Method for preparing biological diesel oil using high acid value cottonseed oil

A technology of biodiesel and cottonseed oil, which is applied in the fields of biological raw materials, biofuels, petroleum industry, etc., can solve the problems of prolonging the reaction time, difficult to achieve, and difficult to separate and wash the reaction product from soap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

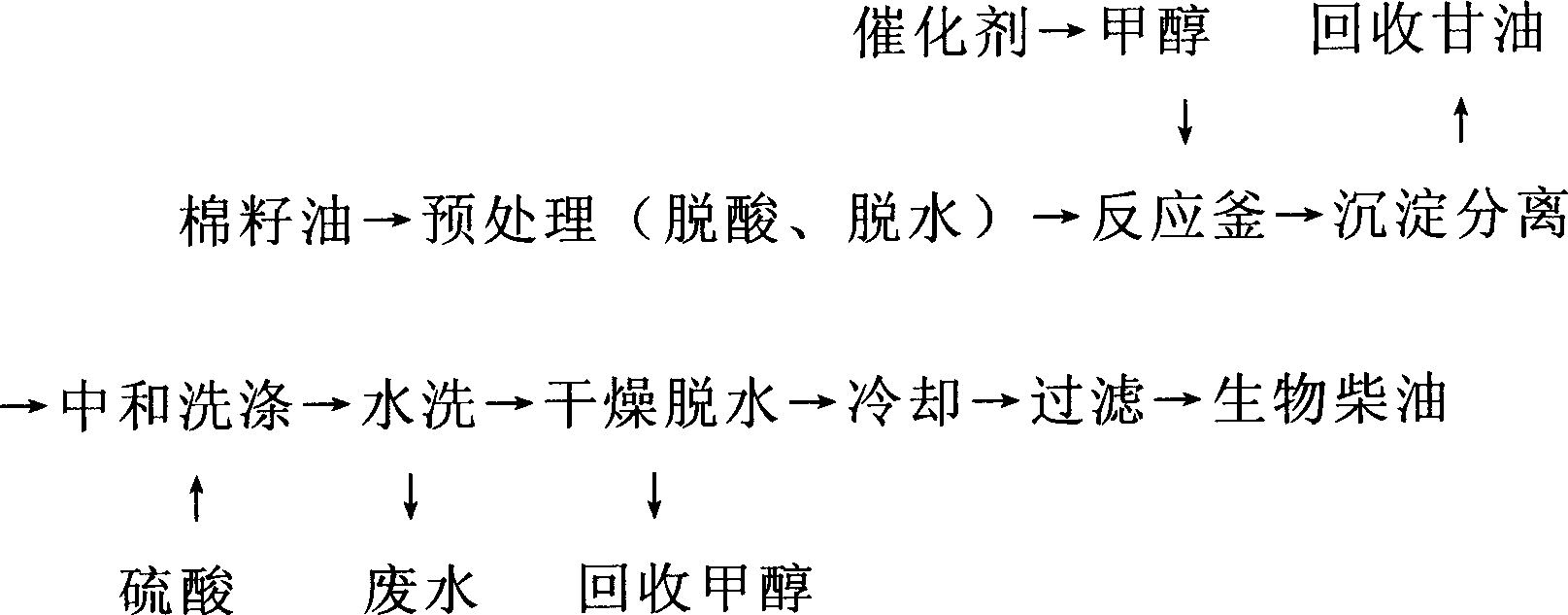

[0035] Example 1, high acidity cottonseed oil is produced biodiesel

[0036] ①Main raw materials and medicines: locally produced wool cotton oil, the measured acid value is 38mg KOH / g; anhydrous methanol, concentrated sulfuric acid, and KOH are all of analytical grade.

[0037] ②Operation steps:

[0038] ●Take 400g of wool cotton oil in a beaker, heat it to 75°C, add hot water at 78°C and stir for 30 minutes, settle for 4 hours, and use a separatory funnel to release the oil residue.

[0039] ●Take 200 g of washed cotton oil in a triangular beaker, add 30 g of anhydrous methanol and 2 mil of concentrated sulfuric acid. Keep the temperature on the water bath at 65-70°C and keep shaking. React for 3 hours.

[0040] ●Pour the mixture into a separatory funnel and let it stand for 2 hours. Release the aqueous glycerin. Then transfer the light phase part into the triangular beaker.

[0041] ●Add 10g of anhydrous methanol and 2mil of concentrated sulfuric acid into the triangul...

