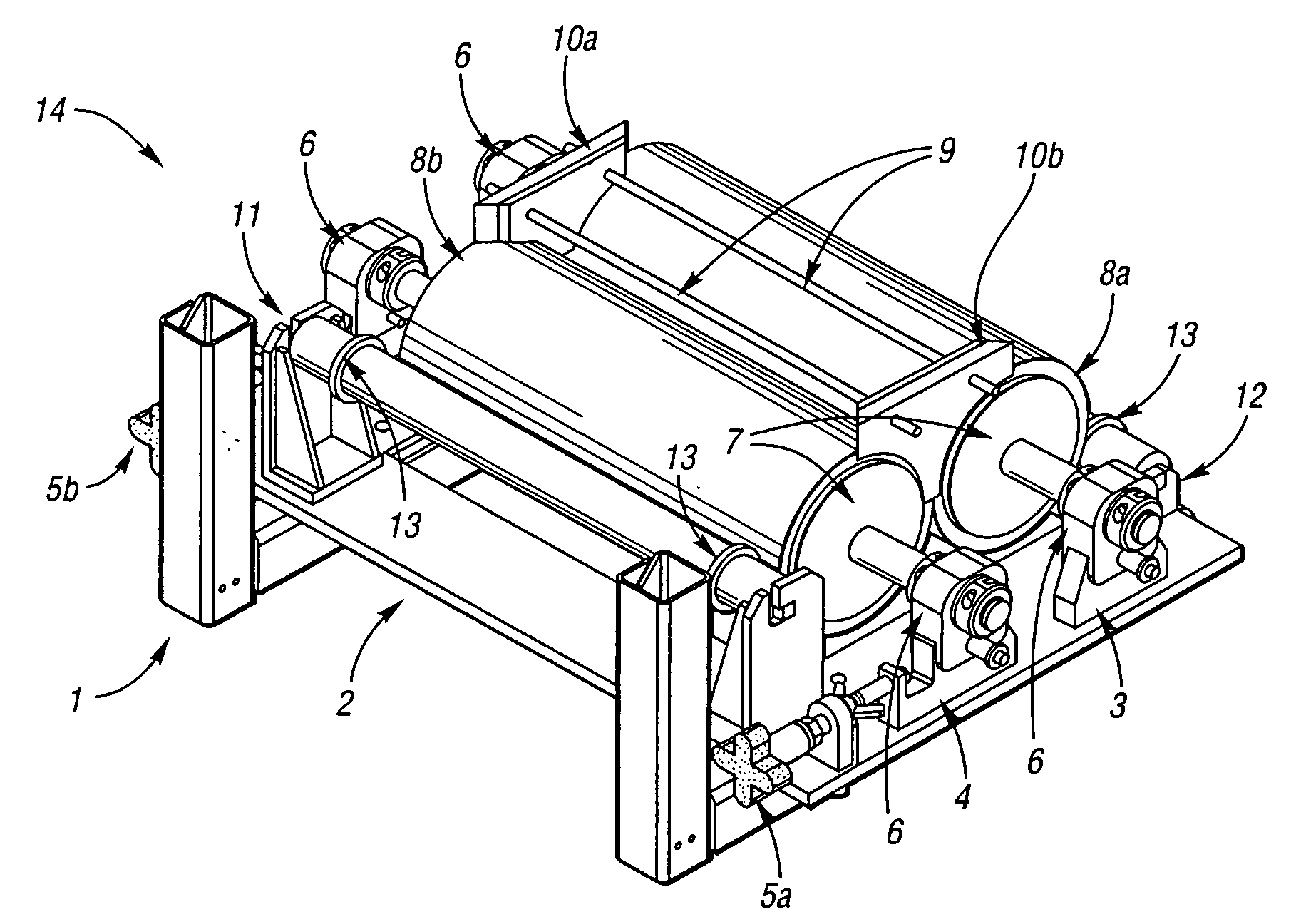

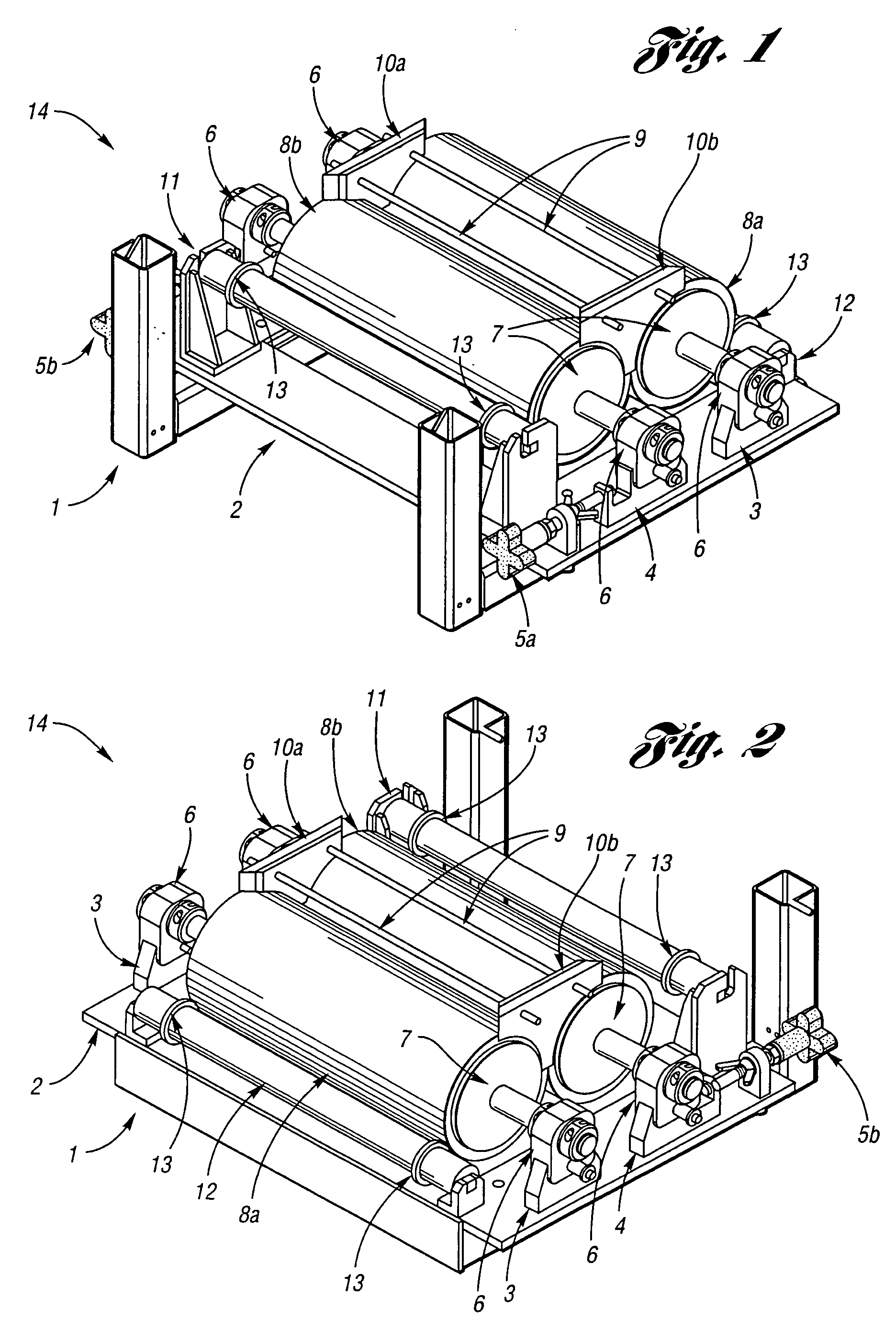

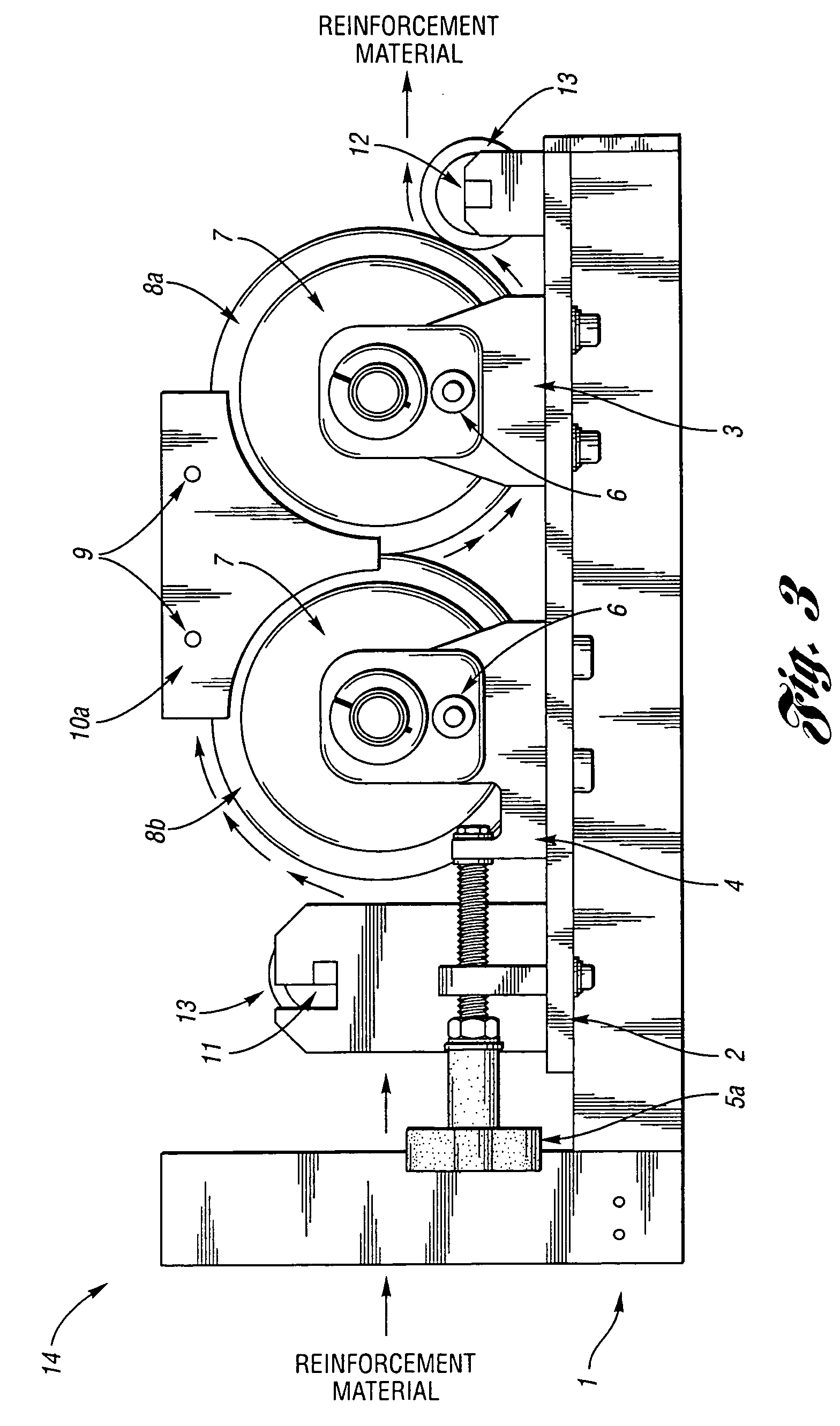

Apparatus for resin-impregnation of fibers for filament winding

InactiveUS7413623B2Increase ratingsHigh viscosityCoatingsLiquid/gas/vapor textile treatmentElastomerEngineering

A two roll impregnator for impregnating fiber reinforcement for use in filament winding operatives contains two abutting rolls, at least one and preferably both having an elastomeric surface. Resin is constrained within a bath whose lower surfaces are defined by the abutting rollers and side dams. Fiber reinforcement is drawn over a first roller through the resin bath and between the closed nip of the abutting rollers, where full impregnation is fostered, excess resin removed, and the impregnated fiber degassed. Substantially dripless operation can be maintained.

Owner:TSE INDS

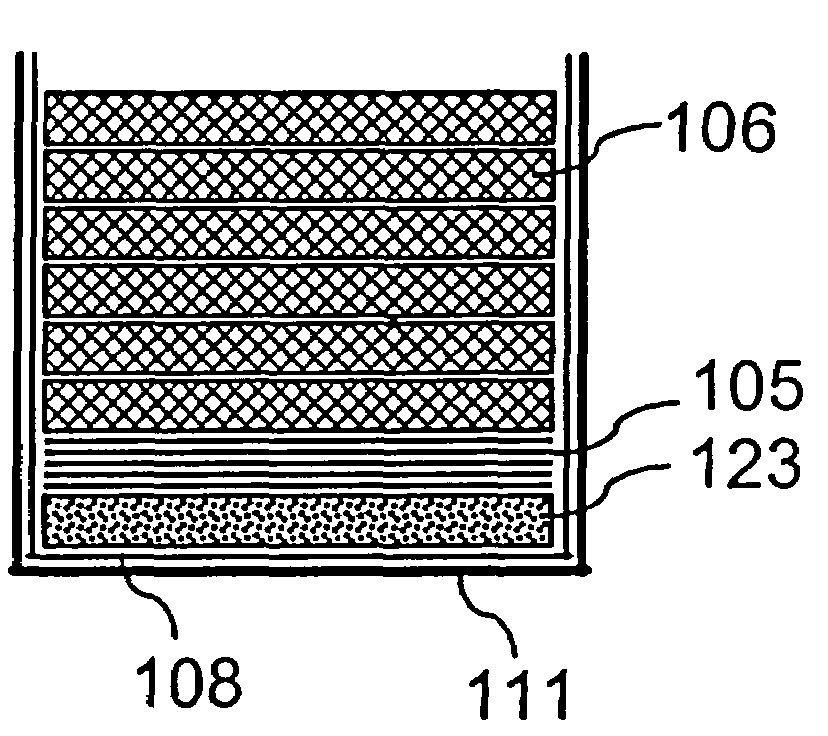

Composites pressure resin infusion system (ComPRIS)

InactiveUS7300894B2Improve fracture toughnessPredictable and improved propertySynthetic resin layered productsWoven fabricsPolyresinBiomedical engineering

Owner:MAINE UNIV OF

Apparatus for resin-impregnation of fibers for filament winding

InactiveUS20060177591A1Increase ratingsHigh viscosityLiquid surface applicatorsCoatingsElastomerEngineering

A two roll impregnator for impregnating fiber reinforcement for use in filament winding operatives contains two abutting rolls, at least one and preferably both having an elastomeric surface. Resin is constrained within a bath whose lower surfaces are defined by the abutting rollers and side dams. Fiber reinforcement is drawn over a first roller through the resin bath and between the closed nip of the abutting rollers, where full impregnation is fostered, excess resin removed, and the impregnated fiber degassed. Substantially dripless operation can be maintained.

