Patents

Literature

110results about How to "Not prone to oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Azacitidine freeze-drying powder injection and preparation method thereof

InactiveCN101632643ANot prone to oxidationLong storage timePowder deliveryOrganic active ingredientsVitamin CMANNITOL/SORBITOL

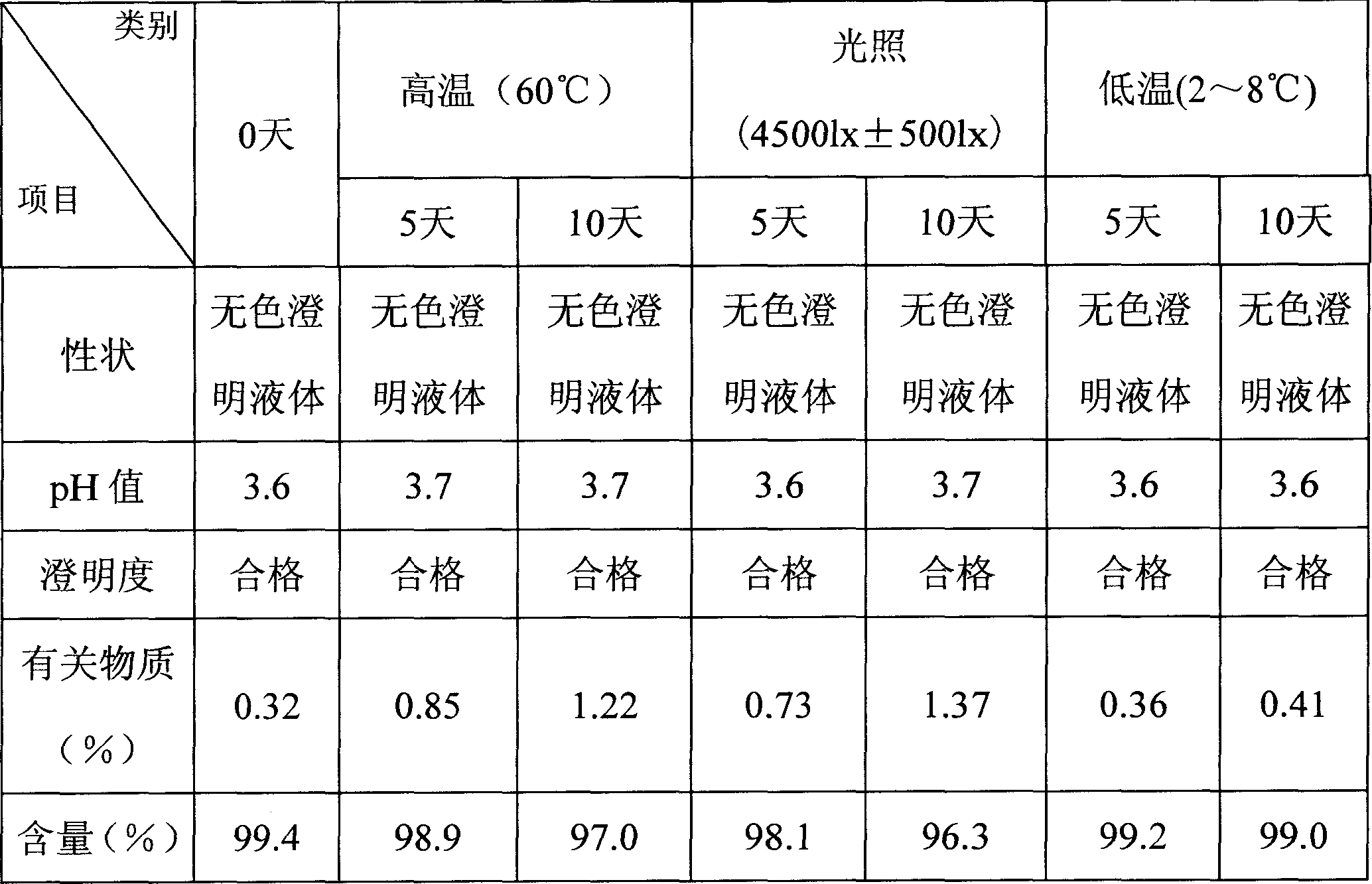

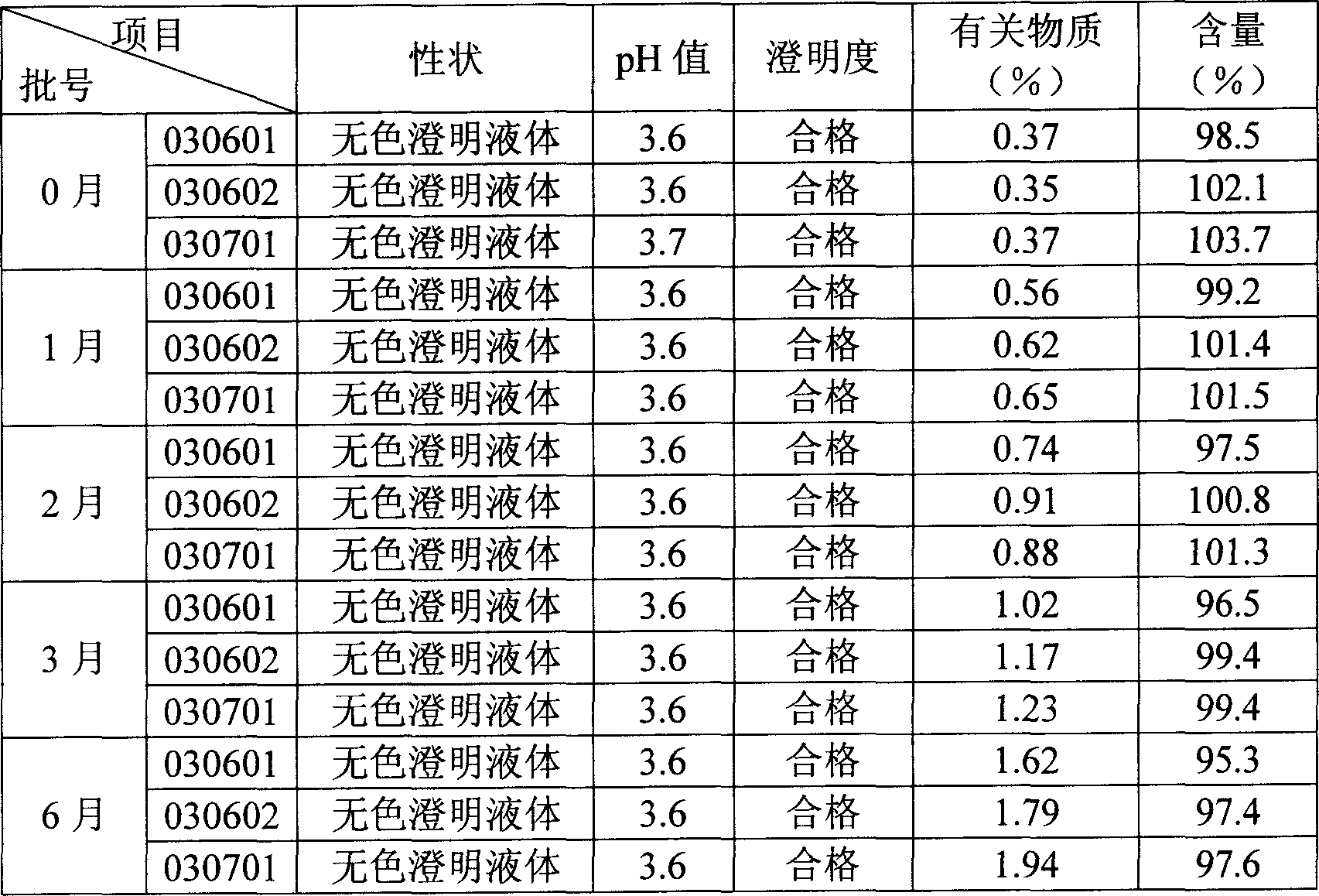

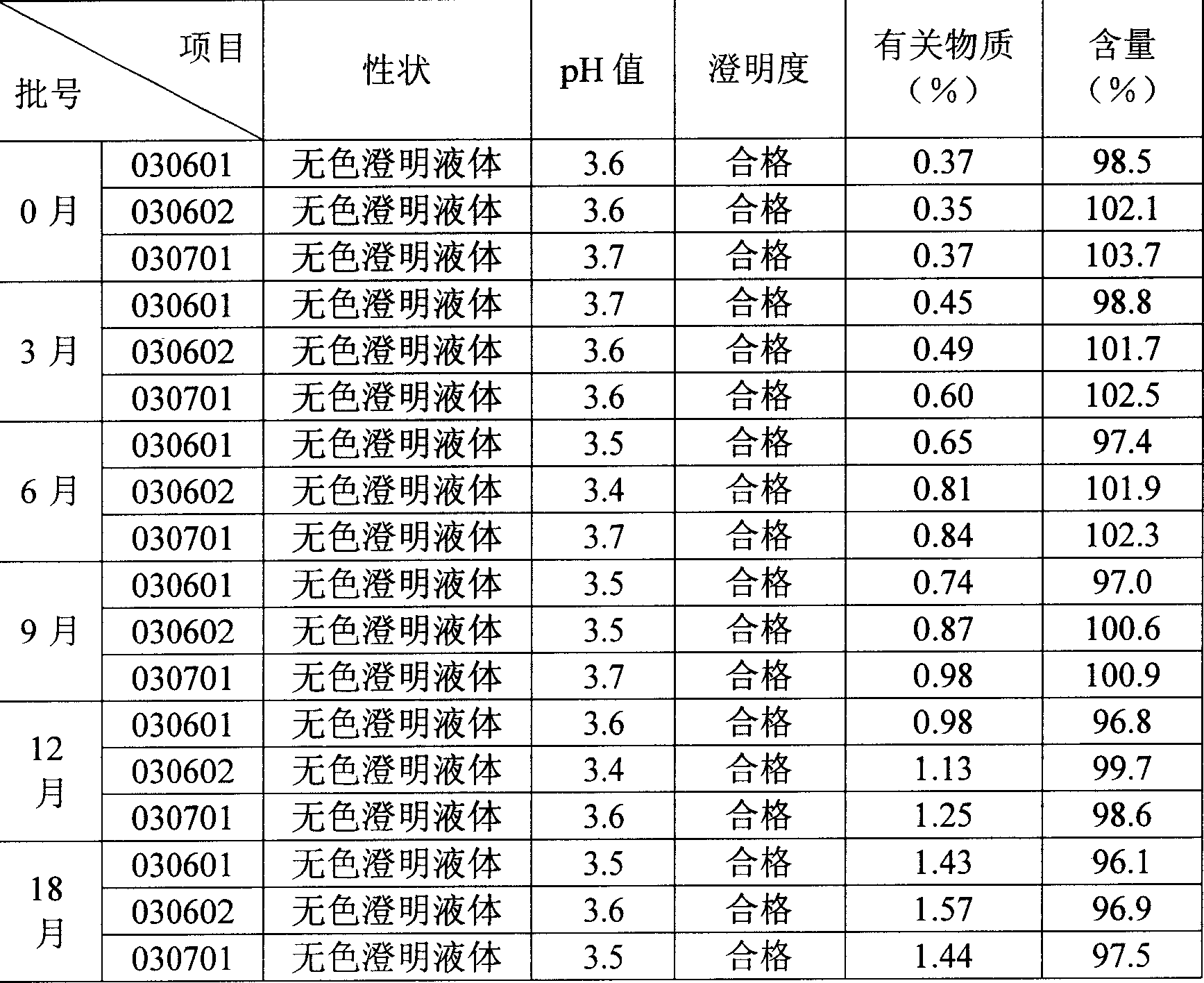

The invention discloses a medicinal azacitidine freeze-drying powder injection for treating myelodysplastic syndrome and a preparation method thereof. The prescription of the azacitidine freeze-drying powder injection comprises azacitidine, mannitol and vitamin C. The invention solves the problem of rapid impurity increase caused by different crystal forms formed in the processes of rapidly freezing and drying the prior powder injection by optimizing the prescription and improving the preparation method.

