Patents

Literature

111 results about "Glycerol ester of wood rosin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

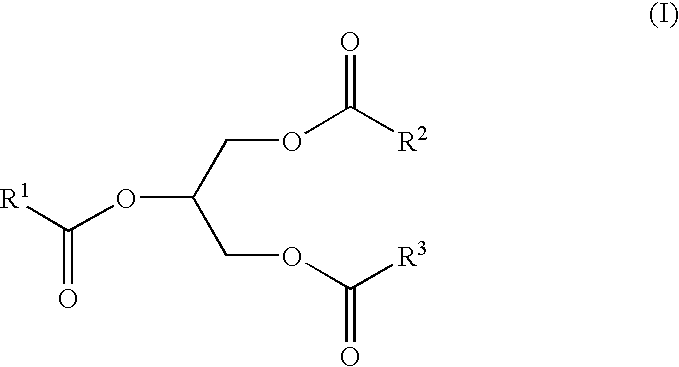

Glycerol ester of wood rosin, also known as glyceryl abietate or ester gum, is an oil-soluble food additive (E number E445). The food-grade material is used in foods, beverages, and cosmetics to keep oils in suspension in water, and its name may be shortened in the ingredient list as glycerol ester of rosin. It is also used as an ingredient in the production of chewing-gum and ice cream. Similar, less pure materials (glycerol ester of gum rosin) are used as a component of certain low-cost adhesives.

Process for the preparation of a fat composition containing sterol esters a product obtained by said process and the use thereof

InactiveUS20040047971A1Cosmetic preparationsHydroxy compound active ingredientsGlycerol ester of wood rosinSterol ester

The invention refers to a process for the preparation of a fat composition containing fatty acid sterol esters, free sterols and glycerides, which process can be characterized as a one pot direct interesterification of sterols with tri-glycerides. The invention also refers to the fat composition obtained by said process, and to the use thereof in a food, cosmetic or pharmaceutical product.

Owner:KARLSHAMNS AB KARLSHAMN

Fatty acid compositions having superior stability and flavor properties

InactiveUS6838109B2Minimize off-flavorsMinimize off-odorsFood ingredientsFood preparationGlycerol ester of wood rosinEmulsion

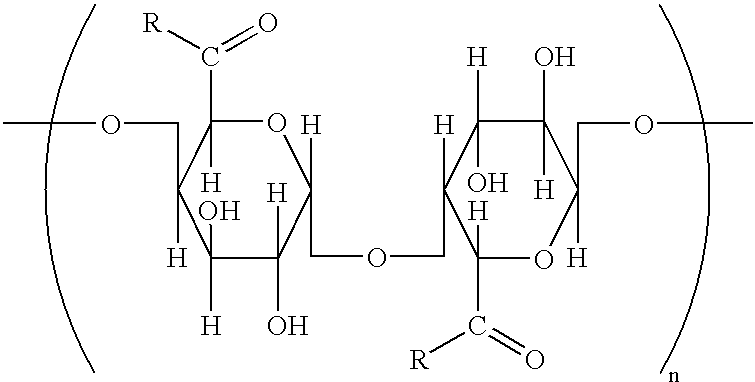

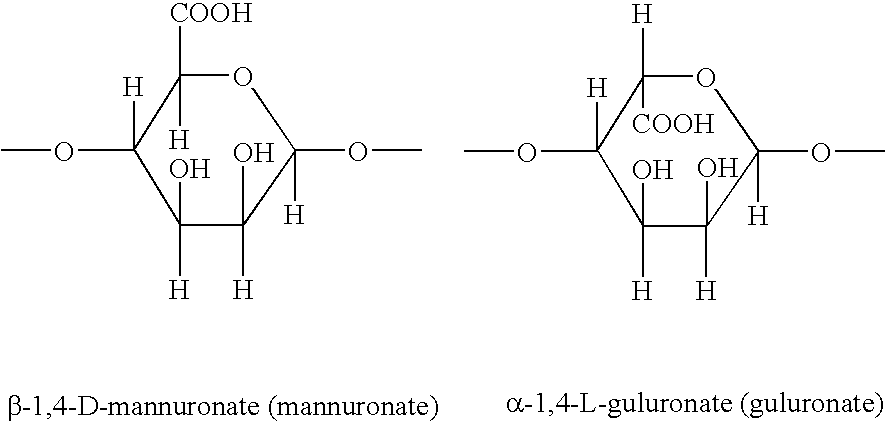

The present invention relates to compositions having a superior stability and flavor profile, despite the presence of a fatty acid material (and even without use of a surfactant or emulsion), and may be utilized as a variety of different finished compositions, for example, cosmetic, health care, food, and beverage compositions, preferably food and beverage compositions, and most preferably beverage compositions. The compositions herein comprise:a) a fatty acid material selected from the group consisting of fatty acids, esters thereof, glycerides thereof, and mixtures thereof;b) a pectin compound; andc) an alginate compound.The present invention further relates to methods of stabilizing a product comprising incorporating into the product a composition as described herein.

Owner:SD IP HLDG

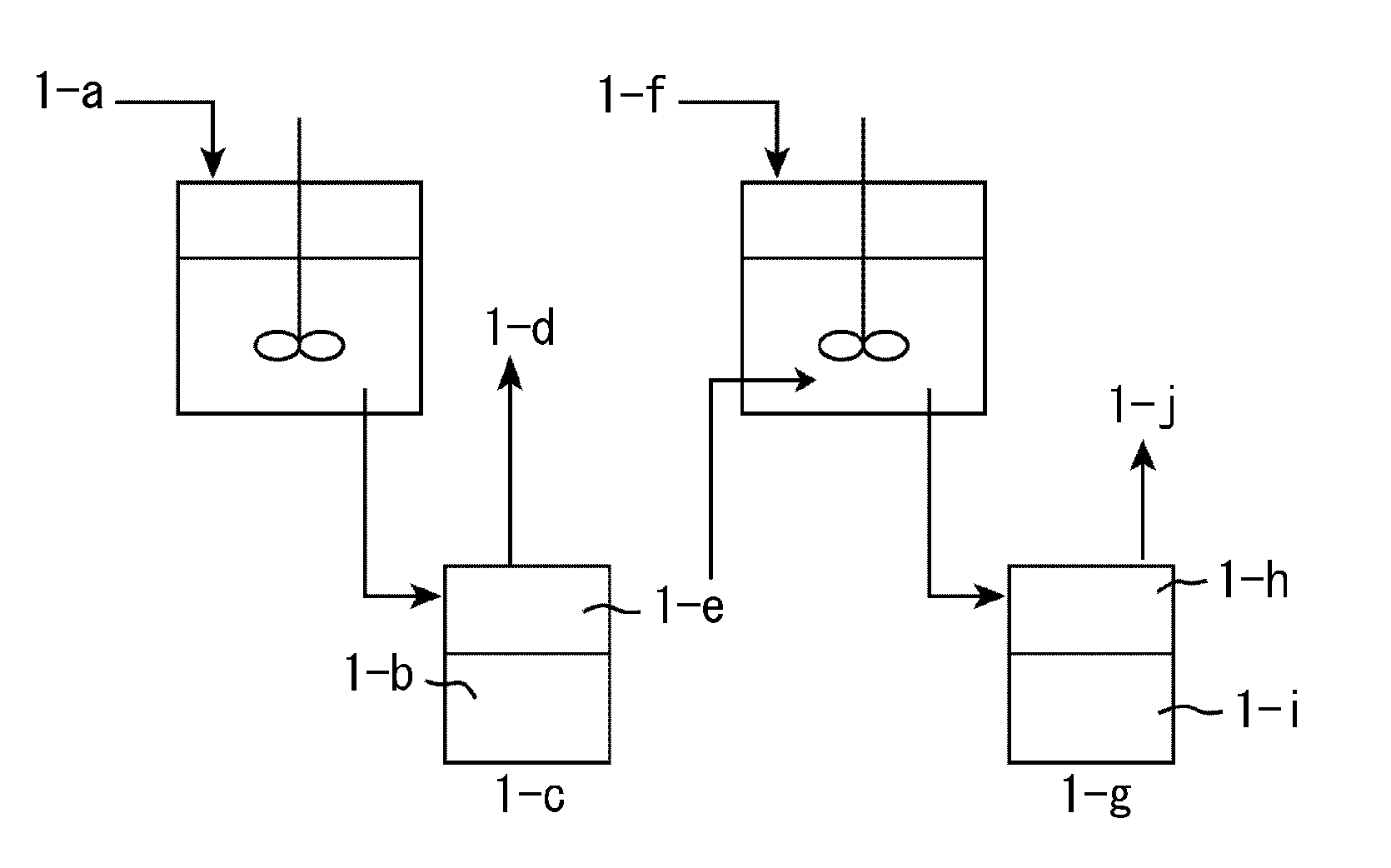

Refined method for manufacturing ethyl esters from fatty substances of natural origin

InactiveUS7652156B2Fatty oils/acids recovery from wasteFatty acid esterificationNatural sourceGlycerol ester of wood rosin

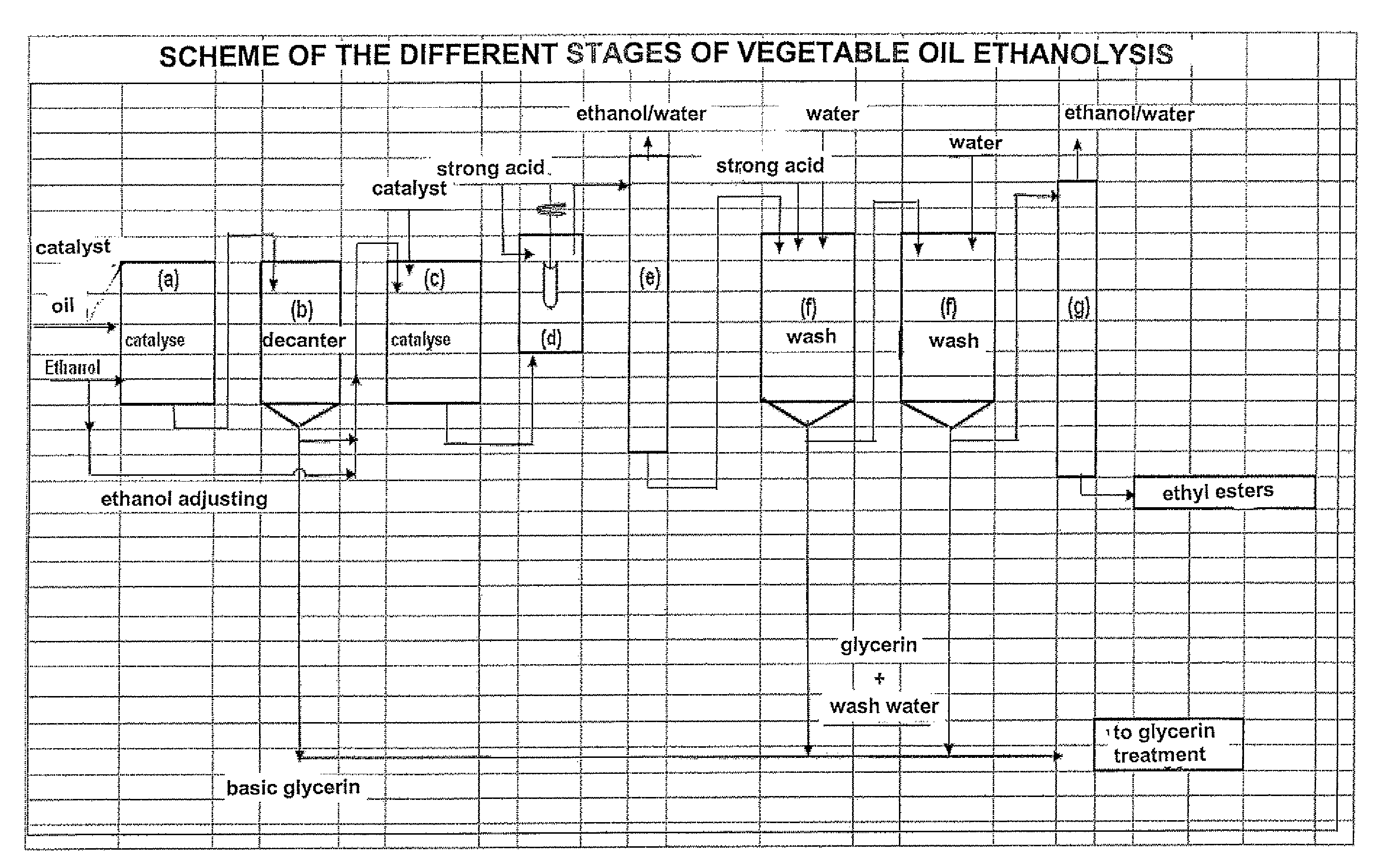

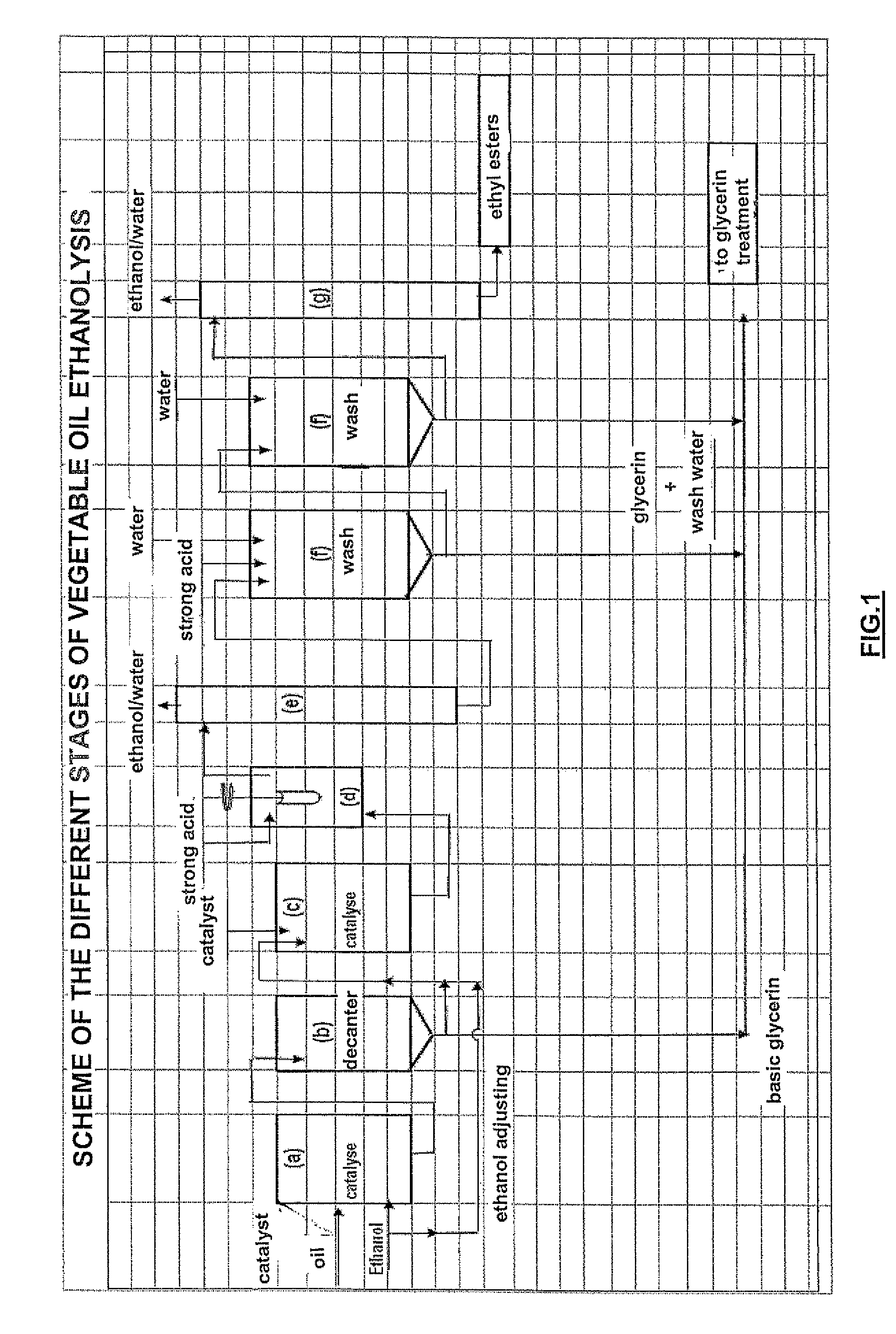

A method allowing, from natural fat or oils, vegetable or animal, or from other glyceride mixtures, to obtain in a quasi-quantitative way fatty acid ethyl esters that can be used as gas oil substitutes, comprises the succession of stages as follows:a stage (a) wherein the oil, the fat or the glyceride mixture is transesterified by ethanol using a soluble catalyst or a catalyst that becomes soluble during the reaction,a stage (b) wherein the glycerin formed is decanted and removed, without requiring an excess ethanol evaporation operation,a stage (c) wherein a second transesterification reaction is carried out so as to obtain a product whose ester content is at least 97% by mass,a stage (d) wherein controlled neutralization of the catalyst is carried out,a stage (e) wherein the excess ethanol is removed by distillation,a stage (f) wherein the ester undergoes purification by means of water wash sequences, anda stage (g) wherein the ester mixture is dried under reduced pressure.