Owner:TSE INDS

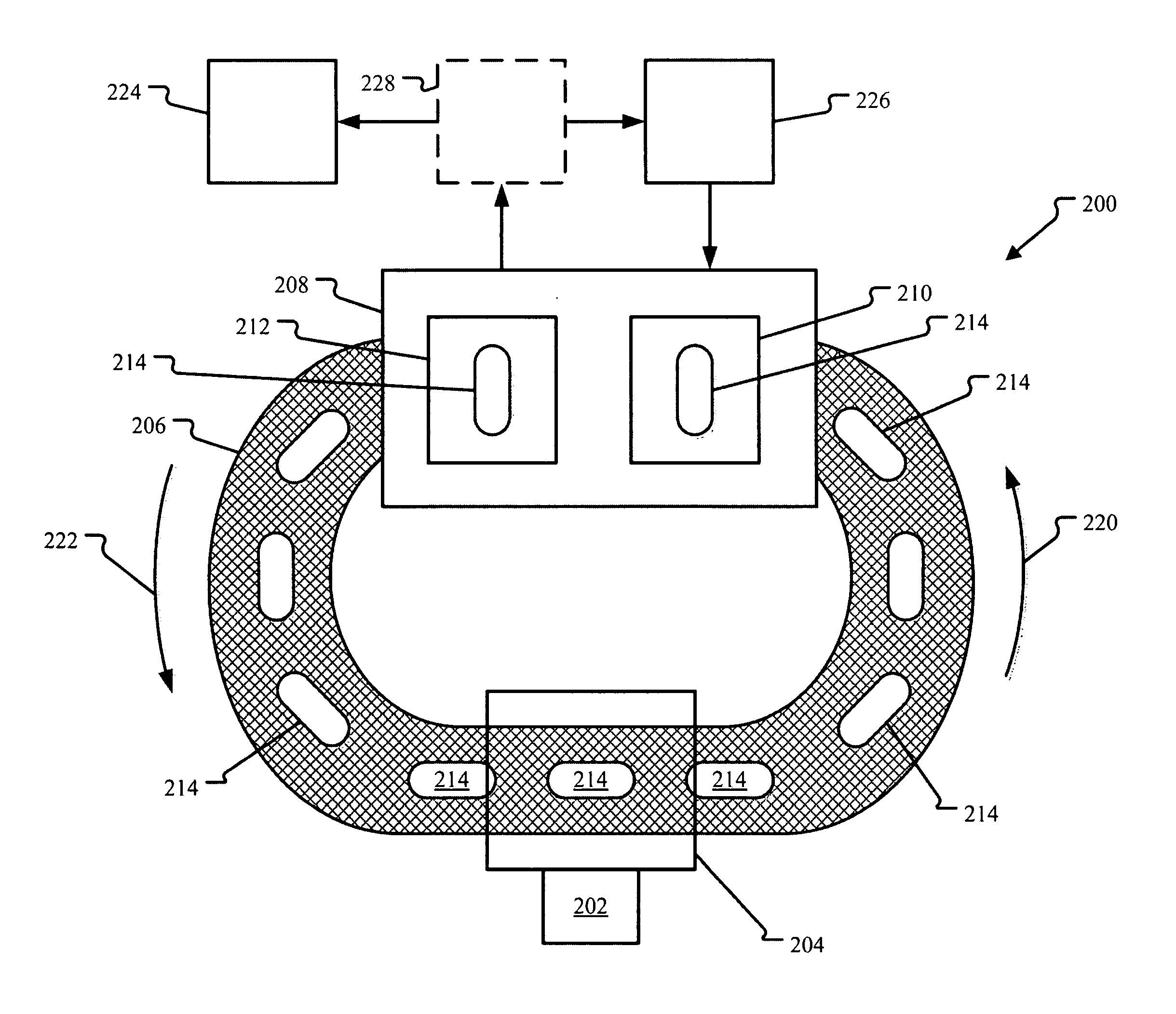

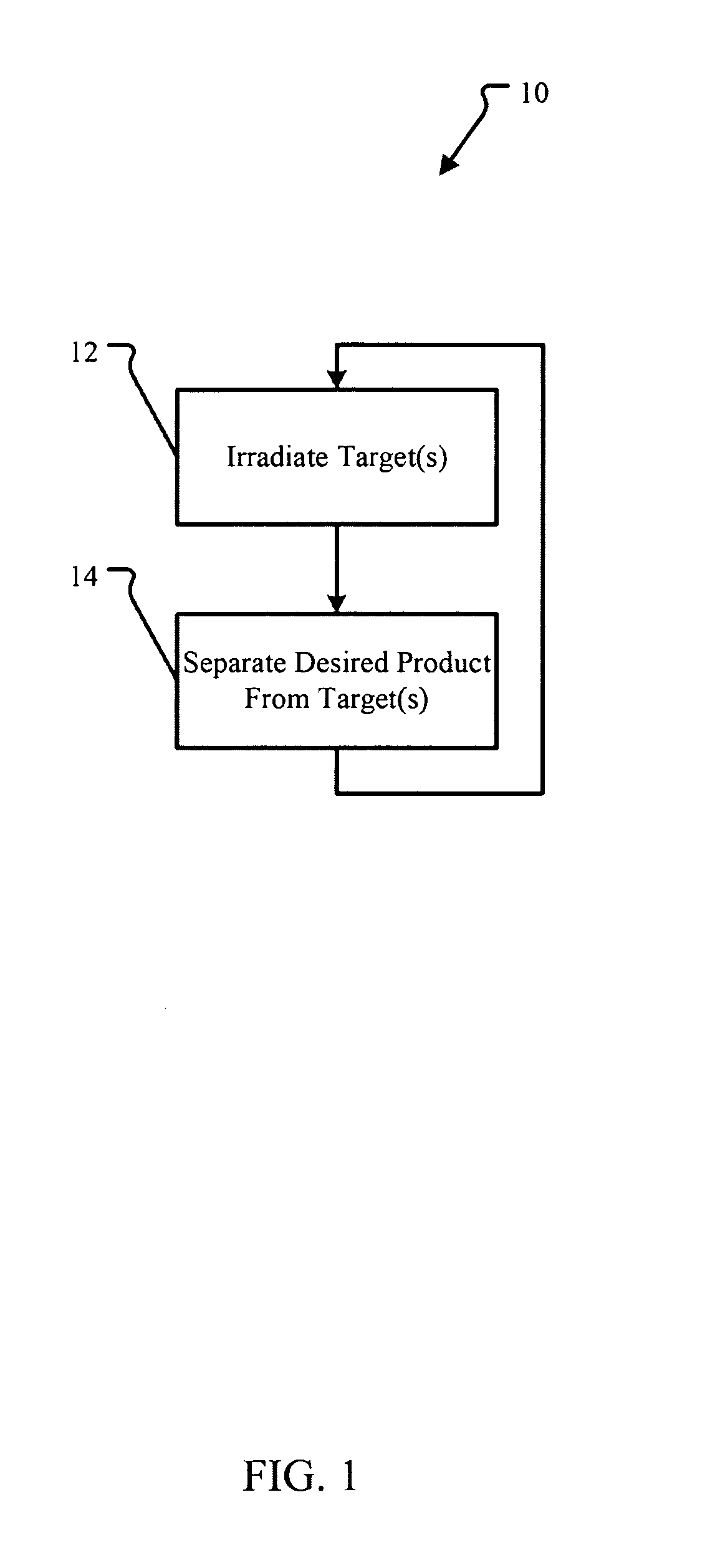

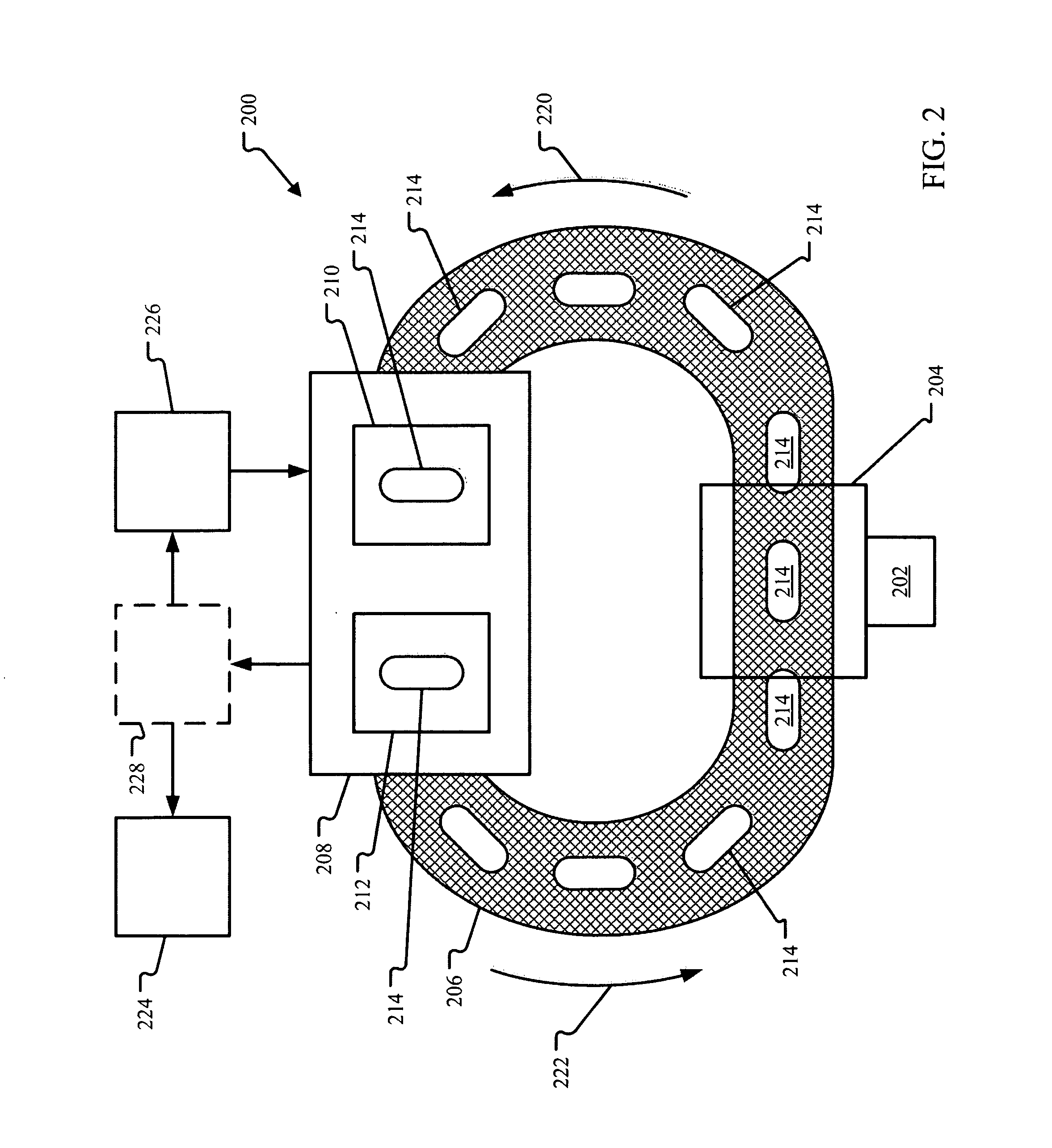

Targetry coupled separations

ActiveUS20160189816A1Minimal wasteLow costSolvent extractionConversion outside reactor/acceleratorsDissolutionEngineering

Targetry coupled separation refers to enhancing the production of a predetermined radiation product through the selection of a target (including selection of the target material and the material's physical structure) and separation chemistry in order to optimize the recovery of the predetermined radiation product. This disclosure describes systems and methods for creating (through irradiation) and removing one or more desired radioisotopes from a target and further describes systems and methods that allow the same target to undergo multiple irradiations and separation operations without damage to the target. In contrast with the prior art that requires complete dissolution or destruction of a target before recovery of any irradiation products, the repeated reuse of the same physical target allowed by targetry coupled separation represents a significant increase in efficiency and decrease in cost over the prior art.