Owner:HANGZHOU XIANDA MEDICINE TECH

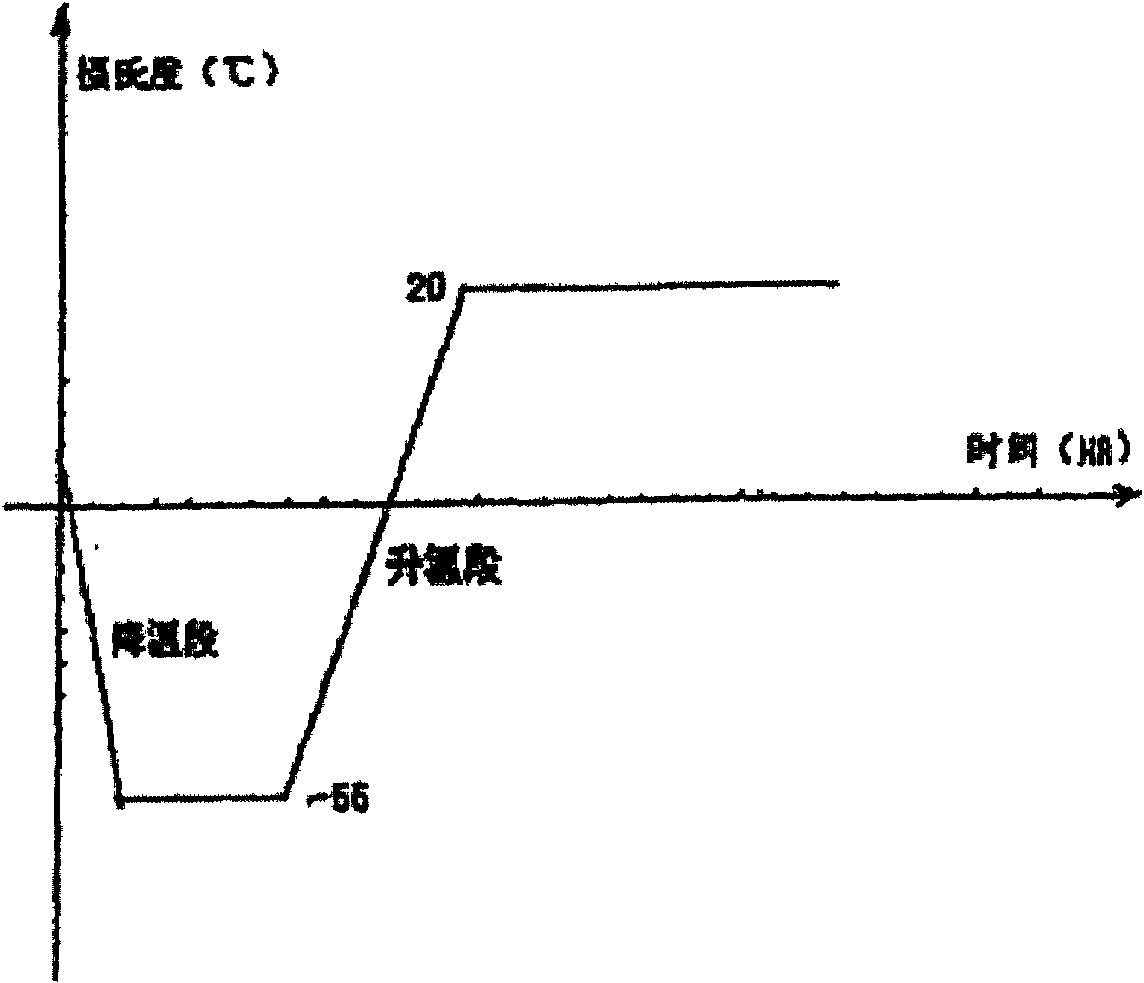

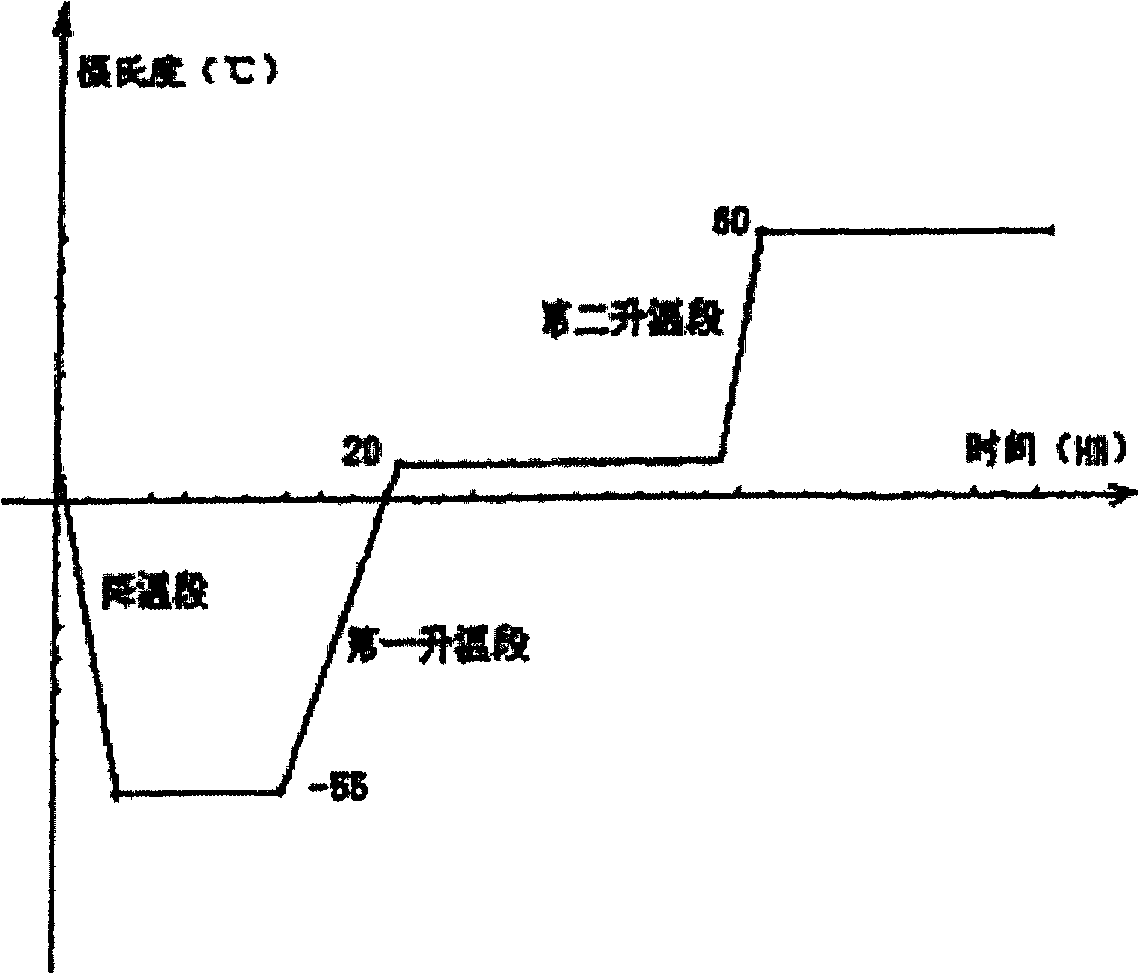

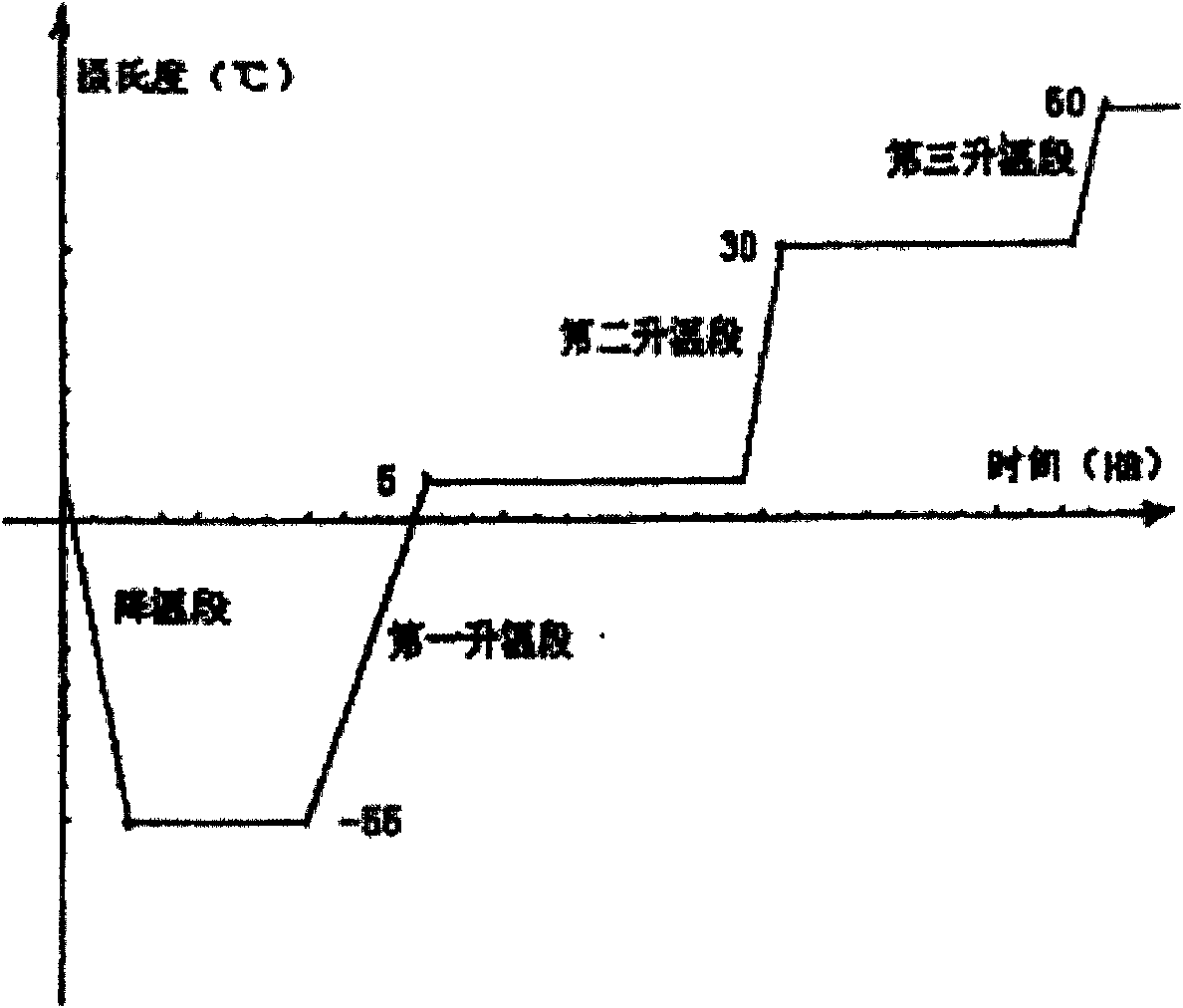

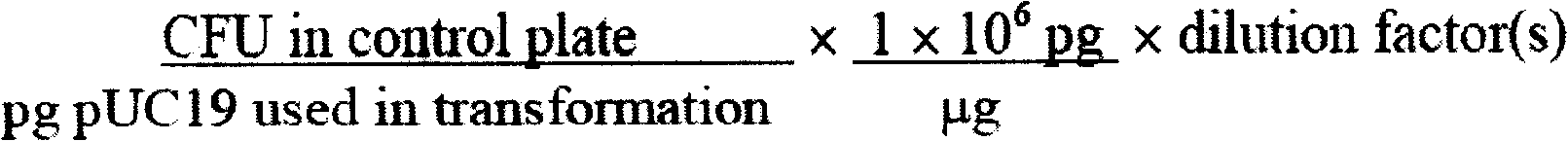

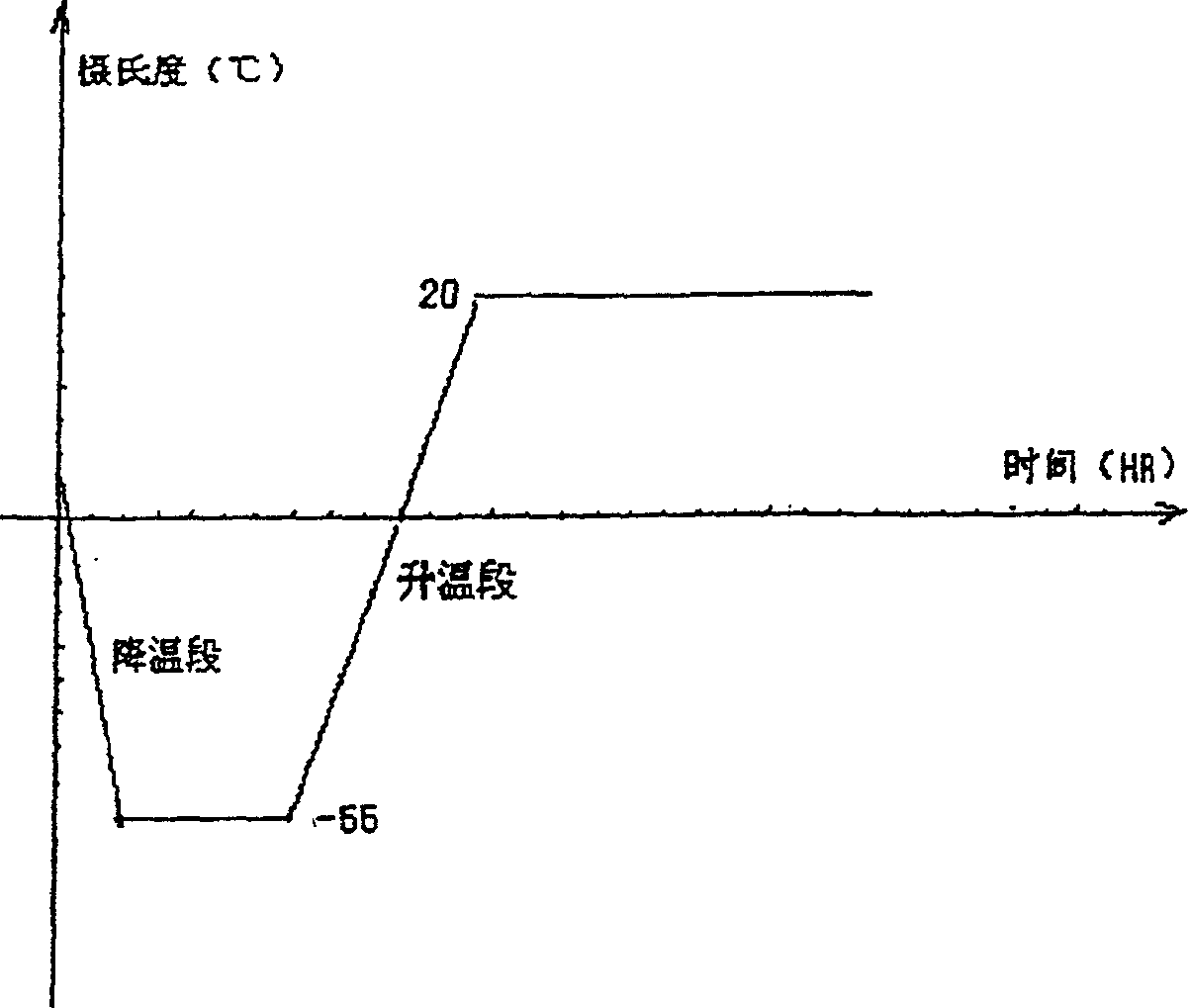

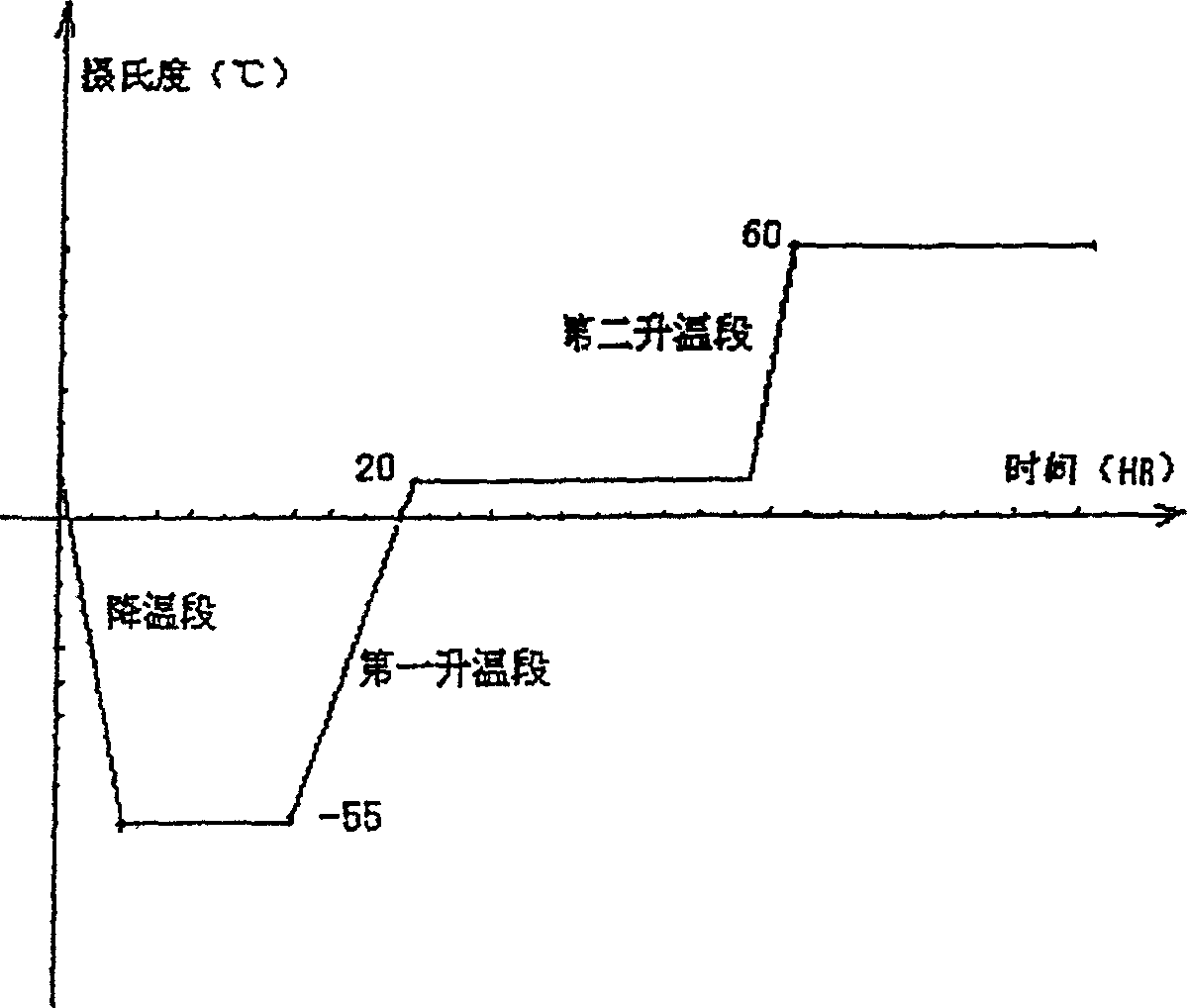

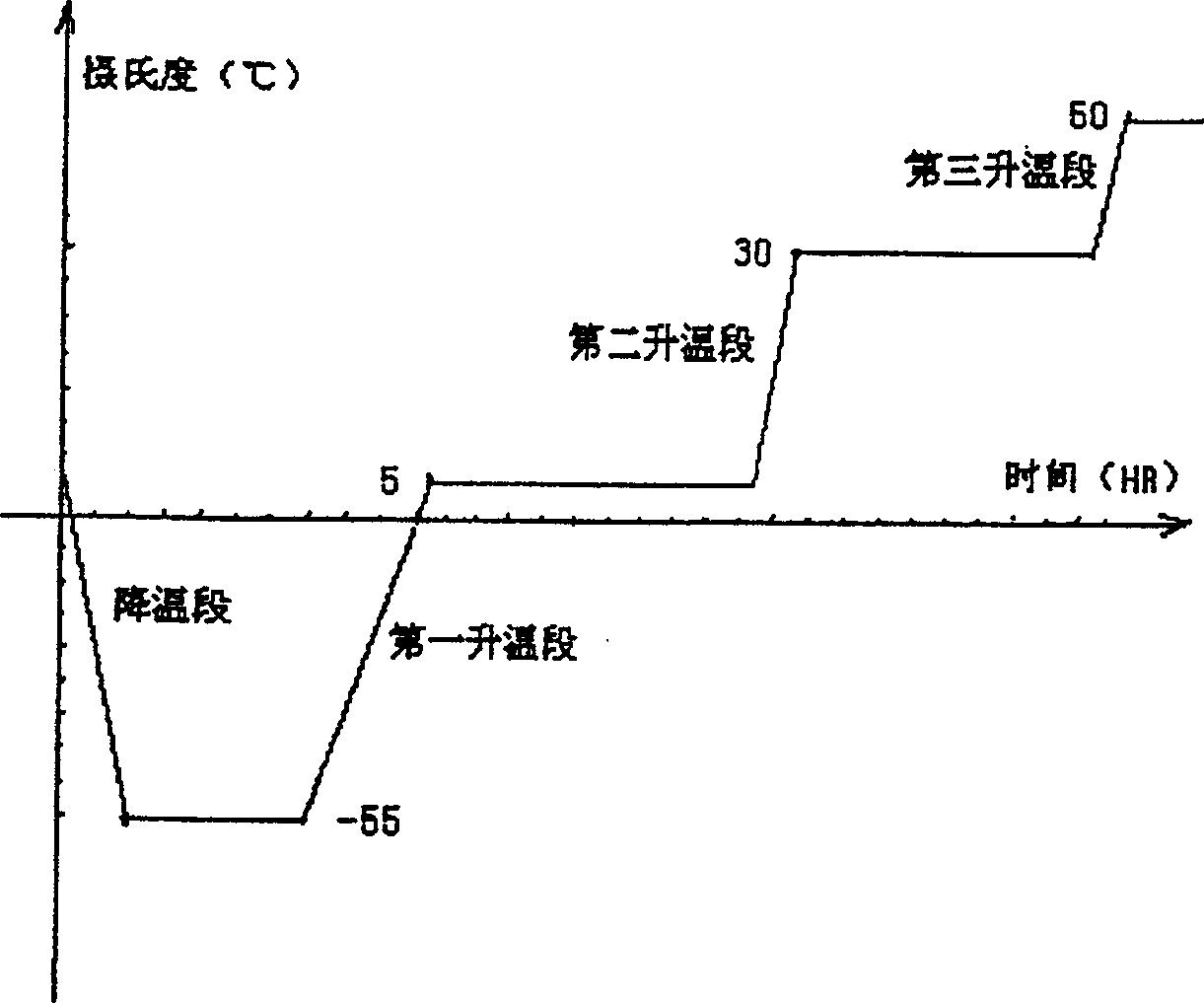

Production technology for preparing freeze-drying genetic engineering bacterium competence cell and protective agent formula

