Foam plastic composite material with wave absorbing property and preparation method thereof

A technology of foam plastics and composite materials, which is applied in the field of composite plastics, can solve the problems of poor softness, easy deformation, and non-environmental protection of composite materials, and achieve the effect of avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

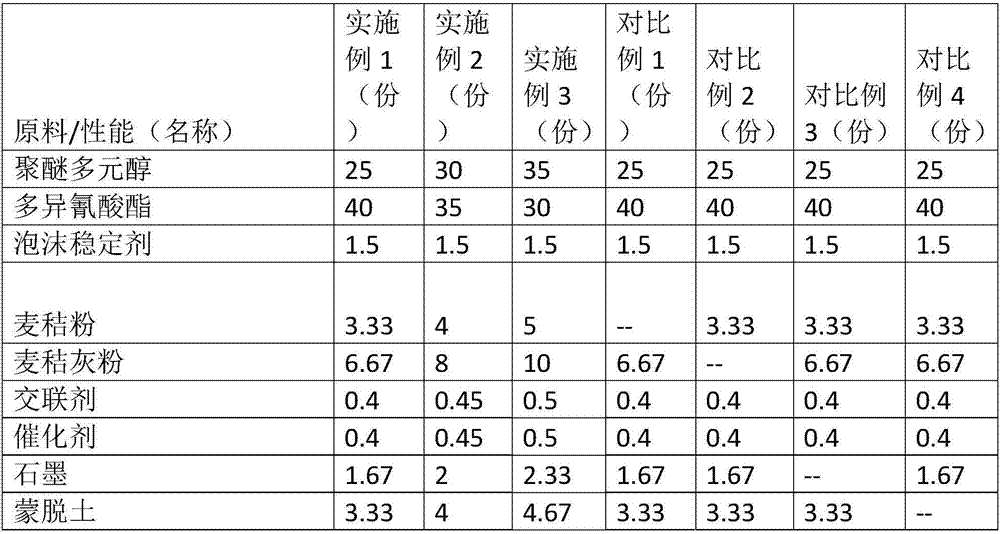

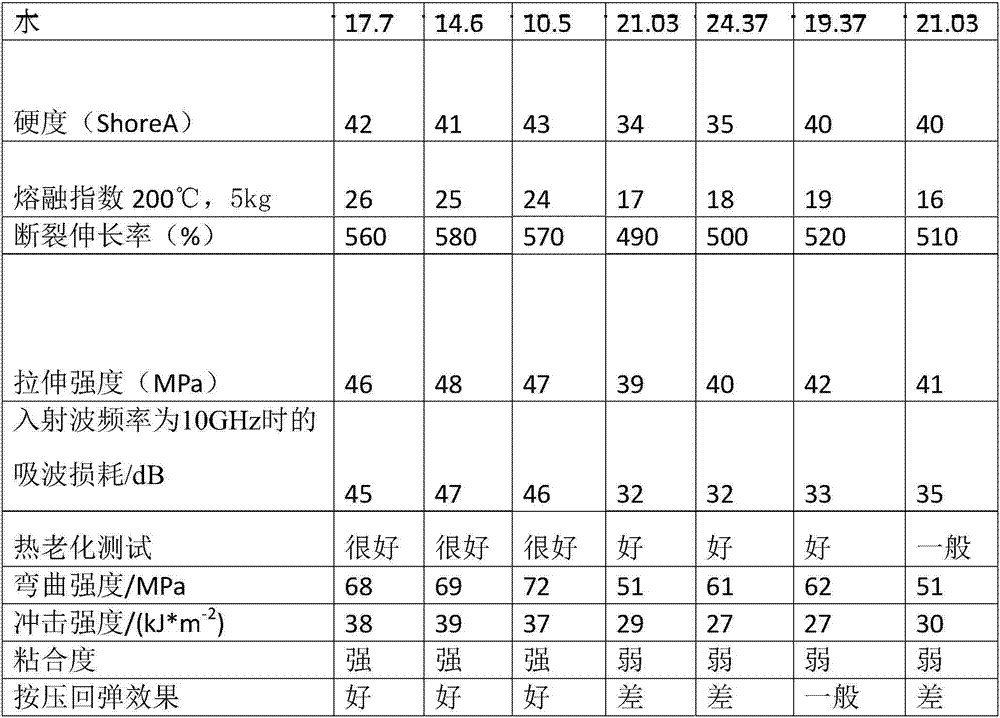

Embodiment 1-3 and comparative example 1-4

[0030] According to the formulas of Examples 1-3 and Comparative Examples 1-2 listed in Table 1 below ("parts" in the table refer to weight fractions, the same below) polyether polyols and polyisocyanates are placed in a vacuum oven at 50°C Vacuum dry for 12 hours, remove moisture, put the wheat straw granules into a drying oven and dry at 80°C, when the moisture content of the wheat straw granules is 7% using a moisture content tester, stop drying, take out the wheat straw granules and put them in the oven. put into a pulverizer, pulverize to a particle size of 50 meshes, and obtain wheat straw powder; after incinerating the wheat straw into ashes, obtain wheat straw ash powder;