Owner:TERRAPOWER

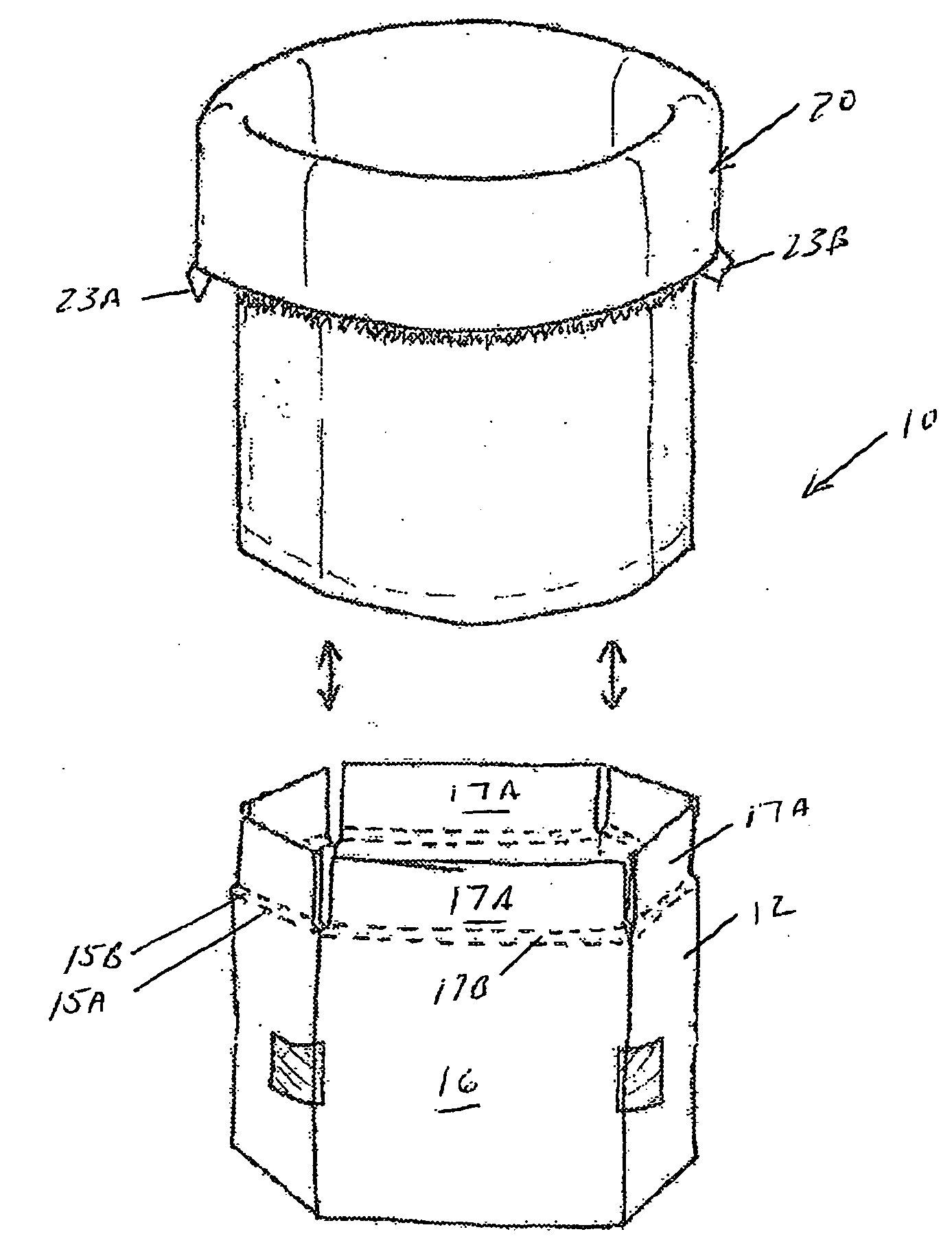

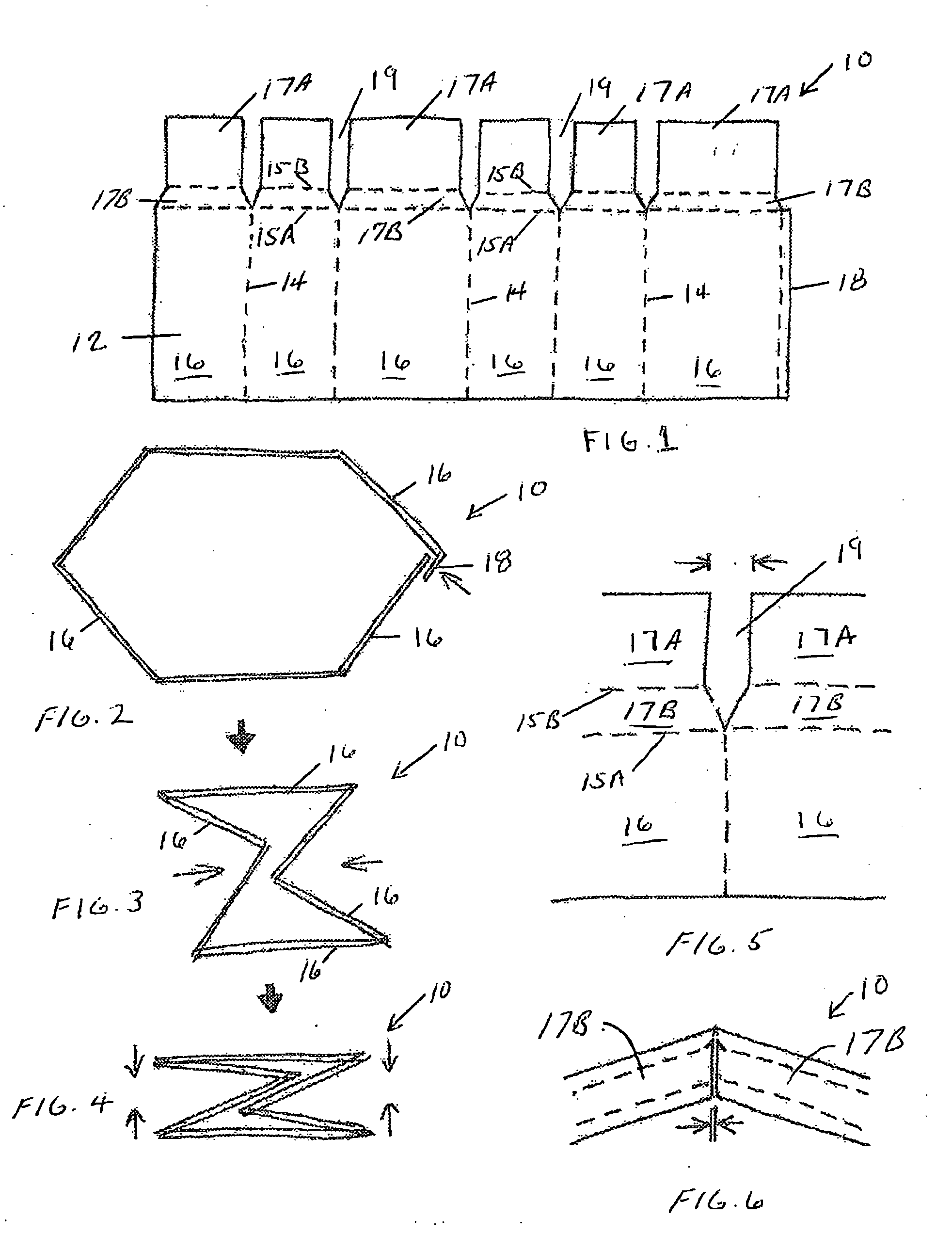

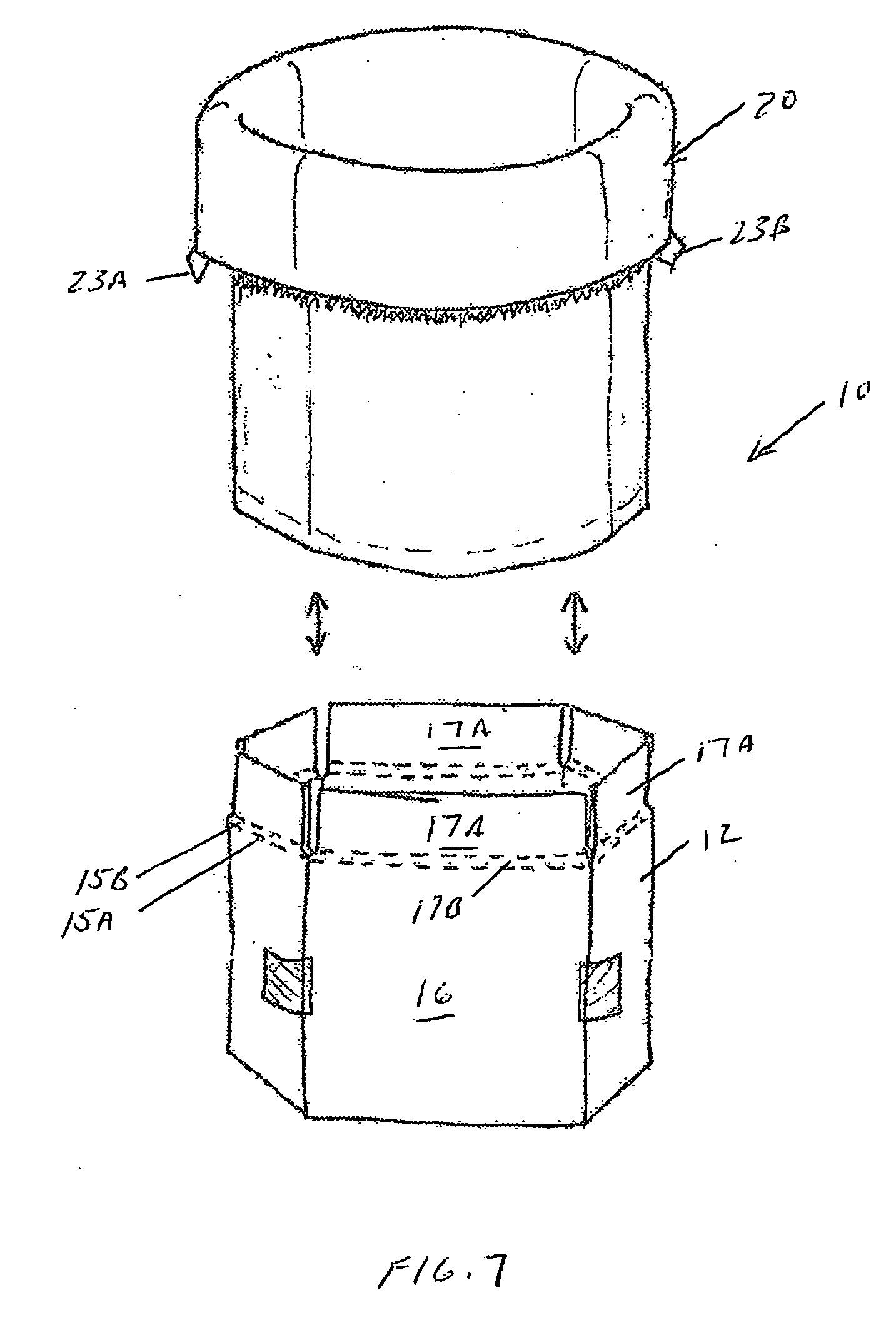

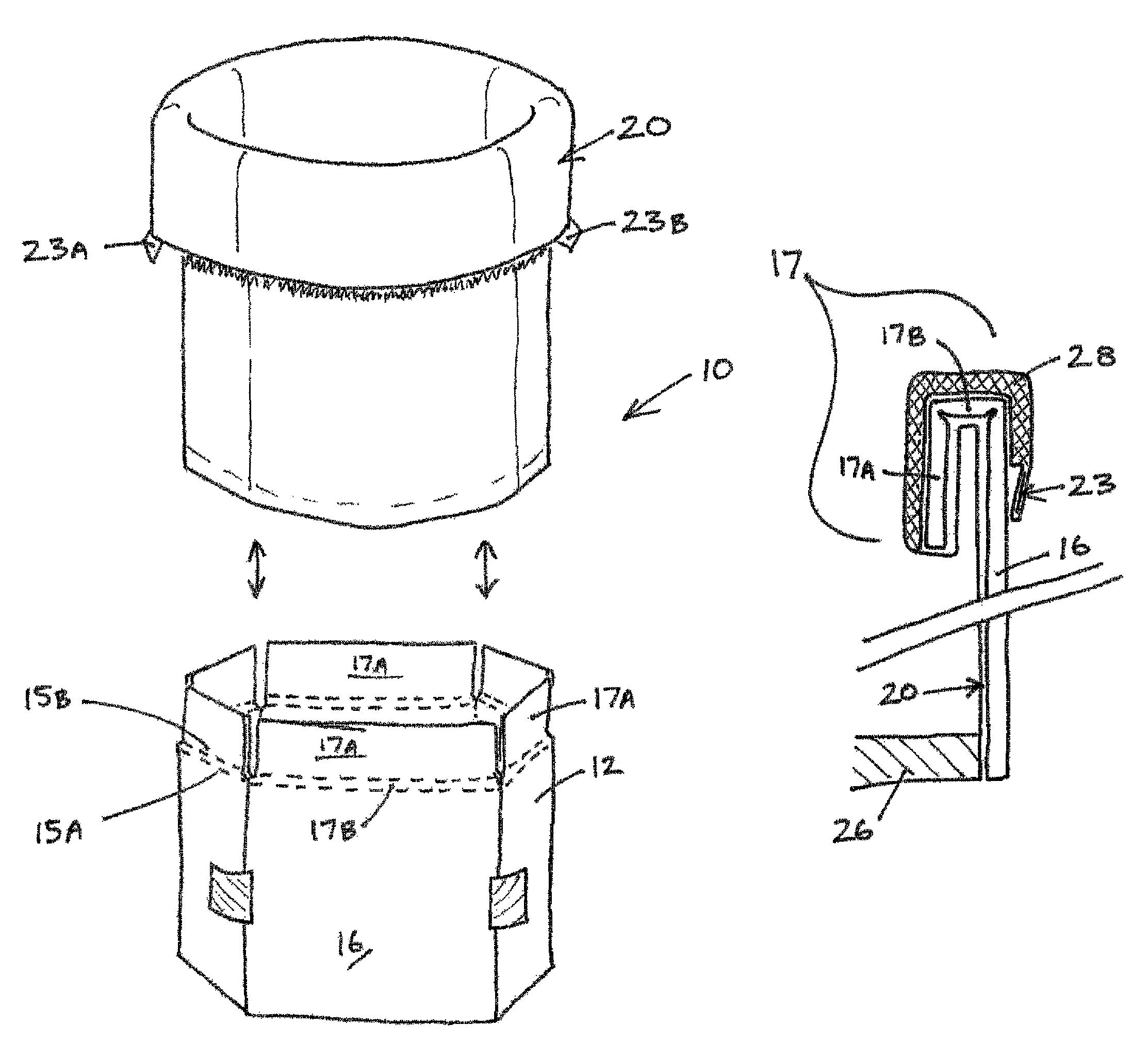

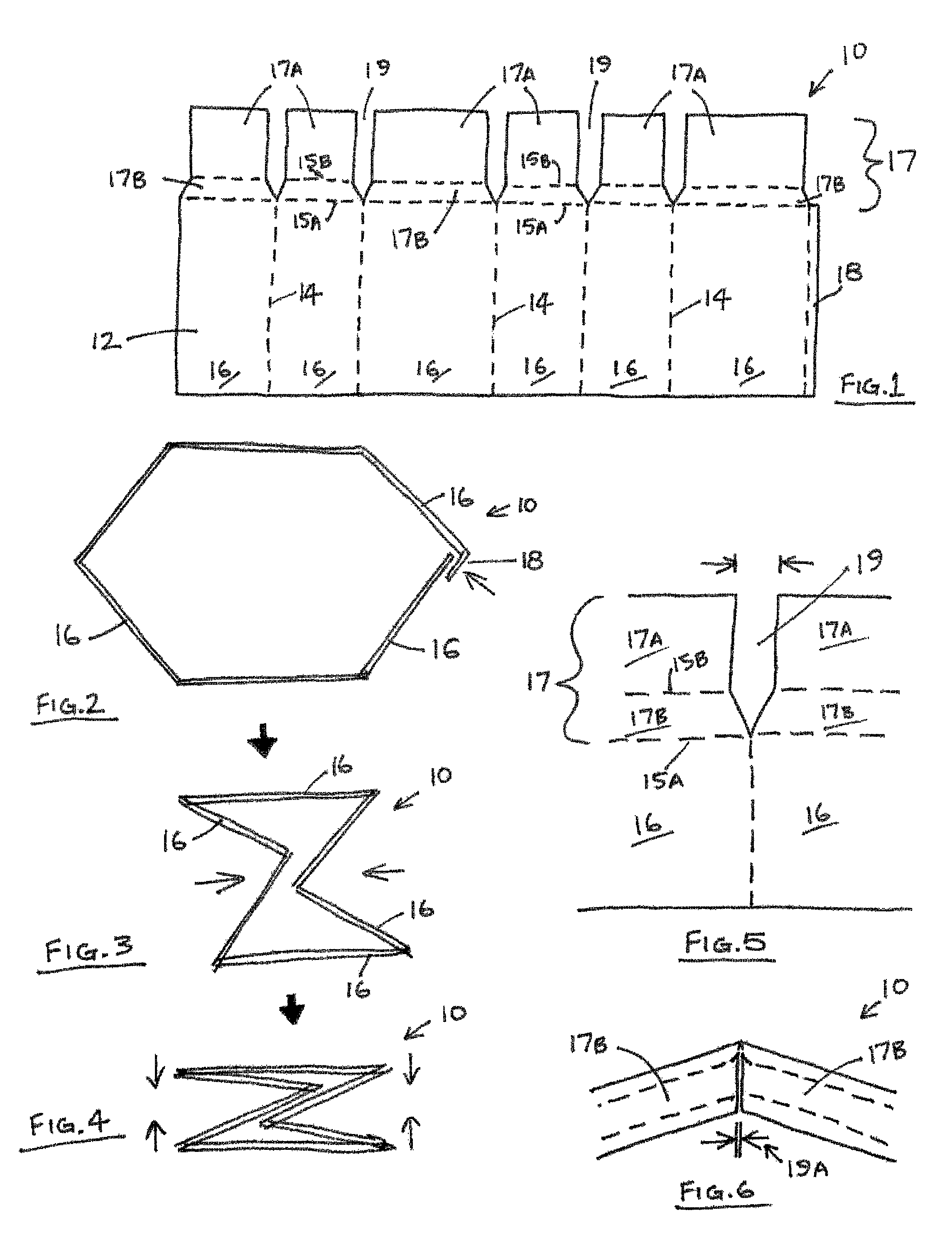

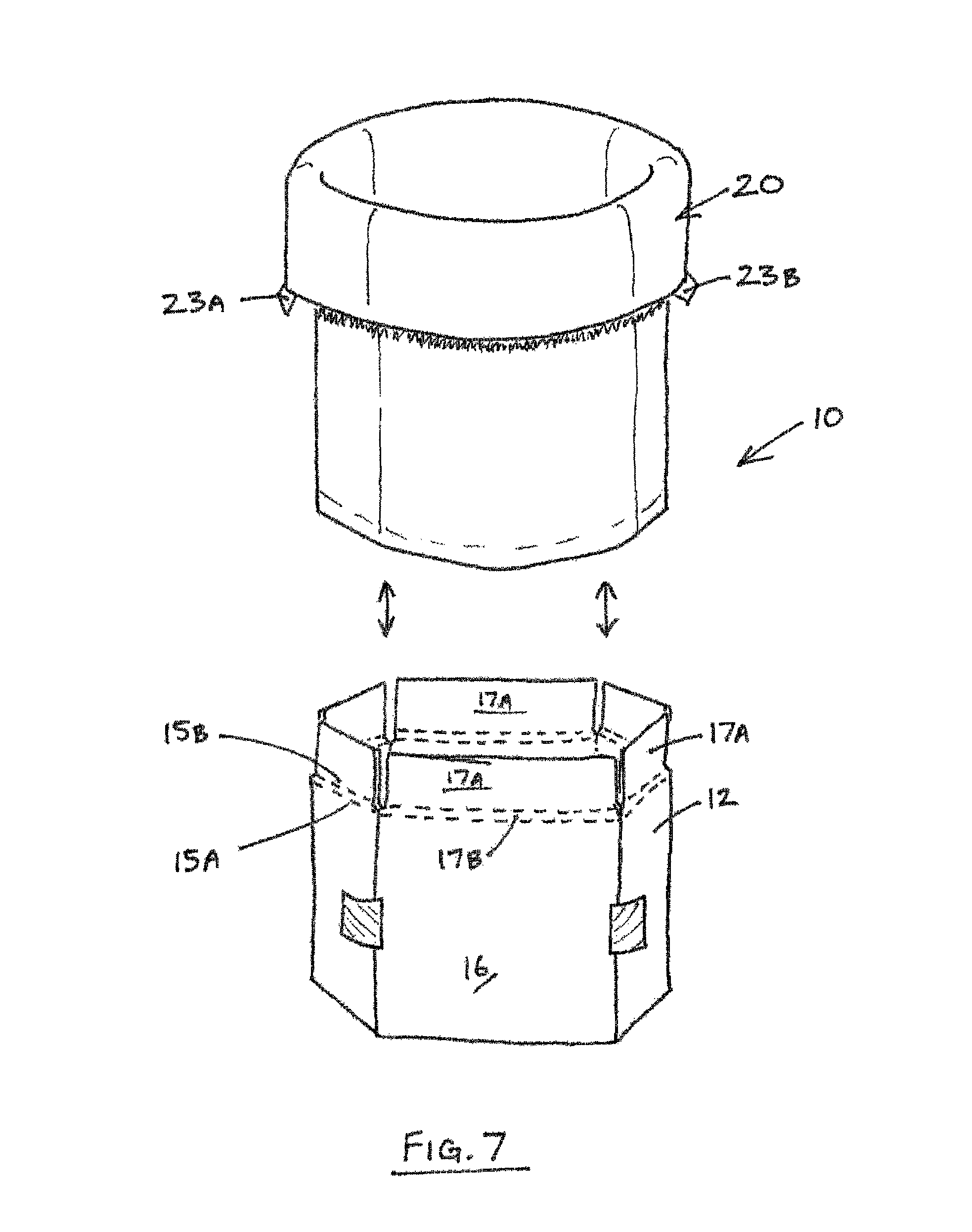

Disposable collapsible portable toilet

InactiveUS20090255046A1Efficient manufacturingMinimal wasteBathroom accessoriesLarge containersCardboardPortable toilet

A disposable portable toilet that is efficiently fabricated from foldable stock, such as corrugated cardboard, with minimal waste and adapted with a fluid absorbing inner liner is disclosed. Foldable stock material is formed as a blank sheet having a plurality of fold lines defining multiple panels disposed in side-by-side relation, and a joining tab. Each panel includes a fold-in tab that functions to provide a rim. The blank sheet provides a structure that may be configured to form a support structure that is selectively configurable from a collapsed configuration to an expanded configuration. An absorbent liner is insertedly received within the support structure. Padding sections are disposed on the liner in proximity to overlay the top rim of the support structure when the liner is received therein thereby providing the device with a padded upper rim. A drawstring functions as a closure member to close the liner after use. The present invention thus provides a disposable toilet that is particularly suited for emergency use by anyone, and particularly for use by small children while away from home.

