Manufacturing method of net-size H-shaped structures

An I-shaped, net-size technology, applied in the field of preparation of net-sized I-shaped structures, can solve the problems of reducing structure forming efficiency and increasing the risk of strip delamination, and achieve the effect of improving structure forming efficiency and avoiding processing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to deepen the understanding of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

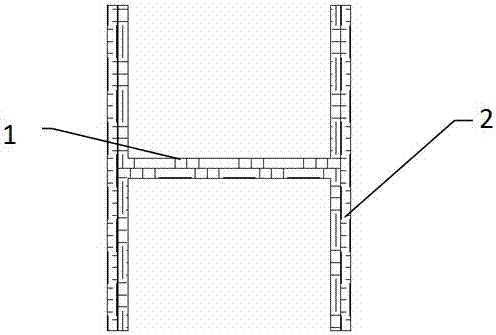

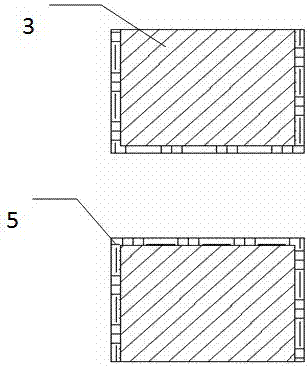

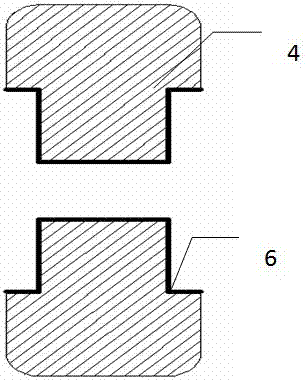

[0022] Such as Figure 1-6 Shown, the present invention is a kind of preparation method of net size H-shaped structure, and described preparation method comprises the steps:

[0023] (A) Prepare the prefabricated body mold and the upper and lower main molds 4; in this step, the prefabricated body mold and the main mold 4 have the same dimension and width of the molding surface, and the height difference is the thickness of one layer of prepreg, and the main mold 4 is set limited hole 8;

[0024] (B) Lay two parts of the C-shaped structure on the prefabricated body mold, and trim it to the net size to obtain the C-shaped prefabricated body mold 3; the thickness of the edge lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com