Horizontal continuous annealing device for tempered glass

The technology of tempered glass and annealing device is applied in the field of tempered glass production equipment, which can solve the problems of difficulty in fully utilizing internal heat, reduce the efficiency of tempered glass annealing, increase the cost of tempered glass annealing, etc., so as to improve the utilization of human resources and increase the temperature conduction. effect, the effect of improving the transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

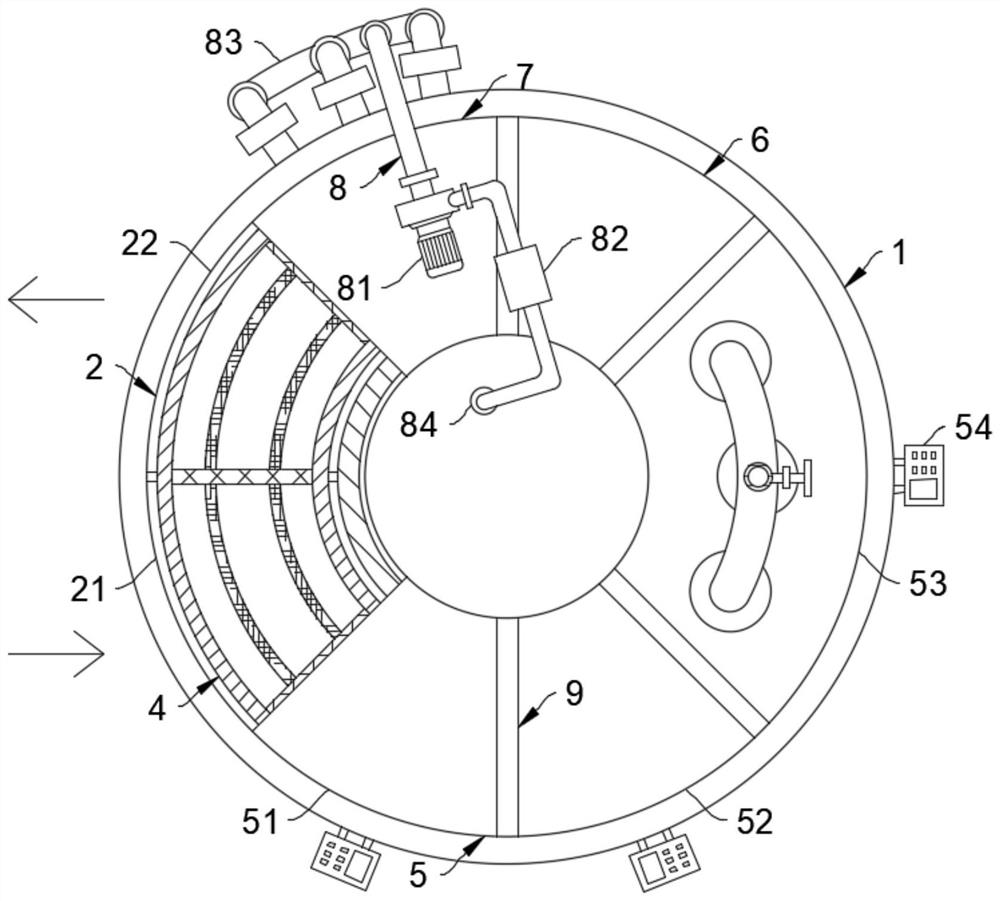

[0032] Such as Figure 1-4 As shown, a tempered glass horizontal continuous annealing device includes a sealed chamber 1. The sealed chamber 1 is provided with an opening 2. The opening 2 is used for feeding and unloading the tempered glass. It should be noted that the opening 2 includes a feed port 21 and the discharge port 22, the feed port 21 and the discharge port 22 are arranged in the same direction of the sealed chamber 1, which is convenient for the staff to load and unload the tempered glass.

[0033] When the device is annealing the toughened glass, the loading and unloading of the toughened glass is directly carried out at the opening 2 position at the same time, and the loading table and the unloading table are correspondingly arranged at the positions of the material inlet 21 and the material outlet 22, which is convenient for work personnel operations.