Owner:INST FR DU PETROLE

External structuring system for liquid laundry detergent composition

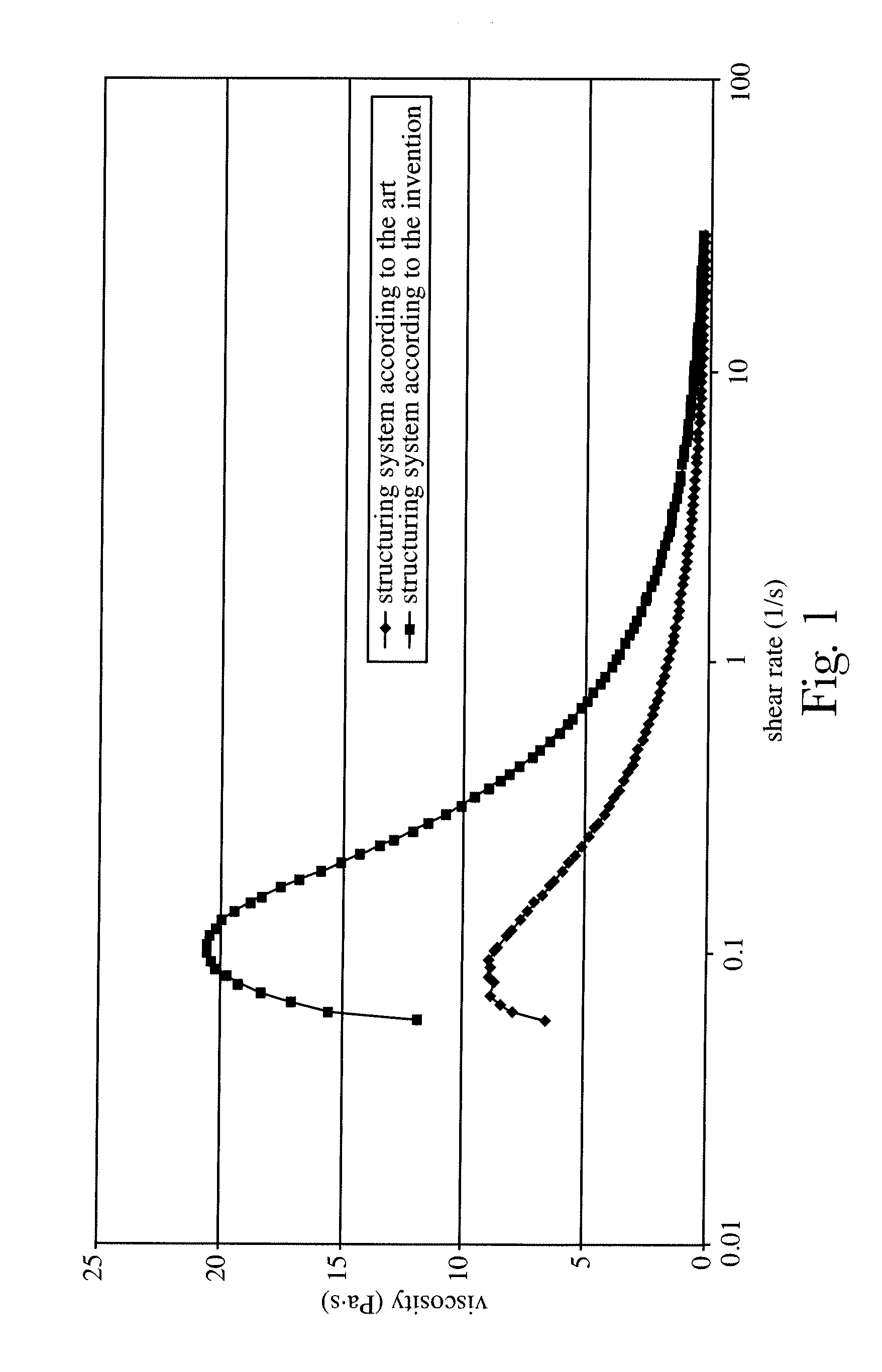

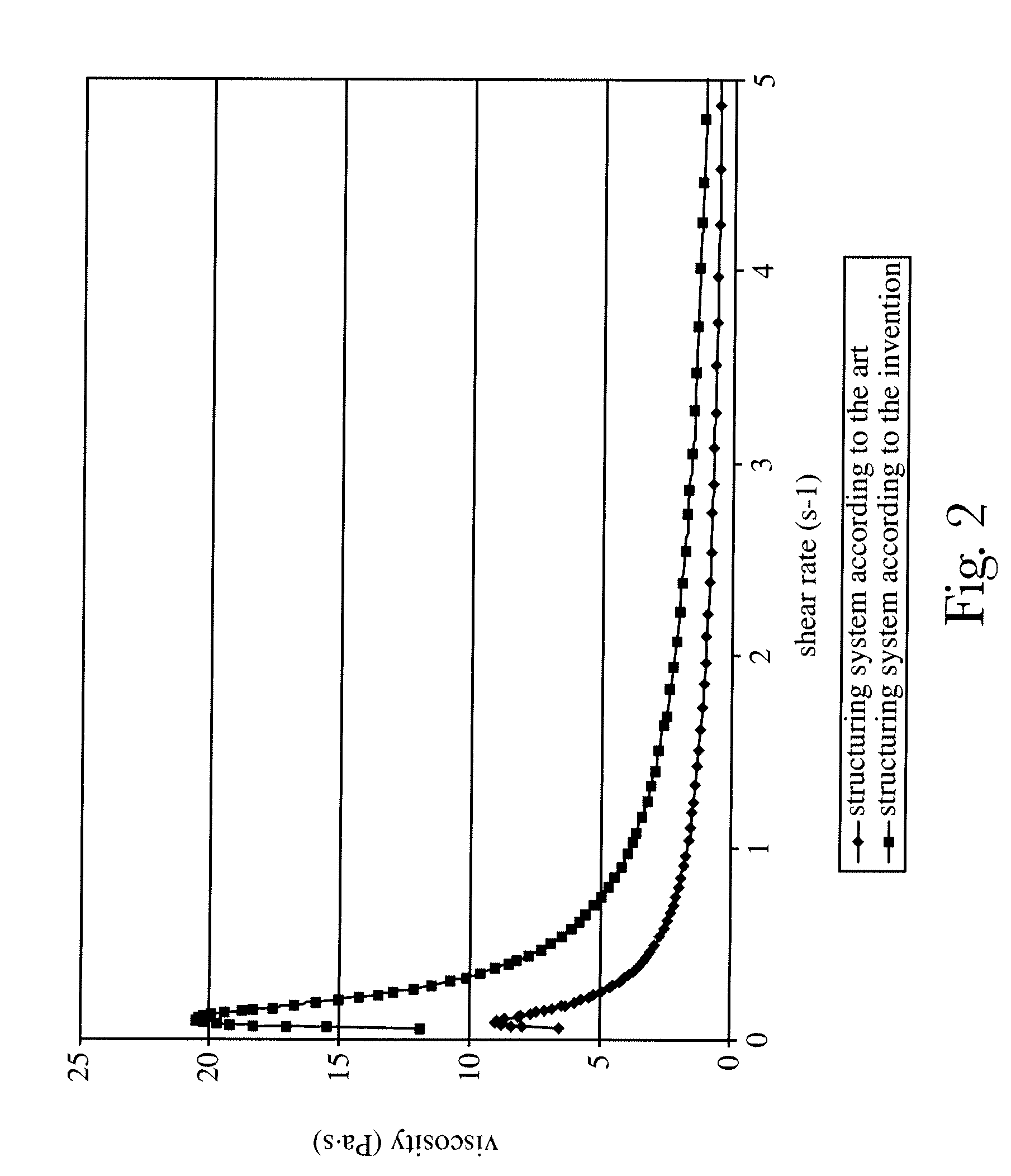

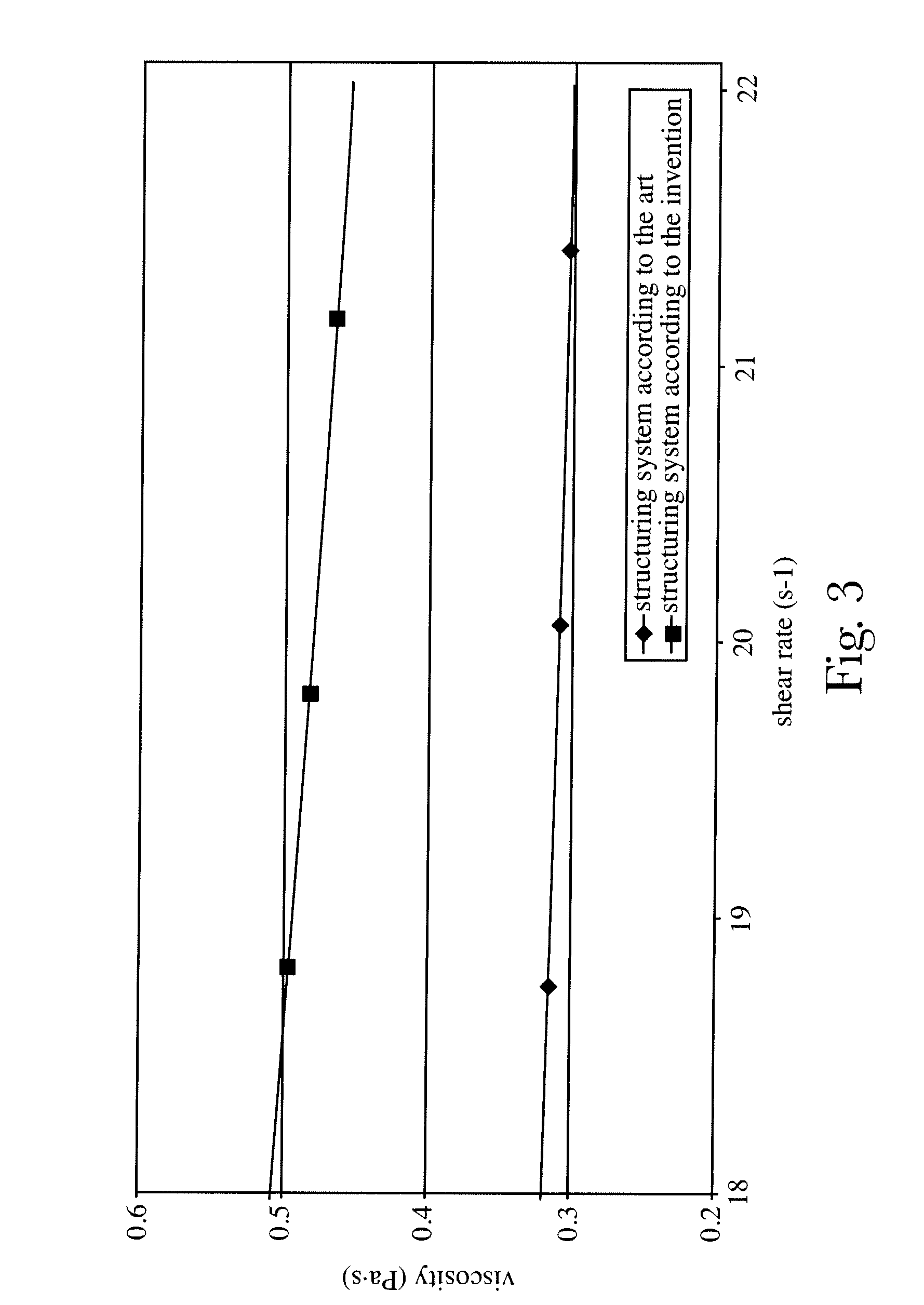

ActiveUS20110065625A1Lower Level RequirementsEffective structureOrganic detergent compounding agentsNon-surface-active detergent compositionsGlycerol ester of wood rosinLiquid laundry detergent

Liquid or gel-form detergents can be externally structured with a structuring system comprising crystallizable glyceride(s) emulsified with an alkanolamine-neutralized anionic surfactant. Crystallizable glyceride(s) of use include hydrogenated castor oil. The liquid or gel-form detergents may be packaged in unit dose form.

Owner:THE PROCTER & GAMBLE COMPANY

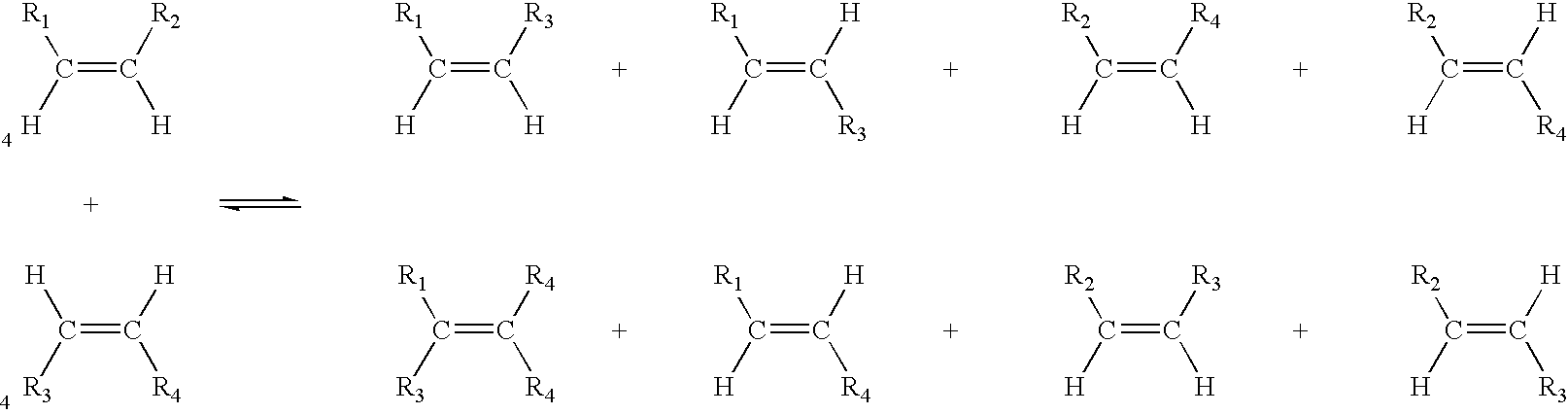

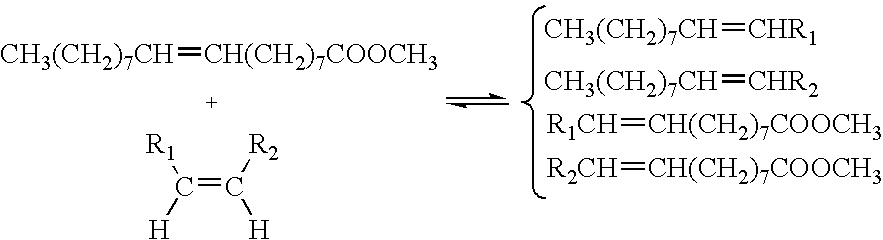

Process for co-producing olefins and esters by ethenolysis of unsaturated fats in non-aqueous ionic liquids

InactiveUS7678932B2Fatty acid chemical modificationOrganic compound preparationGlycerol ester of wood rosinGlycerol

A process is described in which an unsaturated fat is reacted with ethylene in a metathesis reaction in the presence of at least one non-aqueous ionic liquid to produce both an olefinic fraction and a composition of monoalcohol or polyol esters.Particular application to an oleic sunflower seed oil, an oleic rapeseed oil or to a mixture of monoalcohol esters of said oils, the process producing both an olefinic fraction and a monoalcohol or glycerol esters composition generally having more than half of its chains constituted by unsaturated C10 chains.