InactiveCN101264062AReduce moisture contentNot prone to oxidationPowder deliveryGenetic material ingredientsBiotechnology researchFreeze-drying

The invention discloses a manufacturing technique for preparing frozen-out gene engineering bacteria competent cells. The invention also relates to a prescription of protecting agent, which is wide in application by taking as the host bacteria for transferring outer DNA in researching, developing, producing and checking of biotechnology. The protecting agent is one of the most fundamental matching consumption preparations. The invention utilizes vacuum freeze drying technology to deal with the poor gene engineering bacteria competent cells, and can save the cells steadily at a wide temperature range of 20 DEG C below zero to 4 DEG C for long time while keeping high transformation efficiency. The invention enables the cells to store and long-distance transport conveniently. The invention relates to a manufacturing technique for preparing frozen-out competent cells, quality inspection regulation and the frozen-out protecting agent, comprising culture conditions of gene engineering bacteria, technological processes of freezing and drying and the composition and matching of the protecting agent. The protecting agent is formed by water and one or arbitrary combination of the following materials: gelatin, degreasing milk, dextran, trehalose, sucrose, sorbitol or mannitol.

Owner:袁红杰 +2

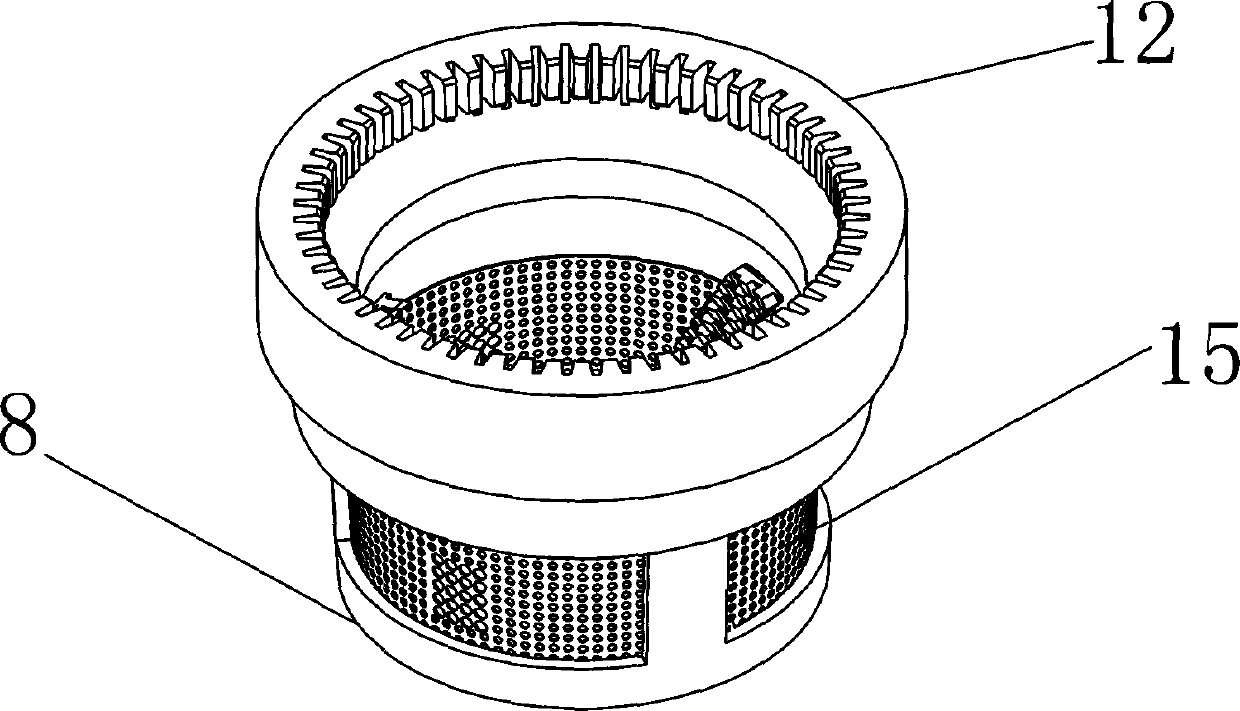

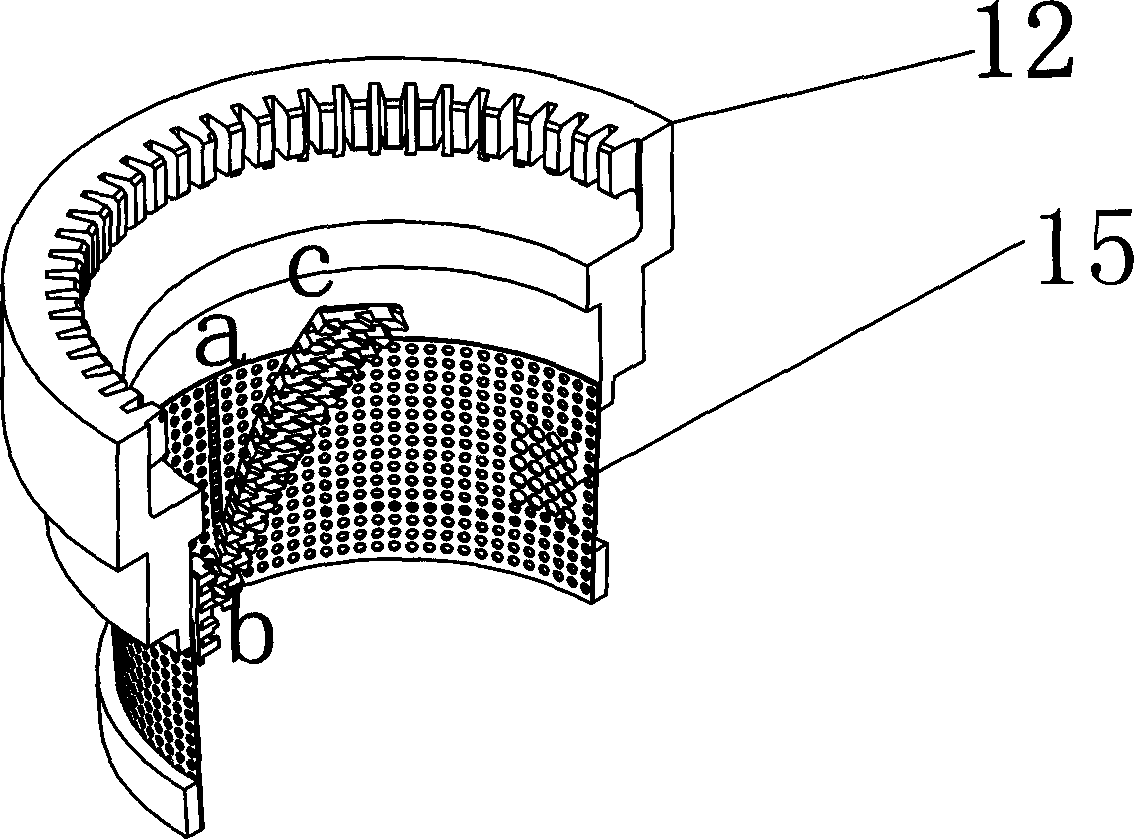

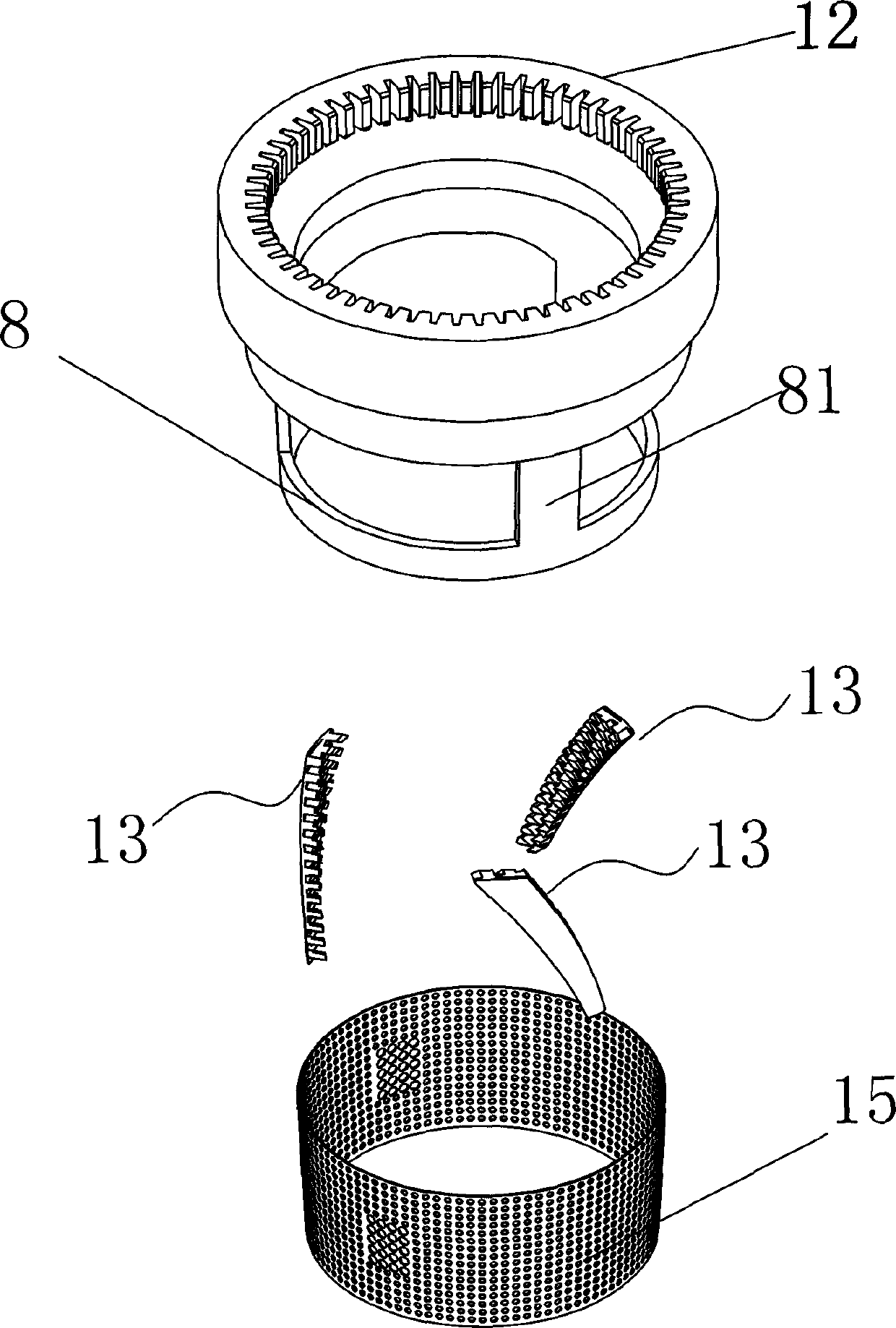

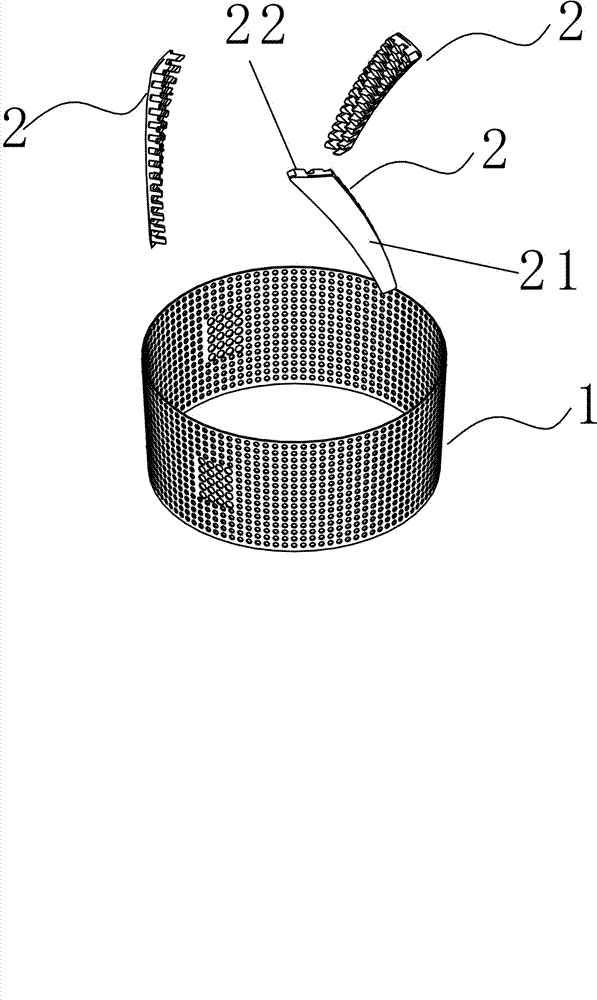

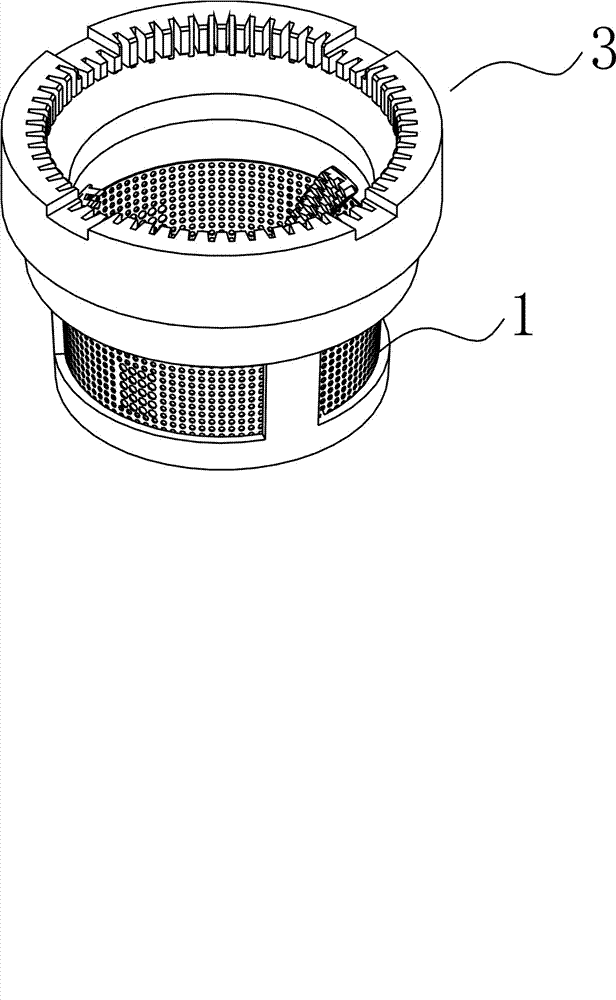

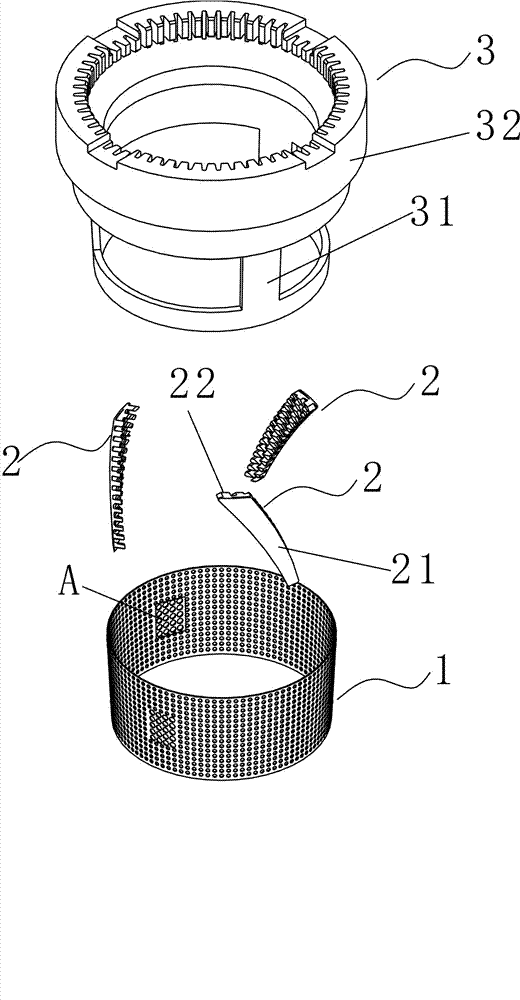

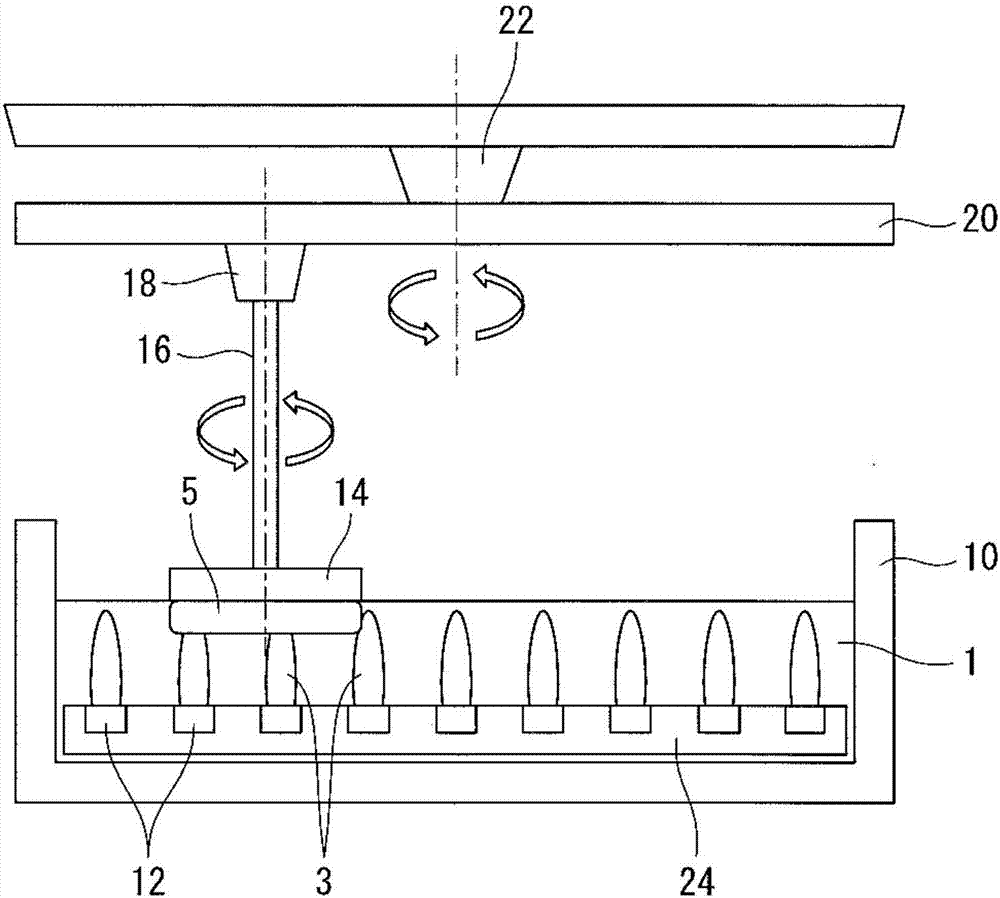

Filter screen mechanism and fruit and vegetable squeezing and grinding machine using same

The invention belongs to the field of a fruit and vegetable machine and particularly discloses a filter screen mechanism for a fruit and vegetable squeezing and grinding machine. The filter screen mechanism comprises an upper filter screen and a lower filter screen; a middle ring screen is also arranged between the upper filter screen and the lower filter screen; the middle ring screen is fixedly provided with a shielding ring; the shielding ring is provided with a plurality of notches; the notches are positioned in a mesh region of the middle ring screen; and the aperture of each mesh of the middle ring screen is respectively greater than those of each mesh of the upper filter screen and each mesh of the lower filter screen. The invention also discloses the fruit and vegetable squeezing and grinding machine utilizing the filter screen mechanism, which comprises the filter screen mechanism and a screw drive mechanism. The screw drive mechanism comprises a screw and a center shaft; the center shaft is connected with the screw; the screw is connected with a motor shaft; the screw is a spinning-cone-shaped sphere with a small upper part and a big lower part; the outer surface of the sphere is provided with a helix-shaped convex strip; the center shaft of the screw is coincided with a center shaft of the upper filter screen; gaps are formed between the edge of the screw and the inner walls of the upper filter screen, the middle ring screen and the lower filter screen; and fruits rotate along with the screw in the gaps to be processed. The filter screen mechanism and the fruit and vegetable squeezing and grinding machine have the advantage of multiple functions.

Owner:杭州富阳正易工贸有限公司

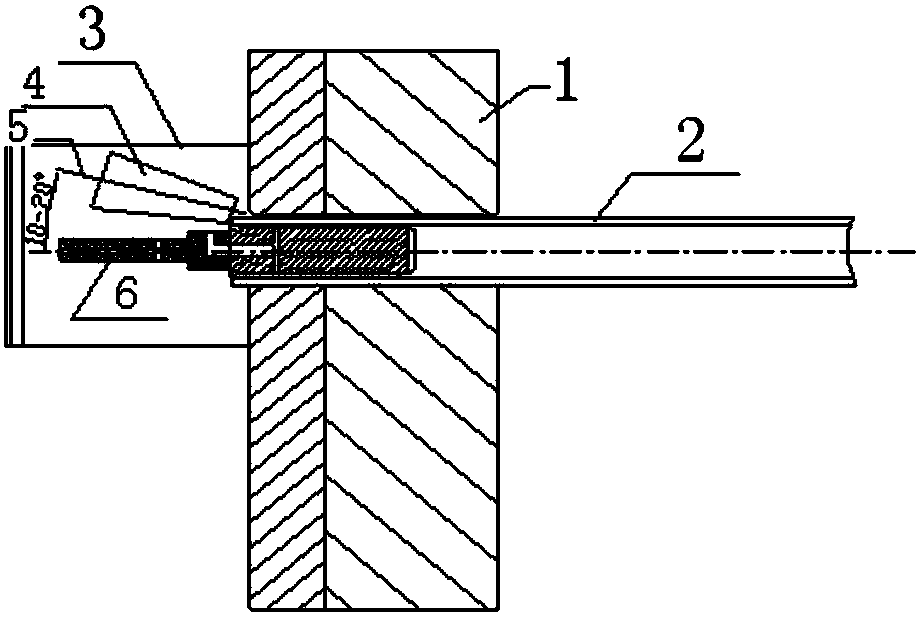

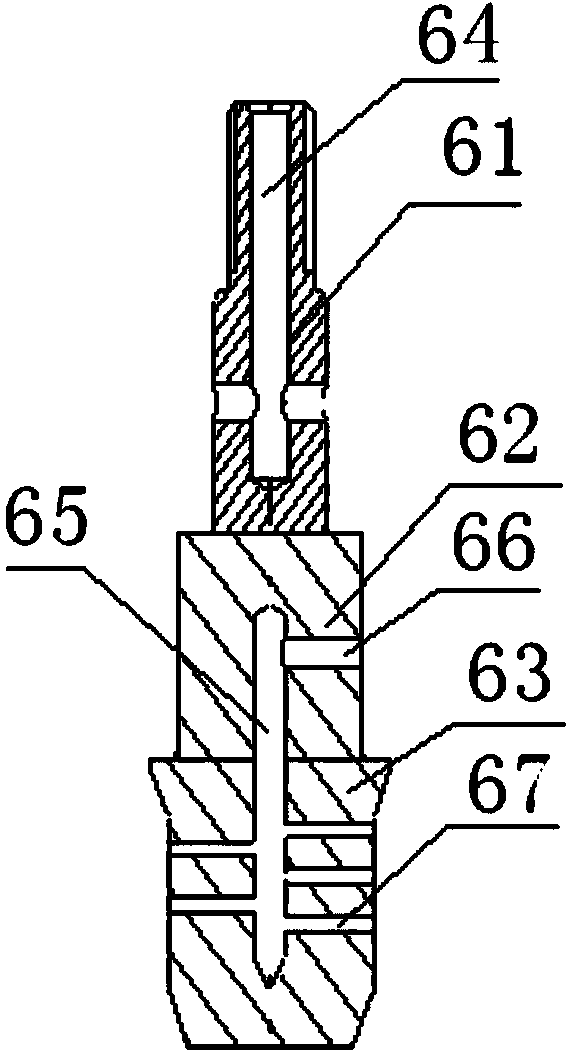

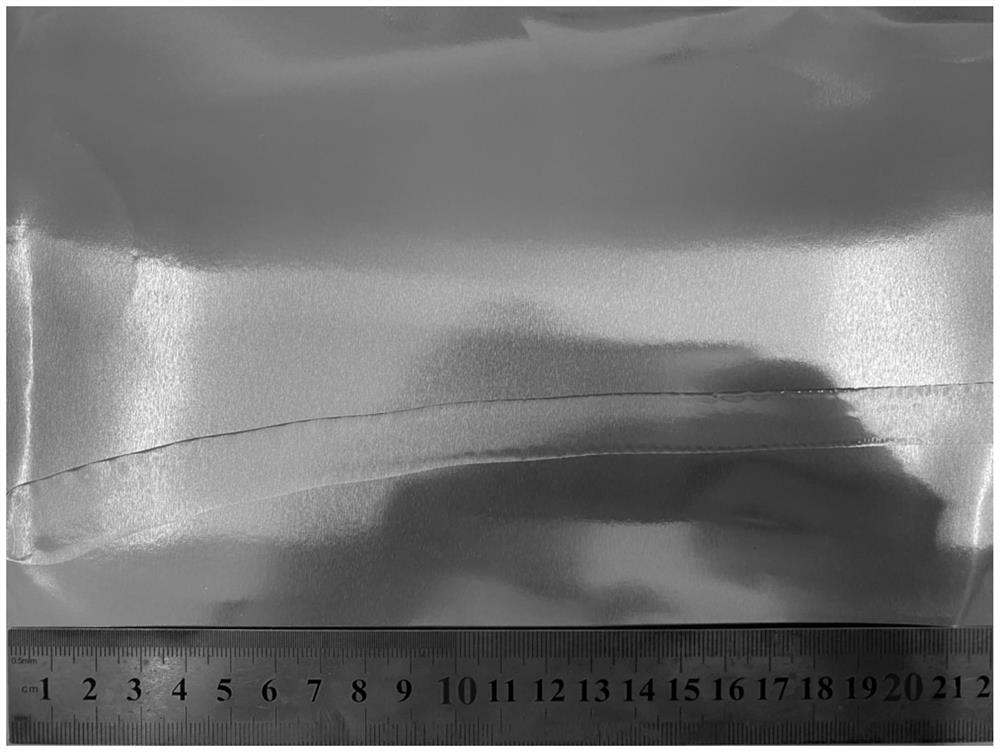

Welding method for titanium tube with ultra-thin wall

InactiveCN103817415AFusion wellReduce gasHeat exchange apparatusWelding/soldering/cutting articlesEngineeringTitanium