Owner:CARTER WILLIAM +1

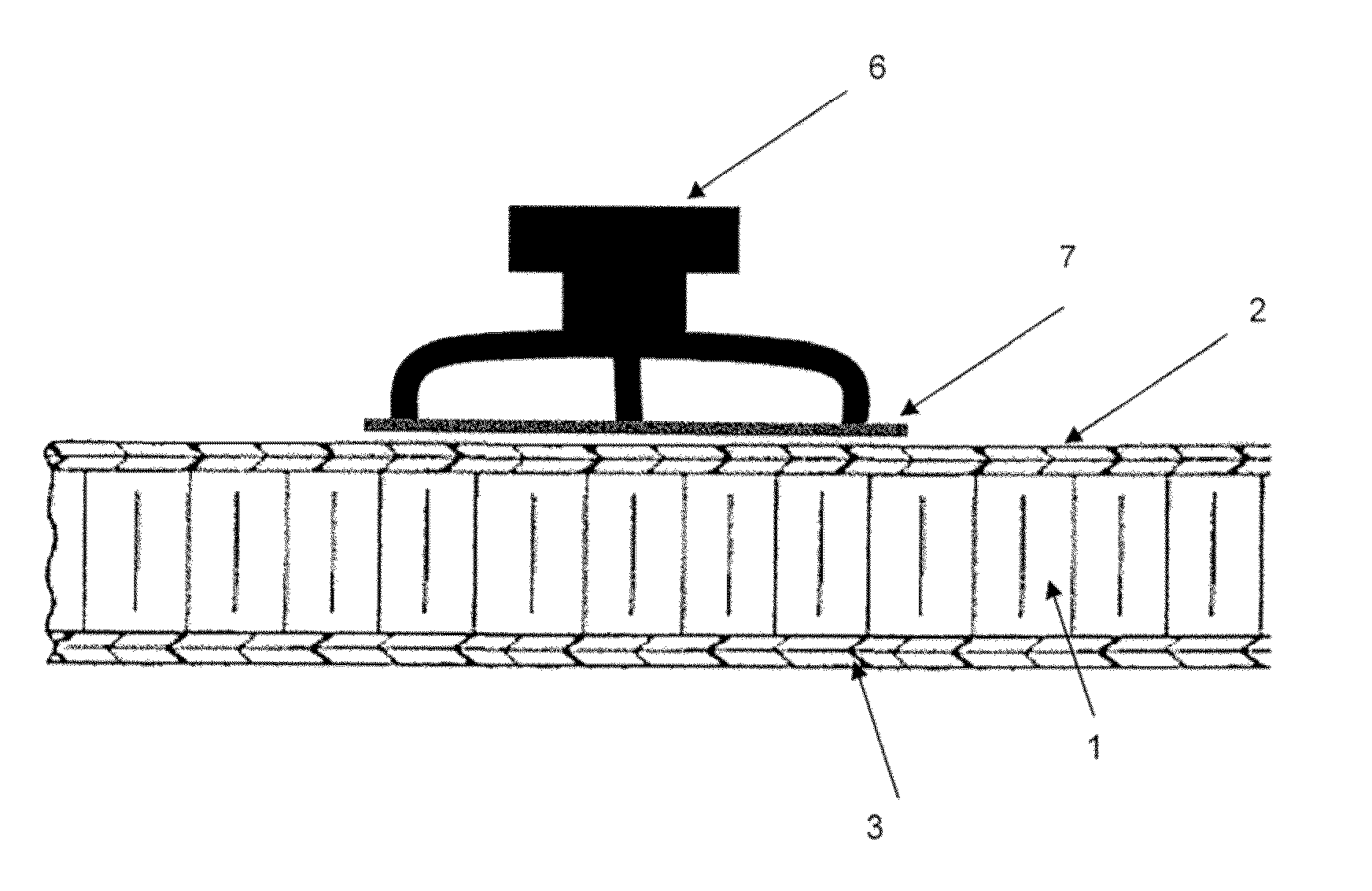

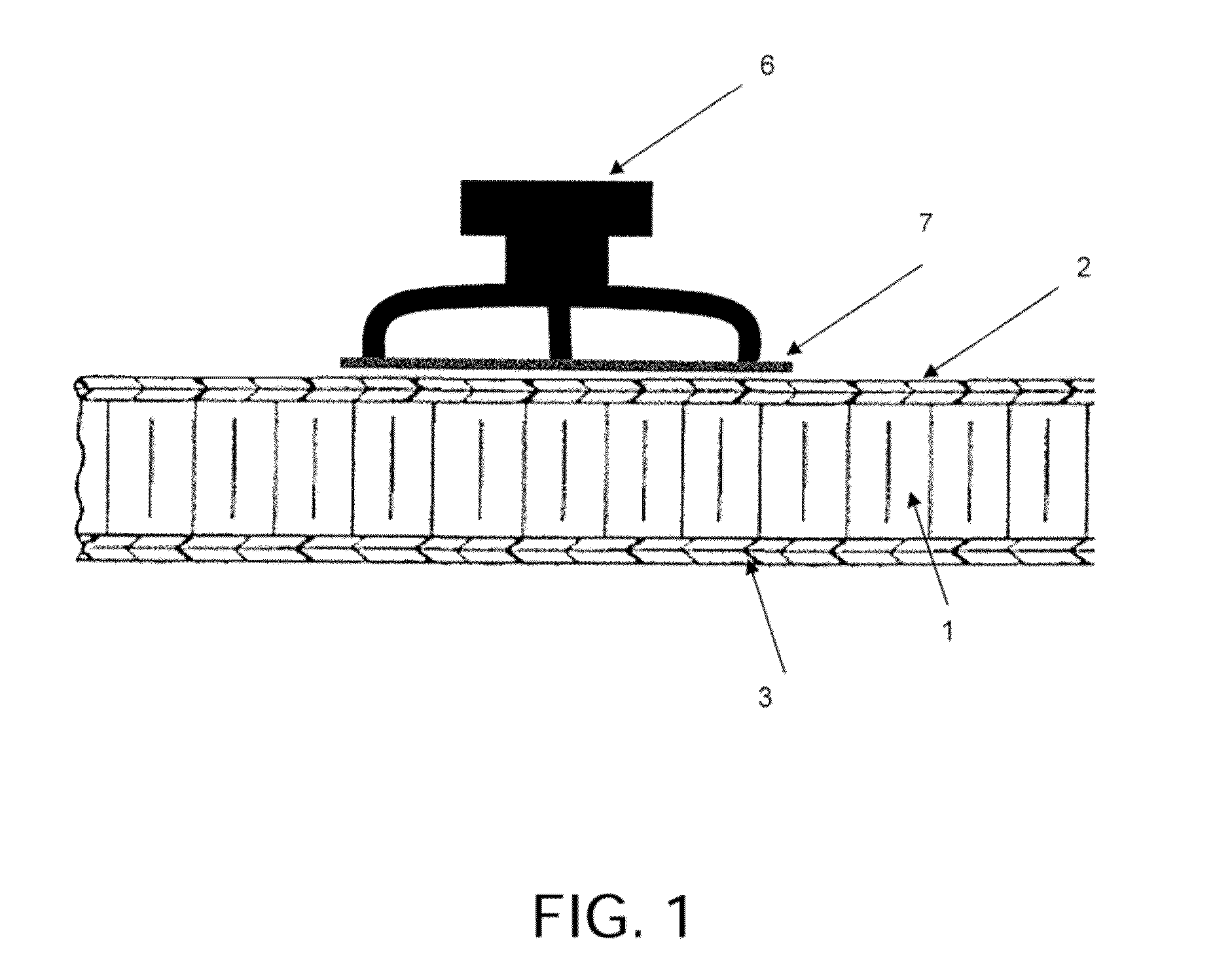

Method and apparatus for adhesion of inserts

ActiveUS20150096678A1Accurate fillingMinimal wasteMaterial gluingSynthetic resin layered productsEpoxyResin adhesive

The present invention contemplates a method for the attachment of a component to a honeycomb structure comprising forming a cavity in the honeycomb structure whereby the cavity is formed within one or more honeycomb cells; placing an insert adapted to enable the attachment of the component to the honeycomb structure whereby a reformable epoxy resin adhesive is injected about the insert or an expandable reformable epoxy resin adhesive is overmolded onto the insert; heating the reformable epoxy resin adhesive; and hardening and adhering the reformable epoxy resin adhesive to one or more interior walls of the cavity upon cooling.

Owner:ZEPHYROS INC

LED lighting lamp

InactiveUS8382331B2Minimal wasteSufficient efficiencyNon-electric lightingPoint-like light sourceBeam angleLight beam

Owner:CHENG YUNG PUN

Process for the production of plant ingredients

InactiveUS20050003061A1Function increaseLight colorProtein composition from vegetable seedsAnimal feeding stuffFood gradeOrganic solvent

Process for the production of lupin protein extracts, food products, containing lupin protein extracts and lupin protein extracts so produced are described. The process of the invention comprises a process for the production of lupin protein extracts from lupins, comprising: (a) extracting lupin meal or flour with water at alkaline pH; (b) separating an alkali soluble lupin protein containing component from an alkali insoluble fibrous component; (c) adjusting the pH of the protein component with acid to a pH between 3-5.0, and thereafter separating a food grade lupin protein extract (PF1) from an acid soluble lupin protein containing component; and optionally, (d) reacting the acid soluble lupin protein containing component with a C1-C6 food grade organic solvent and recovering therefrom a second food grade lupin protein extract (PF3); or (e) raising the pH of the acid soluble lupin protein component to pH 5-7, and optionally recovering a lupin protein isolate, followed by the addition of a C1-C6 food grade organic solvent and recovering therefrom a third food grade lupin protein fraction (PF2).

