Multifunctional optical-axis parallelism rectifying instrument and calibration method thereof

A calibrator and parallelism technology, applied in instruments, optical devices, measuring devices, etc., can solve the problems affecting the accuracy of measurement and calibration, human operation error, long cycle, etc., to achieve strong versatility, avoid processing risks, and operate Simple and orderly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical scheme of the present invention mainly has the following characteristics:

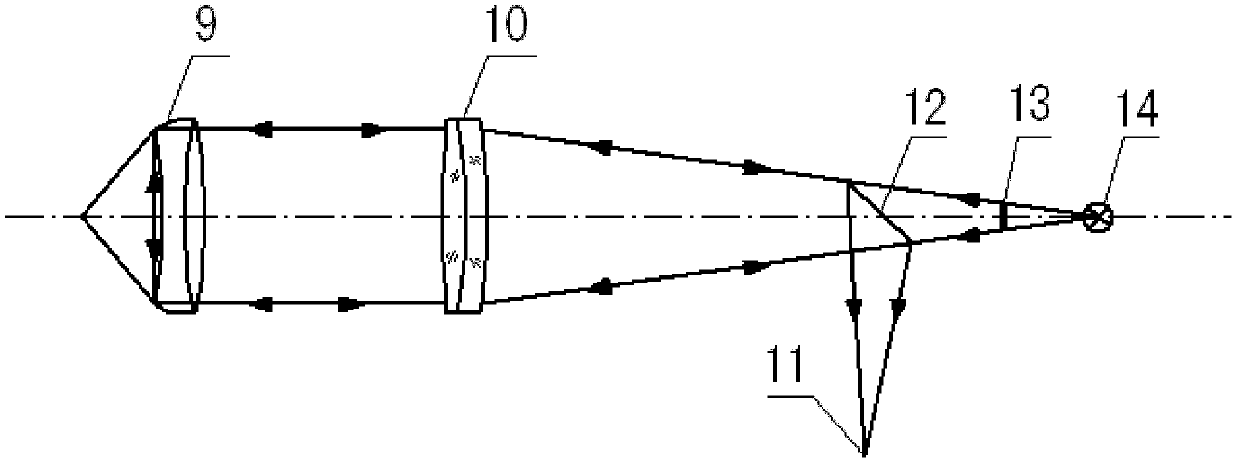

[0051] 1. The measurement of the optical axes of the multiple subsystems of the multi-optical axis system to be calibrated adopts independent and corresponding collimator tubes.