The invention belongs to the field of welding, and particularly relates to a welding method for a titanium tube with an ultra-thin wall. The welding method comprises the following steps: a hole is drilled in a tube plate, and a heat exchange tube and the tube plate are assembled after the ends of the heat exchange tube are cleaned, wherein it is guaranteed that the length of the portion, extending out of the tube plate, of the heat exchange tube ranges from 1mm to 2mm, and the distance between the outer wall of the heat exchange tube and the pore wall of the tube is not larger than 0.15mm; a tube plate automatic welding machine is adopted, and argon shields are formed on both the outer wall and the inner wall of the heat exchange tube; the purity of argon reaches 99.999 percent, so that the argon is high-purity argon, and a welding gun is closely attached to a workpiece to conduct all-position welding. According to the welding method for the titanium tube with the ultra-thin wall, gas shields are formed on both the outer wall and the inner wall of a tube in the welding process, so that welding gas is synchronous with gas inside the tube and gas outside the tube, the gas is saved, and oxidation does not occur easily in the welding process; by the adoption of the welding method, a heat exchange tube with the wall thickness being equal to or smaller than 0.8mm can be welded, the heat exchange tube and the tube plate are well fused after being welded, and a leakage does not easily occur in a striking and pressing process.

Owner:SMARTHEAT SHENYANG HEAT PUMP TECH

Method for preparing functional grease rich in phytosterol ester and diglyceride

ActiveCN103352067ANot prone to oxidationSimple and fast operationFatty acid esterificationHydrolasesAntioxidantEvaporation

The invention relates to a method for preparing functional grease rich in phytosterol ester and diglyceride. The method is characterized by comprising the following steps of: (1) adding reaction raw materials: adding phytosterol, triglyceride, a reaction solvent and molecular sieves into a reaction kettle in a manner that the mole ratio of the phytosterol to the triglyceride is 1: 2 to 1: 6, the proportioning ratio of the phytosterol to the reaction solvent is 100-200mmol: 1L, and the added amount of the molecular sieves is 50 g / L, thereby obtaining a premix; (2) carrying out non-aqueous enzymatic transesterification reaction: adding 5-20 g / L of lipase into the premix, adding 100-200ppm of antioxidant, and carrying out stirring reaction for 8-12 h at the temperature of 50-65 DEG C and normal pressure; and (3) carrying out after-treatment on a product: after the reaction is completed, carrying out centrifugation so as to remove the lipase and the molecular sieves, and carrying out rotary evaporation under reduced pressure so as to remove the reaction solvent, thereby obtaining the functional grease rich in phytosterol ester and diglyceride. The method has the advantages that the functional grease rich in two nutritional active ingredients can be obtained through one-step reaction, the product does not need separation and purification, and the operation is simple and convenient.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Method for producing functional grease containing rich phytosterin ester from high-acid-value vegetable oil

ActiveCN104178531ARealize the processing effectRealize high-value utilizationFermentationOil and greaseVegetable oil

The invention relates to a method for producing functional grease containing rich phytosterin ester from high-acid-value vegetable oil. The method is characterized by comprising the following steps: (1) addition of reaction raw materials: adding phytosterin, high-acid-value grease and molecular sieve into a reaction kettle, adding 100-200ppm of antioxidant, heating to 45-60 DEG C, stirring and carrying out ultrasonic treatment to obtain a premixture, wherein the mole ratio of the phytosterin to free fatty acids in the high-acid-value grease is 1:1-5:1; (2) enzymatic ester exchange reaction: adding 5-40 g / L lipase into the premixture, and stirring to react at 45-60 DEG C under normal pressure for 6-12 hours; and (3) carrying out after-treatment on the product to obtain the functional grease containing rich phytosterin ester. The method can obviously lower the acid value of the high-acid-value vegetable oil and generate the new functional active component phytosterin ester, and the product is simple for separation and purification; and thus, the method can easily implement large-scale amplification.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

