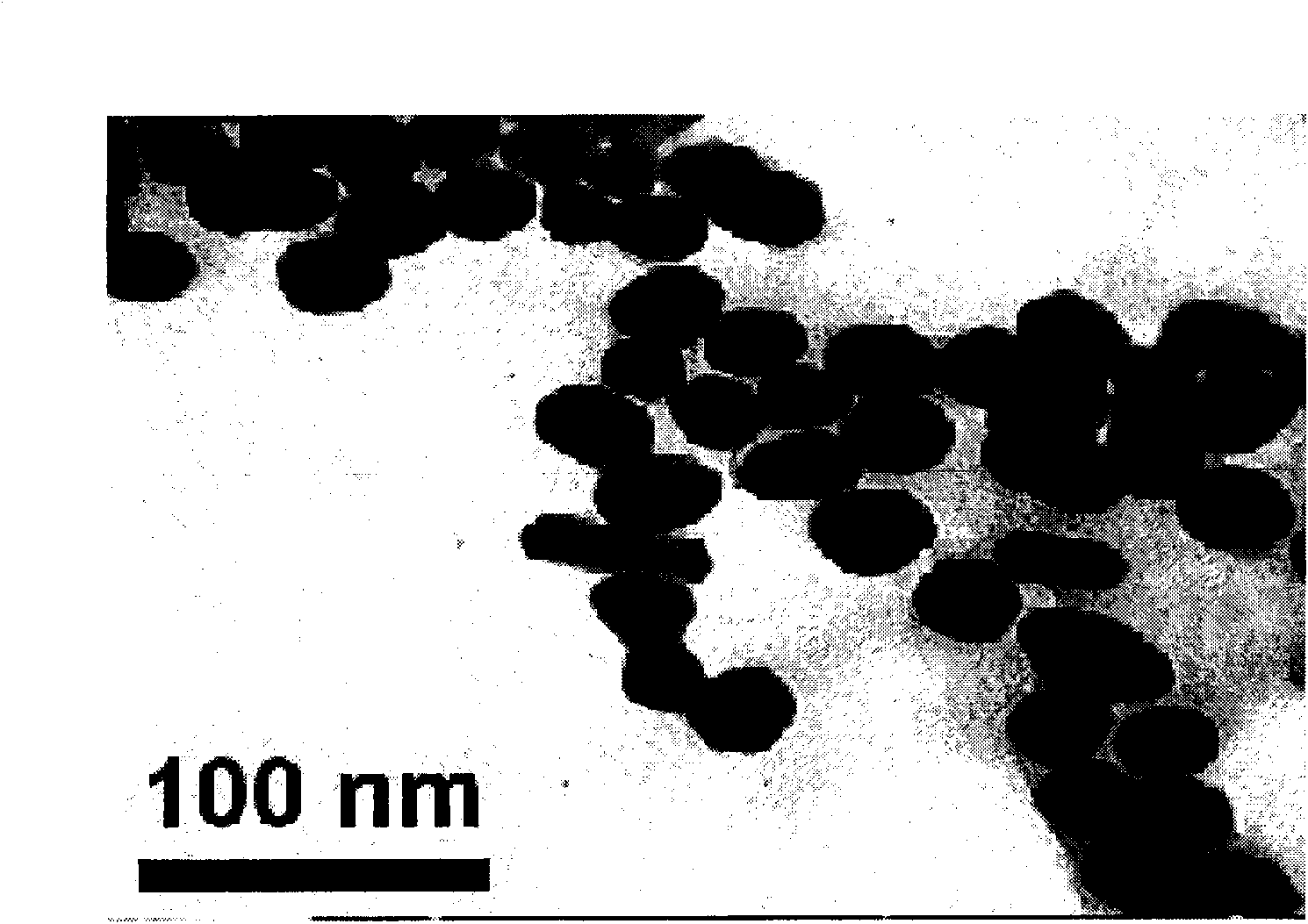

Method for preparing nanometer silver powder by using <60>Co-gamma rays in aqueous solution

A nano-silver powder and γ-ray technology, which is applied in the field of powder materials prepared by nuclear radiation technology, can solve the problems of easy agglomeration, limited silver powder use effect, silver powder particle size, irregular shape, etc., to achieve short production cycle, prevent oxidation and build up block, method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] used in aqueous solution 60 Co-gamma rays prepare the method for nanometer silver powder, comprise the following steps:

[0017] 1) Silver sulfate, isoamyl alcohol and hydroxymethyl cellulose are dissolved in distilled water, stirred and mixed evenly, the content of silver sulfate in the mixed solution is 12g / L, the content of isoamyl alcohol is 130g / L, and the content of hydroxymethyl cellulose is 10g / L, adjust the pH value of the mixture to 5 with sodium hydroxide;

[0018] 2) Put the mixed solution of step 1) into an aluminum-plastic packaging bag and fill it with helium for 3 minutes, discharge the dissolved oxygen in the solution, vacuumize and seal the package with a liquid vacuum packaging machine, and use 60 Co-γ rays were irradiated for reduction, and the irradiation dose was 20kGy.

[0019] 3) Pour the solution treated in step 2) into a beaker, add oleic acid amide for oil-water coating, the content of oleic acid amide is 20g / L. Then use a vacuum suction fi...

Embodiment 2

[0022] 1) Dissolve silver sulfate, n-butanol and hydroxymethyl cellulose in distilled water, stir and mix evenly, the content of silver sulfate in the mixed solution is 80g / L, the content of n-butanol is 150g / L, and the content of hydroxymethyl cellulose is 15g / L, adjust the pH value of the mixture to 7 with sodium hydroxide;

[0023] 2) Put the mixed solution of step 1) into an aluminum-plastic packaging bag and inflate it with helium for 10 minutes, discharge the dissolved oxygen in the solution, vacuumize and seal the package with a liquid vacuum packaging machine, and use 60 Co-γ rays were irradiated for reduction, and the irradiation dose was 50kGy.

[0024] 3) Pour the solution treated in 2) into a beaker, add oleic acid amide for oil-water coating, the content of oleic acid amide is 30g / L. Then use a vacuum suction filter to filter with water, and repeatedly wash the filter membrane in the suction filter with acetone and distilled water alternately to remove organic im...

Embodiment 3

[0027] 1) Dissolve silver chloride, isoamyl alcohol and sodium alginate in distilled water, stir and mix evenly, the content of silver chloride in the mixed solution is 100g / L, the content of isoamyl alcohol is 120g / L, and the content of sodium alginate is 30g / L L, adjust the mixed solution pH value to be 6 with potassium hydroxide;

[0028] 2) Put the mixed solution of step 1) into an aluminum-plastic packaging bag and inflate it with helium for 7 minutes, discharge the dissolved oxygen in the solution, vacuumize and seal the package with a liquid vacuum packaging machine, and use 60 Co-γ rays were irradiated for reduction, and the irradiation dose was 35kGy.

[0029] 3) Pour the irradiated solution in 2) into a beaker, add dodecanethiol for oil-water coating, and the content of oil dodecanethiol is 20 g / L. Then use a vacuum suction filter to filter with water, and repeatedly wash the filter membrane in the suction filter with acetone and distilled water alternately to remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com