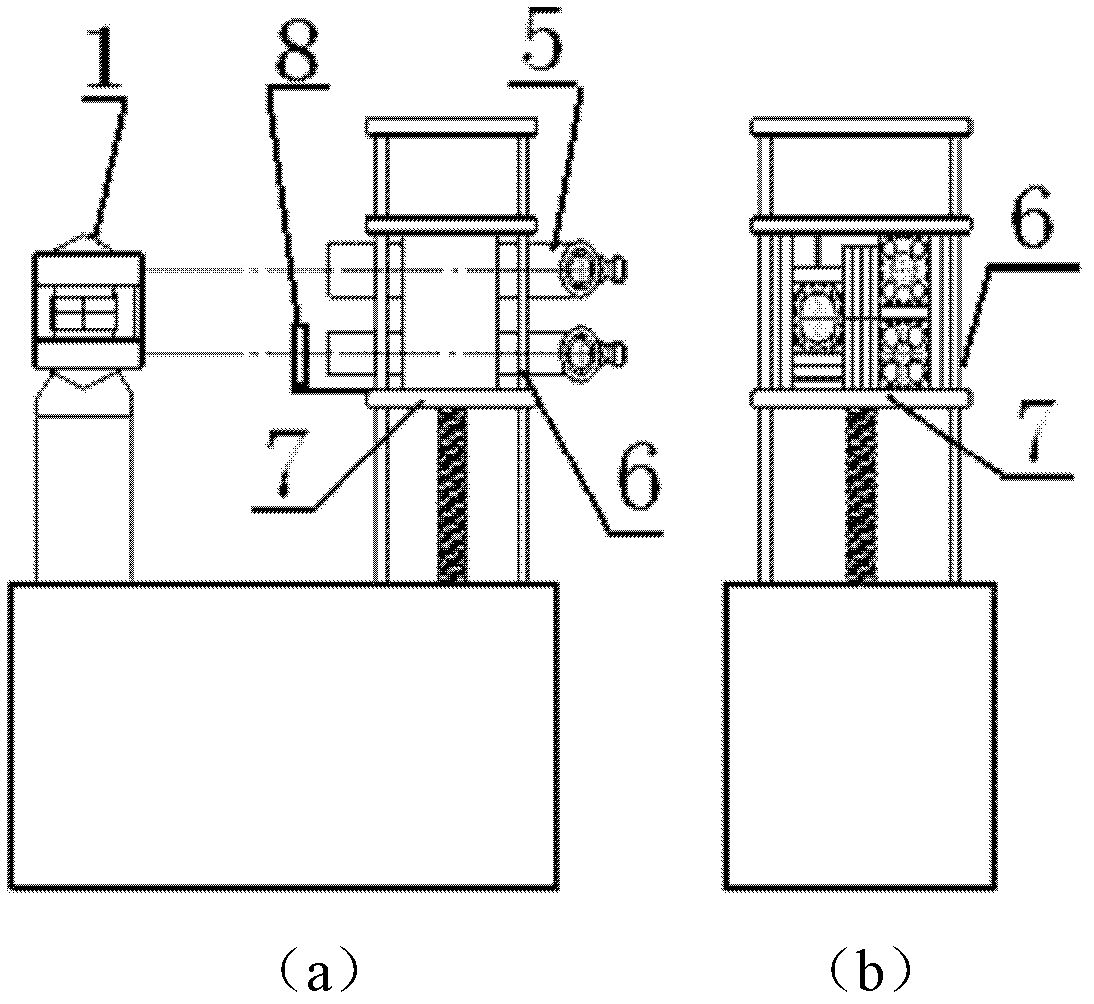

[0052] 2. Correspondingly assemble the required collimator through the assembly table according to the span and position between the optical axes of the multiple subsystems of the multi-optical axis system to be corrected.

[0053]3. Commonly used precision calibration accessories can be used to calibrate and measure the parallelism of the optical axis of the collimator, so that the combined calibrator can meet the requirements of high-precision parallelism detection and calibration.

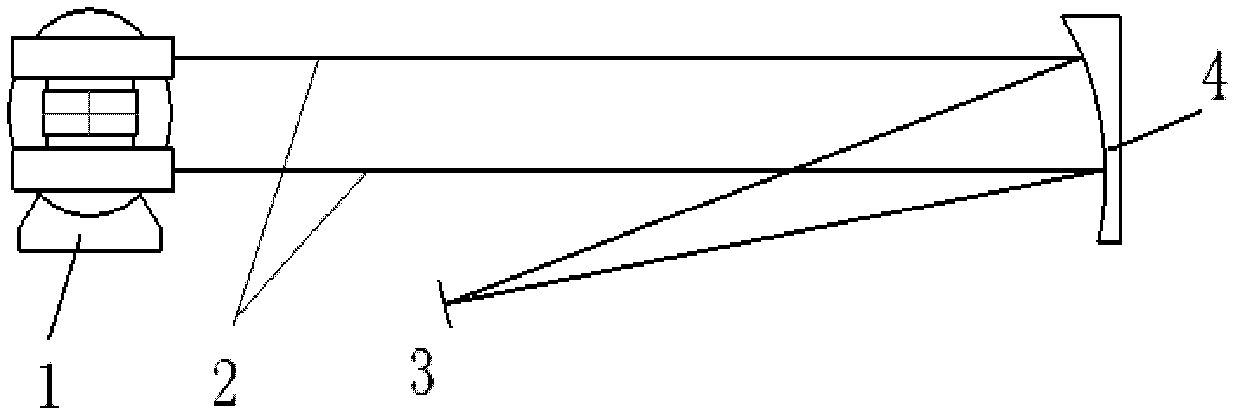

[0054] The calibrated calibrator can be used to detect and calibrate the optical axis parallelism of the multi-axis system to be calibrated, realizing the function of the large-aperture off-axis parabolic reflective collima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com