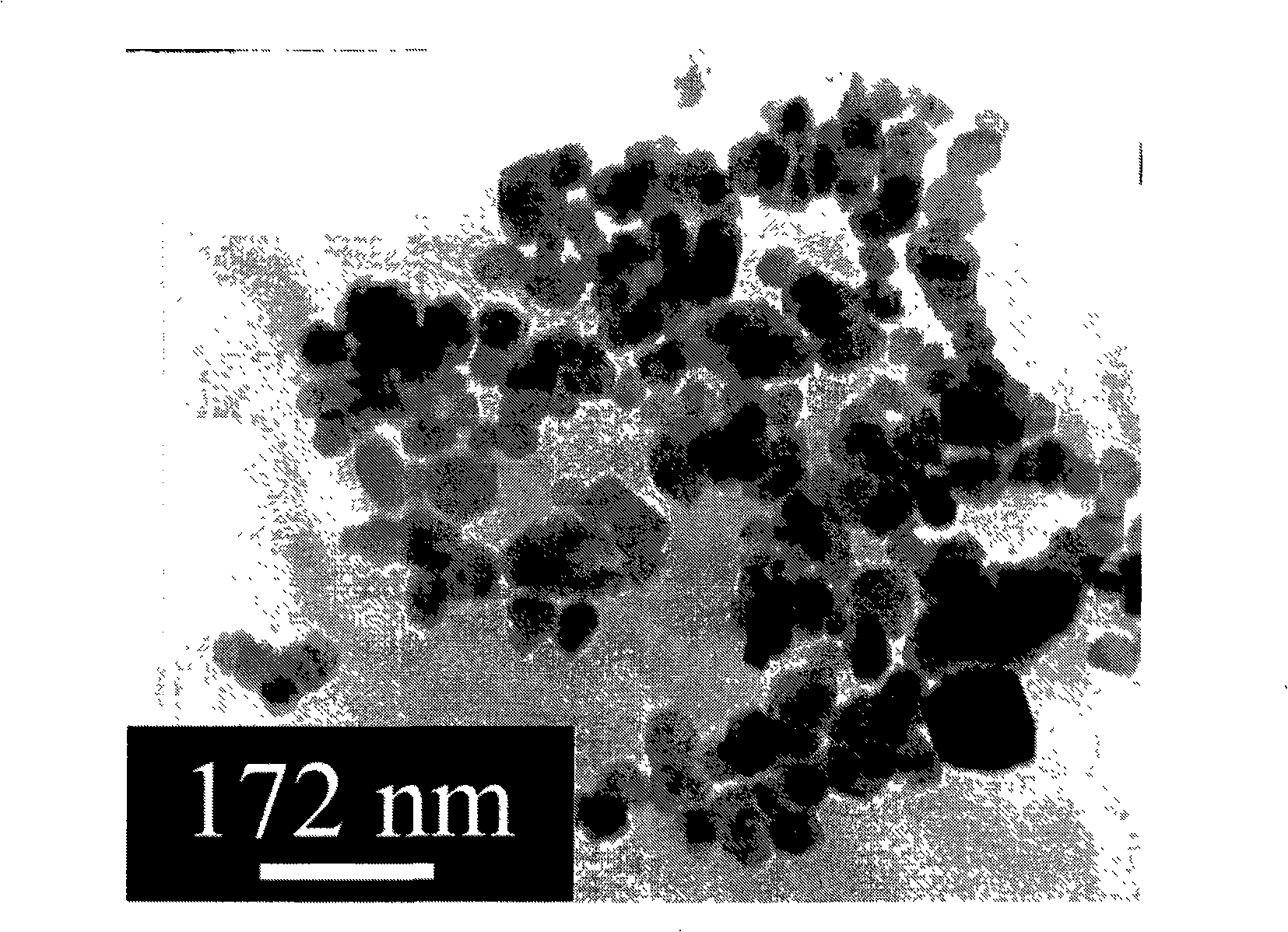

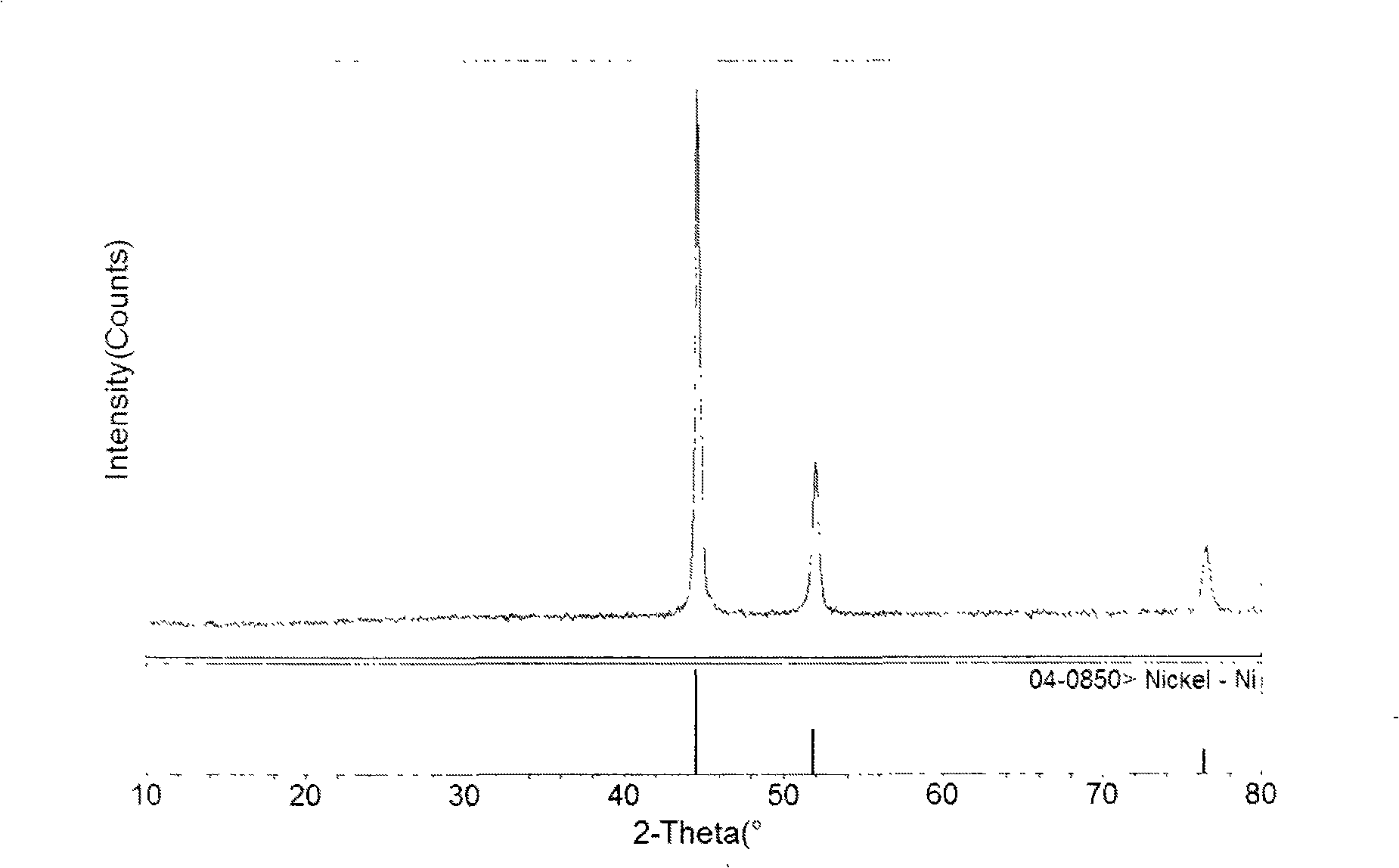

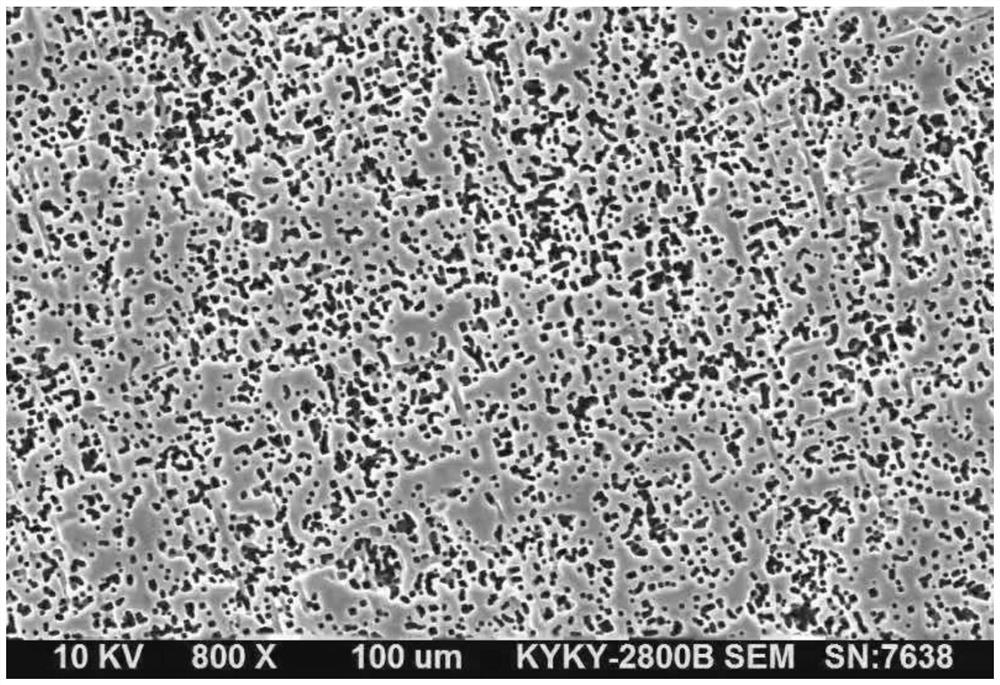

Method for preparing metallic nickel nano powder

The invention provides a preparation method for nickel nano-powder, which belongs to the technical field of the preparation of nano-materials. In the method, aluminum powder, which is more active than nickel, is mixed with inorganic nickel salt at the normal temperature and pressure, the inorganic nickel salt is ground together with a protective agent and then the mixture is put statically for a certain period of time, and nickel ions is replaced as the nickel nano-powder by the intermetallic replacement reaction. The preparation method used is a chemical reduction method, including the steps of reduction, washing, drying, etc. The preparation method is characterized by pure products, easy separation, difficult oxidation, etc. And the method is good for industrial production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

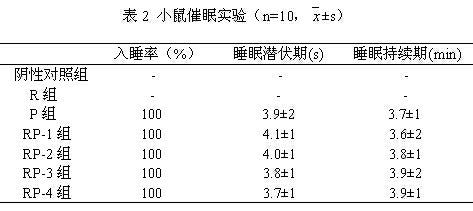

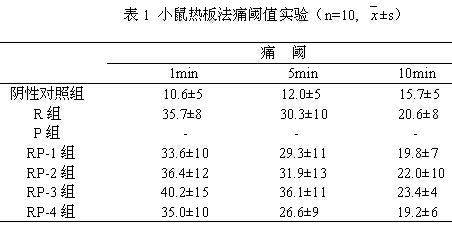

Metaduocine freeze-dried powder injection preparation and its preparation method

InactiveCN1476834AGood resolubilityReduce moisturePowder deliveryOrganic active ingredientsAlcoholismsRat liver

The present invention relates to a medicine for curing alcoholism-metadoxine freeze-dried powder injection and its preparation process. The proper quantity of anti-oxidant and chelator can be added in its medicine preparation formula composition so as to raise the stability of said medicinal component. The pharmacodynamic tests show that it has remittence action for rat liver injury due to carbontetrachloride. Said injection is stable, and is favorable for storage and transportation.

Owner:杭州容立医药科技有限公司

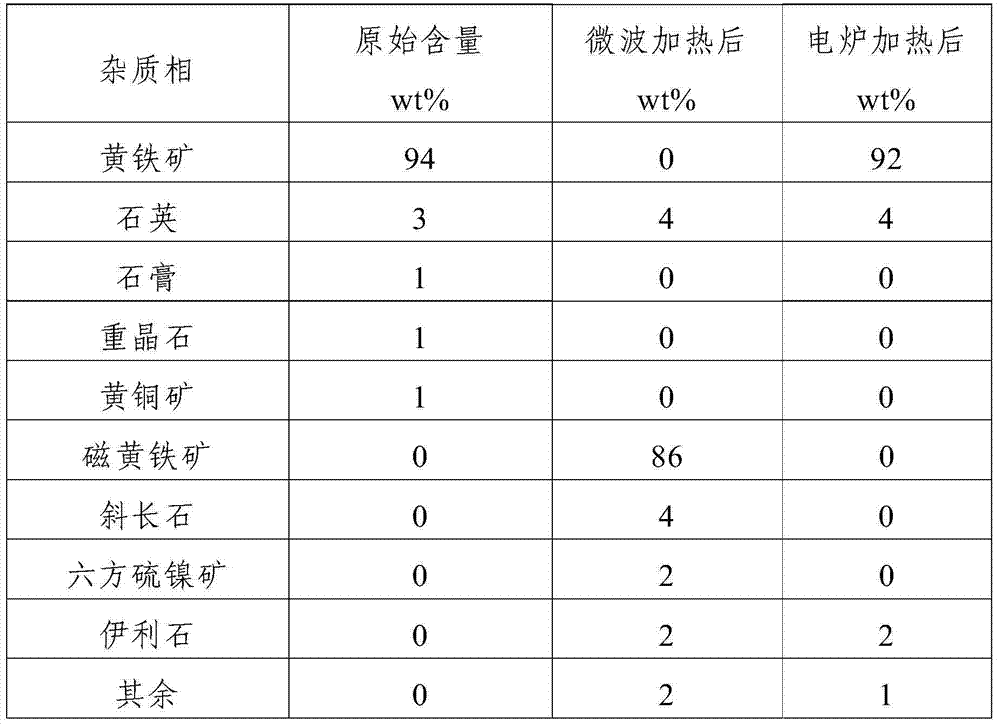

Method for purifying molybdenum concentrate through microwave-acid leaching combined technologies

ActiveCN103667676AHigh reactivityGood removal effectProcess efficiency improvementHydrofluoric acidMicrowave

The invention provides a method for purifying molybdenum concentrate through microwave-acid leaching combined technologies. The method comprises the following steps: 1, performing microwave heating treatment on the molybdenum concentrate; 2, immersing the molybdenum concentrate into a hydrochloric acid-hydrofluoric acid composite pickle liquor for acid leaching treatment, and obtaining the molybdenum concentrate with the MoS2 mass content no smaller than 99 percent after filtering, washing and drying. The invention further provides another method for purifying the molybdenum concentrate through the microwave-acid leaching combined technologies, and the method comprises the following steps: 1, performing microwave heating treatment on the molybdenum concentrate; 2, immersing the molybdenum concentrate into hydrochloric acid for first acid leaching treatment, and then carrying out filtering, washing and drying treatments; 3, immersing the molybdenum concentrate into hydrofluoric acid for second acid leaching treatment, and obtaining the molybdenum concentrate with the MoS2 mass content no smaller than 99 percent through filtering, washing and drying. In the method, the microwave processing technology and the acid pickling technology are organically combined together, fast and effective separating for the molybdenum concentrate from impurities can be achieved, the purifying effect is excellent, and beneficial social value and economic value can be achieved.

Owner:JINDUICHENG MOLYBDENUM CO LTD

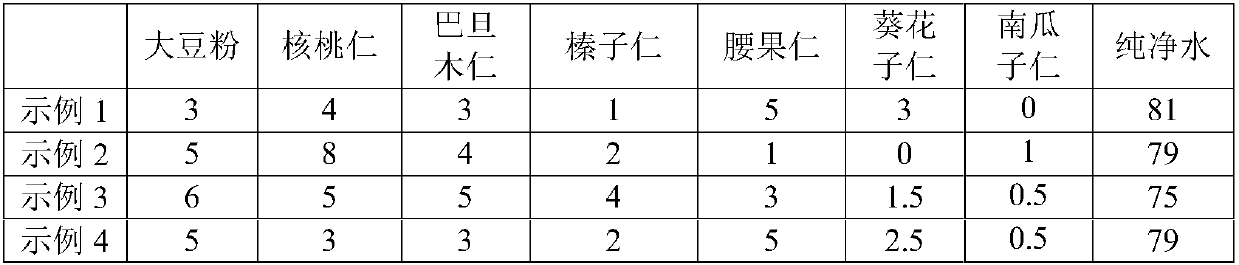

Nut beverage and preparation technology thereof

The invention discloses a nut beverage and a preparation technology thereof, and belongs to the field of food processing. The nut beverage comprises the following components in parts by weight of 3-10parts of soybean flour, 3-8 parts of walnut kernels, 3-8 parts of almond kernels, 1-5 parts of hazelnut kernels, 1-5 parts of cashew kernels and 1-3 parts of melon seed kernels. The preparation technology of the nut beverage comprises the following steps of performing peeling, performing selecting, performing baking, performing premixing, performing refining, performing blending, performing homogenizing and performing sterilization. The nut beverage disclosed by the invention solves the problem that a conventional nut beverage is high in production cost, single in nutrients and poor in mouthfeel and flavor. The soybean flour, the walnut kernels, the almond kernels, the hazelnut kernels, the cashew kernels and the melon seed kernels are matched and mixed in proportion, so that the nut beverage is prepared, the nut beverage is guaranteed to have rich nutrient substances. Besides, the cost is reduced, and the mouth feel and the flavor of the prepared nut beverage are good.

