Doped crosslinking chemical stable ion exchange membrane and preparation method thereof

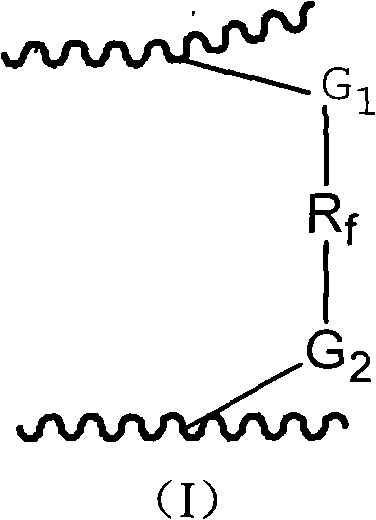

A technology of ion exchange membrane and exchange resin, which is applied in the field of functional polymer composite materials, and can solve the problems of reduced membrane strength and decreased equivalent value of perfluoropolymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

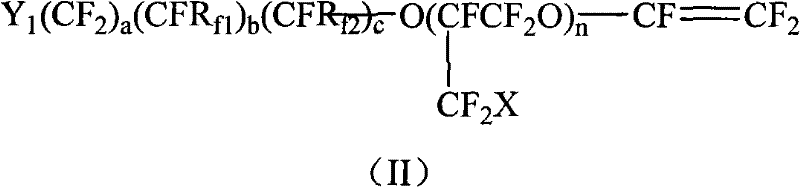

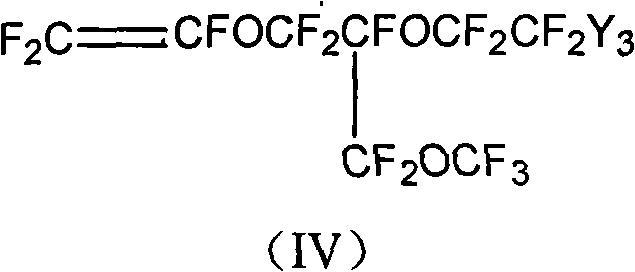

[0095] Convert the repeating unit to

[0096]

[0097] polymer resin (EW=1200) and Zr(HPO 4 ) 2 Mix by 100:5 (mass ratio), then add a small amount of perfluoromalonyl peroxide and Ce 2 o 3 Powder (accounting for 0.1% of the mass of the resin), hot-pressed to form a film, and then put the film in H2O with a molar concentration of 0.5M 2 SO 4 The solution was boiled for 1 hour and washed with deionized water. After heat treatment, the membrane was treated with alkali solution and acid solution in turn to obtain the free radical degradation substance Ce 2 o 3 Modified perfluorosulfonic acid-doped cross-linked chemically stable ionic membrane with a thickness of 50 μm.

Embodiment 2

[0099] The polymer tree in Example 1, 1,2-diiodotetrafluoroethane, SiO 2 (particle size is 0.03μm, mass ratio to resin is 15:100), perfluorosuberoyl peroxide and Mn(OH) 2 Powder (Mn(OH) 2 The addition amount is 1.5% of the mass of the resin) after being fully mixed, heat-treated at 100° C. for 45 minutes, and then melt-extruded to obtain a film with a thickness of 100 μm. Finally, the membrane is sequentially treated with alkaline solution and acid solution to obtain a perfluorosulfonic acid cross-linked doped ion membrane modified by a free radical scavenger Mn ion.

Embodiment 3

[0101] The polymer resin of embodiment 1, H 3 PW 12 o 40 According to the ratio of mass ratio 100: 1, the polymer resin ethylene glycol solution that the mass concentration is 7% is made, then manganese nitrate (III) is added in the solution, the quality of manganese nitrate accounts for 0.05% of the resin mass, and the Method A film with a thickness of 30 μm was prepared at 170° C. for 60 minutes. Then the membrane is cross-linked by 50KGy radiation to obtain a perfluorosulfonic acid cross-linked doped ion membrane modified by a free radical scavenger Mn ion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com