Owner:WESTON FOODS

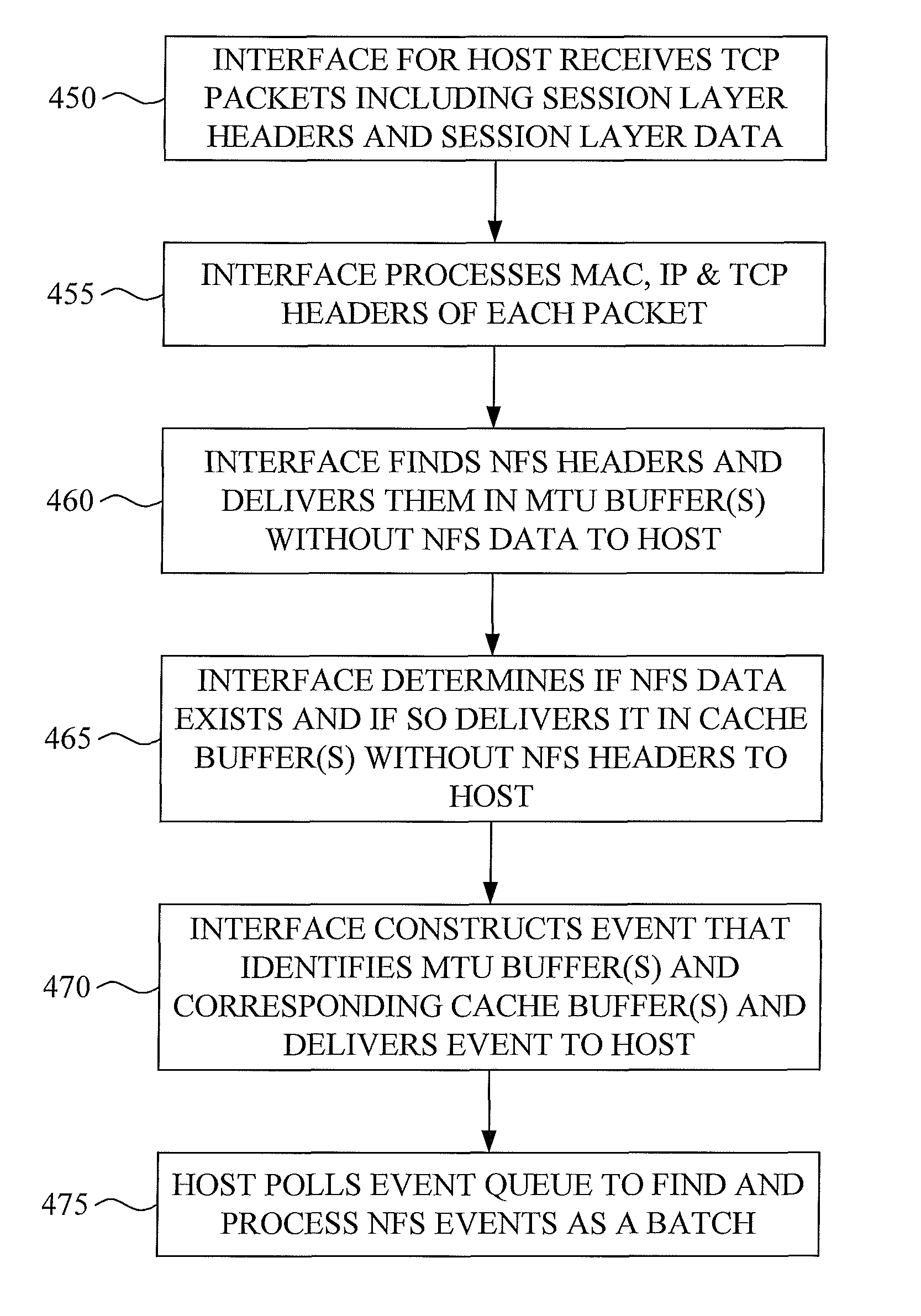

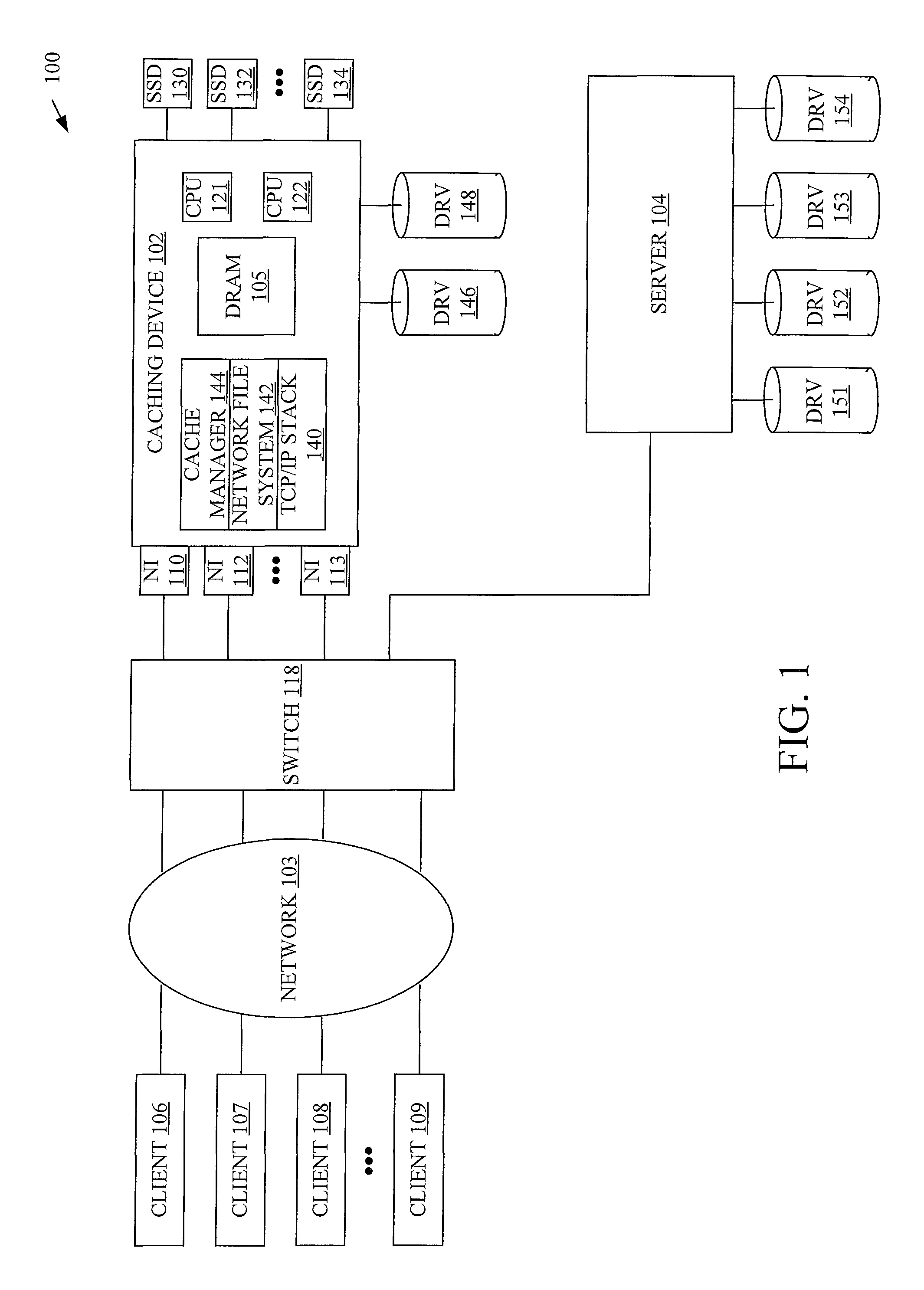

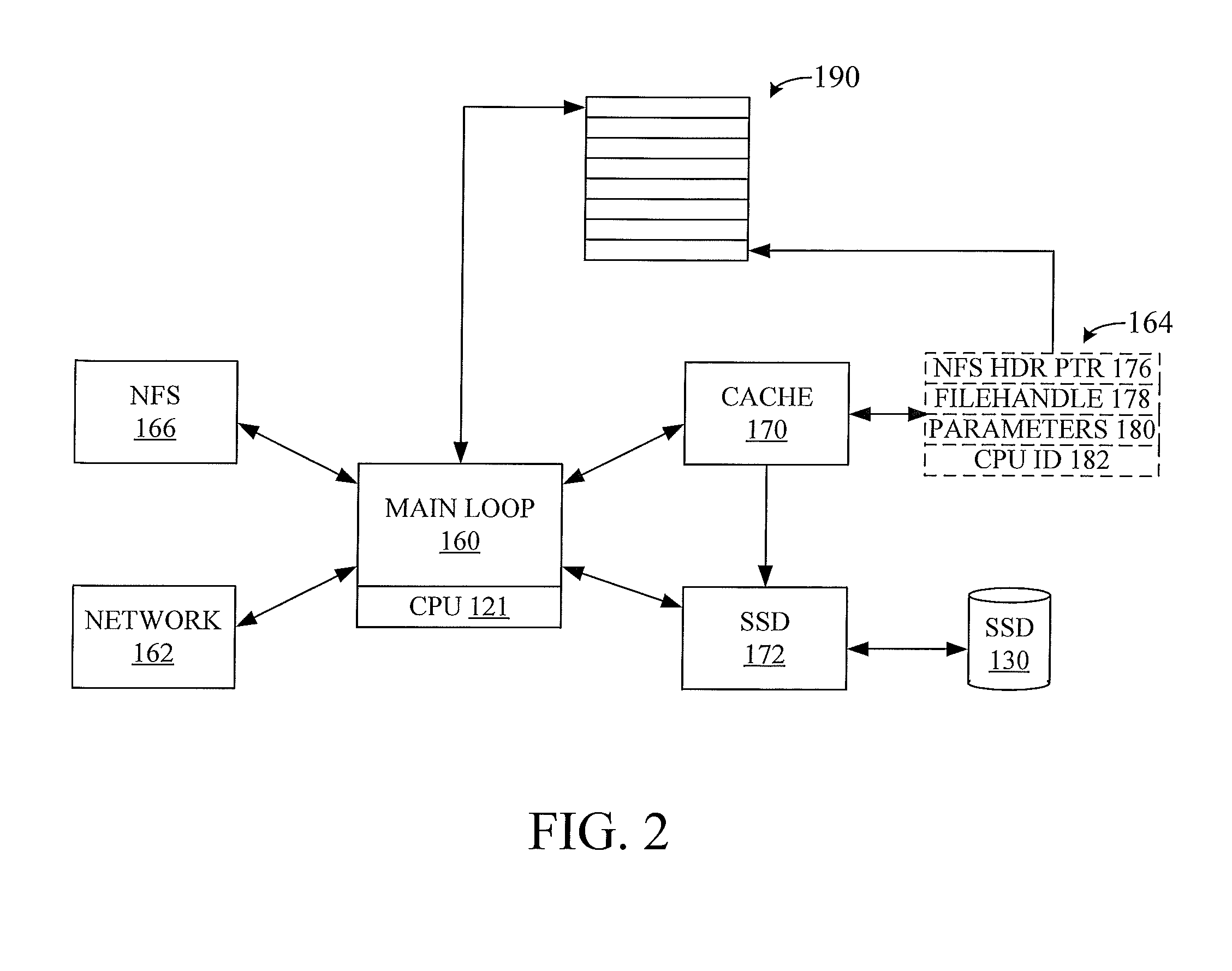

Network cache accelerator

ActiveUS9088592B1Increase speedAccelerate cache readMultiple digital computer combinationsTransmissionData streamProcessor register

A network host such as a caching device is disclosed that greatly increases the speed with which a server reads and writes data for clients. The host may include a specialized network interface that not only processes TCP but also parses received network file system headers, identifying those headers within the TCP data stream, separating them from any corresponding network file system data, and providing them separately from that data to the network file system of the host for processing as a batch, all without any interrupt to the host. Similarly, the network file system of the host may communicate directly with the network interface by writing network file system headers directly to a register of the network interface to transmit data.

Owner:ALACRITECH

Method and apparatus for forming and adhering panel and bracket structures

ActiveUS20150096663A1Minimal massMinimal wasteLamination ancillary operationsMaterial gluingAdhesiveSurface plate

The present invention includes a method for the attachment of a bracket to a panel structure comprising providing an adhesive for attaching the bracket to the panel structure; placing the bracket in a desired location on the panel structure; heating the adhesive; and hardening the adhesive so the bracket is adhered to the panel structure.

Owner:ZEPHYROS INC

Disposable collapsible portable toilet

InactiveUS7996930B2Efficient manufacturingMinimal wasteBathroom accessoriesLarge containersCardboardPortable toilet

A disposable portable toilet that is efficiently fabricated from foldable stock, such as corrugated cardboard, with minimal waste and adapted with a fluid absorbing inner liner is disclosed. Foldable stock material is formed as a blank sheet having a plurality of fold lines defining multiple panels disposed in side-by-side relation, and a joining tab. Each panel includes a fold-in tab that functions to provide a rim. The blank sheet provides a structure that may be configured to form a support structure that is selectively configurable from a collapsed configuration to an expanded configuration. An absorbent liner is insertedly received within the support structure. Padding sections are disposed on the liner in proximity to overlay the top rim of the support structure when the liner is received therein thereby providing the device with a padded upper rim. A drawstring functions as a closure member to close the liner after use. The present invention thus provides a disposable toilet that is particularly suited for emergency use by anyone, and particularly for use by small children while away from home.

