High-temperature lithium battery electrolyte

An electrolyte and lithium battery technology, which is applied in the field of high-temperature lithium battery electrolyte, can solve the problems of poor high-temperature performance of lithium-ion batteries, and achieve the effects of improving composition and thickness, improving high-temperature performance, and improving high-temperature conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

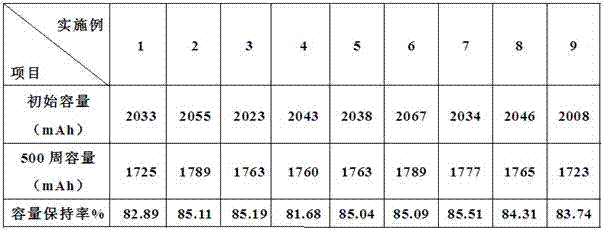

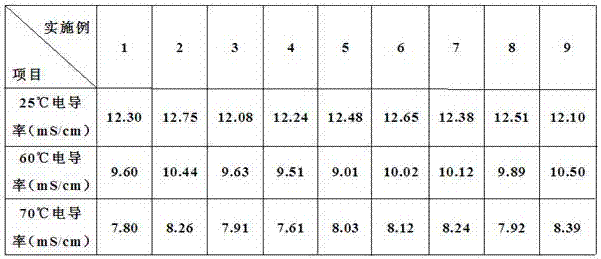

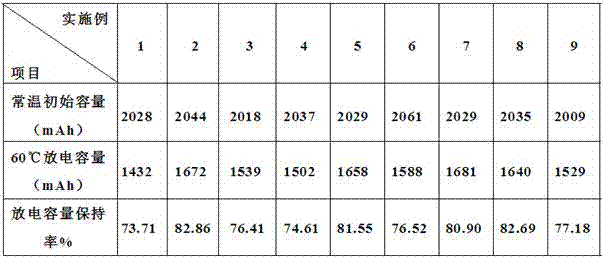

Examples

Embodiment 1

[0022] Add diethyl carbonate (DEC), ethylene carbonate (EC), and propylene carbonate (PC) in sequence according to the mass ratio of 65:32:5. When the temperature drops to 15°C, ensure that the temperature is not higher than 10°C Slowly add lithium salt to prepare an electrolyte solution with a lithium hexafluorophosphate concentration of 1.3mol / L, a lithium difluorosulfonimide concentration of 0.1mol / L, and a lithium difluorooxalate borate of 0.1mol / L, and continue stirring until the solution is clear, and then follow the Calculate the total mass of the electrolyte, add 3% fluoroethylene carbonate, stir well, transfer to a bottle filled with inert gas and store it for later use.

Embodiment 2

[0024] Add diethyl carbonate (DEC), ethylene carbonate (EC), and propylene carbonate (PC) in sequence according to the mass ratio of 65:32:5. When the temperature drops to 15°C, ensure that the temperature is not higher than 10°C Slowly add lithium salt to prepare an electrolyte solution with a lithium hexafluorophosphate concentration of 1.3mol / L, a lithium difluorosulfonimide concentration of 0.1mol / L, and a lithium difluorooxalate borate of 0.1mol / L, and continue stirring until the solution is clear, and then follow the Calculate the total mass of the electrolyte, add 2% sulfites, stir well, and transfer to a bottle filled with inert gas for storage.

Embodiment 3

[0026] Add diethyl carbonate (DEC), ethylene carbonate (EC), and propylene carbonate (PC) in sequence according to the mass ratio of 65:32:5. When the temperature drops to 15°C, ensure that the temperature is not higher than 10°C Slowly add lithium salt to prepare an electrolyte solution with a lithium hexafluorophosphate concentration of 1.3mol / L, a lithium difluorosulfonimide concentration of 0.1mol / L, and a lithium difluorooxalate borate of 0.1mol / L, and continue stirring until the solution is clear, and then follow the The total mass of the electrolyte is calculated by adding 2% vinylene carbonate, fully stirred, and transferred to a bottle filled with inert gas for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com