Method for controlling glycidyl ester in grease

A technology of glycidol and fat, which is applied in the direction of edible oil/fat, fat production, fat oil/fat refining, etc., to achieve the effect of industrial scale production and increase factory cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: dry degumming VS. water washing degumming

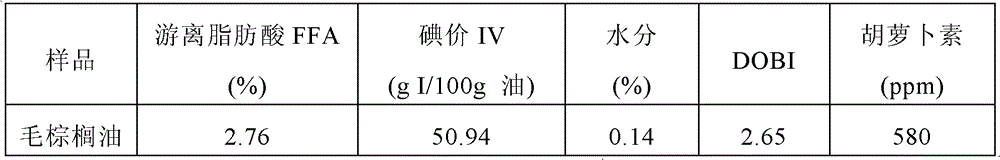

[0082] Crude palm oil: See Table 1 for quality

[0083] Activated clay: Taiko Supreme 1B (PH=6.23, H 2 SO 4 activation)

[0084] The process flow is as follows:

[0085] Take crude palm oil as follows:

[0086] 1. Degumming: in two ways

[0087] Dry degumming: add 0.5% oily heavy citric acid (made into a 50% mass concentration solution) to the oil, keep vacuum stirring at 75°C for 30 minutes, then centrifuge to get the light phase;

[0088] Water elution and degumming: add 0.5% oily heavy citric acid (to make a 50% mass concentration solution) and 10% oily heavy pure water into the oil, stir at 75°C for 30 minutes, then centrifuge to get the light phase;

[0089] 2. Alkali refining: at 80°C, add alkali solution, stir from fast to slow, react for 30 minutes, centrifuge to take the light phase; the amount of alkali added = 7.13×10 -4 × oil weight × acid value × (1+ super-alkali content), the super-alkali con...

Embodiment 2

[0097] Embodiment 2: the activated clay contrast of different pH values

[0098] Crude palm oil: See Table 1 for quality

[0099] Activated clay: Tonsil 212FF, Taiko Supreme 1B, B-80

[0100] The process flow is as follows:

[0101] Take crude palm oil as follows:

[0102] 1. Degumming: Acidified water elution Degumming: Add 0.5% oily heavy citric acid (made into a 50% mass concentration solution) and 10% oily pure water to the oil, stir at 75°C for 30 minutes, then centrifuge to get the light phase;

[0103] 2. Alkali refining: at 80°C, add alkali solution, stir from fast to slow, react for 30 minutes, centrifuge to take the light phase; the amount of alkali added = 7.13×10 -4 × oil weight × acid value × (1+ super-alkali content), the super-alkali content is 20%, and the concentration of lye is 14%;

[0104] 3. Soap removal: Stir with 20% oil-heavy deionized water at 85°C for 15 minutes. The deionized water needs to be preheated to 85°C, and then centrifuged to take the upp...

Embodiment 3

[0111] Embodiment 3: Comparative experiment of different citric acid crystal addition amounts (added to the deodorization section)

[0112] Crude palm oil: See Table 1 for quality

[0113] Activated clay: Taiko Supreme 1B

[0114] The process flow is as follows:

[0115] Take crude palm oil as follows:

[0116] 1. Degumming: Acidified water elution Degumming: Add 0.5% oily heavy citric acid (made into a 50% mass concentration solution) and 10% oily pure water to the oil, stir at 75°C for 30 minutes, then centrifuge to get the light phase;

[0117] 2. Alkali refining: at 80°C, add alkali solution, stir from fast to slow, react for 30 minutes, centrifuge to take the light phase; the amount of alkali added = 7.13×10 -4 × oil weight × acid value × (1+ super-alkali content), the super-alkali content is 20%, and the concentration of lye is 14%;

[0118] 3. Soap removal: Stir with 20% oil-heavy deionized water at 85°C for 15 minutes. The deionized water needs to be preheated to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com