Owner:CHACHA FOOD CO LTD

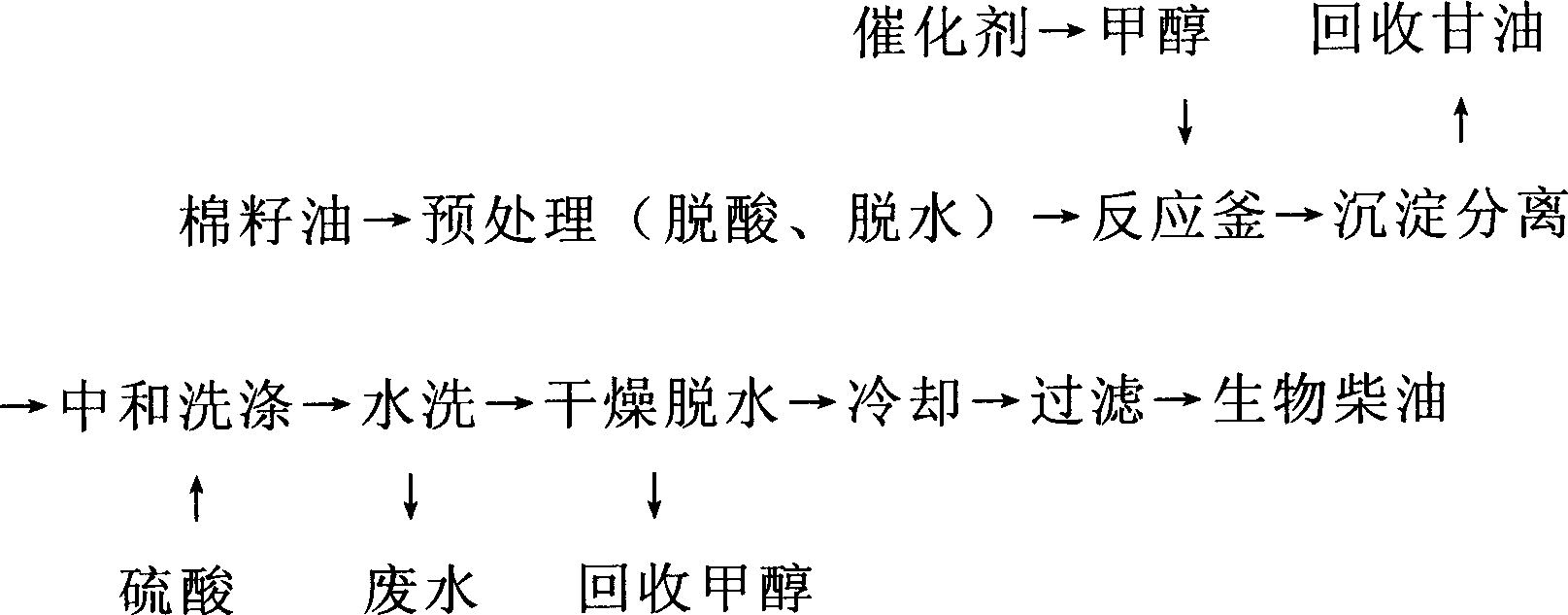

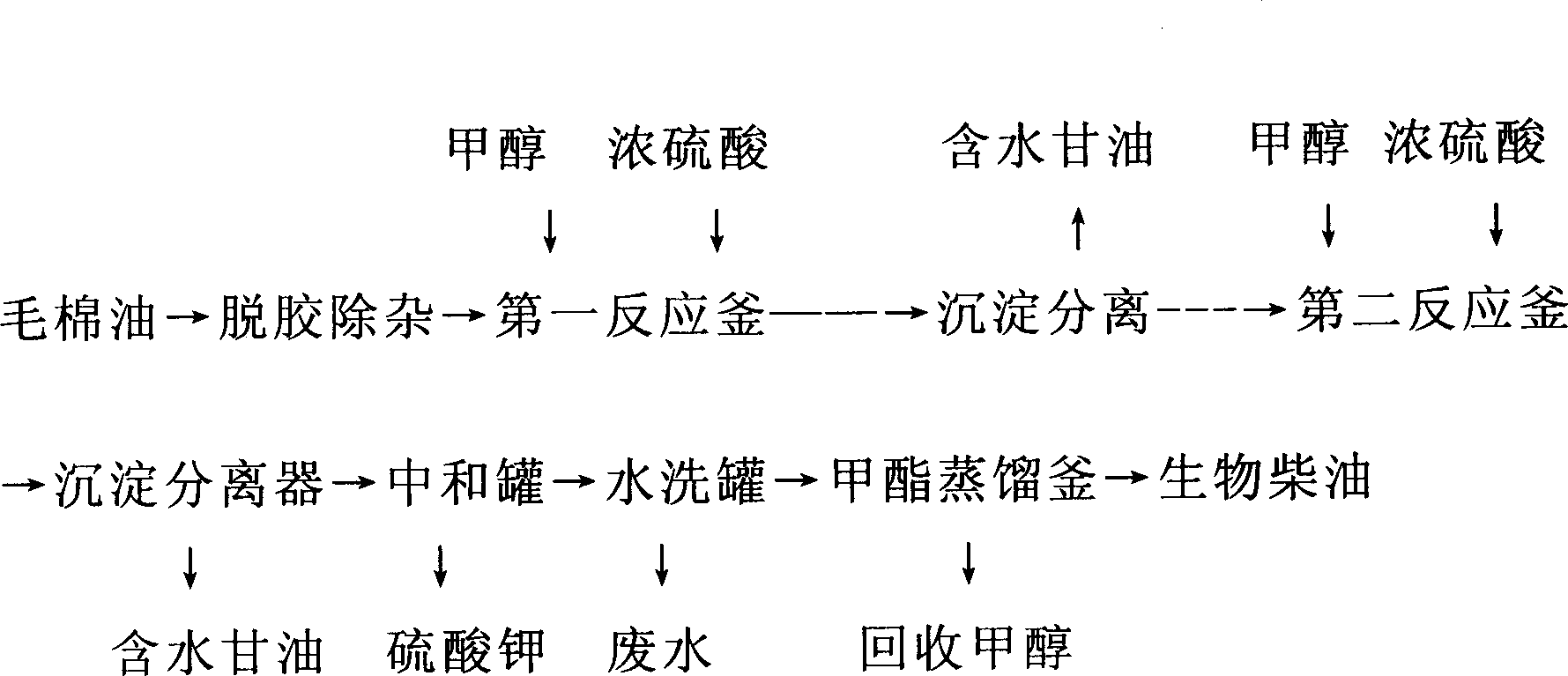

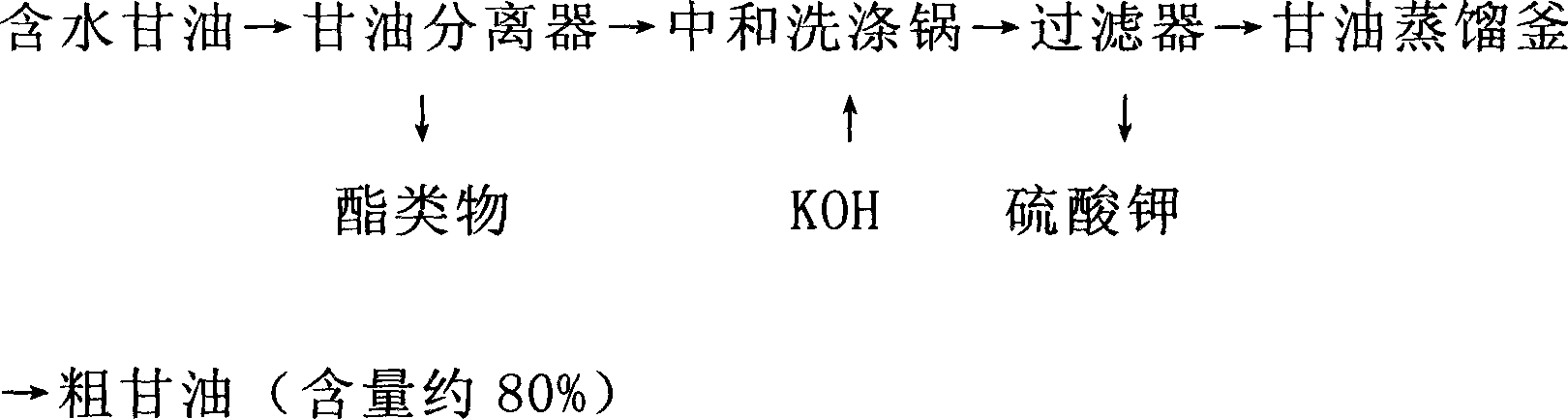

Method for preparing biological diesel oil using high acid value cottonseed oil

InactiveCN1865401AAvoid processing risksReduce pollutionBiofuelsLiquid hydrocarbon mixture productionChemical reactionBiodiesel

The invention discloses a biological diesel preparing method from high-acid value cotton seed oil, which comprises the following steps: the first step: adopting concentrated sulfuric acid as catalyst under normal pressure and temperature; injecting certain quantity of carbinol; reacting most of glyceride and a little of aliphatic acid with carbinol; sedimenting and separating glycerin and water; the second step: adopting concentrated sulfuric acid as catalyst under normal pressure and temperature; injecting excessive carbinol; lengthening reacting time to react glyceride and aliphatic acid with carbinol. The invention can utilize cotton oil reasonably, which reduces the environmental pollution in the refinery course.

Owner:菏泽华瑞油脂有限责任公司

Organic adhesive composite used for silicon solar cell silver paste and preparation method thereof

InactiveCN102304287AGood dispersionEasy to wrapInksNon-conductive material with dispersed conductive materialSilver pasteOrganic solvent

The invention provides an organic adhesive composite used for silicon solar cell silver paste, comprising the following raw materials according to parts by weight: 5-13% of polyamide resin, 8-25% of abietic resin or phenolic aldehyde modified terpene resin, 65-80% of organic solvent and 0-1% of wetting dispersant. The organic adhesive composite exists in silver paste to serve as a carrier or dispersion medium, proper fluid performance is endowed to slurry to fully wet silver powder or inorganic adhesive powder in the wetting silver paste, and the slurry can be dissolved with other accessory ingredients in a mixed mode.

Owner:IRICO

Ondansijiong hydrochleride freeze dried powder ampoule for injection and its preparation method

InactiveCN1555795AReasonable compositionGood resolubilityPowder deliveryOrganic active ingredientsPharmaceutical preservativesFreeze dry

An ondansetron hydrochloride injection in the form of freeze dried powder for treating the nausea and emesis caused by chemicotherapy or radiotherapy is prepared from ondansetron hydrochloride, pharmacological acceptable excipient and water for injection through dissolving ondansetron hydrochloride in the water, adding excipient, stirring, regulating pH value, filtering, and freeze drying.

Owner:陈庆财 +1

Powder injection of dolasetron and its pharmaceutically acceptable salt, and its preparation method

InactiveCN1843356AAvoid breakingExtended shelf lifeOrganic active ingredientsPowder deliveryDolasetronPharmacology

The invention relates to an powder injection of Dolasetron and pharmaceutically acceptable salts and its preparing process, wherein the preparation is the combination of one or more of Dolasetron free amine, Dolasetron's mesilates, hydrochlorates, acetates or lactates. The process for preparing the powder injection includes filtering and degerming through microporous filtering film, and low temperation drying.

Owner:CHENGDU XINJIE HIGH TECH DEV CO LTD

Method for preparing nanometer silver powder by using <60>Co-gamma rays in aqueous solution

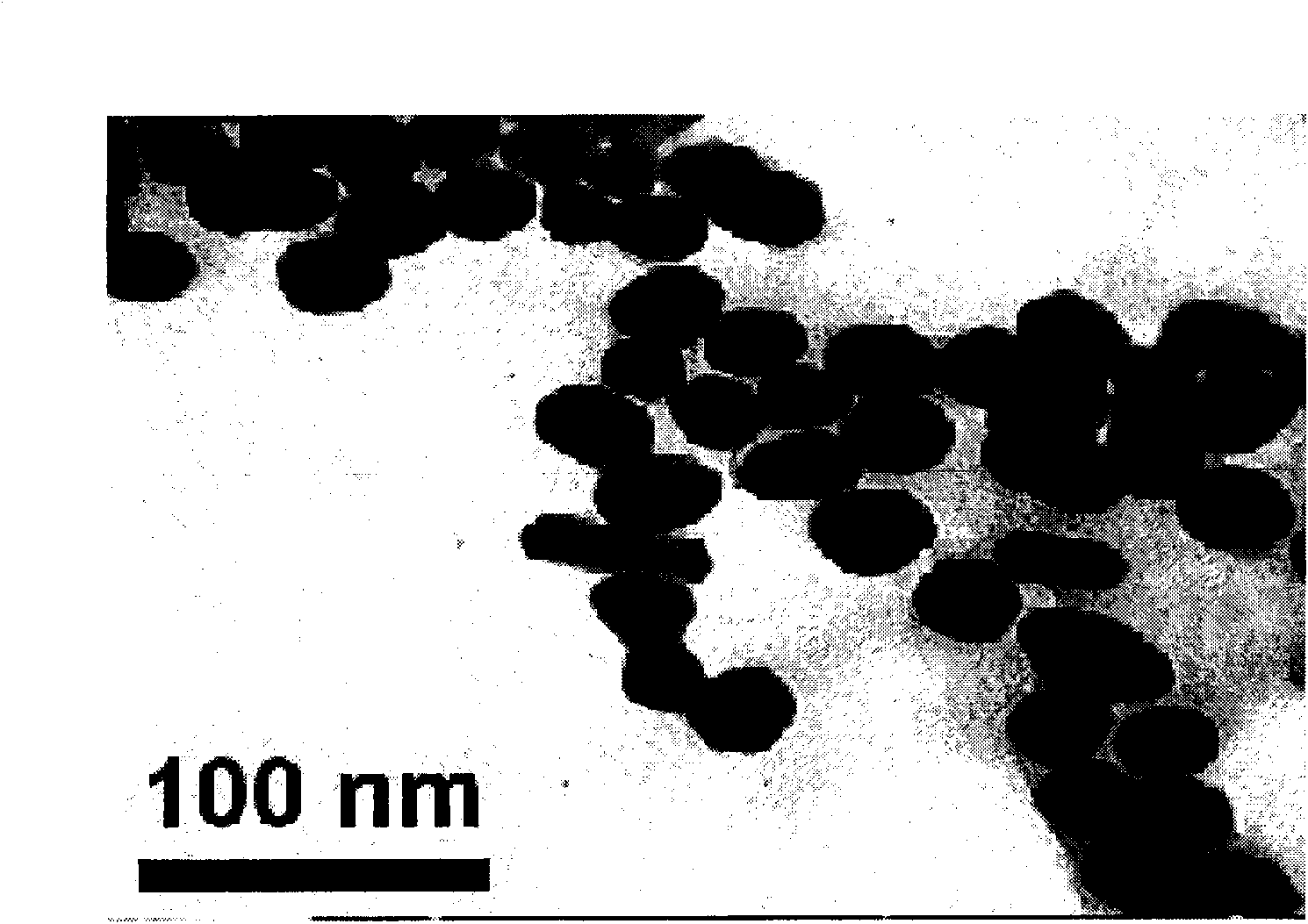

The invention discloses a method for preparing nanometer silver powder by using <60>Co-gamma rays in aqueous solution, comprising the following steps: dissolving silver salt, active particle trapping agents and surfactants into distilled water, stirring and mixing the components evenly and regulating pH value to 5-7; placing mixed liquor into an aluminum-plastic package and introducing helium, vacuumizing, sealing and packing the package and using the <60>Co-gamma rays for radiation reduction; adding oleamide or dodecyl mercaptans into solution treated by radiation, then using a water vacuum filter for filtration, repeatedly washing filter membranes in the filter by acetone and the distilled water alternately, taking out the filter membranes and immersing the filter membranes into a beaker with anhydrous ethanol, and using ultrasonic waves to collect the silver powder in the filter membranes; vacuum-freezing and drying the silver powder to obtain the nanometer silver powder. The method is convenient in operation and short in production cycle, can carry out continuous production,without environmental pollution. The prepared nanometer silver powder is not easy to oxidize and has granularity between 10-50nm.

