Deep-drawing-resistant water-based acrylic modified polyester resin and preparation method thereof

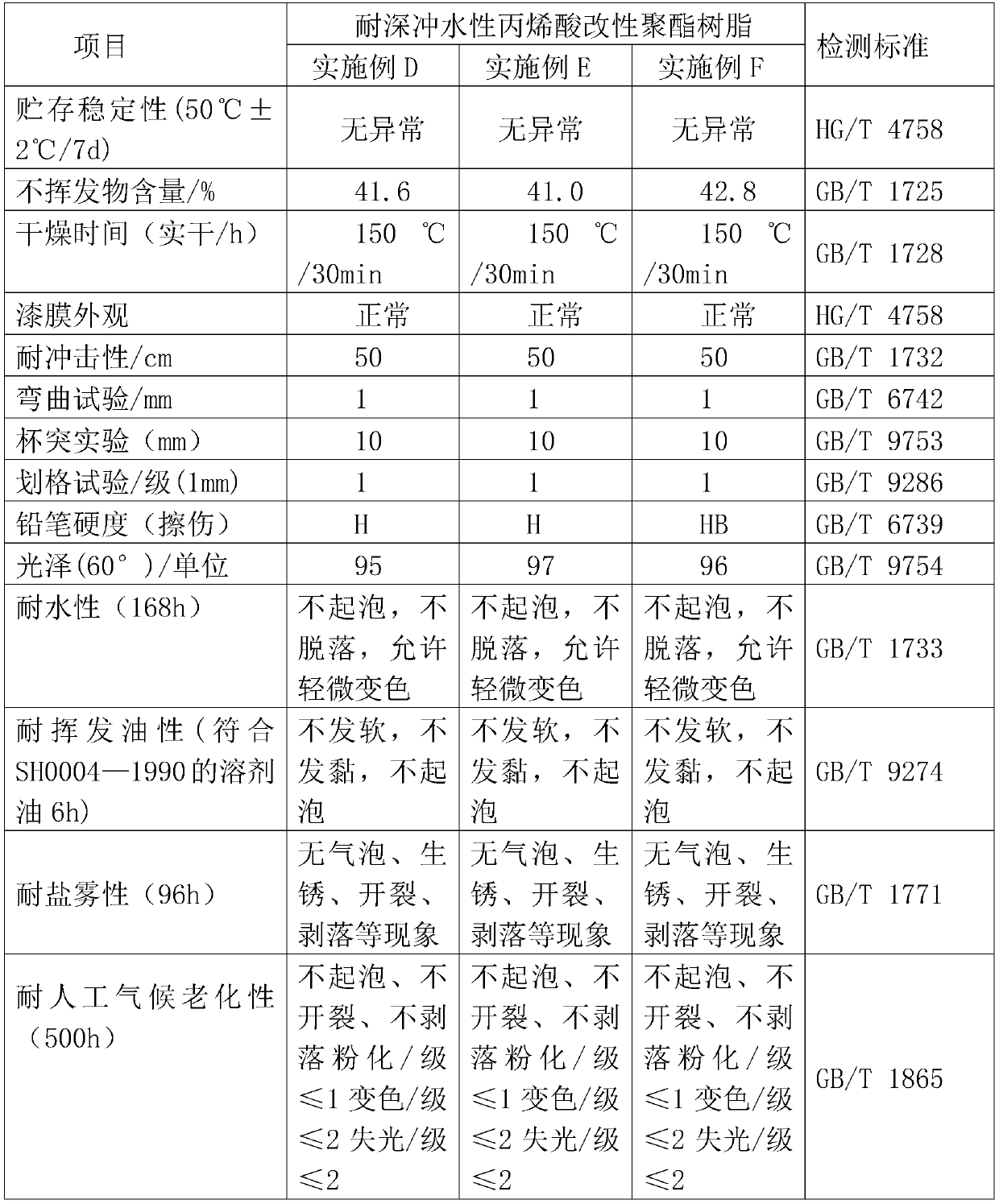

A technology of water-based acrylic and modified polyester, which is applied in the direction of polyester coatings and coatings. It can solve the problems of poor paint film gloss, ethanol resistance, and impact resistance, and achieve good hydrolysis resistance and storage stability. Good mechanical stability and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: prepare acrylic acid prepolymer A:

[0023] Weigh 160 kilograms of ethylene glycol butyl ether and 150 kilograms of glycidyl tert-carbonate into a reactor equipped with a stirring device, a reflux condensing device, a dropping device and a temperature control device, and heat up to 120-130 ° C under stirring. 200 kg of methyl methacrylate, 160 kg of styrene, 100 kg of butyl acrylate, 90 kg of lauryl methacrylate, 80 kg of methacrylic acid and 15 kg of di-tert-butyl peroxide form a mixed monomer, in the reaction system Add 70% of the total amount of the mixed monomer dropwise, and finish dripping under stirring for 3 hours; add 30 kg of KH570 to the remaining mixed monomer, and add dropwise to the reaction system within 1.5 hours under stirring; keep warm for 0.5-1 hour, The remaining 5 kg of initiator was added to the remaining 40 kg of co-solvent, and added to the reaction system, kept stirring at 130° C. for 1 hour, cooled and discharged.

Embodiment 2

[0024] Embodiment 2: Preparation of acrylic acid prepolymer B:

[0025] Weigh 160 kilograms of ethylene glycol butyl ether and 150 kilograms of glycidyl tert-carbonate into a reactor equipped with a stirring device, a reflux condensing device, a dropping device and a temperature control device, and heat up to 120-130 ° C under stirring. 200 kg of methyl methacrylate, 160 kg of styrene, 100 kg of butyl acrylate, 90 kg of lauryl methacrylate, 80 kg of methacrylic acid and 15 kg of di-tert-butyl peroxide form a mixed monomer, in the reaction system Add 70% of the total amount of the mixed monomer dropwise, and finish dripping under stirring for 3 hours; add 60 kg of KH570 to the remaining mixed monomer, and add dropwise to the reaction system within 1.5 hours under stirring; keep warm for 0.5 to 1 hour, The remaining 5 kg of initiator was added to the remaining 40 kg of co-solvent, and added to the reaction system, kept stirring at 130° C. for 1 hour, cooled and discharged.

Embodiment 3

[0026] Embodiment 3: prepare acrylic acid prepolymer C:

[0027] Weigh 160 kilograms of ethylene glycol butyl ether and 150 kilograms of glycidyl tert-carbonate into a reactor equipped with a stirring device, a reflux condensing device, a dropping device and a temperature control device, and heat up to 120-130 ° C under stirring. 170 kilograms of methyl methacrylate, 110 kilograms of styrene, 180 kilograms of butyl acrylate, 90 kilograms of lauryl methacrylate, 80 kilograms of methacrylic acid and 15 kilograms of di-tert-butyl peroxide form a mixed monomer, in the reaction system Add 70% of the total amount of the mixed monomer dropwise, and finish dripping under stirring for 3 hours; add 30 kg of KH570 to the remaining mixed monomer, and add dropwise to the reaction system within 1.5 hours under stirring; keep warm for 0.5-1 hour, The remaining 5 kg of initiator was added to the remaining 40 kg of co-solvent, and added to the reaction system, kept stirring at 130° C. for 1 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com