Owner:INST FR DU PETROLE

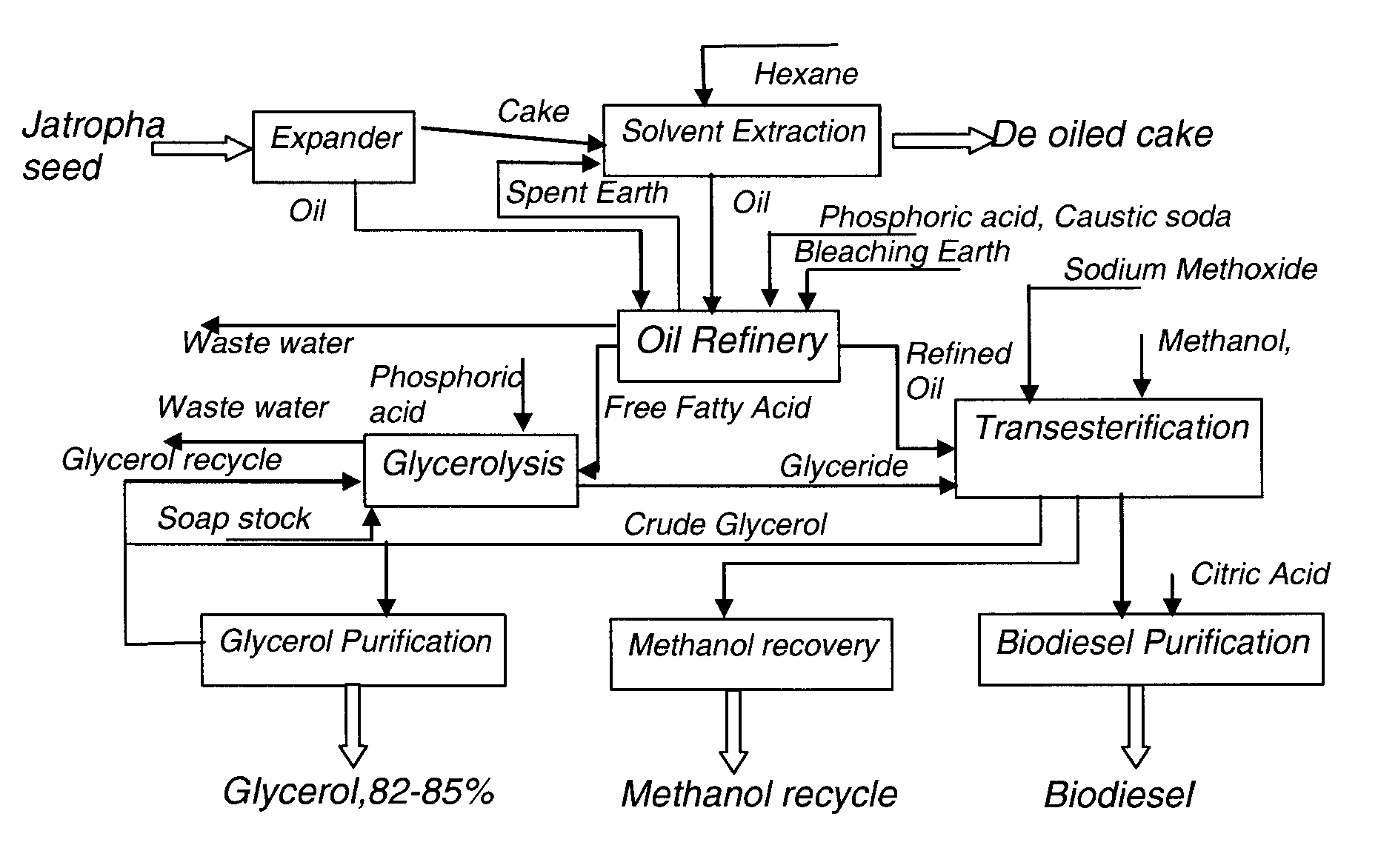

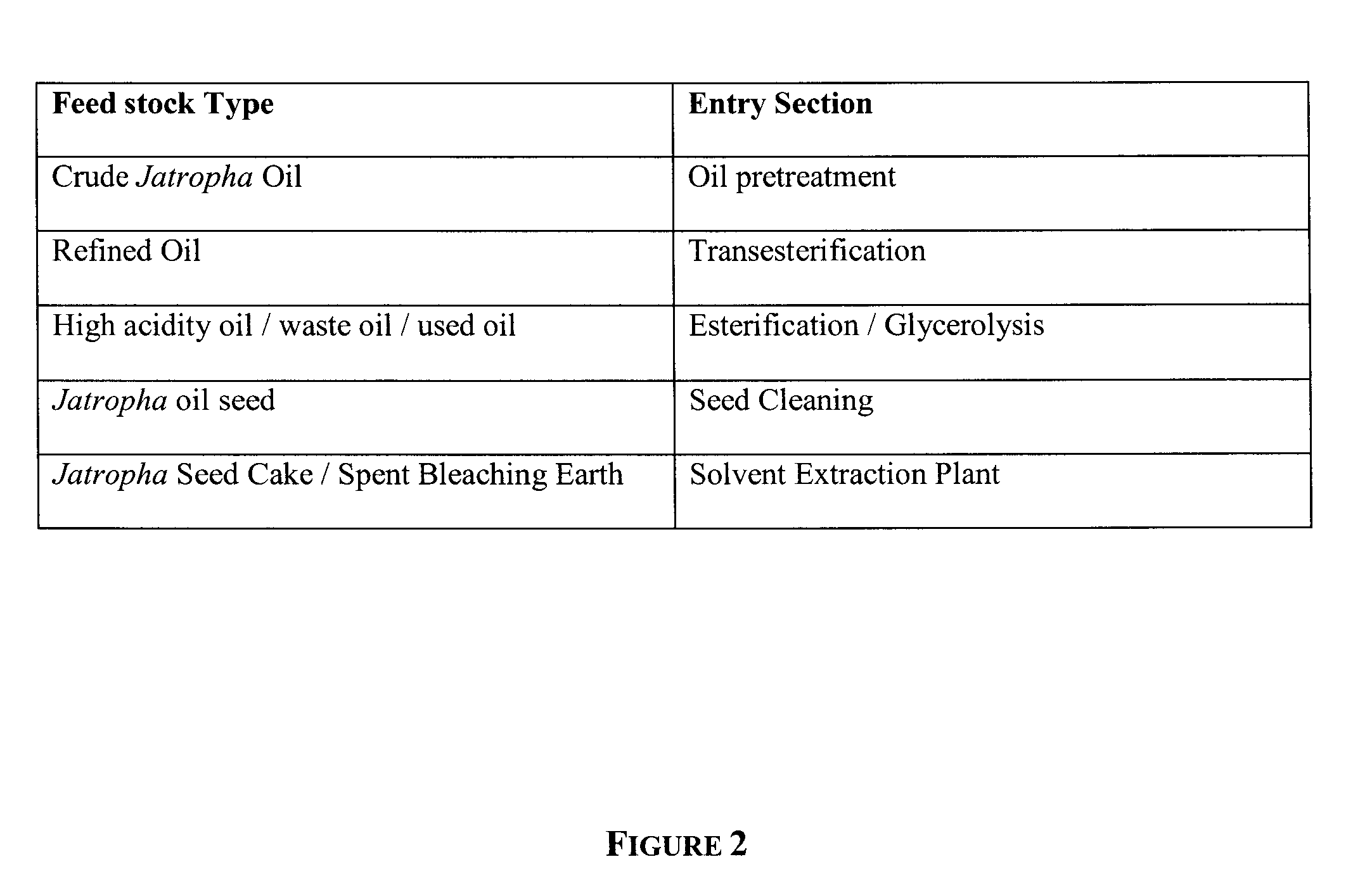

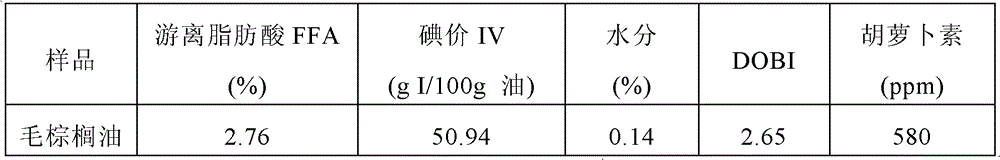

Integrated Process for the Preparation of Fatty Acid Methyl Ester (Biodiesel)

InactiveUS20080269513A1Fatty oils/acids recovery from wasteFatty acid esterificationVegetable oilGlycerol ester of wood rosin

The disclosure provides methods and systems for the production of biodiesel from biological feedstocks such as vegetable oils or animal fats. In particular, the disclosure is directed to the product of biodiesel from seeds such as non-edible oil seeds. Methods for maximizing oil recovery from the feedstocks are provided, as well as methods to convert free fatty acids in the feedstocks into glycerides amenable to transesterification. Thus the methods and systems provide for efficient biodiesel production.

Owner:RELIANCE LIFE SCI PVT

Fabric care composition

ActiveUS20120142578A1Surface-active detergent compositionsOrganic/inorganic per-compounds compounding agentsGlycerol ester of wood rosinMedicine

The instant disclosure relates to compositions comprising glycerol esters. Methods of making and using such compositions are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

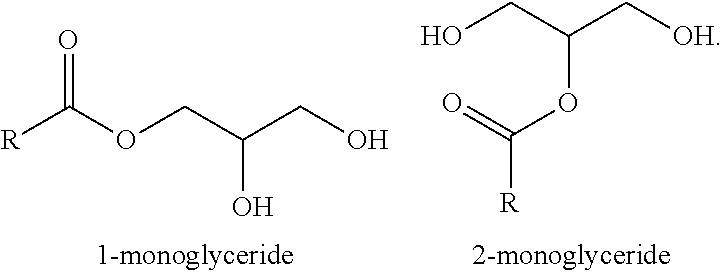

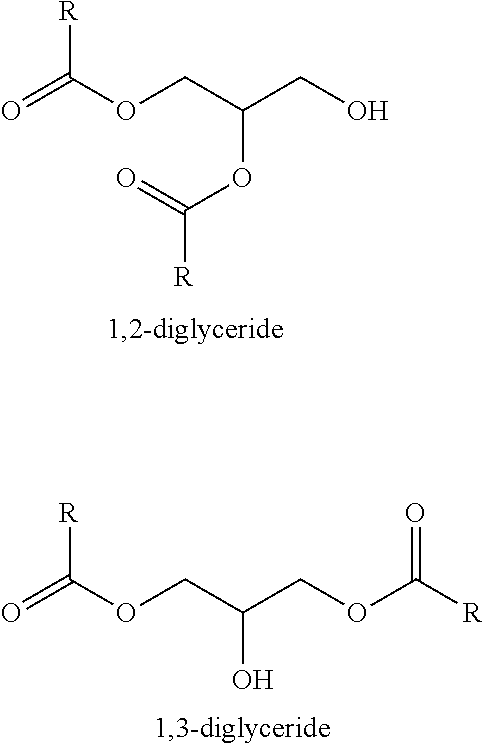

Oil/fat powder

InactiveUS7141265B2Good dispersibilityImprove stabilitySugar food ingredientsDough treatmentOil and greaseMonoglyceride

Provided is an oil / fat powder comprising the following Components (A), (B) and (C): (A) 15 to 79.9 wt. % of a glyceride mixture containing 5 to 84.9 wt. % of triglycerides, 0.1 to 5 wt. % of monoglycerides and 15 to 94.9 wt. % of diglycerides, and having, as at least 50 wt. % of all the constitutive fatty acids, unsaturated fatty acids; (B) 20 to 84.9 wt. % of one or at least two powder forming bases selected from carbohydrates, proteins and peptides; (C) 0.1 to 5 wt. % of water. The diglyceride-containing oil / fat powder according to the present invention exhibits good taste, and excellent dispersibility in water and storage stability. Moreover, owing to good handling use and workability when it is added to food, it can be used readily for various forms of foods. Foods containing this oil / fat powder taste good and have good storage stability.

Owner:KAO CORP

High-solid low-viscosity acrylic resin and preparation method thereof

InactiveCN104672366AShort synthesis timeLow degree of branchingPolyurea/polyurethane coatingsPolymer scienceButyl acetate

The invention discloses high-solid low-viscosity acrylic resin and a preparation method thereof. The high-solid low-viscosity acrylic resin comprises butyl acetate, methylacrylic acid, glycidyl tertiary carboxylic ester, styrene, styrene dimer, an initiating agent and acrylate. The preparation method of the high-solid low-viscosity acrylic resin comprises the following steps: stirring mixed solution of part of butyl acetate and part of glycidyl tertiary carboxylic ester, heating, carrying out heat preservation, and refluxing for 0.5-1 hour; then dropwise adding part of mixture of initiating agent, acrylate, styrene, styrene dimer and methylacrylic acid, carrying out copolymerization reaction, and then carrying out heat preservation for 0.5-1.5 hours; and finally dropwise adding the rest mixture of butyl acetate, initiating agent and glycidyl tertiary carboxylic ester, then carrying out heat preservation for 1-2 hours, cooling and discharging. The high-solid low-viscosity acrylic resin disclosed by the invention has the advantages that the acrylic resin synthesis time is shortened, the production cost is reduced, the polymer molecular weight is low, and the branching degree is low; meanwhile, the problems that common acrylic resin on the market is high in viscosity and poor in acid and alkali resistance and water resistance are solved.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Method for controlling glycidyl ester in grease

InactiveCN103060088AEffective control of glycidolEffectively control its ester contentFatty-oils/fats refiningEdible oils/fatsGlycerol ester of wood rosinGlycerol

The invention relates to a method for controlling glycidyl ester in grease and the grease obtained by the method. The method for controlling glycidyl ester in grease is characterized in that a proper amount of citric acid crystals or solution can be added in bleached oil and the final deodorization is carried out. The method provided by the invention greatly reduces the content of glycidol and / or its ester in refined grease.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