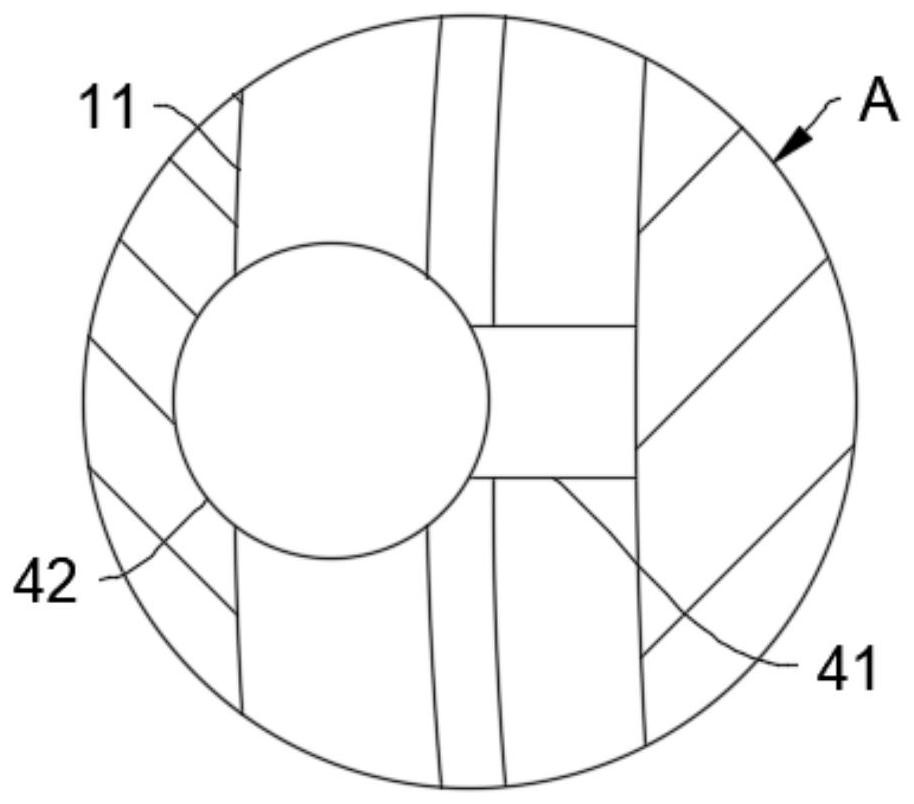

[0034] The sealing chamber 1 is connected with the support plate 4 through the rotation of the motor 3, and t...

Embodiment 2

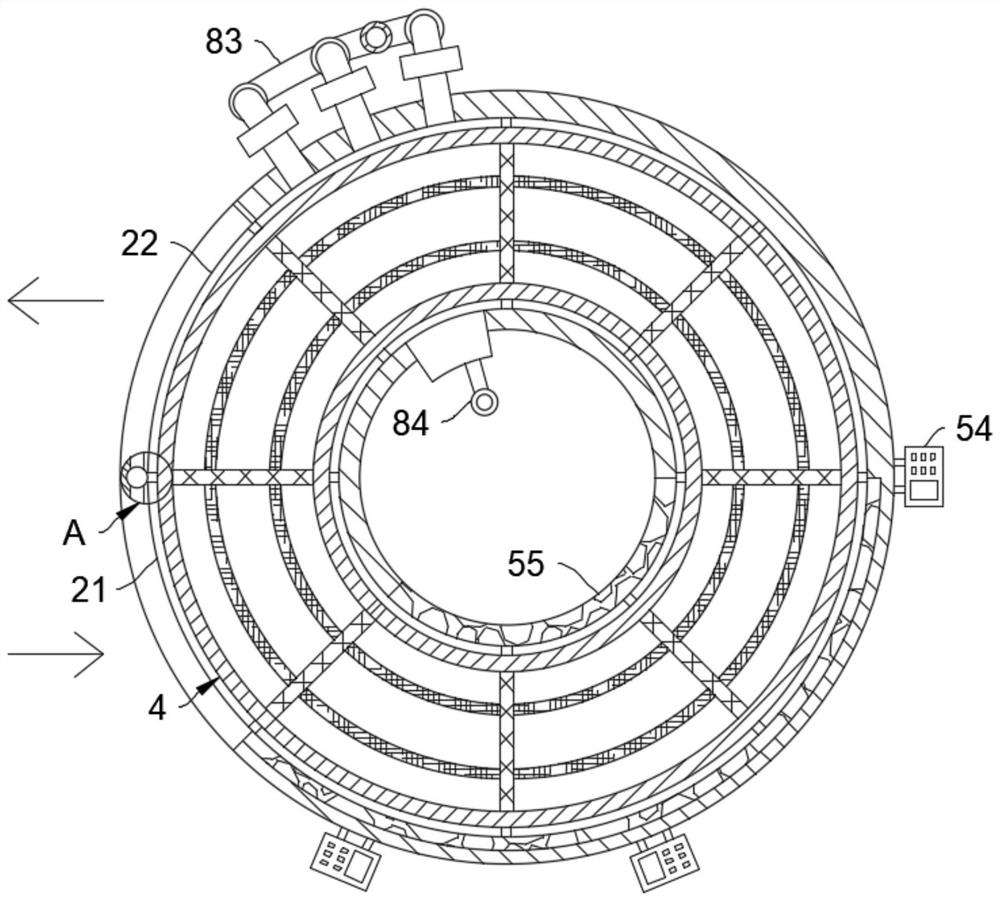

[0050] Such as Figure 5 Shown, the difference between this embodiment and embodiment 1 is:

[0051] One group of heat insulating boards 9 is symmetrically provided with a heat conduction layer 91, one end of the heat conduction layer 91 communicates with the cooling chamber 7, the other end of the heat conduction layer 91 communicates with the annealing chamber 6, and multiple groups of adjacent heat conduction layers 91 are arranged. Thermoelectric sheet 92, thermoelectric sheet 92 and motor 3 are connected and arranged, it is worth mentioning that the temperature difference received by both sides of heat shield 9 between annealing chamber 6 and cooling chamber 7 is the largest, and thermoelectric sheet 92 can effectively Utilize the energy of the cooling chamber 7 and the annealing chamber 6, convert this energy into electric energy and send it to the motor 3, reduce the electric energy consumption generated during the operation of the equipment, and improve the resource ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com