Preparation method for anticorrosion art paper

A kind of art paper, anti-corrosion technology, applied in the field of papermaking, can solve the problems of increased corrosion of paper and insufficient long-term storage of art works, etc., and achieves the effects of moderate permeability, low thermal expansion coefficient, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

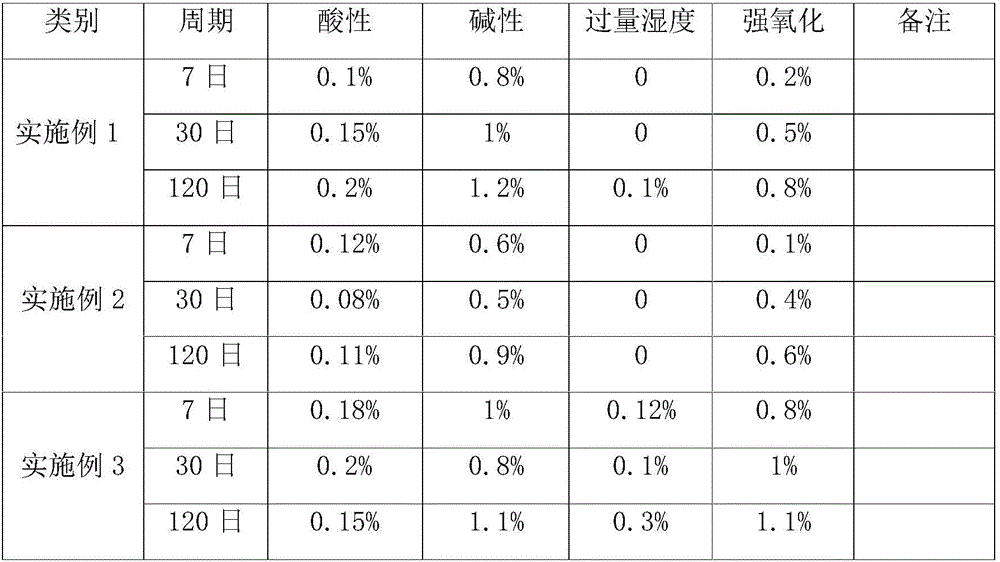

Examples

Embodiment 1

[0019] A preparation method of corrosion-resistant art paper, said preparation method comprising the following steps:

[0020] (1) Preparation of slurry: Put the trees or waste paper from which impurities have been removed into a shredder for mixing and crushing, then add water 100 times the weight of the crushed material, mechanically stir for 2 hours at a speed of 240r / min, and then add the weight of water 0.1 times the powdered ammonium sulfate continues to stir and mix. During the stirring and mixing process, the temperature is raised to 60°C, and the temperature is maintained for 10 minutes. After being bleached by alkaline bleaching process, beating with a beater, the beating degree is controlled at 40OSR, and the pretreatment is obtained. Good slurry, spare;

[0021] (2) anti-corrosion treatment: add 1% corrosion inhibitor of slurry weight, 3% sodium carboxymethyl cellulose, 0.05% titanium dioxide, 0.1% fire retardant, 0.8% to the slurry prepared in step (1) Antibacter...

Embodiment 2

[0025] A preparation method of corrosion-resistant art paper, said preparation method comprising the following steps:

[0026] (1) Preparation of slurry: Put the trees or waste paper from which impurities have been removed into a shredder for mixing and crushing, then add water 110 times the weight of the crushed material, mechanically stir at a speed of 270r / min for 2.5h, and then add water The powdered ammonium sulfate with a weight of 0.15 times the weight continues to be stirred and mixed. During the stirring and mixing process, the temperature is raised to 70 ° C, and the temperature is maintained for 15 minutes. After being bleached by an alkaline bleaching process, beating with a beater, the beating degree is controlled at 45OSR, and the pre-mixed Treated pulp, spare;

[0027](2) anti-corrosion treatment: add 2% anti-corrosion agent of slurry weight, 4% sodium carboxymethyl cellulose, 0.065% titanium dioxide, 0.2% flame retardant, 0.9% to the slurry prepared in step (1)...

Embodiment 3

[0031] A preparation method of corrosion-resistant art paper, said preparation method comprising the following steps:

[0032] (1) Preparation of slurry: Put the trees or waste paper from which impurities have been removed into a shredder for mixing and crushing, then add water 120 times the weight of the crushed material, stir mechanically at a speed of 300r / min for 3 hours, and then add the weight of water Continue to stir and mix 0.2 times the powdered ammonium sulfate, heat up to 80°C during the stirring and mixing process, keep the temperature for 20 minutes, bleach through alkaline bleaching process, beat with a beater, and control the beating degree at 50OSR to obtain pretreatment Good slurry, spare;

[0033] (2) anti-corrosion treatment: add 3% anti-corrosion agent of slurry weight, 5% sodium carboxymethyl cellulose, 0.08% titanium dioxide, 0.3% flame retardant, 1% to the slurry prepared in step (1) Antibacterial agent, 1.2% toughening agent, stirred by a mixer for 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com