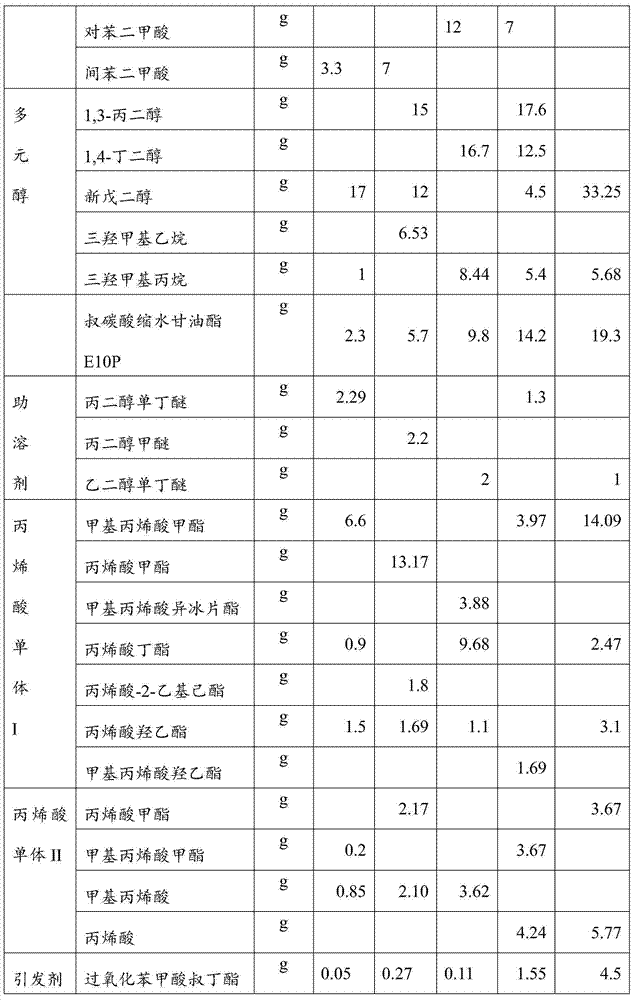

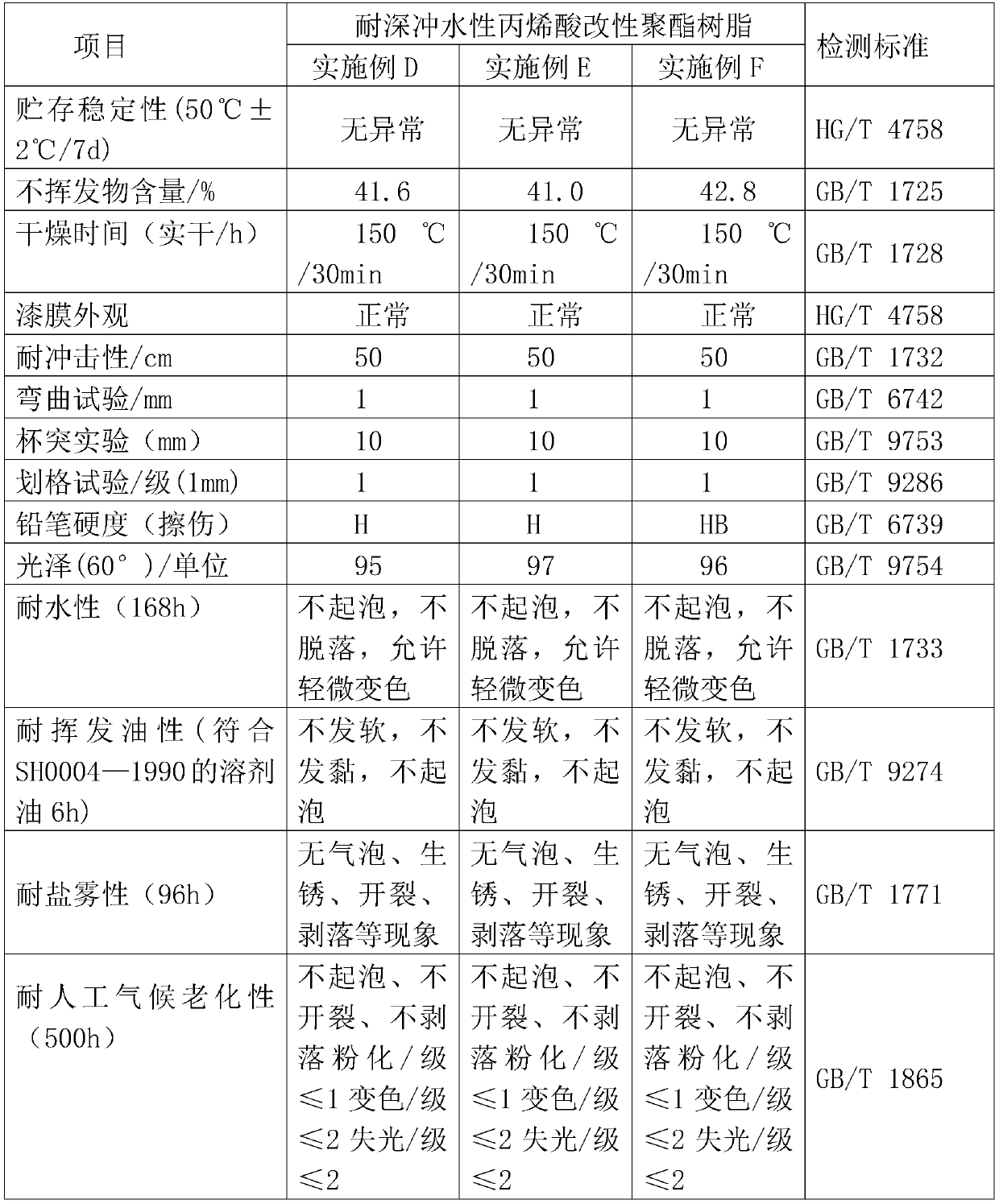

Waterborne acrylic modified saturated polyester resin

InactiveCN104761684AImprove hydrolysis resistanceImprove protectionPolyester coatingsGlycerol ester of wood rosinPolyol

The present invention relates to an aqueous acrylic acid modified saturated polyester resin, comprising the following materials of parts by weight: 5-25 parts of a polyacid, 15-40 parts of a polyol, 1-3 parts of a solubilizing agent, 5-20 parts of an acrylic acid monomer I, 0.5-10 parts of acrylic acid monomer II, 0.01-8 parts of an initiator, 0.5-10 parts of a neutralizer, 2-20 parts of glycidyl ester tertcarbonate, and 40-50 parts of deionized water. The aqueous acrylic acid modified saturated polyester resin prepared in the present invention has excellent stability, high solid-ness, low viscosity, and low VOC content, and can be mainly used for amino baked-on coating for aqueous coatings.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD +1

Asphalt binders containing a glyceride and fatty acid mixture and methods for making and using same

Asphalt binders and methods for making and using same. In at least one specific embodiment, the asphalt binder can include a bitumen and a glyceride and fatty acid mixture. The glyceride and fatty acid mixture can include one or more triglycerides, at least 1 wt % of one or more diglycerides, and at least 5 wt % of one or more fatty acids, based on the combined weight of the one or more triglycerides, the one or more diglycerides, and the one or more fatty acids. The asphalt binder can be made by combining a bitumen and a glyceride and fatty acid mixture. A paving composition can be made by combining a plurality of solids and the asphalt binder. A road can include a plurality of solids mixed with the asphalt binder.

Owner:FLINT HILLS RESOURCES LP

Preparation method of fluorin modified crylic acid resin for helicopter skining paint

the invention discloses a fluorine modified acrylic resin and preparing method for helicopter covering paint, which comprises the following steps: blending composite monomer methacrylic acid borneol ester, n-butyl methacrylate, hydroxyethyl methacrylate, butyl acrylate, methacrylic acid and fluorine monomer in the composite solvent with xylene, propylene glycol methyl ether acetic ester, methyl isobutyl ketone and 100# solvent oil; dripping carbonic glycide ester to polymerize acted by trigger pentaphen peroxide to obtain the product.

Owner:ZHEJIANG UNIV +1

Asphalt binders containing a glyceride and fatty acid mixture and methods for making and using same

Asphalt binders and methods for making and using same. In at least one specific embodiment, the asphalt binder can include a bitumen and a glyceride and fatty acid mixture. The glyceride and fatty acid mixture can include one or more triglycerides, at least 1 wt % of one or more diglycerides, and at least 5 wt % of one or more fatty acids, based on the combined weight of the one or more triglycerides, the one or more diglycerides, and the one or more fatty acids. The asphalt binder can be made by combining a bitumen and a glyceride and fatty acid mixture. A paving composition can be made by combining a plurality of solids and the asphalt binder. A road can include a plurality of solids mixed with the asphalt binder.

Owner:FLINT HILLS RESOURCES LP

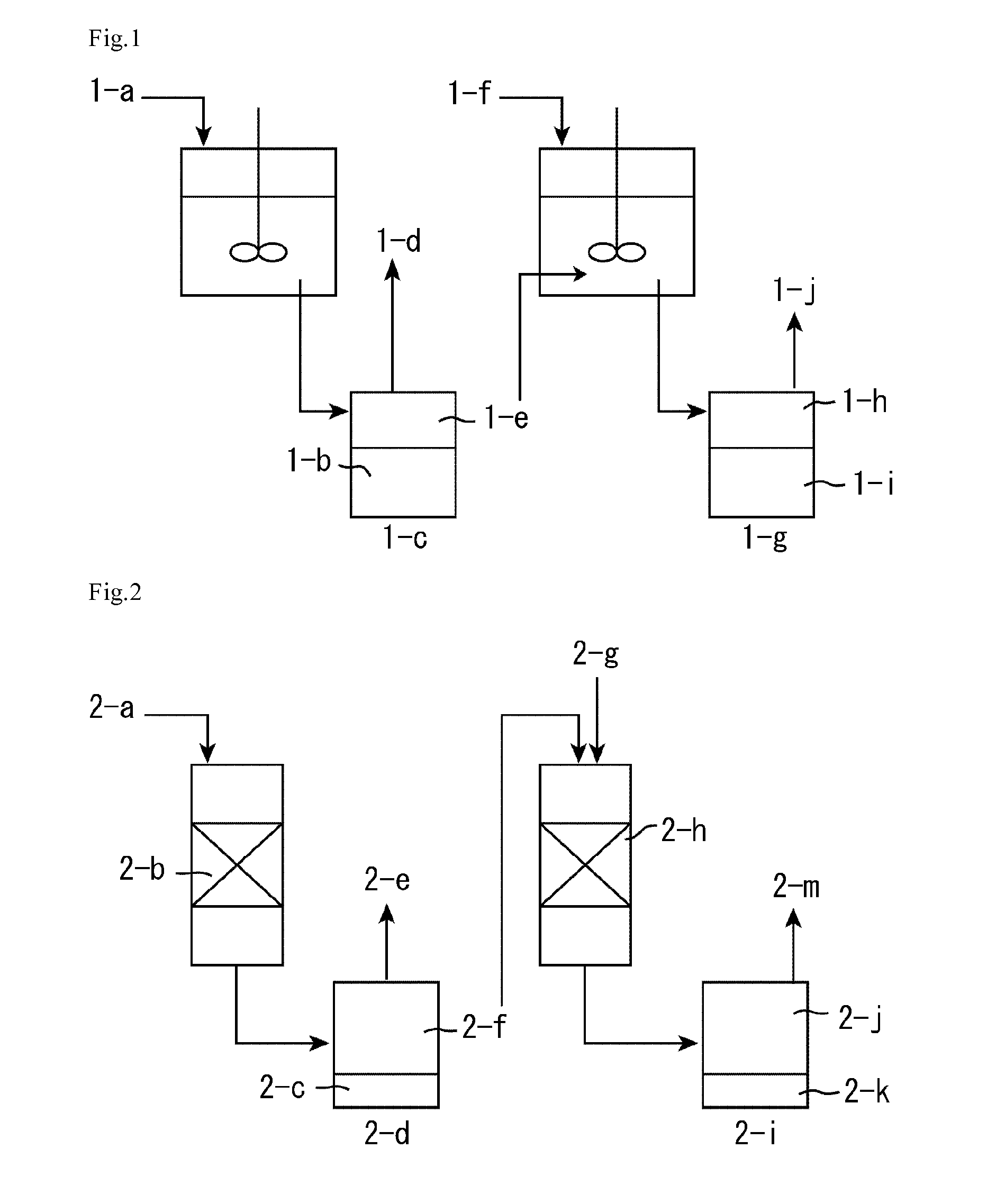

Method for producing fatty acid alkyl esters and/or glycerin using fat or oil

InactiveUS20100286420A1Simple processEasy to produceOxygen-containing compound preparationFatty acid esterificationAlcoholGlycerol ester of wood rosin

The present invention has an object to provide the following method for producing fatty acid alkyl esters and / or glycerin and the following catalyst used in the production method.According to the production method, a fat or oil is reacted with an alcohol to give a fatty acid alkyl ester and / or glycerin suitably used in a food or fuel application, etc., with high efficiency, and complicated steps such as a step of recovering a catalyst can be simplified or omitted. According to the catalyst, an active metal component is not eluted even if the catalyst is used repeatedly or for a long period of time, and further, such a catalyst can maintain an excellent catalyst activity for a long time even in the presence of water and exhibit a high activity to both of transesterification of a glyceride contained in the fat or oil and esterification of free fatty acid. In addition, the catalyst can exhibit a high catalyst activity even in the presence of an impurity such as a free fatty acid (FFA) contained in the fat or oil.The present invention is a method for producing fatty acid alkyl esters and / or glycerin including a step of bringing a fat or oil into contact with an alcohol in the presence of a catalyst, wherein the catalyst includes a manganese element and a trivalent metal element.

Owner:NIPPON SHOKUBAI CO LTD

Modified UV photocuring pure acrylic resin and preparation method thereof

InactiveCN101935387AImprove water resistanceImprove performanceEpoxy resin coatingsGlycidyl methacrylateAcrylic resin

The invention discloses modified UV photocuring pure acrylic resin and a preparation method thereof. The modified UV photocuring pure acrylic resin comprises the following raw materials in part by mass: 17 to 23 parts of glycidyl tertcarbonate, 20 to 30 parts of glycidyl methacrylate, 3 to 8 parts of methyl methacrylate, 12 to 18 parts of butyl methacrylate, 3 to 8 parts of butyl acrylate, 10 to 14 parts of methacrylic acid or crylic acid, 8 to 12 parts of methacrylic isobornyl thiocyanoacetate, 10.5 to 13.5 parts of adipic acid, 1.5 to 2.5 parts of para-toluenesulfonic acid, 0.2 to 0.5 part of open-loop catalyst, 0.01 to 0.05 part of polymerization inhibitor and 1.0 to 3.0 parts of initiator. The modified UV photocuring pure acrylic resin has good water resisting property and maintains the excellent performance of pure acrylic resin; simultaneously, the modified UV photocuring pure acrylic resin is used for UV photocureable coatings, and the films have the advantages of low shrinkage rate and excellent combination property.

Owner:JIANGMEN PAINT FACTORY

High-performance water-soluble acrylic resin and preparation method thereof

ActiveCN102838707AGood alkali resistanceImprove boiling water resistanceCoatings(Hydroxyethyl)methacrylateAcrylic resin

The invention relates to high-performance water-soluble acrylic resin, which is characterized in that the high-performance water-soluble acrylic resin is prepared by using the following raw materials in parts by weight: 2-5 parts of 2-hydroxyethyl methacrylate, 1-3 parts of hydroxyethylacrylate, 5-8 parts of methyl methacrylate, 3-4 parts of 2-ethylhexyl methacrylate, 6-9 parts of n-butyl acrylate, 3-6 parts of ethyl acrylate, 1-2 parts of acrylic acid, 2-5 parts of tertiary carboxylic glycidyl ester, 1-3 parts of hexafluorobutyl methacrylate, 0.08-0.4 part of initiator, 1-2 parts of neutralizer, 0.01-0.02 part of defoaming agent, 8-15 parts of isopropanol and 10-50 parts of deionized water. By adding two modifiers, i.e. the tertiary carboxylic glycidyl ester and the hexafluorobutyl methacrylate in raw materials for conventional water-soluble acrylic resin, the prepared water-soluble acrylic resin has high alkali resistance and high boiling water resistance, the gloss of products coated with the water-soluble acrylic resin is good and the needs of people are met.