[0031] Pour the polyether polyol, montmorillonite, wheat straw powder and wheat straw ashes into a blender, and stir evenly, then add water, vibrate in an ultrasonic wave at 55°C for 2 hours, and obtain the first mixture;

[0032] Put the first mixture into a mixer, then add a catalyst and a foam st...

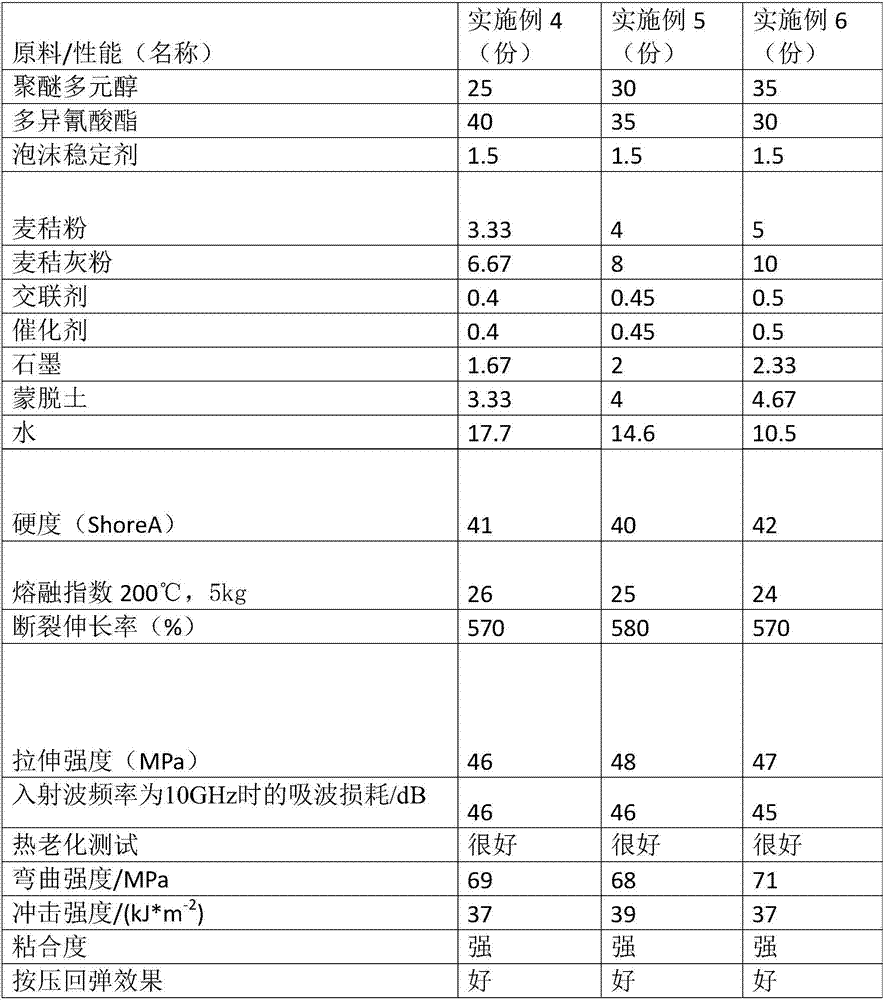

Embodiment 4-6

[0039] According to the formula of Examples 4-6 listed in the table below ("parts" in the table refer to weight fractions, the same below), put polyether polyol and polyisocyanate into a 60°C vacuum drying oven for 12h to remove moisture, The wheat straw granules are put into a drying oven and dried under the condition of 90° C., and when the moisture content of the wheat straw granules is measured by a moisture content tester to be 10%, the drying is stopped, and the wheat straw granules are taken out and put into a pulverizer, and pulverized to The particle size is 60 mesh, and the wheat straw powder is obtained, and the wheat straw ash powder is obtained after the wheat straw is incinerated into ashes;

[0040] Pour the polyether polyol, montmorillonite, wheat straw powder and wheat straw ashes into a blender, and stir evenly, then add water, vibrate in an ultrasonic wave at 60°C for 2.5 hours, and obtain the first mixture;

[0041] Put the first mixture into a mixer, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com