Owner:浙江省技术物理应用研究所 +1

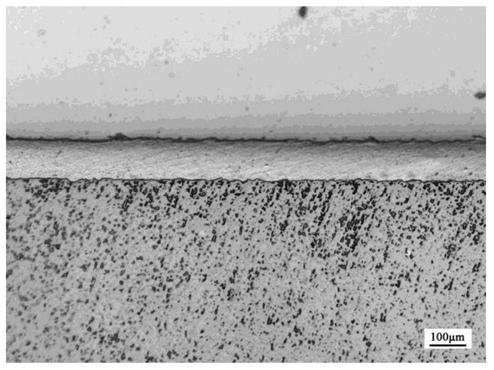

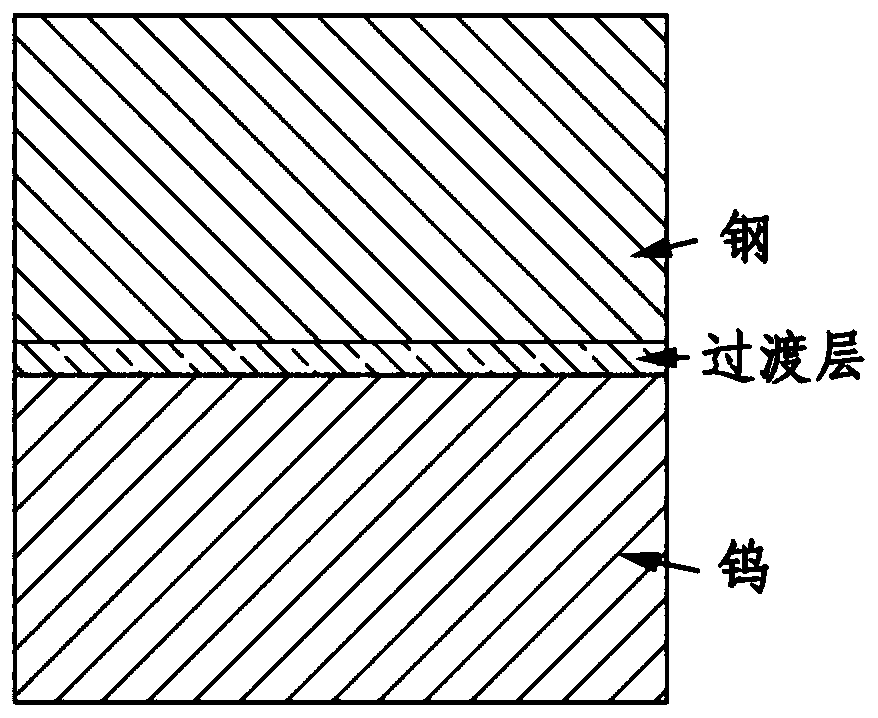

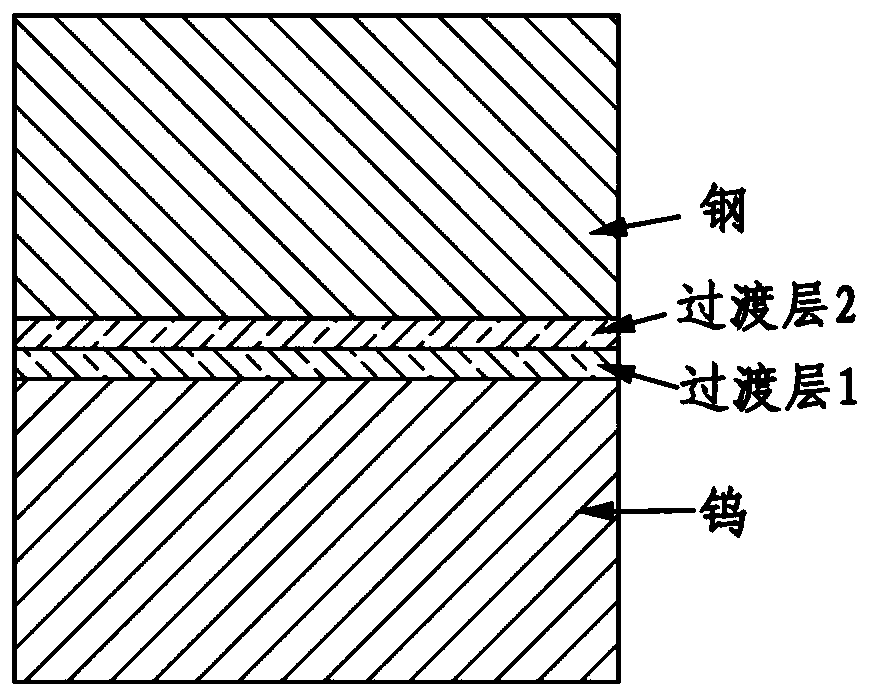

Hot isostatic pressure diffusion connection method for tungsten or tungsten alloy and high-strength steel

InactiveCN110303236AFully deformedFully deformed fullyWelding/soldering/cutting articlesPressure inorganic powder coatingSputteringHigh intensity

The invention discloses a hot isostatic pressure diffusion connection method for tungsten or tungsten alloy and high-strength steel. The method mainly comprises the following steps of cleaning beforewelding operation, transition layer preparation and hot isostatic pressure diffusion connection, wherein a cold spraying treatment mode is adopted for the transition layer preparation. The connectionmethod can realize the hot isostatic pressure diffusion connection of samples with special-shaped curved surfaces of an arc surface, a U-shaped surface and the like, can realize the preparation of themultiple layers of transition layers, the bonding performance is good, the connection strength is high, and compared with magnetron sputtering, the method is simpler, more practical and more economical. In addition, by adopting the hot isostatic pressure diffusion connection method, the defects of air holes and the like are overcome, batch production can be realized, the production efficiency ishigh, and the yield is high.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Grinding disc filter screen structure for fruit and vegetable processing machine

The invention discloses a grinding disc filter screen structure for a fruit and vegetable processing machine. The grinding disc filter screen structure comprises a filter screen in a conical drum shape, and a plurality of blades are arranged on the inner wall of the filter screen. Each blade on the inner wall of the filter screen is flaky with one side abutted against the inner wall of the filter screen, the other side of each blade is a rough grinding surface, and a cutting edge surface is positioned on the left side edge or right side edge of the blade. The side edge of each blade and the generatrix of the conical drum of the filter screen are arranged at an inclination angle. The filter screen structure for a fruit and vegetable processing machine, disclosed by the invention, also comprises a filter screen holder, wherein the filter screen with the plurality of blades arranged on the inner wall is arranged on the filter screen holder; the filter screen holder is in a conical drum shape, the middle part of the conical drum wall is hollow, and a plurality of spaced vertical reinforcing ribs are arranged in the hollow part; and an inner gear is connected above the conical drum of the filter screen holder. The grinding disc filter screen structure disclosed by the invention has the advantages that the fruit juice primary pulp is difficult to oxidize, and screen meshes are difficult to block.

Owner:徐小鸿

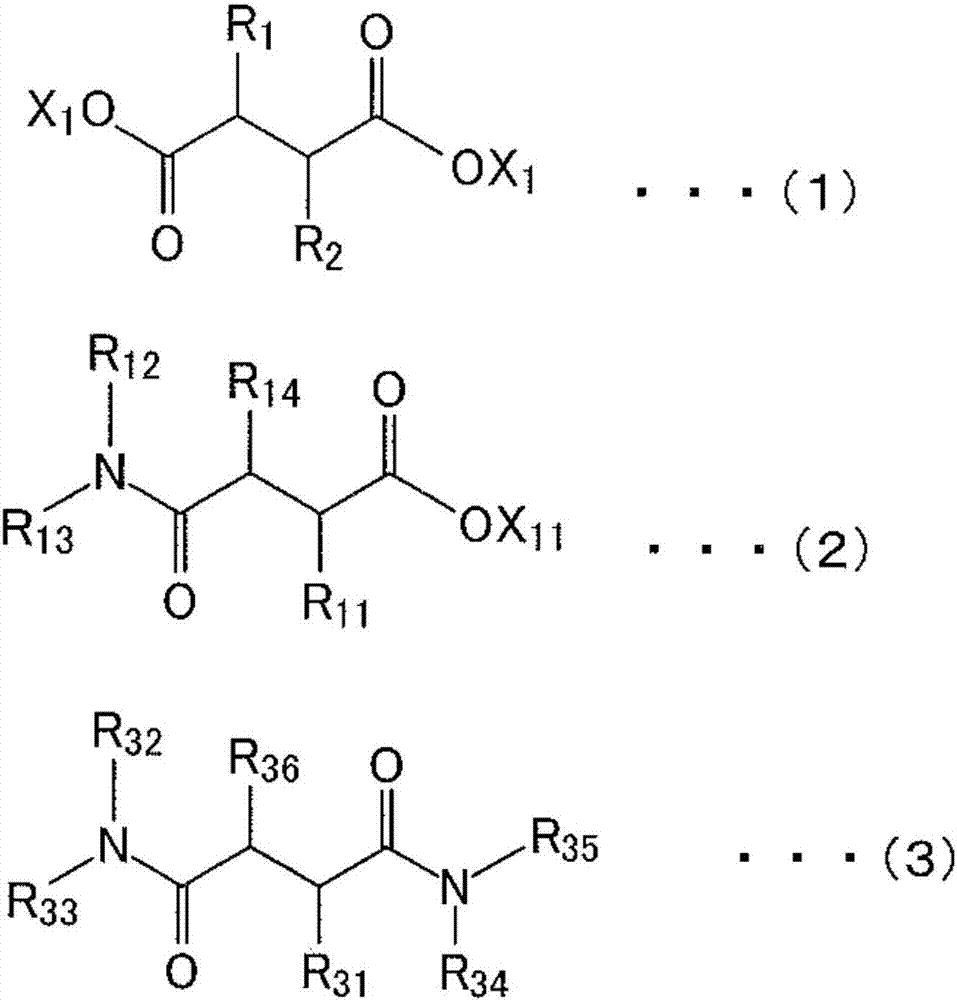

Polishing composition, a method for producing same, and magnetic polishing method

ActiveCN106994627ANot easily oxidizedNot prone to oxidationOther chemical processesLapping machinesMaterials scienceMagnetic field

The present invention relates to a polishing composition, a method for producing the same, and a magnetic polishing method. The present invention provides a polishing composition in which magnetic particles are less likely to be oxidized and a magnetic polishing method. The polishing composition (1) contains magnetic particles, an antioxidant for suppressing oxidation of magnetic particles, and water. A magnetic field is applied to the polishing composition (1) to form a magnetic particle cluster (3) containing magnetic particles, so that the particle cluster (3) contacts a to-be-ground object (5) and grinds the to-be-ground object (5).

Owner:FUJIMI INCORPORATED

Preparation method for aluminum plate painting

InactiveCN105235437AHigh glossHigh surface glossDecorative surface effectsSpecial ornamental structuresFadingCoating

The invention relates to the technical field of technological decorative paintings and provides a preparation method for an aluminum plate painting which is good in three-dimensional effect, bright in color, high in surface glossiness and free of color fading and color losing. The preparation method comprises the following steps of (1) aluminum plate grinding, (2) hand drawing and coloring, (3) ink jetting, (4) washing, (5) coating spraying, (6) polishing, (7) thinning agent spraying, and (8) protective layer applying.

Owner:南安市亿辉油画工艺有限公司

Non-conductive film vacuum coating process

InactiveCN101423926AEvaporate completelyNot prone to oxidationVacuum evaporation coatingSputtering coatingIndiumSemi automatic

The invention relates to the technical field of plastic piece surface treatment, in particular to a non conducting film vacuum filming process. The process comprises the following steps: 1. the filming materials of silver and indium are prepared to be as follows: the weight ratio is 4 to 3 and the volume ratio is 1 to 1; 2. the prepared filming materials of the silver and the indium are placed in a material basket in a vacuum room of vacuum filming equipment; 3. the filming product is charged, a door of the vacuum room is closed, and the vacuum room is vacuum pumped; 4. the semi-automatic evaporation function of the vacuum room of the vacuum filming equipment is started, the voltage is adjusted to 1.70V, and the pre-heating is performed for 28 seconds; 5. the voltage is adjusted to 3.10V, and the pre-evaporation is performed for 12 seconds; 6. the voltage is adjusted to 3.85V, and the evaporation is performed for 10 to 12 seconds; and 7. the door of the vacuum room is opened, and the product is taken out. The process effectively solves the problem that the non conducting film is a little yellow.

Owner:GUANGDONG JANUS SMART GRP CO LTD

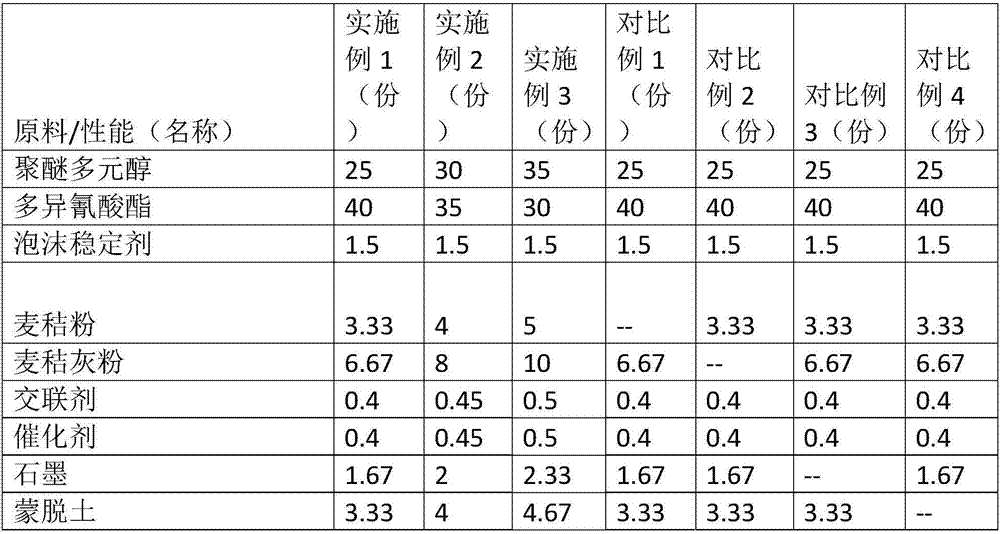

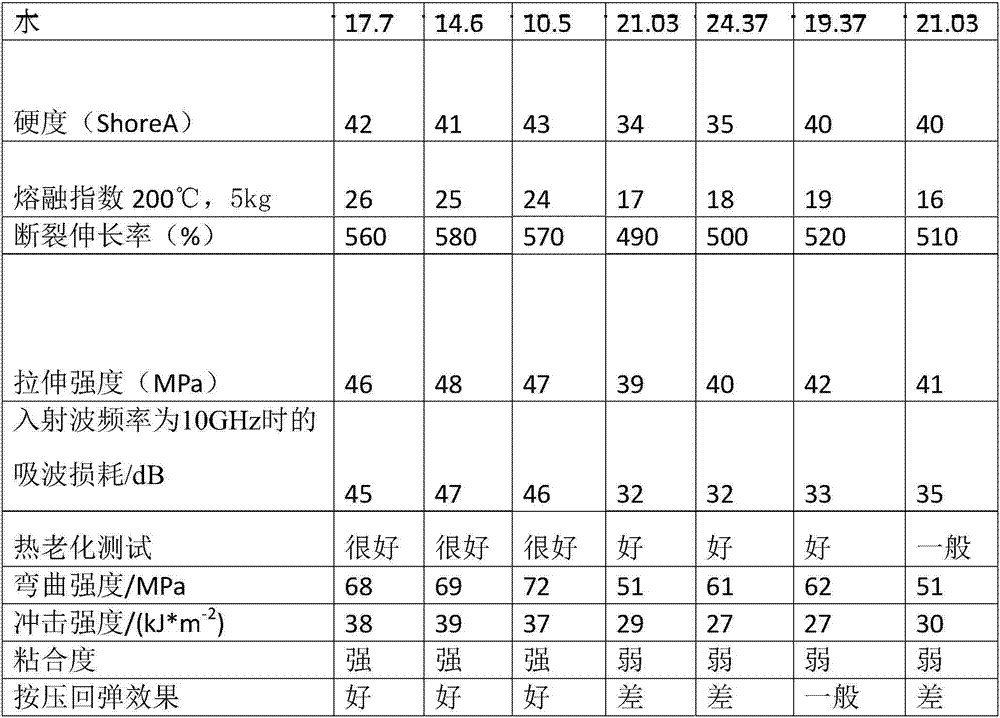

Foam plastic composite material with wave absorbing property and preparation method thereof

The invention relates to a foam plastic composite material with wave absorbing property. The foam plastic composite material is prepared from the following raw materials of polyether polyol, polyisocyanate, a foam stabilizer, plant powder, a crosslinking agent, a catalyst, graphite, montmorillonite and the balance of water. The invention also relates to a preparation method of the foam plastic composite material with wave absorbing property. The foam plastic composite material has the advantages that by adding the graphite, the plant powder, the montmorillonite and the like, the wave absorbing property and the sticking degree can be greatly improved; the easiness in breaking is avoided; the thermoplastic property is strong, the anti-impact strength is good, and the environment-friendly effect is realized.

Owner:卢路平

Preparation method for anticorrosion art paper

InactiveCN106223110AAbsorb and preserve wellEasy to prepareNon-macromolecular organic additionPulp bleachingChemistryTitanium dioxide

The invention discloses a preparation method for anticorrosion art paper. The preparation method comprises the following steps that firstly, a sizing agent is prepared, wherein trees or waste paperis mixed and smashed, auxiliary materials are added, stirring, bleaching and beating are carried out, and the sizing agent is prepared for use; secondly, anticorrosion treatment is carried out, wherein corrosion inhibitor, sodium carboxymethylcellulose, titanium dioxide, fire retardant, an antibacterial agent and flexibilizer are added, and after stirring is carried out, pulp grinding is carried out; thirdly, paper forming is carried out, wherein the mixed sizing agent is subjected to drying, hot rolling, press polishing, drying, clipping and packaging, and the anticorrosion art paper is prepared. The prepared anticorrosion art paper can resist damage of corrosive chemical products in the environment to work of art, the preparation method is simple, operation is easy, the prepared paper is high in specific strength and high in specific modulus, resistant to chemical corrosion, low in coefficient of thermal expansion and moderate in permeability and can be widely applied to the field of art paper.