Owner:江阴恒兴涂料有限公司

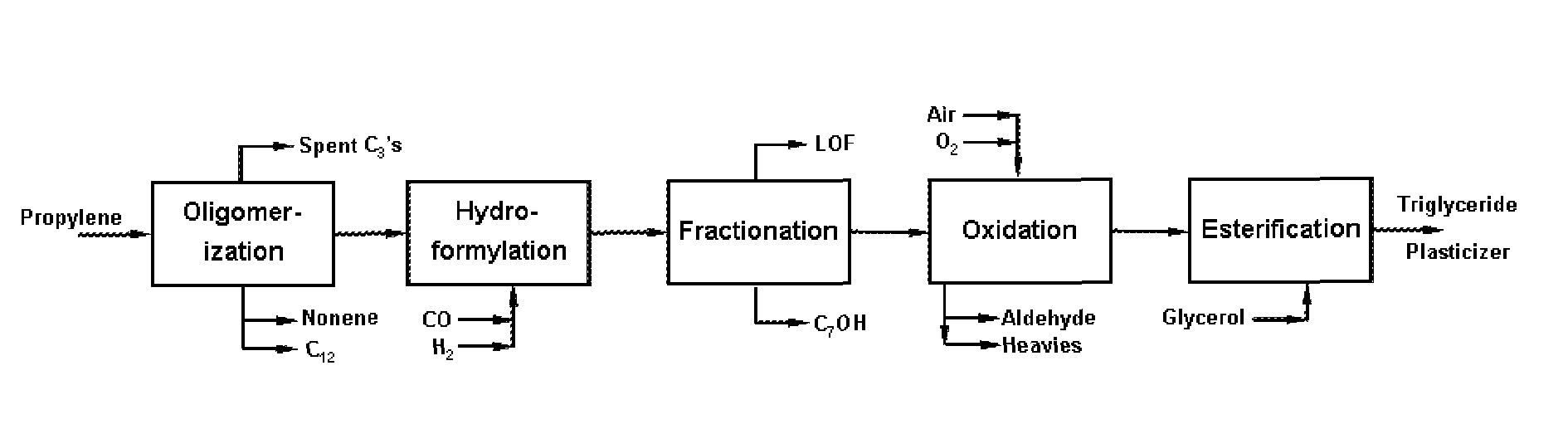

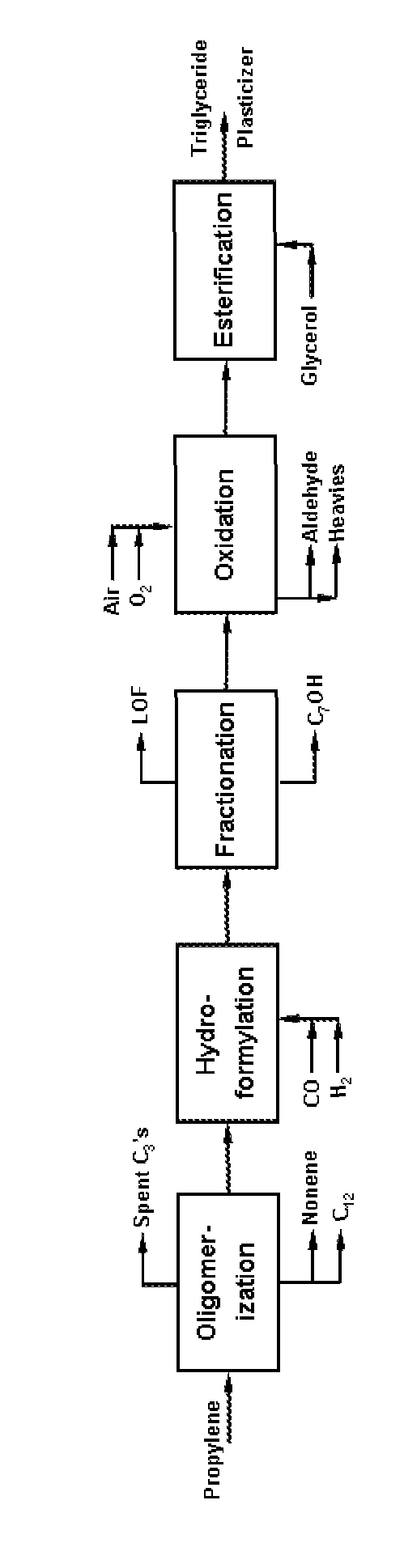

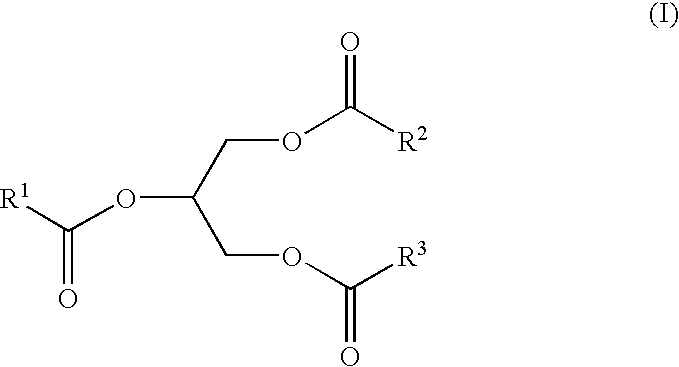

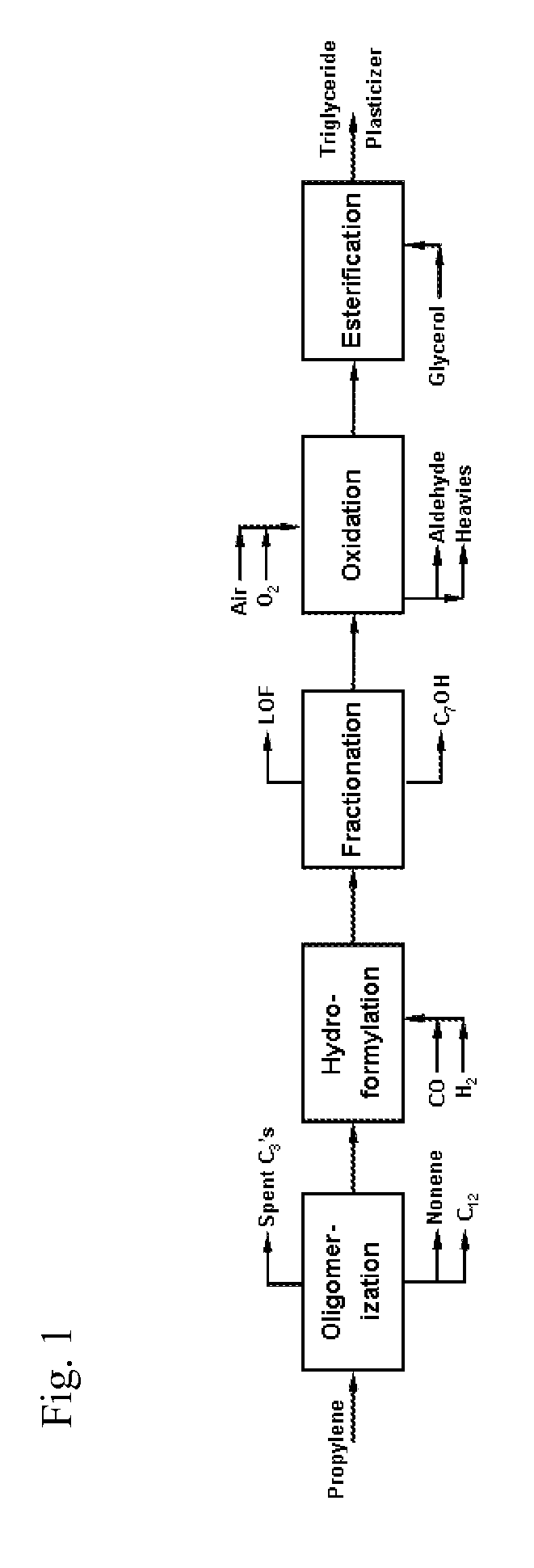

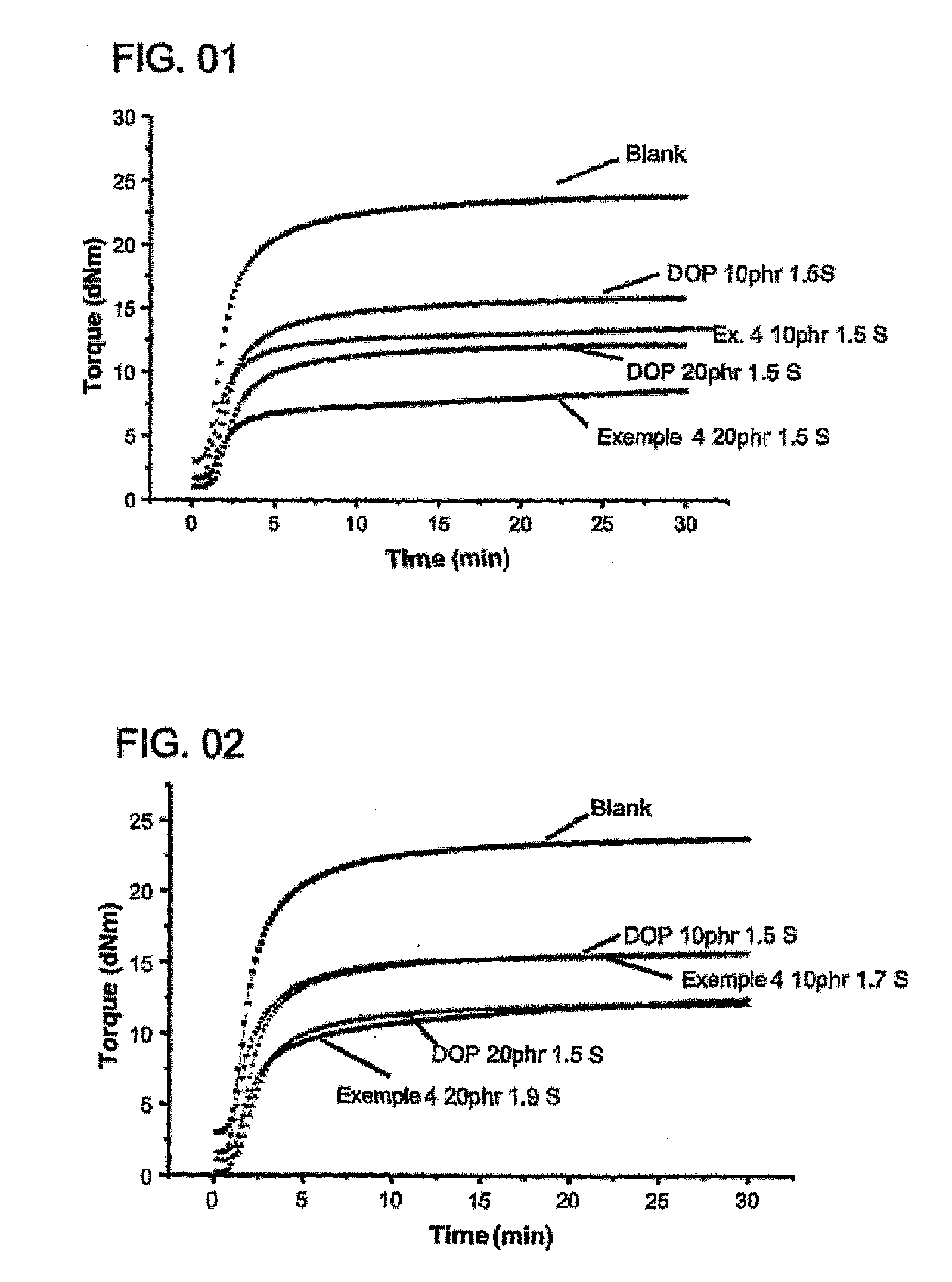

Triglyceride plasticizers having low average levels of branching and process of making the same

InactiveUS8163825B2Fatty acid esterificationOrganic compound preparationGlycerol ester of wood rosinPlasticizer

Triglyceride PVC plasticizers can be produced by recovery of C5 to C10 aldehydes having low average levels of branching from a hydroformylation product, oxidizing the aldehydes with oxygen and / or air to form an acid, recovery of the resulting acid, and esterification with glycerol. Plasticizer compositions including such products or linear triglycerides combined with a secondary plasticizer and articles made therefrom are disclosed.

Owner:EXXONMOBIL CHEM PAT INC

Hair care compositions

ActiveUS20190125650A1Improve manageabilityCosmetic preparationsHair cosmeticsGlycerol ester of wood rosinMedicine

The present disclosure relates to composition and method for treating hair. A hair care composition comprising, in a cosmetically acceptable solvent: (a) one or more carboxylate anionic surfactants; (b) one or more cationic guar compounds; (c) one or more polysaccharide gums; and (d) one or more glyceryl esters, present in a total amount of at least 2 wt. % based on the total weight of the hair are composition. The composition of the present invention may optionally comprise one or more secondary surfactants.

Owner:LOREAL SA

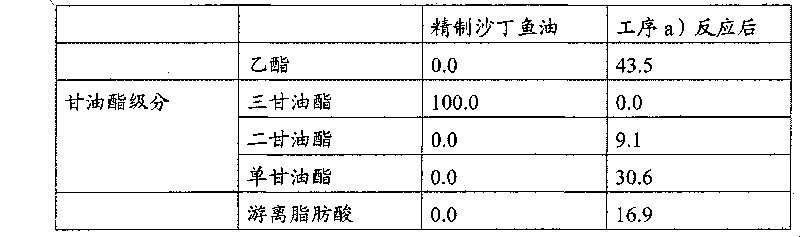

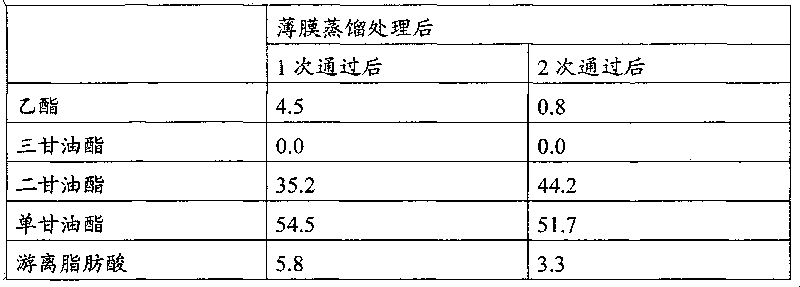

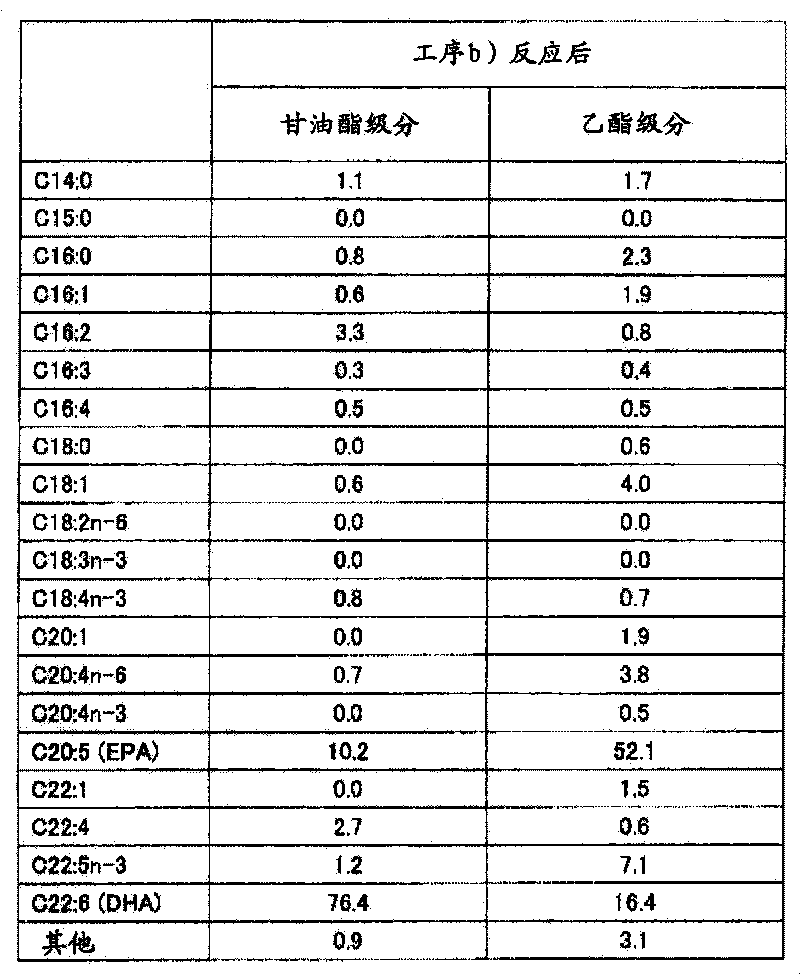

Process for production of EPA-enriched oil and DHA-enriched oil

InactiveCN101765662ACheap manufacturingImprove responseFatty acid esterificationFatty acids production/refiningGlycerol ester of wood rosinAlcohol

Disclosed is a process for producing an EPA-enriched oil and a DHA-enriched oil simultaneously by: subjecting an oil-and-fat containing EPA and DHA to the alcoholysis with a lipase having a substrate specificity to a fatty acid having 18 or less carbon atoms in the presence of a reaction additive such as magnesium oxide; separating a glyceride fraction from the reaction solution; and subjecting the glyceride fraction to the alcoholysis with a lipase having a substrate specificity to a fatty acid having 20 or less carbon atoms in the presence of a reaction additive such as magnesium oxide.