Owner:CARTER WILLIAM +1

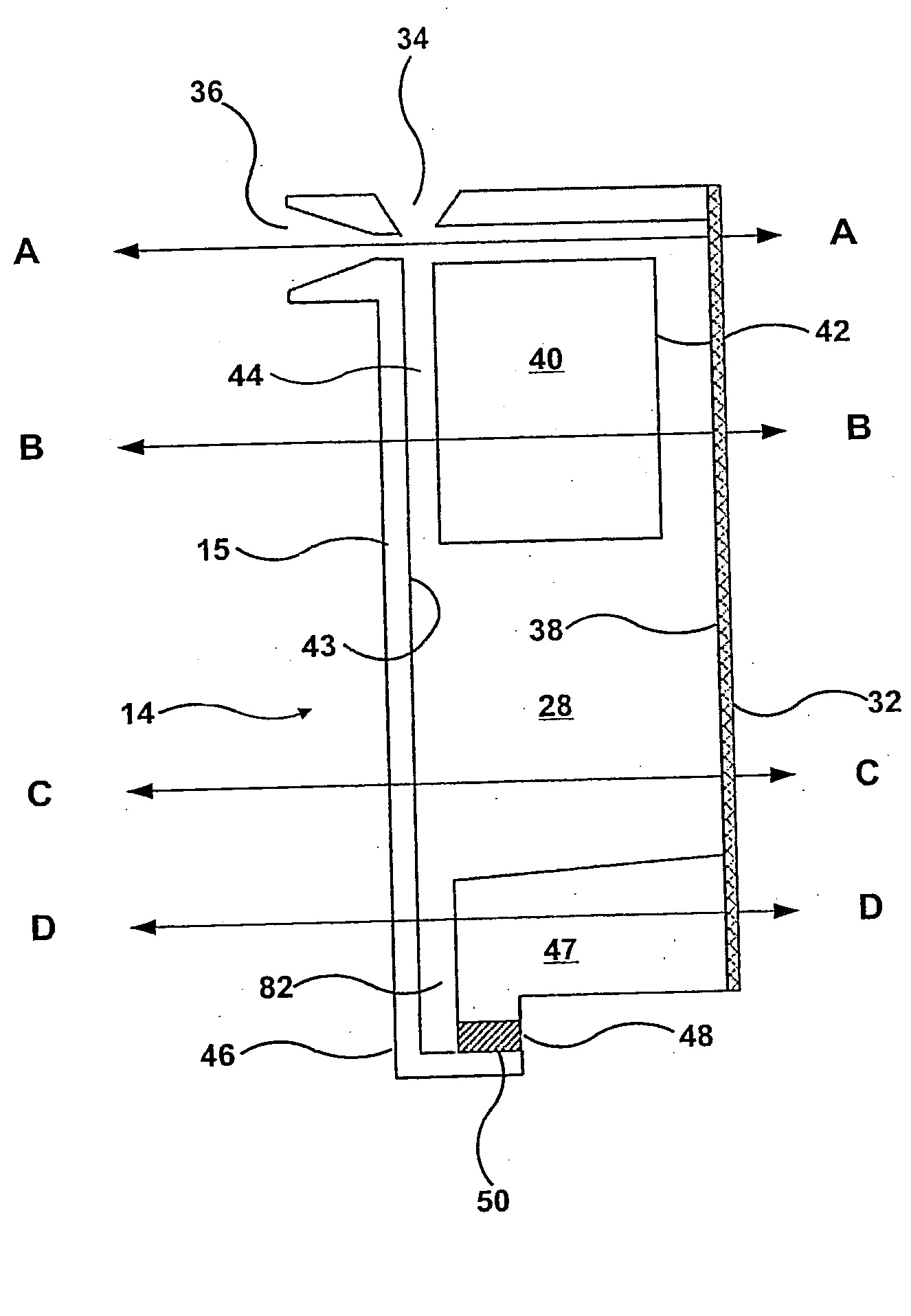

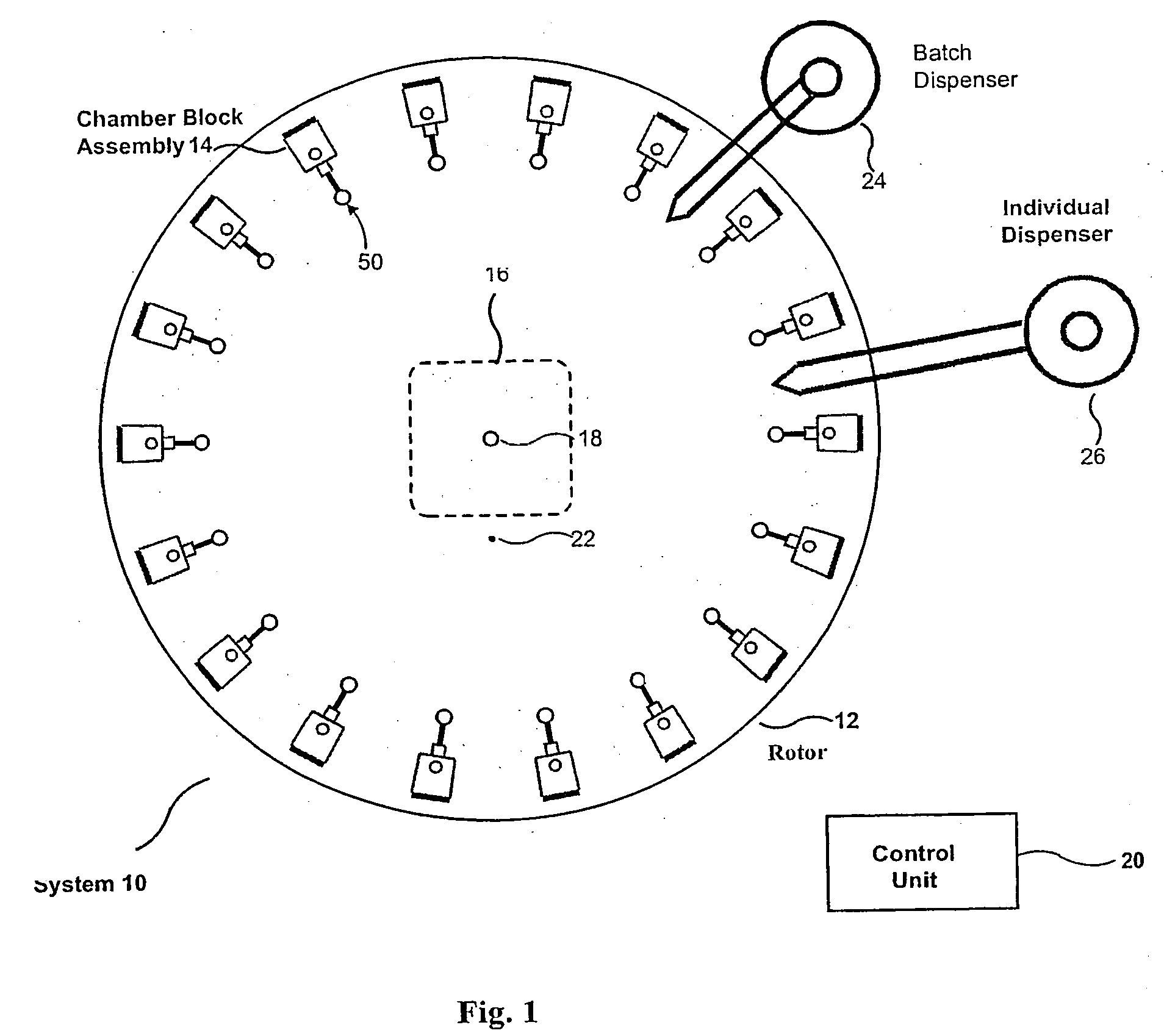

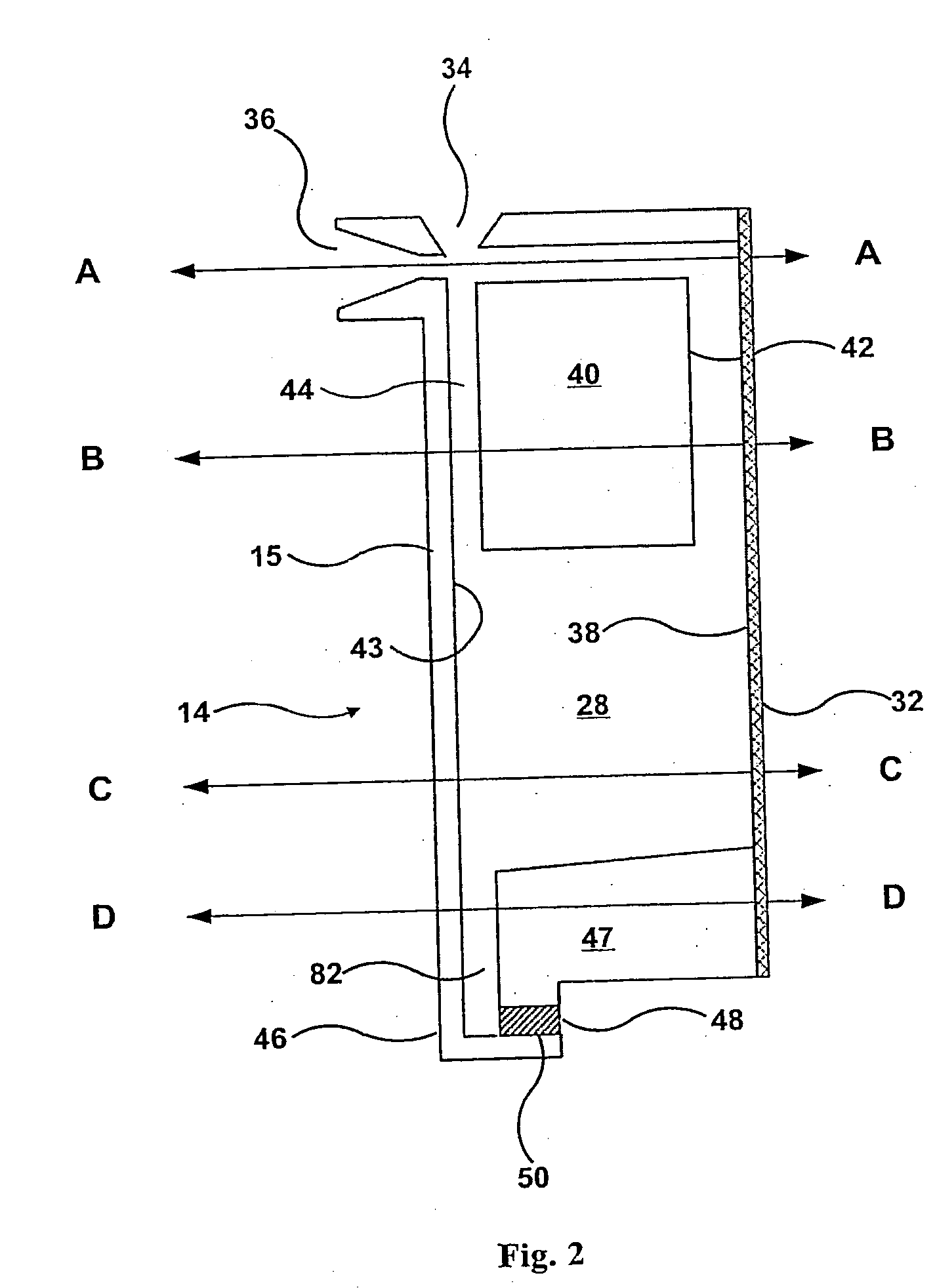

Centrifugal cytology system, chamber block and method for the preparation of treated monolayers of sample material

InactiveUS20050260100A1Minimize cell lossRisk minimizationAnalysis using chemical indicatorsWithdrawing sample devicesCytologyControl system

An apparatus and method for the automated preparation of treated monolayers of sample material, comprising: a centrifuge having a rotor (12) carrying removable chamber blocks (14); sample and reagent dispensers (26) and control systems (20). First, centrifugal force sediments sample material discretely to form a monolayer onto a receiving surface member (32) on one of the chamber blocks (14), while the same centrifugal force opens a valve (48) in the chamber block (14) to drain sample material. Then, centrifugal force delivers sequentially into discrete chamber blocks (14) discrete treating agents, during which time the sampler material monolayer is held in place on the receiving surface member (32) by centrifugal force. Then, each chamber block (14) is drained centrifugally through its already opened valve (48). Each treated sampler material is confined to an individual chamber block (14). Batch and random access delivery of treating agents can be employed. Each chamber block (14) includes separate inlets for the sample and treating agents.

Owner:NEWPORT INSTR

Multipurpose concrete anchor clip

ActiveUS20150184371A1Optimal material consumptionAvoid serious wasteWallsBuilding reinforcementsMaterial consumptionBolt connection

A connector with two flanges for making a variety of connections between structural members, in particular cold formed steel structural members, with the added utility of a accommodating a heavy bolted connection to one of the structural members with an extended tab on one flange that matches a recess on the other for optimal material consumption and minimal waste in manufacturing.

Owner:SIMPSON STRONG TIE

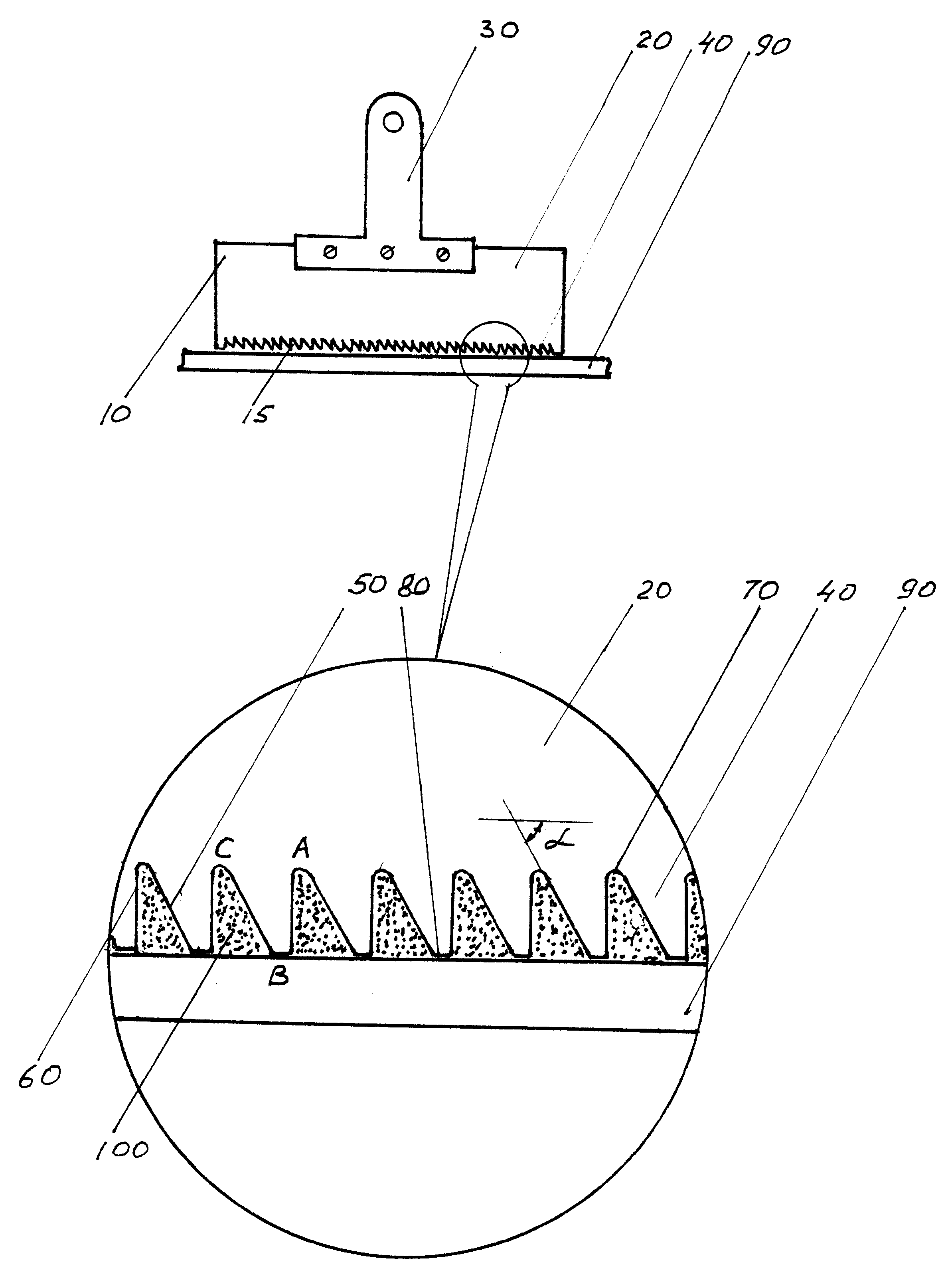

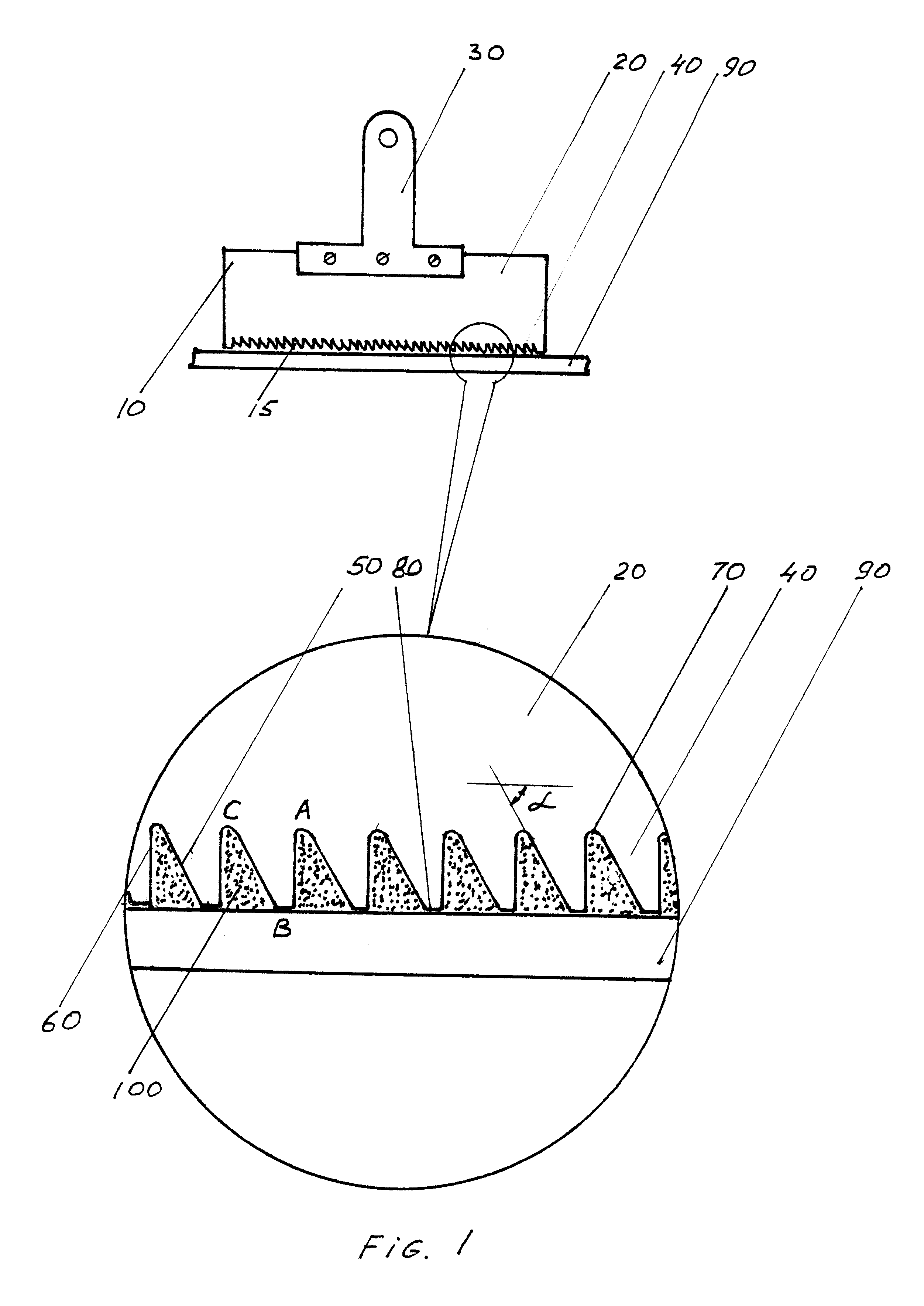

Serrated hand tool for plaster application over a surface joint

InactiveUS6606758B1Shorten the timeLower levelLiquid surface applicatorsBuilding constructionsEngineeringHand tool

A method and a serrated hand tool for construction are disclosed. A novel hand tool for plaster application over a taped surface joined includes a blade having a central section and two serrated side sections. The central section contains a cutout with a straight edge of sufficient width to allow a thicker layer of plaster to be placed over the tape. The serrated side sections contain a number of teeth with a triangular shape. According to the method, the plaster is applied in a plurality of parallel lines under the side sections and in a smooth straight layer under the central section of the tool all at one time to reduce the overall construction time, plaster consumption, and the skill level required to perform the task.