example 2

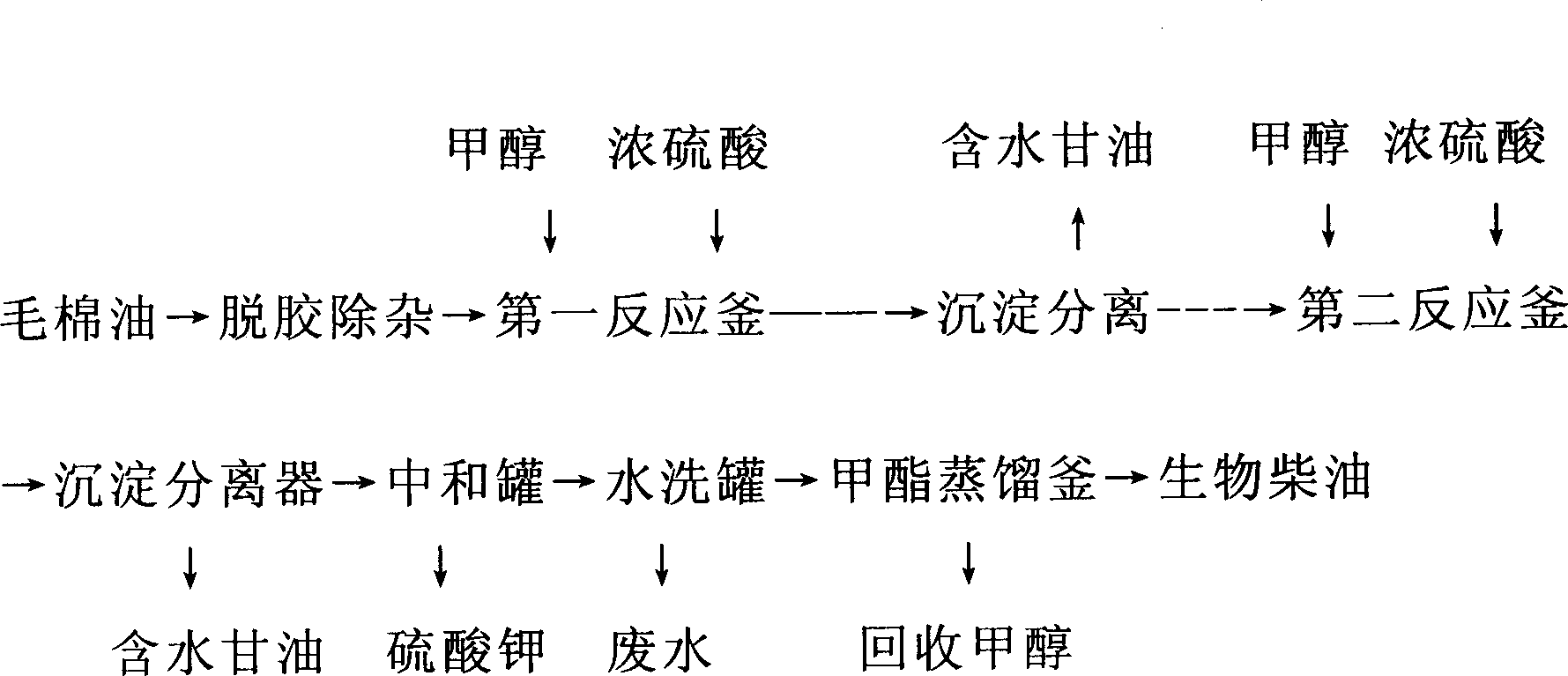

[0048] Example 2, medium acidity cottonseed oil is produced biodiesel

[0049] ①Main raw materials and medicines: locally produced wool cotton oil, the measured acid value is 5.6mg KOH / g; anhydrous methanol, concentrated sulfuric acid, and KOH are all of analytical grade.

[0050] ②The operation steps are as follows: figure 2 Shown:

[0051] ●Pump 500 kg of wool cotton oil into the hydration tank, stir and heat to 85°C, add light alkaline water with a temperature slightly higher than 87°C, settle for 6 hours, and release the oil foot;

[0052] Turn on the vacuum pump to make the first reactor in a vacuum state, suck the washed cotton oil into the reactor, and then inhale 12-15% of methanol by weight of the oil and concentrated sulfuric acid of 1% by weight of the oil;

[0053] ●Break the vacuum, start the stirrer (rotating speed is 60rpm), maintain the temperature in the kettle at 60-70°C, and react for 3 hours;

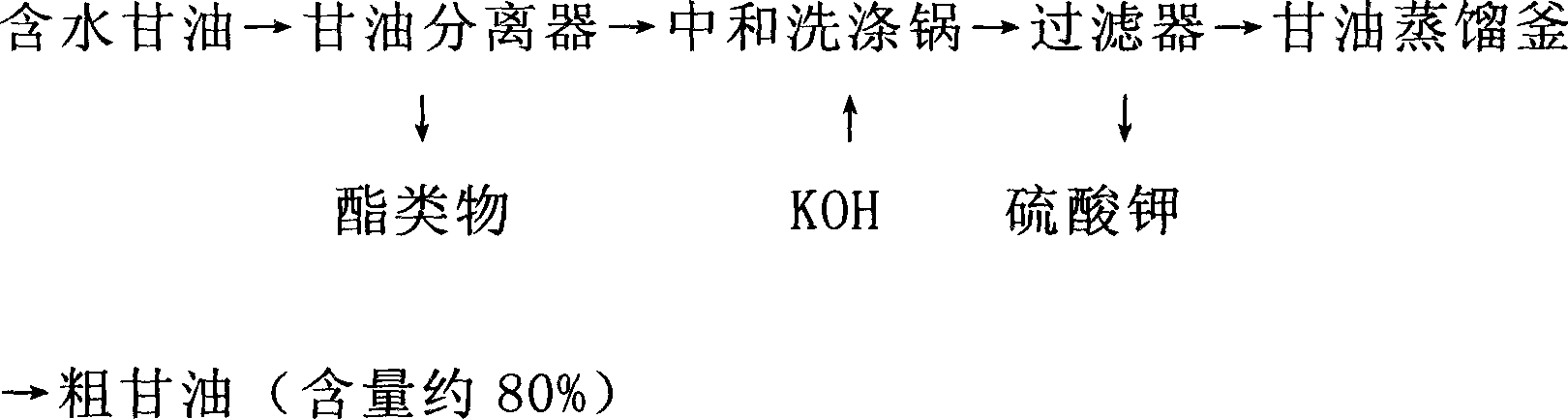

[0054] ●Stop stirring, settling for 2 hours, release the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com