Owner:NIPPON SUISAN KAISHA LTD

Triglyceride plasticizers having low average levels of branching and process of making the same

InactiveUS20100056681A1Lower levelFatty acid esterificationOrganic compound preparationGlycerol ester of wood rosinPlasticizer

Triglyceride PVC plasticizers can be produced by recovery of C5 to C10 aldehydes having low average levels of branching from a hydroformylation product, oxidizing the aldehydes with oxygen and / or air to form an acid, recovery of the resulting acid, and esterification with glycerol. Plasticizer compositions including such products or linear triglycerides combined with a secondary plasticizer and articles made therefrom are disclosed.

Owner:EXXONMOBIL CHEM PAT INC

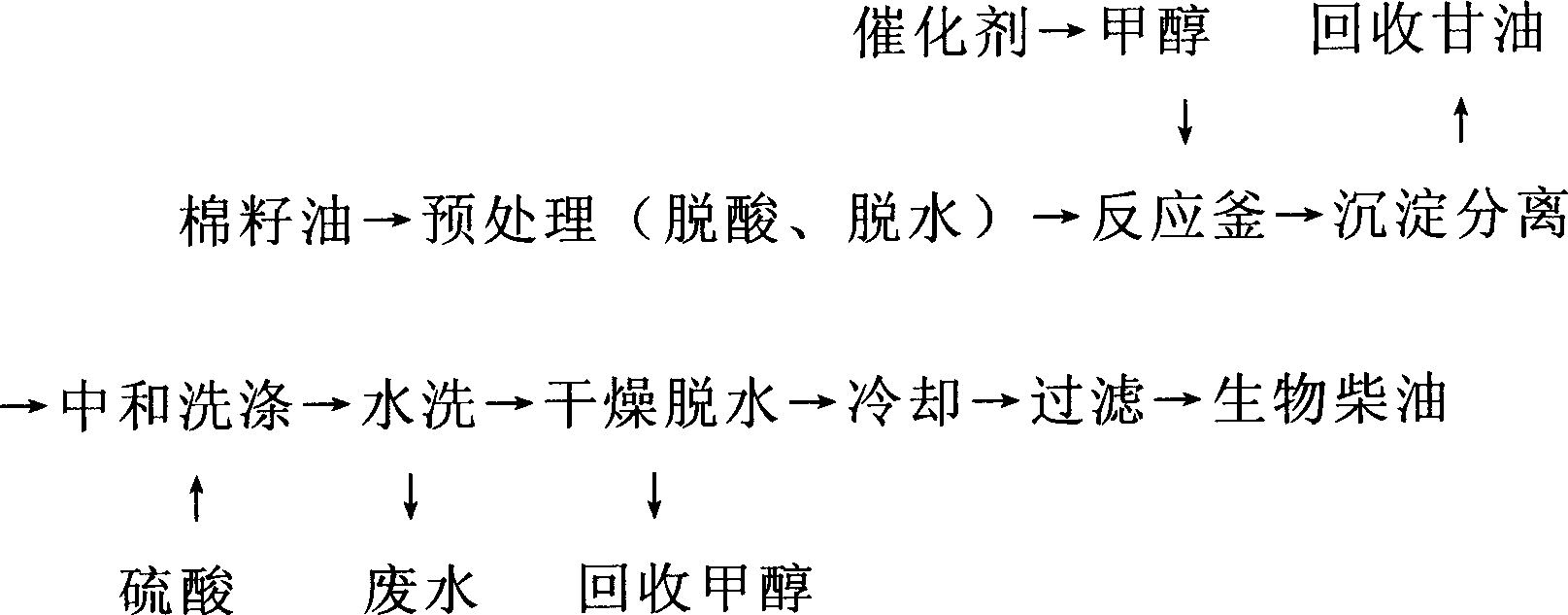

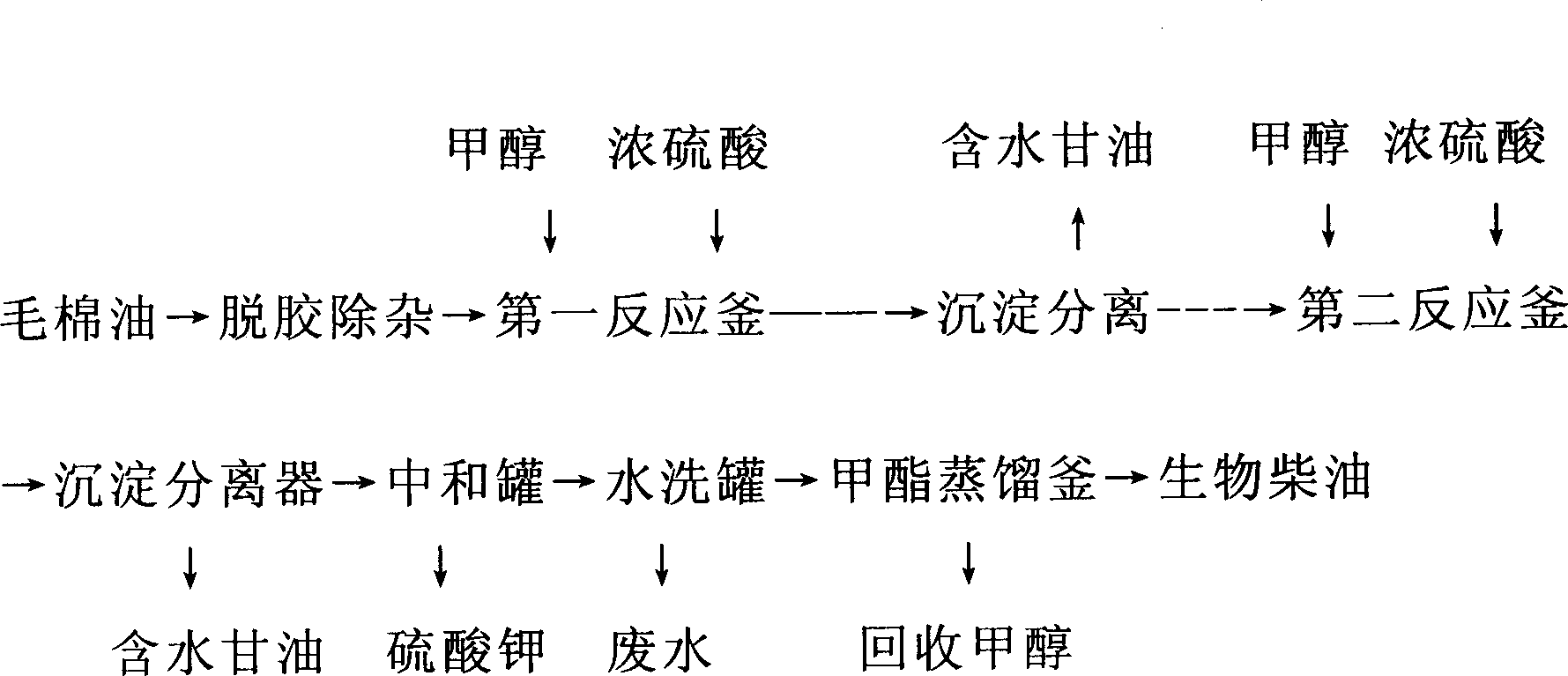

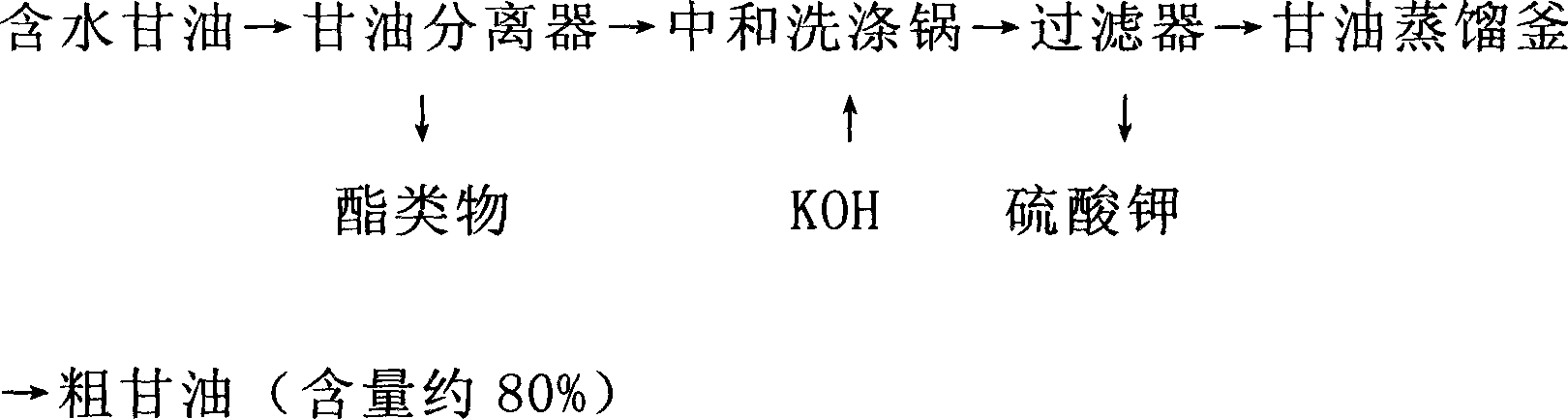

Method for preparing biological diesel oil using high acid value cottonseed oil

InactiveCN1865401AAvoid processing risksReduce pollutionBiofuelsLiquid hydrocarbon mixture productionChemical reactionBiodiesel

The invention discloses a biological diesel preparing method from high-acid value cotton seed oil, which comprises the following steps: the first step: adopting concentrated sulfuric acid as catalyst under normal pressure and temperature; injecting certain quantity of carbinol; reacting most of glyceride and a little of aliphatic acid with carbinol; sedimenting and separating glycerin and water; the second step: adopting concentrated sulfuric acid as catalyst under normal pressure and temperature; injecting excessive carbinol; lengthening reacting time to react glyceride and aliphatic acid with carbinol. The invention can utilize cotton oil reasonably, which reduces the environmental pollution in the refinery course.

Owner:菏泽华瑞油脂有限责任公司

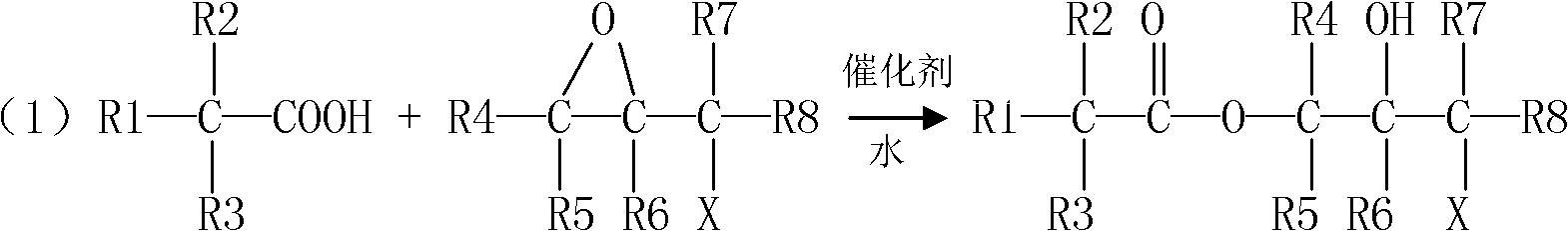

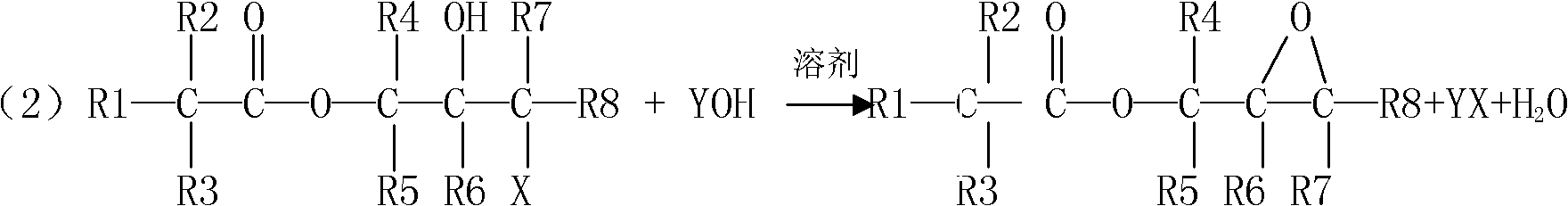

Preparation method for tert-carbonic acid glycidyl ester

ActiveCN103183652AHigh purityInitial color lightOrganic compound preparationCarboxylic acid esters preparationEpoxyGlycerol ester of wood rosin

The invention provides a preparation method for tert-carbonic acid glycidyl ester. The tert-carbonic acid glycidyl ester is synthesized through two steps, i.e., a first step of subjecting tert-carbonic acid and a halogenated epoxy compound to a reaction under the action of a catalyst to produce tert-carbonic acid halohydrin ester and a second step of removing halogen hydride from the tert-carbonic acid halohydrin ester to form the tert-carbonic acid glycidyl ester, wherein in the first step of synthesis of the tert-carbonic acid halohydrin ester, the tert-carbonic acid reacts with the halogenated epoxy compound only in the presence of water and the catalyst and the water comprises water added in the reaction in advance. With the preparation method provided by the invention, product output per unit volume can be substantially increased, and the method is especially applicable to large-scale industrial production of tert-carbonic acid glycidyl ester with low cost, high purity and a light and stable color.