Owner:FRIDMAN EMILIAN

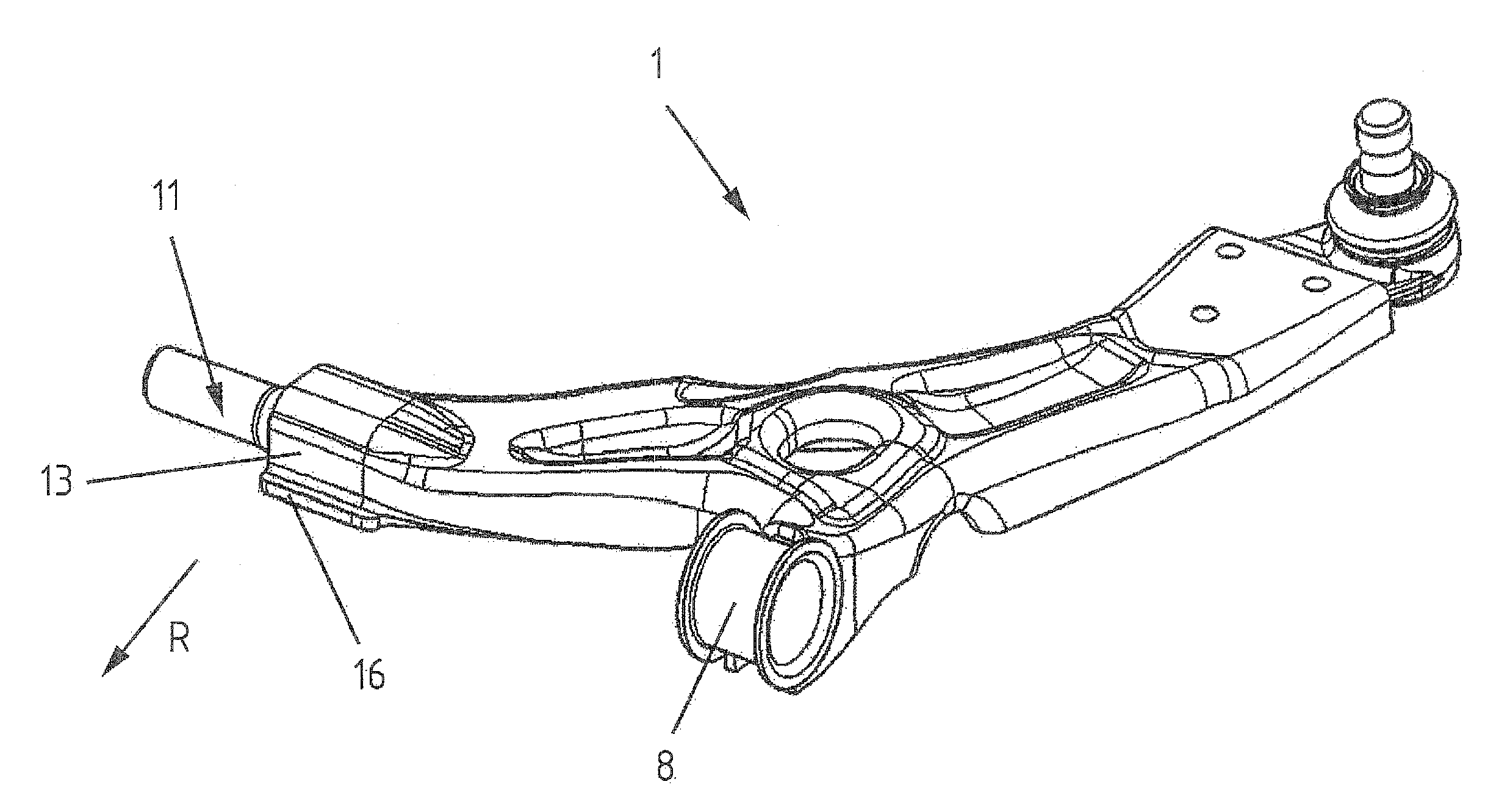

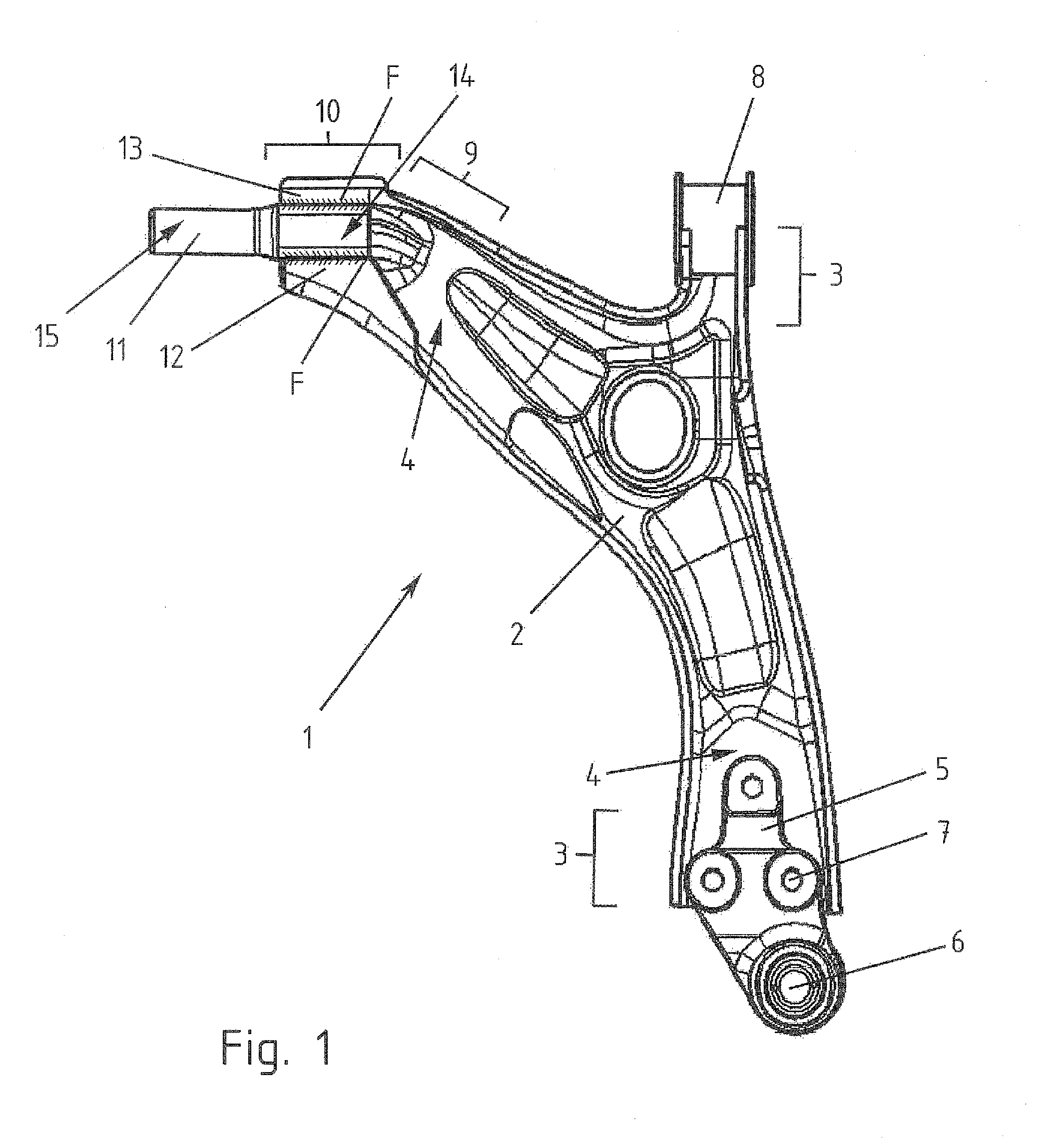

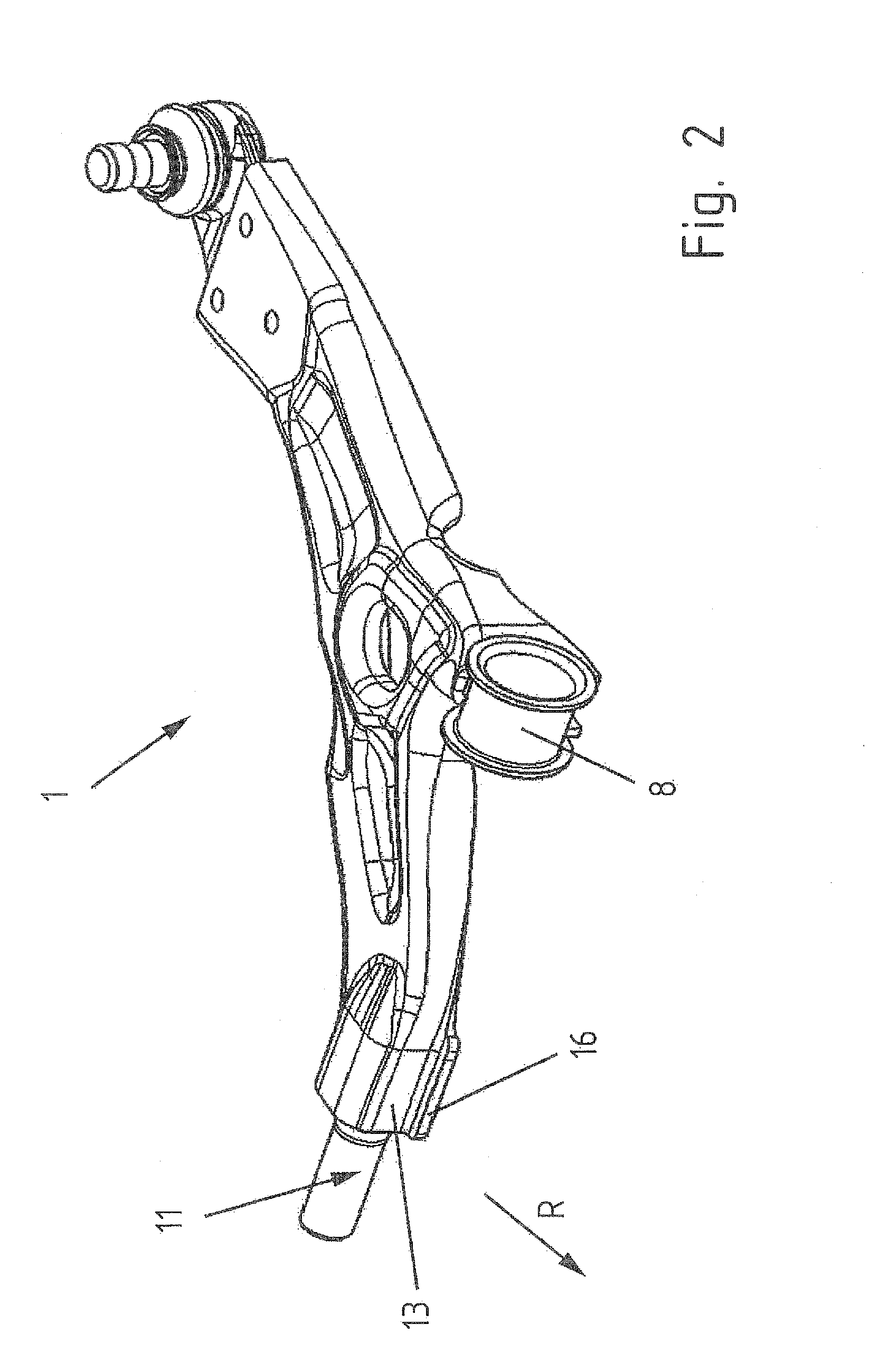

Transverse control arm

InactiveUS20120018974A1High strengthEasy to insertResilient suspensionsPivoted suspension armsControl armEngineering

A transverse control arm for a motor vehicle is produced in one piece from a sheet metal blank. The transverse control arm includes a base body region with bearing regions formed thereon. A bearing journal is arranged in a bearing region with a material joint. The material joint is oriented in the direction of a longitudinal axis of the bearing journal, thereby providing a transverse control arm with high durability.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

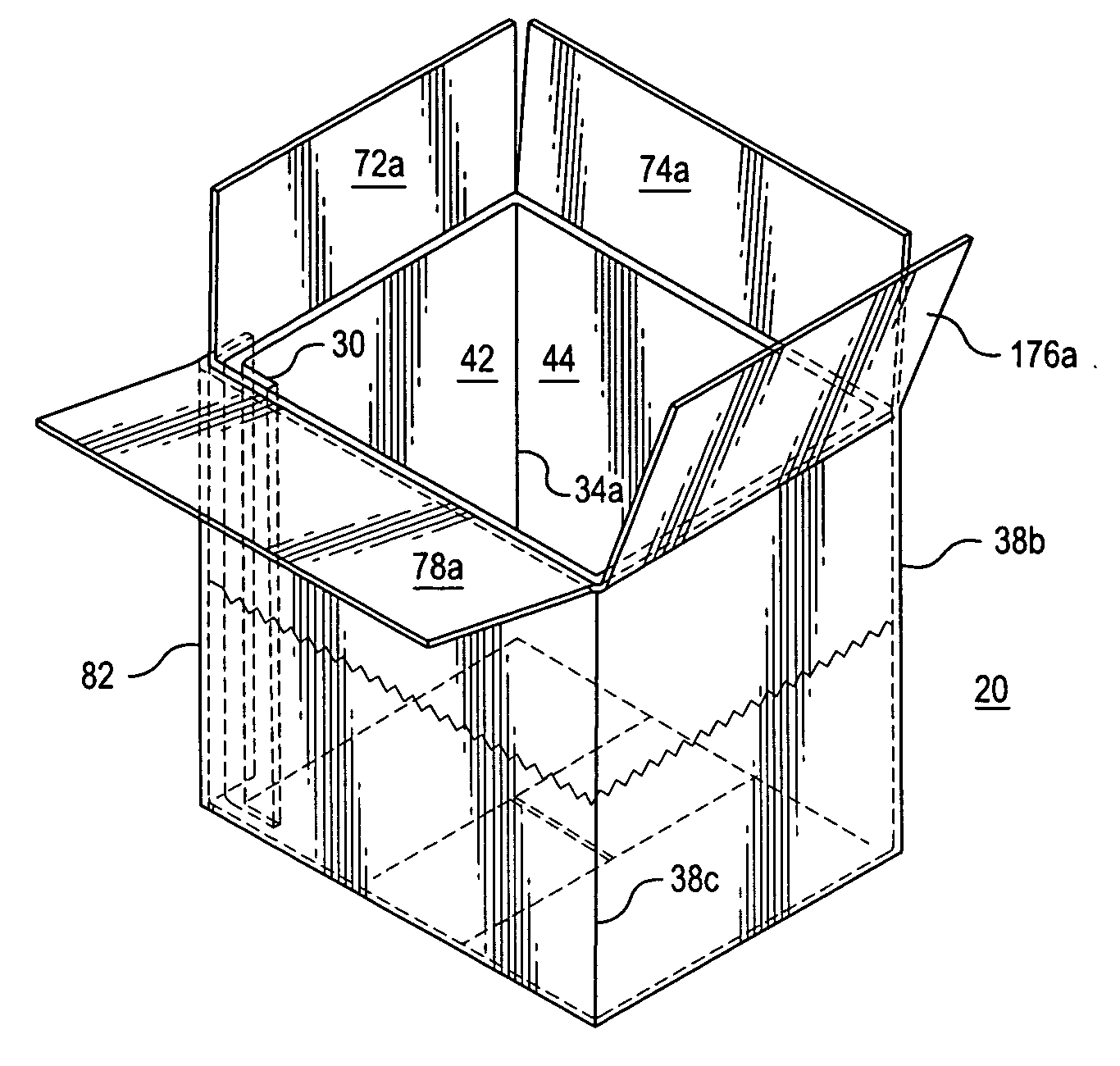

Methods for creating multi-walled containers and articles produced there from

InactiveUS20080054060A1Minimal wasteLess susceptible to tearing and breakageBoxes/cartons making machineryBox making operationsRest positionStress relief

Methods for making multi-walled containers from a single blank, preferably using a continuous process approach, and the resulting containers are disclosed. Various embodiments of the invention include, alone or in combination, intermediate panels formed from flap precursors that are in- or out-folded such that their distal ends are in proximate relationship to each other; outer flaps sized to overlap exposed edges of a container formed from the blank; stress relief features a joint corners to reduce stresses thereat. Methods for making select containers of the invention include folding and adhering the flap precursors to an inner panel, up-folding the inner panel / intermediate panel combination about a mandrel, and continuing to up-fold the outer panel until a container having a “use” position as a resting position is formed.