Owner:刘奎然

Alloy improved material and preparation method thereof

InactiveCN109943742APrevent impurity phase segregationEliminates slag removal stepHardnessSilicon oxide

The invention relates to an alloy improved material and a preparation method thereof and relates to the field of aluminum alloy modifier. The alloy improved material is composed of spraying depositionpowder, sodium salt modifier and a binding agent. The weight ratio of the spraying deposition powder to the sodium salt modifier to the binding agent is (5-10):(1-3):1. Three modifiers strontium, sodium and rare earth neodymium are combined according to the characteristic, the modification activity is effectively retained, and the alloy improved material has the characteristics of being short inmodification incubation period, long in effective modification time and stable in modification effect. Kaolinite clay powder in raw materials can serve as a modifier carrier to remove gas and slag, the smelting efficiency is improved, and rich aluminum oxide and silicon oxide can improve hardness of an alloy. The luminescence property of a neodymium element enables the aluminum alloy to have the luminescence characteristics, and coating of luminescent materials is not needed. According to the preparation method, the spraying deposition method is adopted for further smelting and preparing tinyintermediate alloy powder, the intermediate alloy powder is bonded with the sodium modifier for extrusion forming, the modifier can be dissolved and dispersed rapidly, the incubation period is shortened, and rapid and effective modification is achieved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Esmolol Hydrochloride freeze dried powder for injection and its preparation method

InactiveCN1634002AReasonable compositionReduce moisturePowder deliveryOrganic active ingredientsFreeze-dryingPharmaceutical formulation

The invention discloses an Esmolol Hydrochloride freeze dried powder for injection and its preparation method, wherein the esmolol hydrochloride freeze dried injection is prepared from esmolol hydrochloride as active compound, pharmacologically acceptable freeze dried excipient and water for injection. The weight ratio of esmolol hydrochloride and freeze dried excipient is 5-30 : 5-50, the preparing process is also disclosed by the invention.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

High reliability low-silver lead-free solder and preparation method thereof

InactiveCN101642856AInexpensive solderLow costWelding/cutting media/materialsSoldering mediaCopperCobalt

The invention relates to a high reliability low-silver lead-free solder based on Sn-Ag-Cu lead-free solder alloy and a preparation method thereof. Based on the total weight of the low-silver lead-freesolder, the lead-free solder comprises: 0.2-0.6% of silver, 0.01-0.06% of nickel, 0.5-0.8% of copper, 0.01-0.06% of cobalt and the rest of tin. The preparation method of the lead-free solder comprises the steps: first, in a state of melting protection, respectively smelting and preparing tin-silver preliminary alloy, tin-copper preliminary alloy, tin-nickel preliminary alloy and tin-cobalt preliminary alloy; then, mixing the obtained preliminary alloys and the rest tin at the temperature of 400-550 DEG C, and preparing the low-silver lead-free solder. The lead-free solder is low in cost and good in welding spot reliability, and can meet the demand of the clients. Furthermore, the preparation method can be carried out at lower temperature, has simple and convenient operation and lower cost.

Owner:太仓市首创锡业有限公司

Pharmaceutical composition containing propofol and opioid analgesics and use thereof

InactiveCN102626411AReasonable compositionGood resolubilityNervous disorderHydroxy compound active ingredientsSedative EffectsAdditive ingredient

The invention discloses a pharmaceutical composition containing propofol and opioid analgesics and a use thereof. The pharmaceutical composition comprises pharmaceutically acceptable carriers, propofol as a first active component and opioid analgesics as second active components selected from fentanyl, remifentanil, sufentanil and alfentanil. The pharmaceutical composition containing propofol and opioid analgesics utilizes the combination of narcotic analgesics and a narcotic sedative, has effects of analgesia and sedation, reduces the frequency of drug administration carried out by an analgesist, makes an anesthesia induction process more convenient, obviously reduces an incidence rate and the severity of the propofol injection pain, and reduces adverse reactions of monotherapy.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Novel precious metal snowflake pattern manufacturing method

ActiveCN104588609AThere will be no breakage and reorganizationImprove the display effectMetallurgyAtmospheric pressure

The invention discloses a novel precious metal snowflake pattern manufacturing method. The novel precious metal snowflake pattern manufacturing method comprises the steps that precious metal is manufactured to be of the needed specification in a pneumatic casting forming mode, then acid pickling and electrolysis are carried out on the precious metal, and therefore the precious metal with snowflake patterns is formed. By means of the method, as the pneumatic casting forming is adopted directly on the precious metal, crystal lattices will not crack or regroup, namely the crystal lattices can maintain the basically consistent size, and the display effect of the snowflake patterns is greatly improved.

Owner:海丰县龙兴机械科技有限公司

Annealing method in high-voltage electronic aluminum-foil production for high-capacity high-strength capacitor

ActiveCN113235024ANot prone to oxidationEasy to cleanAnti-corrosive paintsMetal rolling arrangementsAluminum foilCapacitor

The invention discloses an annealing method in high-voltage electronic aluminum-foil production for a high-capacity high-strength capacitor. The annealing method comprises the following steps: performing intermediate annealing in a belt mode through a continuous type gas cushion furnace, uniformly heating an aluminum belt, controlling speed by the continuous type gas cushion furnace during heating, guaranteeing growth consistency of grown crystalline grains as annealing time is stable and controllable, thereby obtaining a uniform structure; eliminating internal stress, and reducing aluminum foil processing hardening degree; performing aluminum foil finished product annealing by the continuous type gas cushion furnace, and controlling a regrowth rate of the crystalline grains in a mode of annealing at different temperatures in multiple regions, changing a non-cubic texture into a cubic texture, increasing the proportion of the cubic texture, enriching trace elements on the surface, and increasing a corrosion porosity; and quickly cooling and coiling after discharging to prevent surface damages due to blocking under warming.

Owner:广西广投正润新材料科技有限公司

Annealing treatment method of copper stranded wire

InactiveCN103805926ABright surfaceBeautiful surfaceFurnace typesHeat treatment furnacesPositive pressureCopper wire

The invention relates to a production technique of a copper stranded wire, particularly an annealing treatment method of a copper stranded wire. The technical scheme is as follows: the annealing treatment method sequentially comprises the following steps: (1) putting a copper stranded wire into an annealing furnace, removing air in the furnace to form negative pressure, and charging protective gas carbon dioxide to form positive pressure; (2) heating under pressure; (3) stopping heating, relieving pressure and cooling; (4) reheating; and (5) opening the furnace door, and naturally cooling to room temperature. The method can effectively eliminate stress of the copper wire, enables the copper wire to have a bright and beautiful surface, and is beneficial to clearing pollutants on the surface of the copper wire, so that the copper wire can be stored for a long time or can not be easily oxidized when in use.

Owner:浙江正导光电股份有限公司

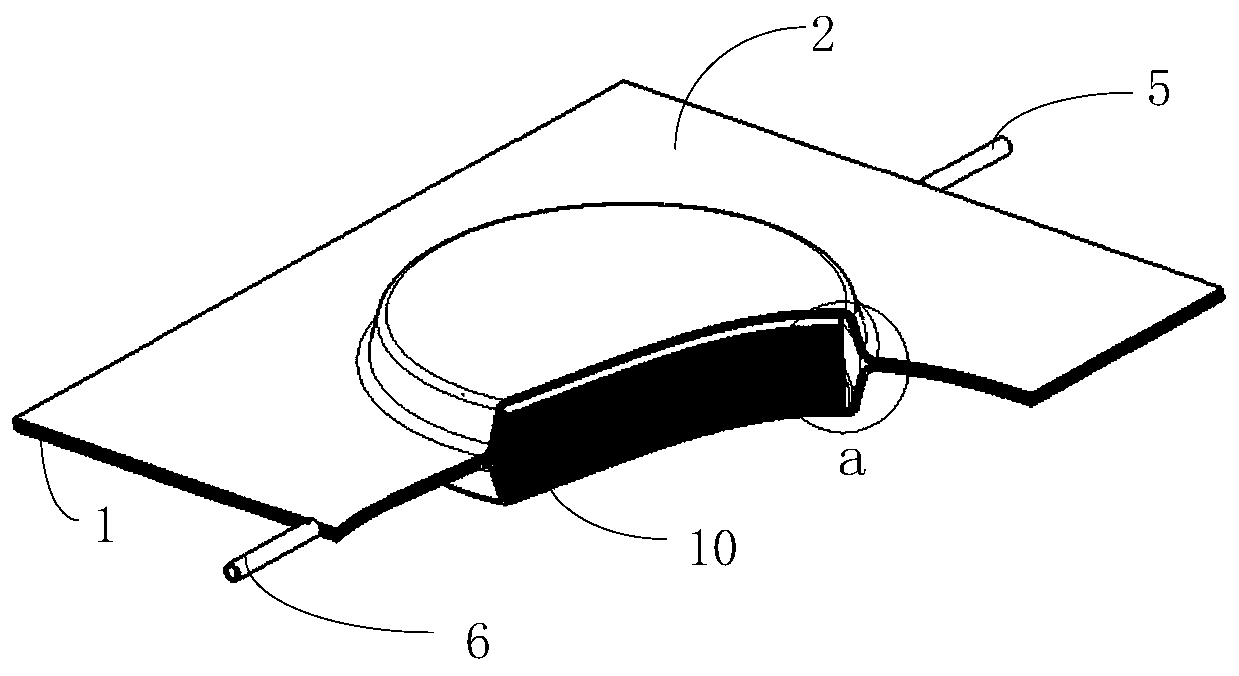

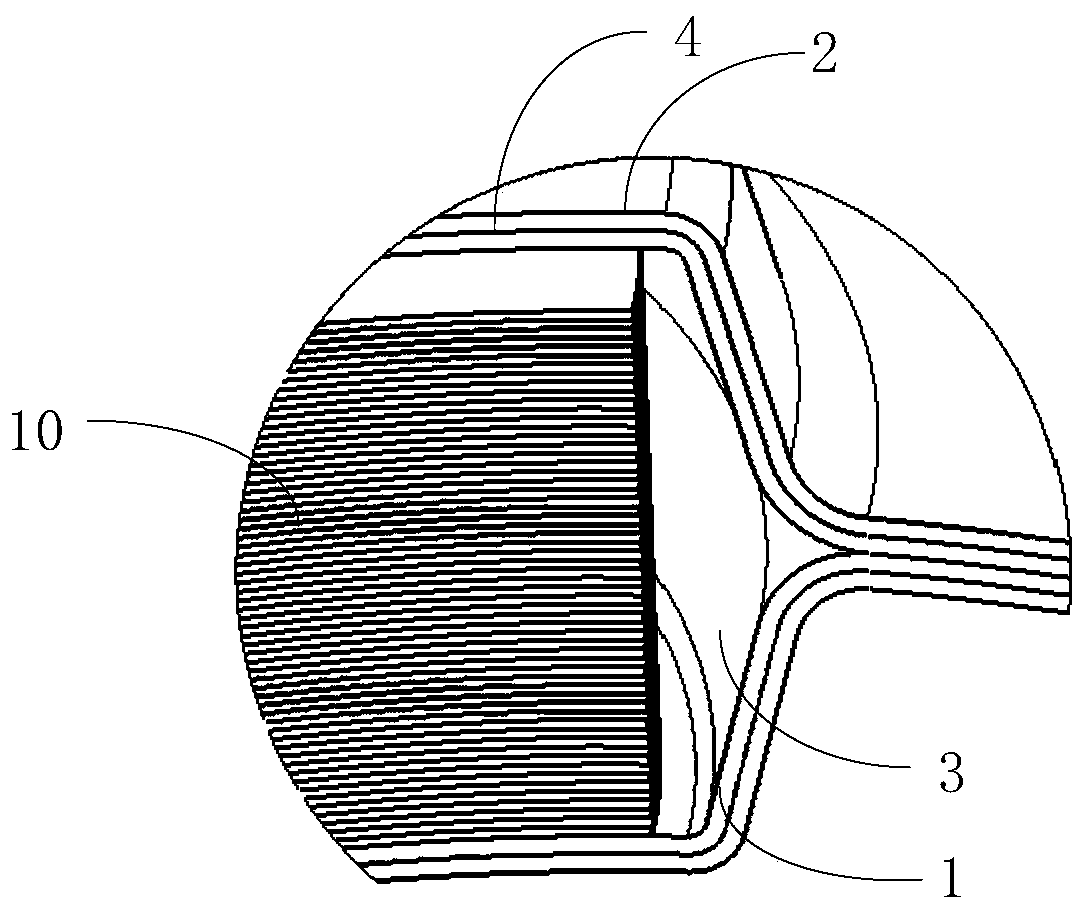

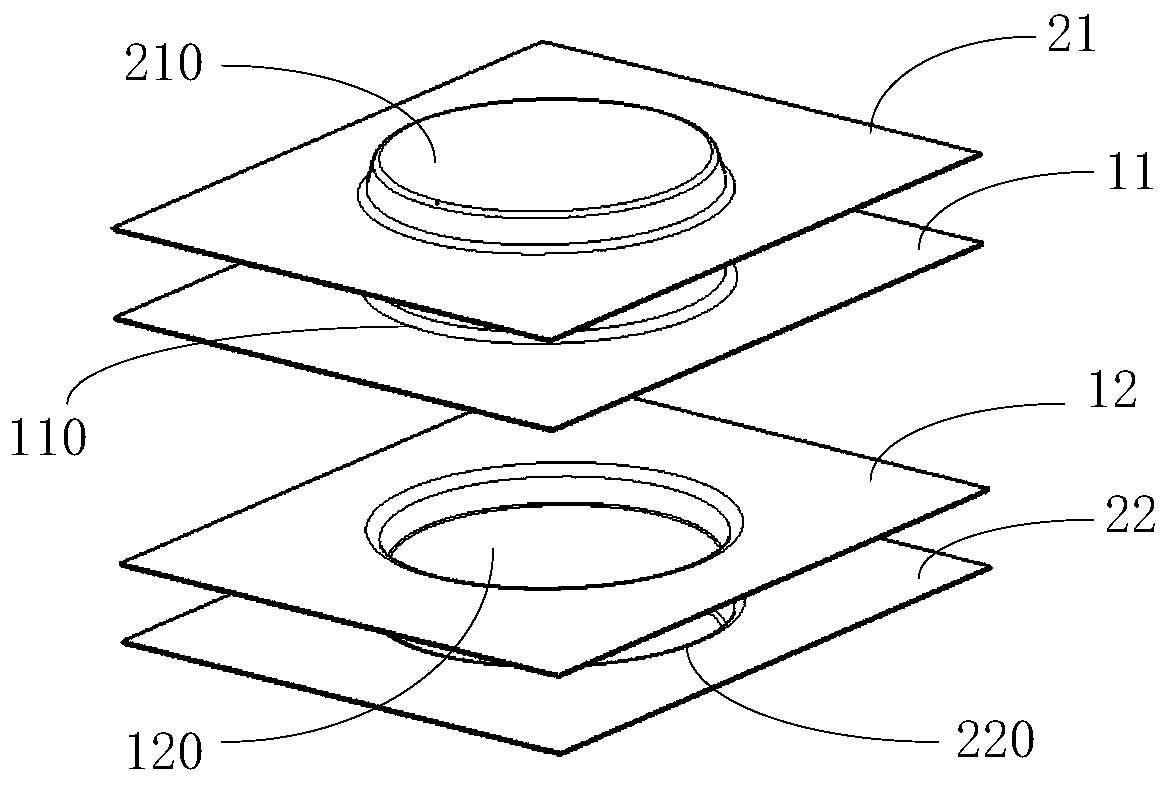

Sheath assembly sealing device and method, sheath forming device and processing method

ActiveCN111037086AThe overall structure is simple and reliableImprove sealingNon-electric welding apparatusEngineeringPumping vacuum

The invention discloses a sheath assembly sealing device and method, a sheath forming device and a processing method. The sheath assembly sealing device comprises an inner layer sheath and an outer layer sheath, an inner layer sealing cavity for sealing a to-be-diffused part is arranged in the inner layer sheath, and an outer layer sealing cavity covering the outer portion of the inner layer sealing cavity is arranged in the outer sheath; a vacuum channel for vacuumizing is formed in the inner layer sealing cavity, and an air inlet channel for introducing inert gas is formed in the outer layersealing cavity; and the inner layer sealing cavity and the outer layer sealing cavity are independent from each other, so that tight fit of a connection interface of the to-be-diffused part is promoted when the to-be-diffused part is under the action of vacuum and the pressure of the inert gas, and then a diffusion connection joint for sheath assembly is formed. According to the scheme, good sealing and diffusion connection effects can be achieved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com