Owner:河北四友卓越科技有限公司

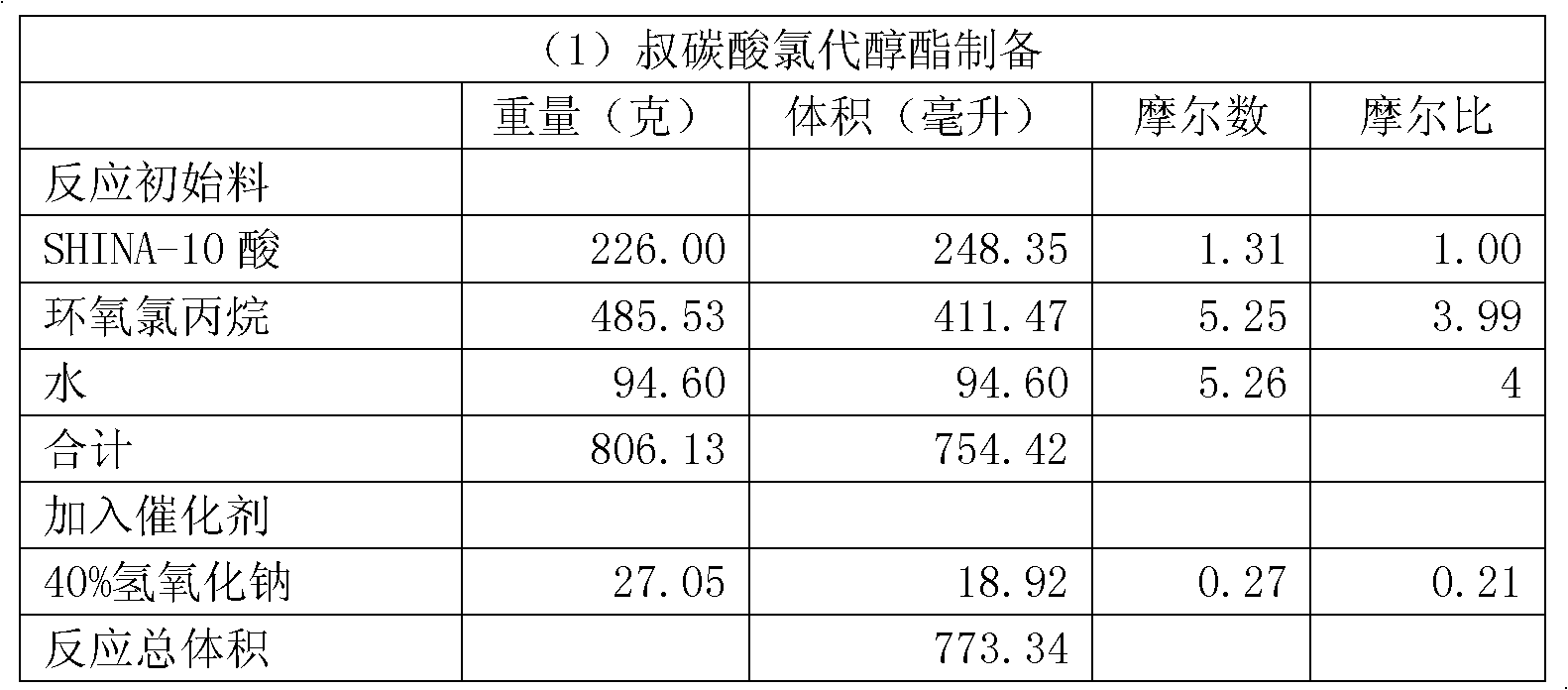

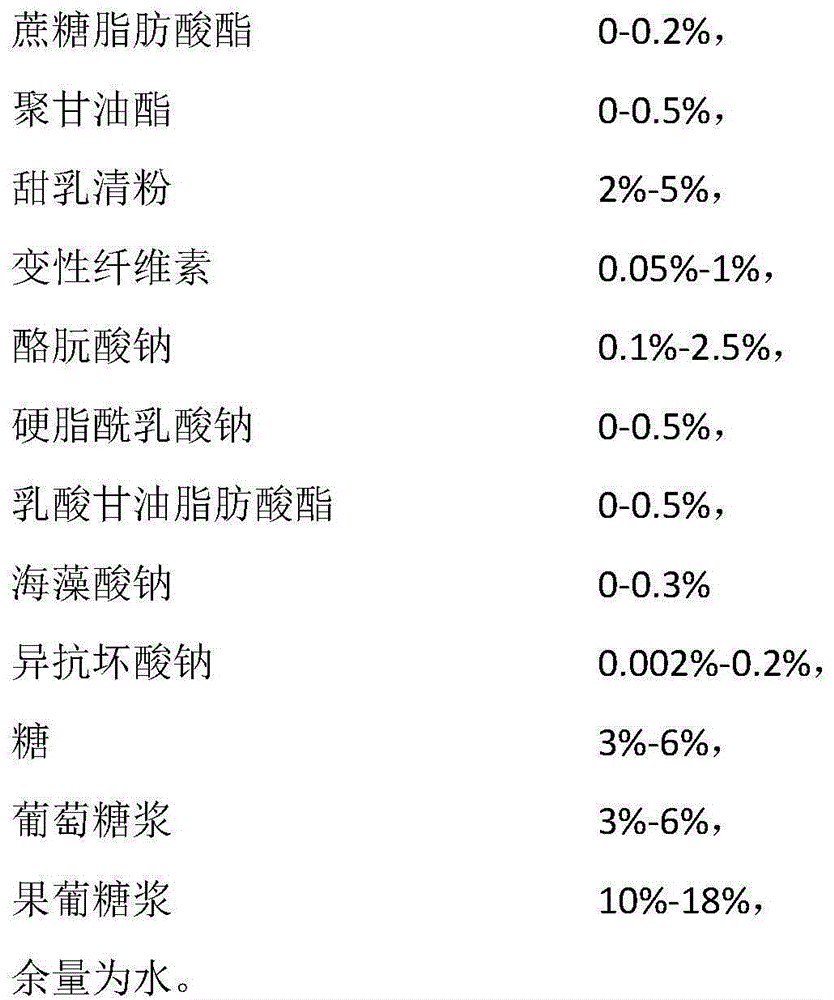

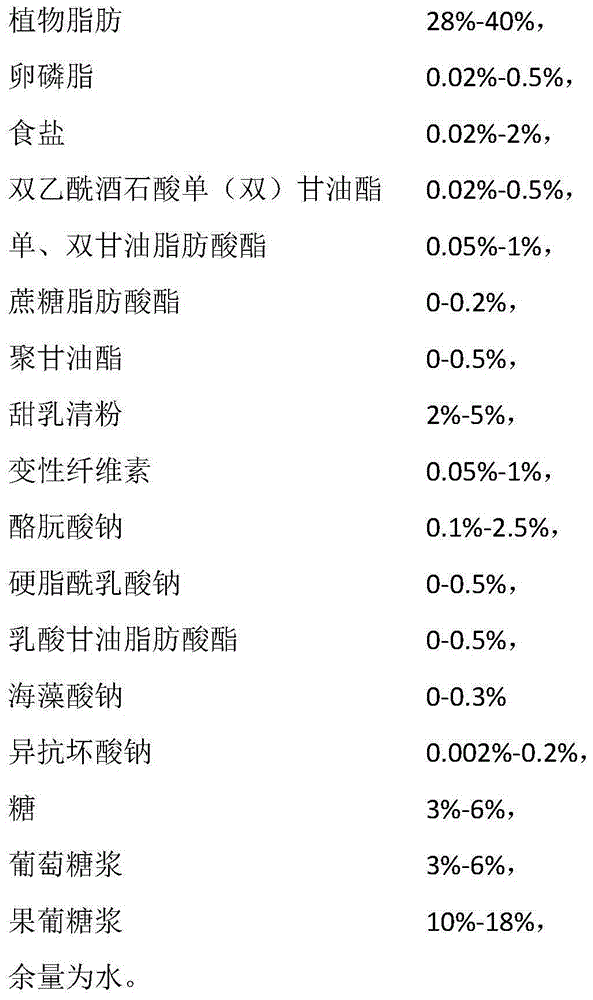

Baking composite non-dairy cream and preparation method thereof

InactiveCN105211322AEasy to operateImprove efficiencySugar food ingredientsFood freezingSucroseSodium Caseinate

The invention discloses a baking composite non-dairy cream and a preparation method thereof. The baking composite non-dairy cream is prepared from the following raw materials in percentage by weight: 28 to 40 percent of vegetable fat, 0.02 to 0.5 percent of lecithin, 0.02 to 2 percent of edible salts, 0.02 to 0.5 percent of diacetyl tartaric acid ester of mono-and diglycerides, 0.05 to 1 percent of mono-and diglycerides of fatty acids, 0 to 0.2 percent of sucrose fatty acid ester, 0 to 0.5 percent of polyglycerol ester, 2 to 5 percent of crino whey powder, 0.05 to 1 percent of modified cellulose, 0.1 to 2.5 percent of sodium caseinate, 0 to 0.5 percent of sodium stearoyl lactylate, 0 to 0.5 percent of lactic acid glycerin fatty acid ester, 0 to 0.3 percent of sodium alginate, 0.002 to 0.2 percent of sodium scorbate, 3 to 6 percent of sugar, 3 to 6 percent of glucose syrup, 10 to 18 percent of high fructose corn syrup and the balance of water. The baking composite non-dairy cream and the preparation method thereof disclosed by the invention have the beneficial effects that operation steps are simplified, and the efficiency is improved; the influence of human experience is avoided, and the finished product rate is improved; by using the synergistic effect of the modified cellulose, the sodium caseinate and stearoyl lactylate, a cake is automatically cracked when a pound cake is baked and the condition that the cake is pulled out of a baking chamber for artificially cutting is avoided, so that the baking time and energy consumption are saved; better water holding and wetting properties are obtained, and the shelf life is prolonged.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

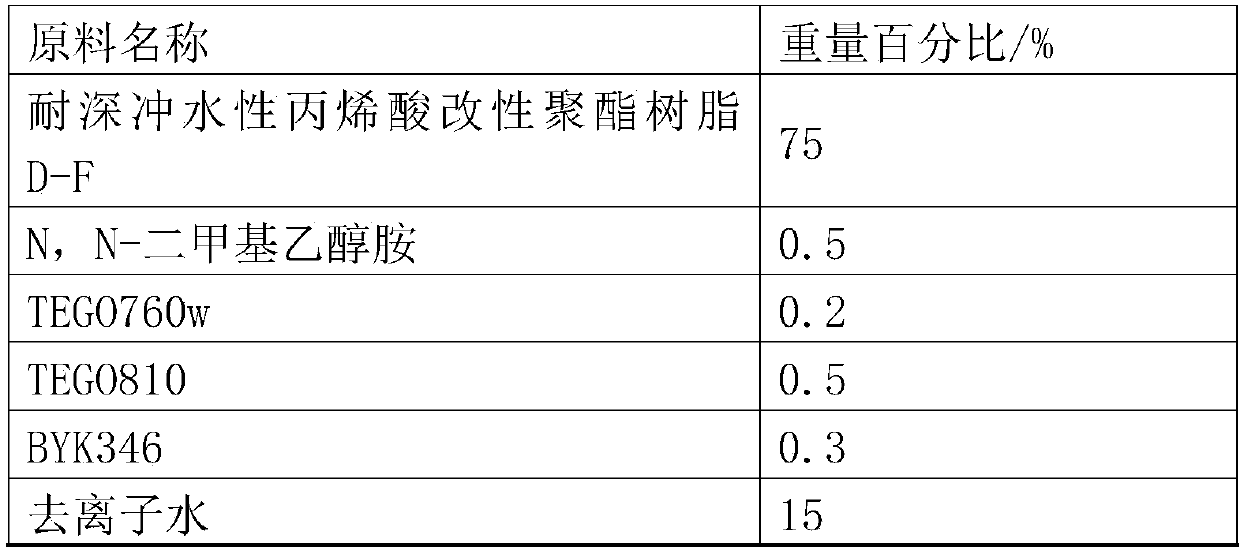

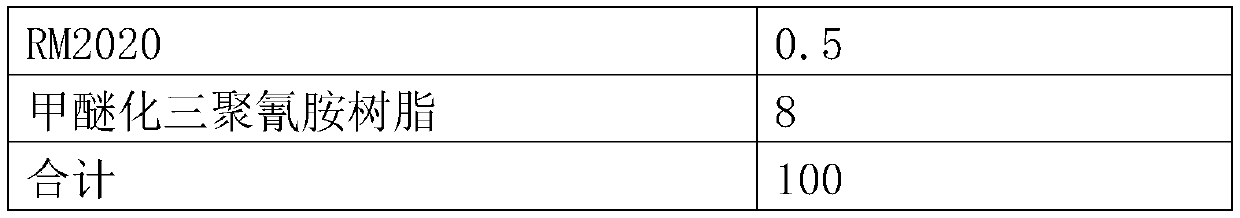

Deep-drawing-resistant water-based acrylic modified polyester resin and preparation method thereof

The invention relates to the technical field of paint preparation, in particular to deep-drawing-resistant water-based acrylic modified polyester resin and a preparation method thereof. The preparation method includes the steps: firstly, performing free radical polymerization on acrylate mixed monomers with preset acid values (hydroxyl values), vinyl siloxane and tert-carboxylic acid glycidyl ester in organic solvents to form an acrylic prepolymer; secondly, esterifying the acrylic prepolymer with monoacid, polyacid and polyols, and synthesizing the water-based acrylic modified polyester resinafter neutralization. Amino baking paint is prepared from the resin and completely methylated amino resin or high-imino-group amino resin, a paint film is full and bright, and the amino baking paintis good in adhesion, high in hardness, good in impact resistance, good in cup drawing and applicable to places requiring high toughness.

Owner:ZHEJIANG TIANNU GROUP PAINT MFG

Method for preparing low condensation point biodiesel from high acid value oil

InactiveCN101880603ALowering the freezing pointImprove low temperature fluidityFatty acid esterificationBiofuelsVegetable oilMethanol

The invention discloses a method for preparing low condensation point biodiesel from high acid value oil. Animal and vegetable oils with the acid value higher than 80mgKOH / g serving as a raw material and mixed alcohol of methanol, ethanol and isopropanol undergo esterification and interesterification two-step reaction to prepare the low condensation point biodiesel. The intersolubiltiy of the oil and the methanol is improved by the ethanol so as to promote the methyl esterification reaction; meanwhile, the product contains a small amount of fatty acid ethyl esters, and new solid catalysts of tungsten molybdophosphate and phosphotungstic acidesterification replace concentrated sulfuric acid in the esterification reaction; and in the interesterification reaction, the ethanol and the isopropanol promote the conversion of glyceride, and simultaneously the product contains partial fatty acid ethyl esters and branched-chain aliphatic esters. Therefore, the reaction is easy to carry out, the cold flow properties of the biodiesel can be improved and the condensation point of the biodiesel can be reduced.

Owner:YUNNAN MINGHUI PETROCHEM

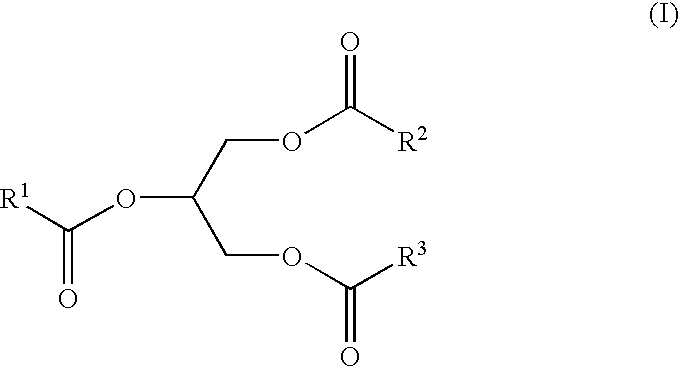

Vegetal Oil Derivatives

InactiveUS20100010126A1Fatty acid esterificationPreparation by transesterificationGlycerolTG - Triglyceride

This invention comprises the use of the interesterification reaction between vegetal or animal oils as monoacid esters (preferentially with 1 to 12 carbons) and monoalcohol esters (preferentially with 1 to 12 carbons). The use of ethyl acetate is preferred as it is a product that may be obtained from ethanol (renewable) and has a boiling point (77 deg. C.), which facilitates separation by vacuum distillation at the end of the reaction and its reuse. By varying the molar ratio between glycerol triester (oil or fat) and monoalcohol ester, different proportions of glycerol esters are obtained with 1 or 2 linked fatty acids and 1 or 2 linked acids of short chain, along with the formation of fatty acid ester and monoalcohol ester. After the distillation of excess residual ethyl acetate, products are obtained with viscosity from 21 to 33 cPs at 25 deg. C., in the case of the reaction with soy oil.