Owner:GREENFIELD BIN

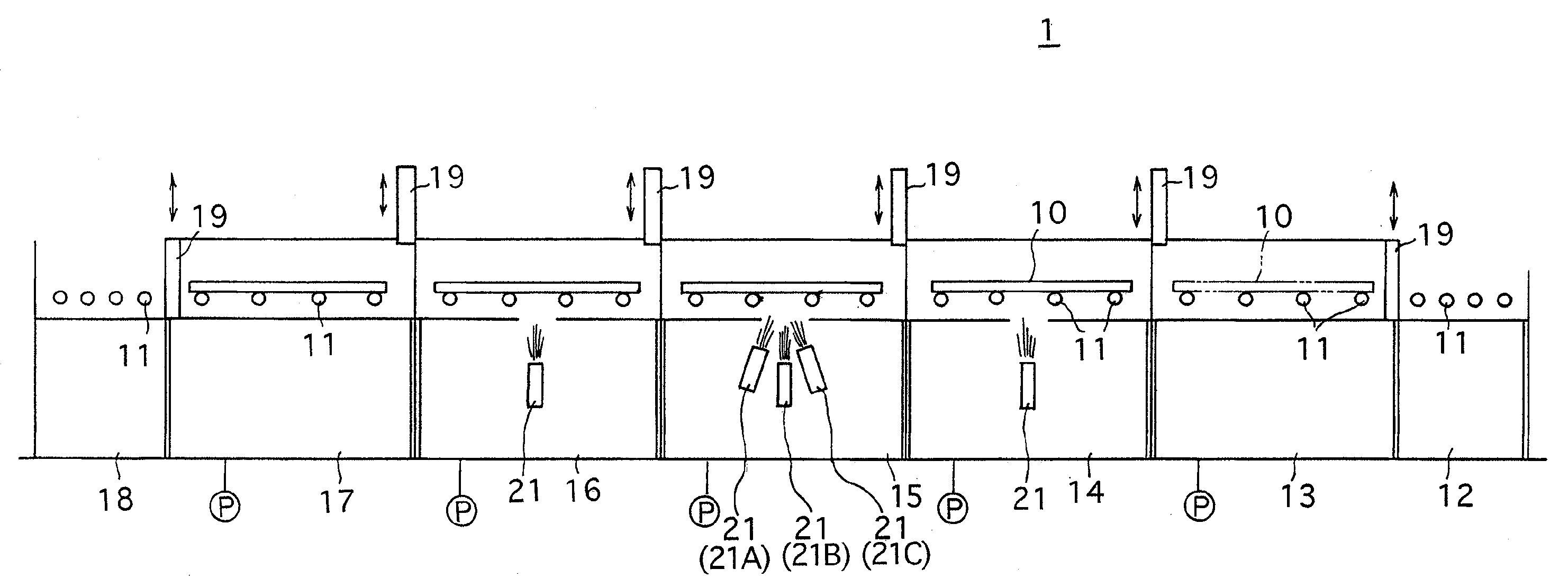

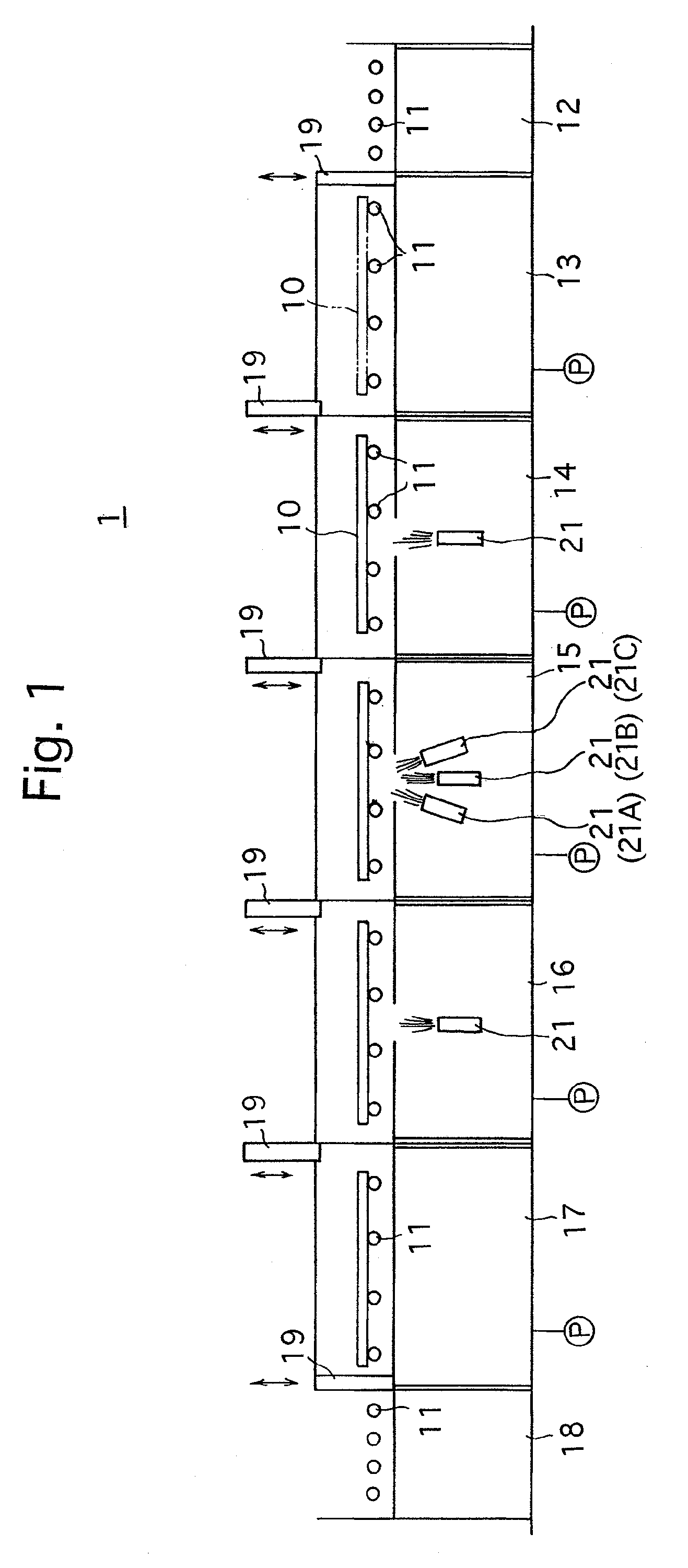

Successive vapour deposition system, vapour deposition system, and vapour deposition process

InactiveUS20080299296A1Effective timeMinimal wasteElectroluminescent light sourcesSolid-state devicesGas phaseChemistry

A successive vapor deposition system in which a vapor deposition material is heated, vaporized in a vacuum, and deposited onto a vapor deposition area of a substrate, includes a conveyer which conveys the substrate in a conveying direction parallel to a plane on which the substrate lies, wherein the vapor deposition area faces downward and is exposed through the underside of the conveyer; a plurality of vapor deposition chambers aligned in the conveying direction, each the vapor deposition chamber including a space through which the substrate is conveyed; at least one container positioned in each of the plurality of vapor deposition chambers below the plane on which the substrate lies, and containing the vapor deposition material, wherein a width of the container covers the vapor deposition area in a direction perpendicular to the conveying direction; and a heating medium provided for the container.

Owner:ROHM CO LTD

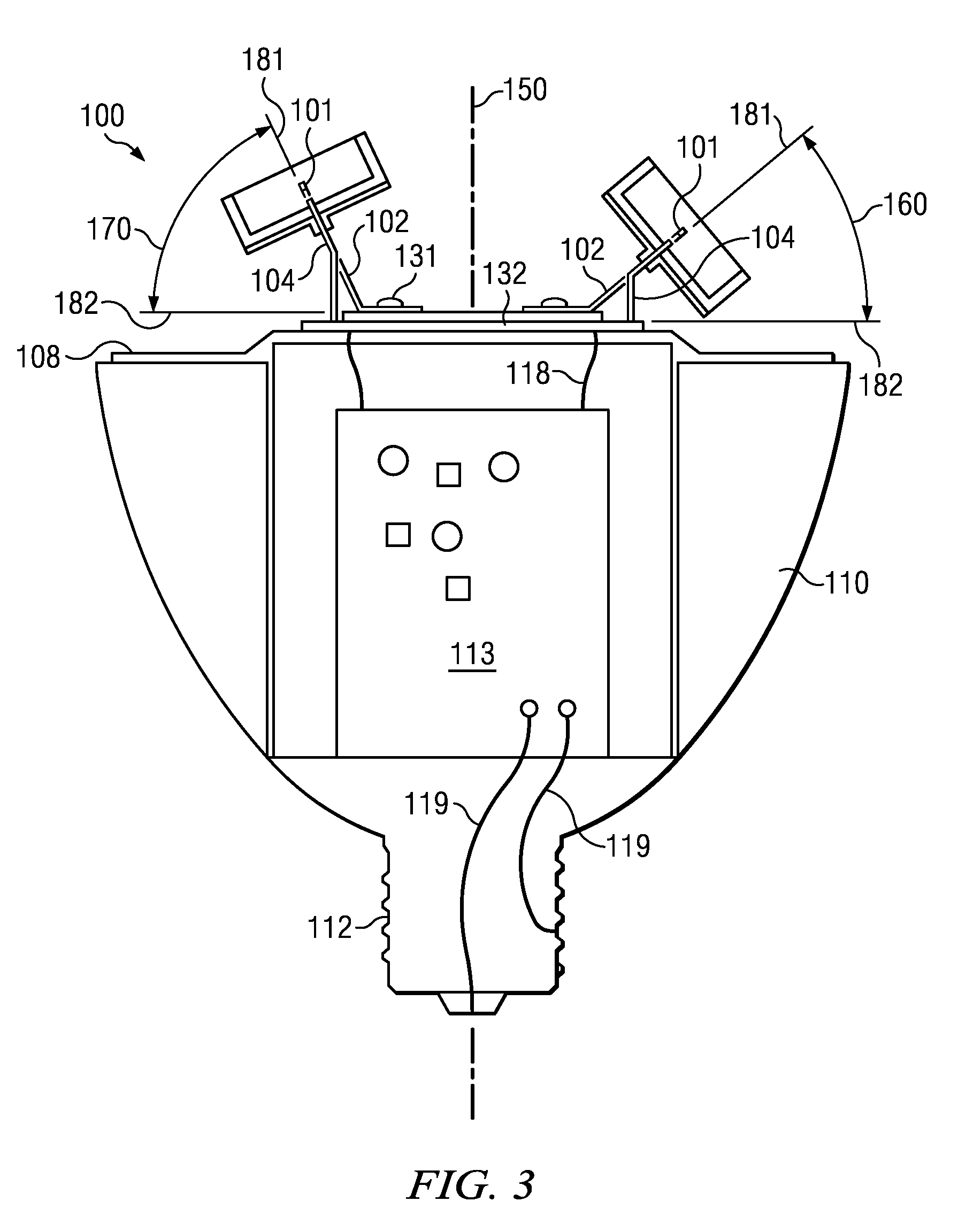

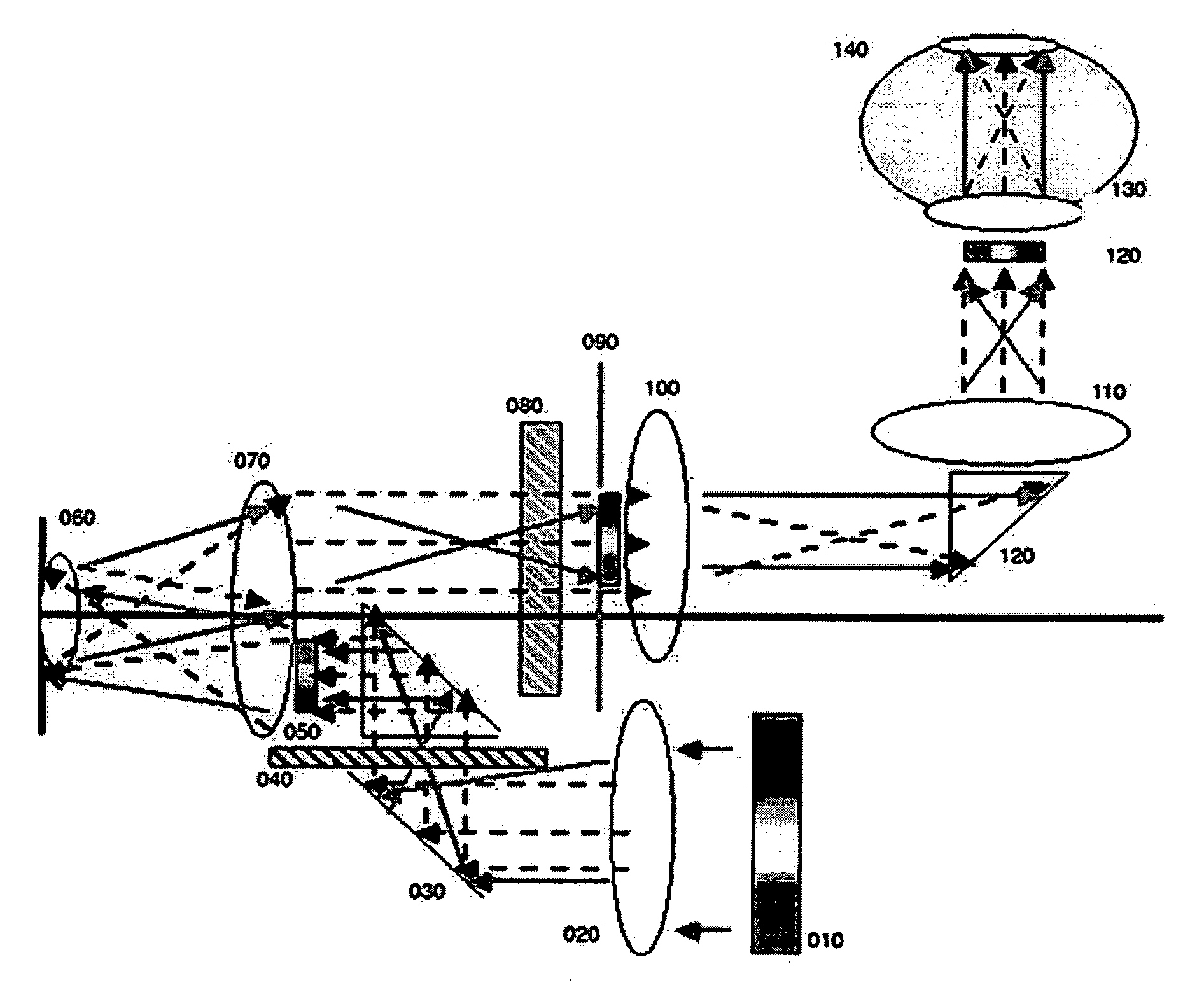

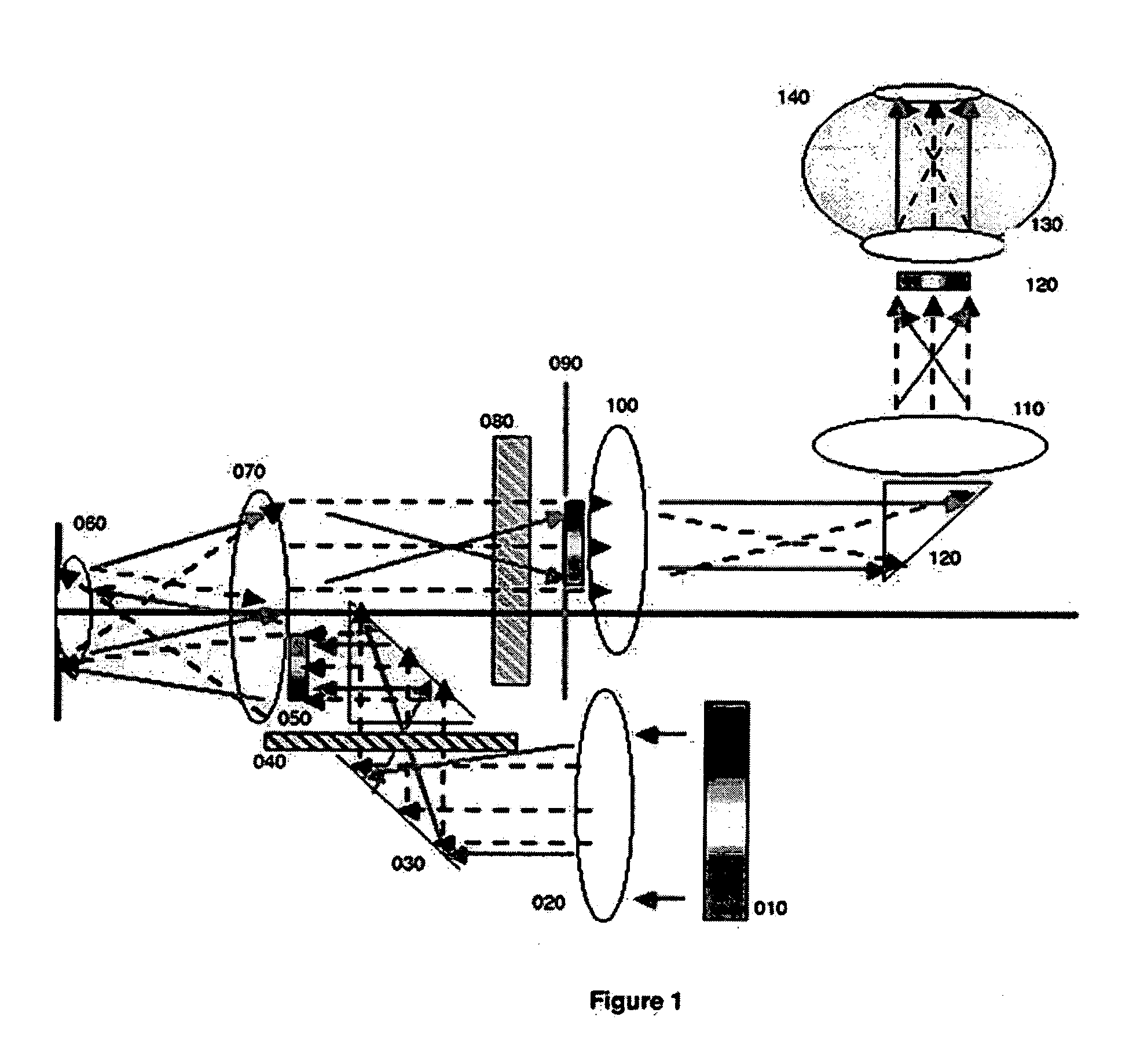

Actinic light colposcope and method to detect lesions in the lower female genital tract produced by human papilloma virus using an actinic light colposcope

The present invention involves an apparatus and method to detect lesions in the lower female genital tract produced by the Human Papilloma Virus using an actinic light colposcope. The apparatus of the present invention comprises mechanical, electrical and optical (also referred to herein as the actinic light) components. The method of the present invention comprises the general steps of: (1) illumination, (2) excitement, and (3) suppression. The method disclosed and claimed herein in the clinical context takes between 15 and 20 minutes and reliable results are obtained during the patient's office visit.

Owner:AVM LICENSING CORP

Serrated hand tool for plaster application

InactiveUS6167585AShorten the timeLower levelLiquid surface applicatorsBuilding constructionsEngineeringHand tool

A novel plaster application method includes the first step of applying the plaster in a plurality of parallel and spaced apart lines using a novel hand tool so that the upper edges of each plaster line define the plane of the final plaster surface. After allowing the plaster lines to dry and harden, the second step is to fill the spaces between the lines with more plaster forming the final plaster surface by raising the level of plaster to the plane of the final surface. More layers of plaster may be applied if needed. A serrated hand tool is proposed for aiding the plaster spreading which contains a plurality of generally triangular teeth with oval upper portions and blunt lower ends defining the distal edge of the tool. The new method allows a faster application of plaster in a construction practice with reduced consumption of plaster material.

Owner:FRIDMAN EMELIAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com