Owner:SGS POLIMEROS

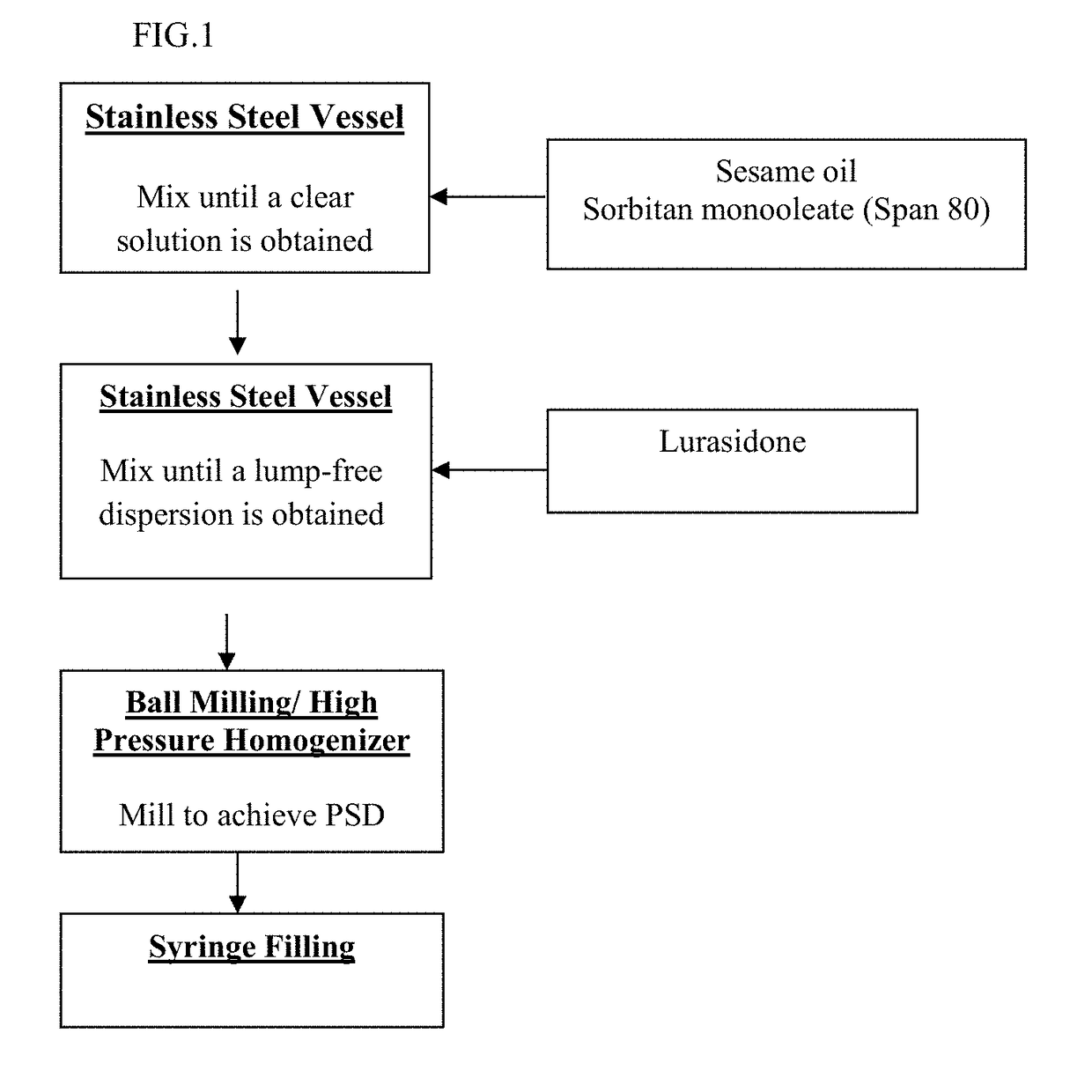

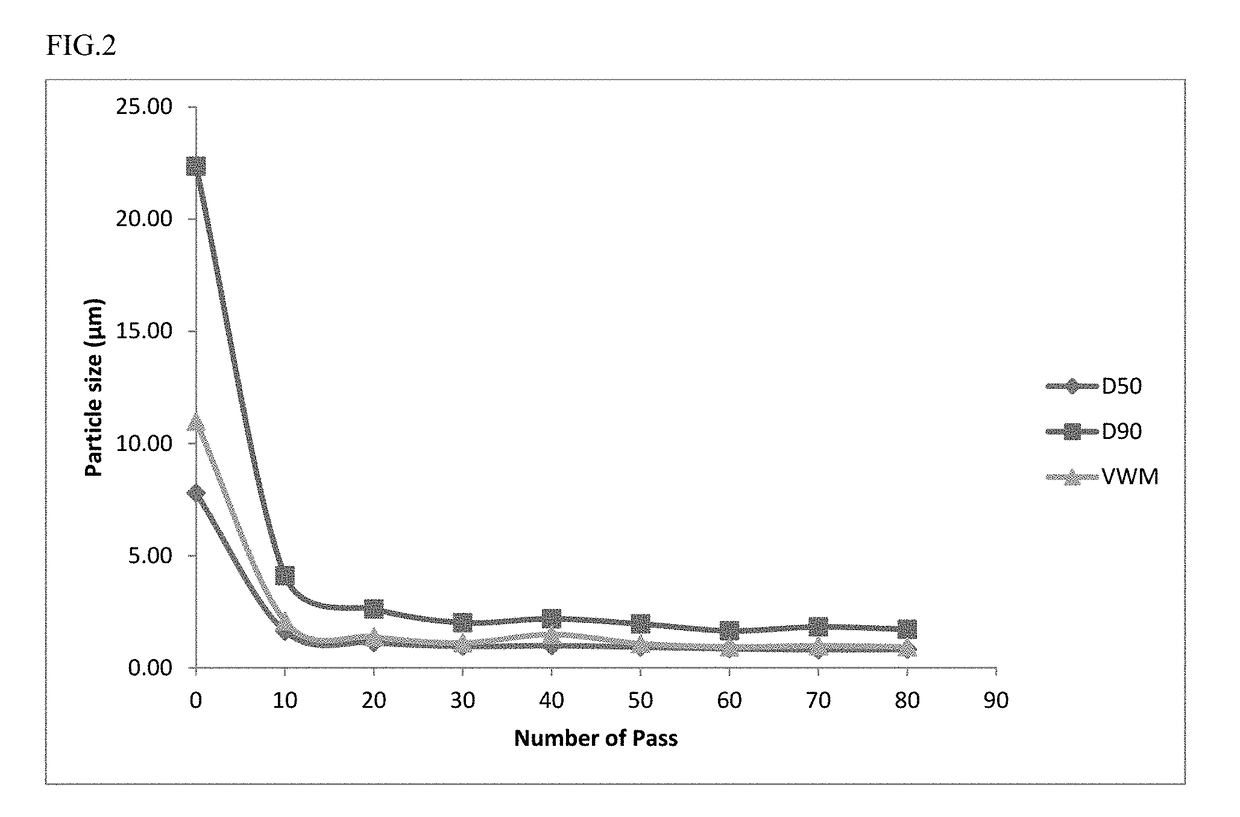

Long Acting Injectable Formulations

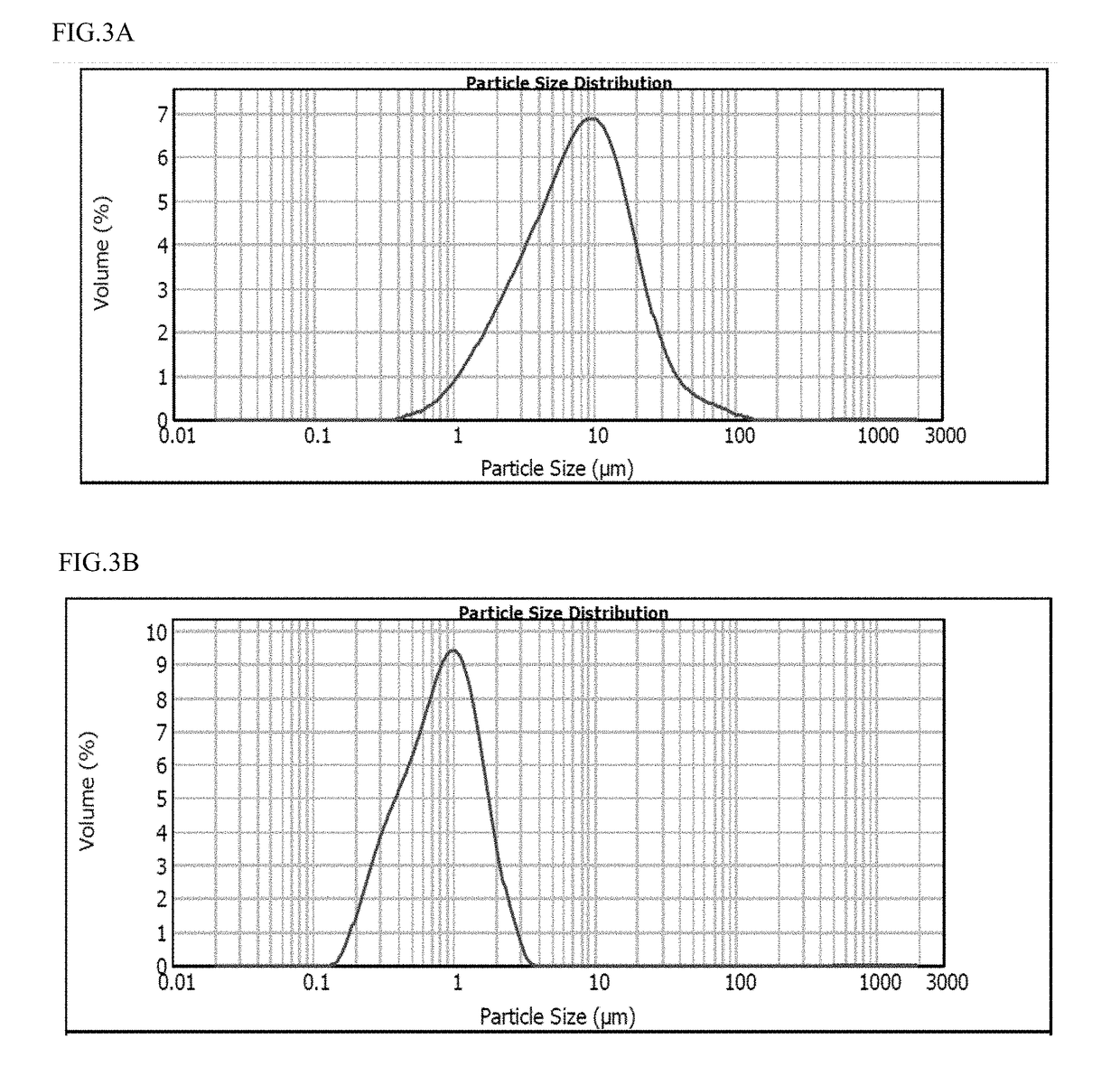

The invention relates to extended-release formulations comprising: (i) a poorly water-soluble active pharmaceutical ingredient; and (ii) a non-aqueous liquid vehicle comprising (a) a hydrophobic lipid comprising a glyceryl ester of a C6-C24 fatty acid, or (b) a hydrophilic organic compound selected from the group consisting of polyethylene glycol, propylene glycol, glycerin, and dimethylsulfoxide, or (c) a combination of (a) and (b), and (iii) an amphiphilic agent wherein the active pharmaceutical ingredient is dispersed as discrete particles having a D90 particle size of about 0.5 μm to about 25 μm in the formulation, and wherein the formulation is non-gelling and thixotropic with a viscosity of less than 10 poise at a shear rate of 10 / s at 25° C.

Owner:ABON PHARMA

Production method for extracting VE and sterol from soybean oil deodorized distillate by using enzyme-chemistry combined technology

The invention provides a production method for extracting VE and sterol from a soybean oil deodorized distillate by using an enzyme-chemistry combined technology. The method comprises the steps of firstly, converting fatty acids in the deodorized distillate into fatty acid methyl ester by using immobilized lipase as a catalyst, then, carrying out an ester exchange reaction on the material by using sodium methylate as a catalyst so as to convert glyceryl esters and sterol esters in the deodorized distillate into fatty acid methyl ester, glycerine and sterol, carrying out water washing to remove the glycerine, carrying out cooling, crystallizing and filtrating so as to obtain crude sterol, and carrying out distillation, thereby obtaining the fatty acid methyl ester and the VE. According to the method, the esterification reaction is carried out by replacing strong acid with the lipase, the fatty acids in the deodorized distillate are converted into the fatty acid methyl ester under mild conditions, no wastewater is generated, the operation is simple, no environmental pollution is caused, industrialization is easy to achieve, the yield of the fatty acid methyl ester and the sterol is remarkably increased; and through an enzyme method and a chemical method, the VE with relatively high purity and the crude sterol are finally obtained.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Glycerol Ester-Free Functionalized Vegetable Oil Derivatives and Their Latex Compounds

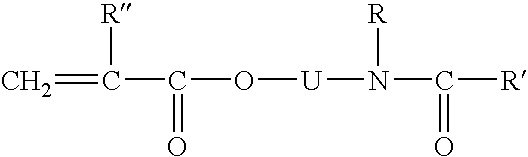

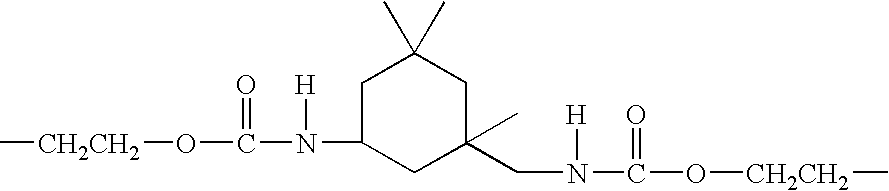

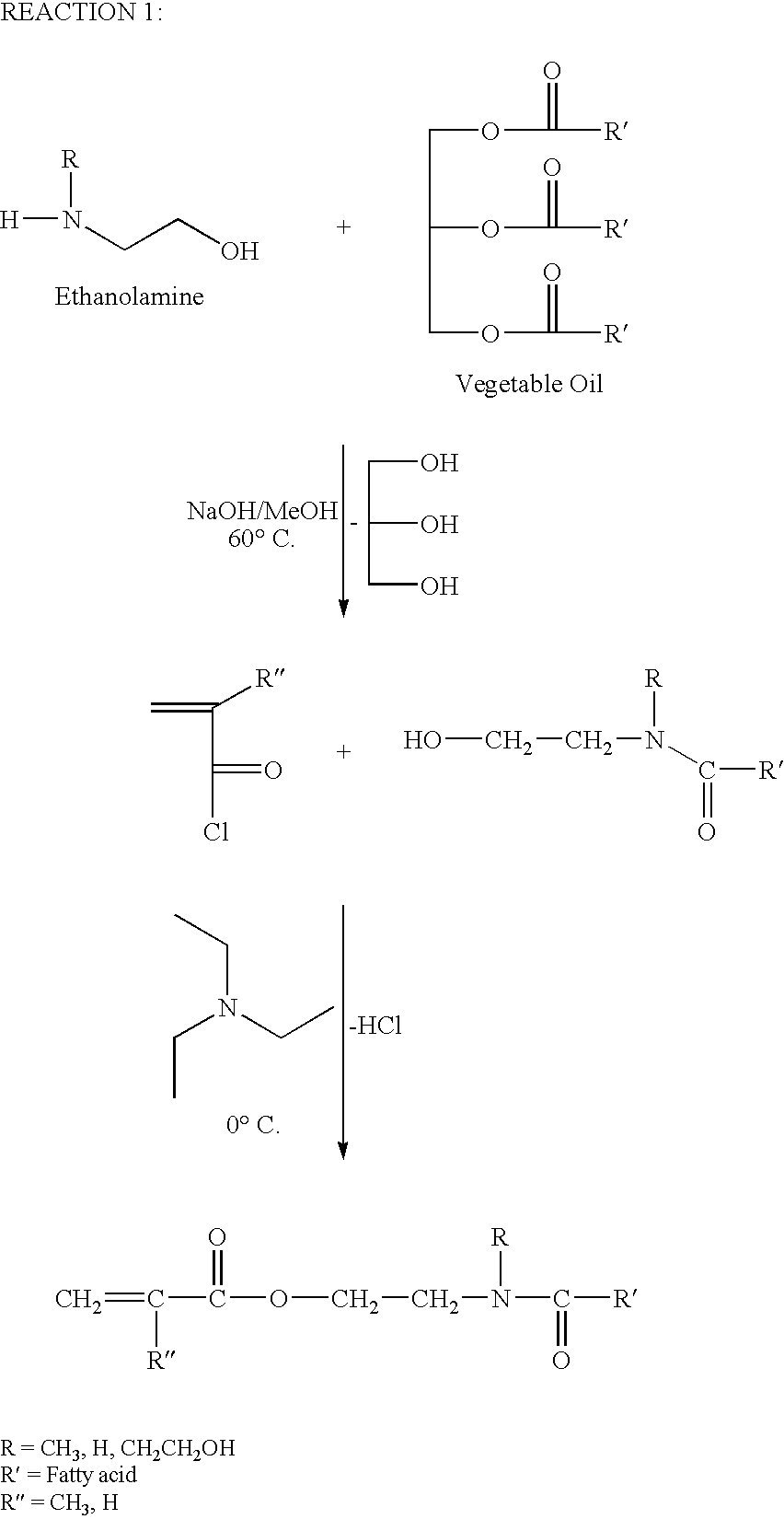

The present invention is directed to a fatty amide (meth)acrylate monomer, methods of making the monomer, and latex polymers comprising the fatty amide (meth)acrylate monomer. The monomers are derived by reacting unsaturated vegetable oils with ethanolamine or substituted ethanolamine. The vegetable oil derivative is then reacted with either (meth)acryloyl chloride or (meth)acrylic acid to form a fatty amide (meth)acrylate monomer or the product of the reaction of hydroxyethyl (meth)acrylate reacted with isophorone diisocyanate to form a urethane fatty amide (meth)acrylate monomer. The increased hydrophilicity of the fatty amide (meth)acrylate monomer facilitates the diffusion through the aqueous phase. The monomer synthesis is designed to be glycerol ester-free to increase long term stability for monomers and polymers.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com