Patents

Literature

42results about How to "Improve boiling water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

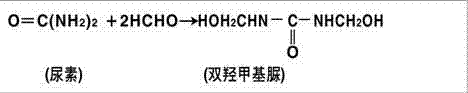

Cyanurotriamide modified urea resin and prepn. process

InactiveCN1834186AImprove boiling water resistanceHigh activityAldehyde/ketone condensation polymer adhesivesCyanurotriamideAmmonium hydroxide

This invention provides a method for manufacturing melamine-modified urea-formaldehyde resin adhesive used on wood cement templates. The method adopts formaldehyde and urea at a molar ratio of 1.2-1.4 as the raw materials, and urea is added into formaldehyde in four times. Before the first time of urea addition, formaldehyde is activated at 50 minus or plus 5 deg.C for 15-25 min. in the third time of urea addition, melamine 3-20 wt. % of total urea is also added. After the fourth time of urea addition, ammonia solution is added for post treatment so that the content of free formaldehyde in the modified urea-formaldehyde resin adhesive is below 0.2 wt. %. at the same time the boiling water-resistance of the urea-formaldehyde resin adhesive can be improved. This invention can be used as a substitute for expensive phenol-formaldehyde resin adhesive; therefore the cost is reduced while the performance of wood cement templates can be guaranteed.

Owner:EVERFIRST WISEFUND TECH BEIJING +1

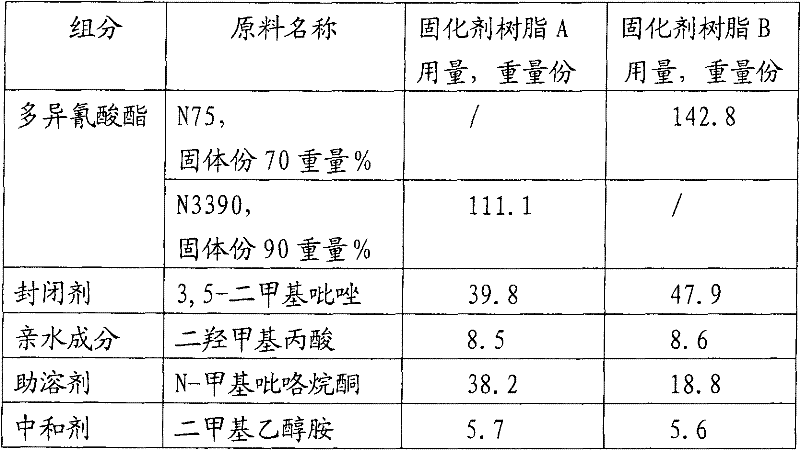

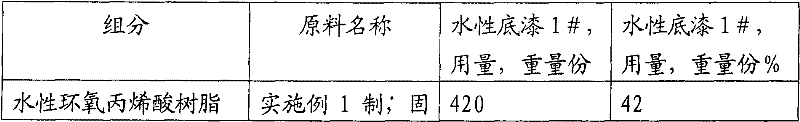

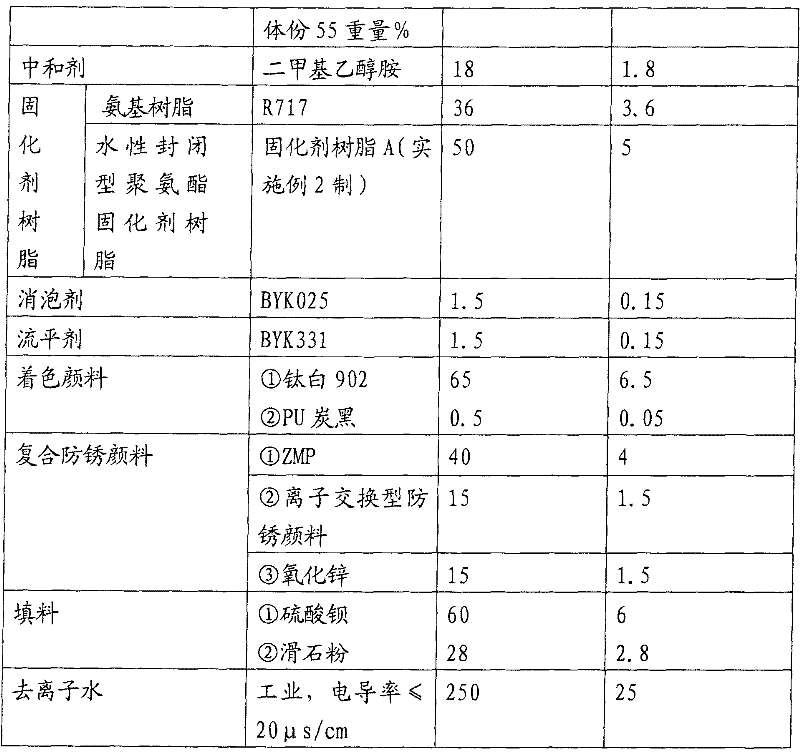

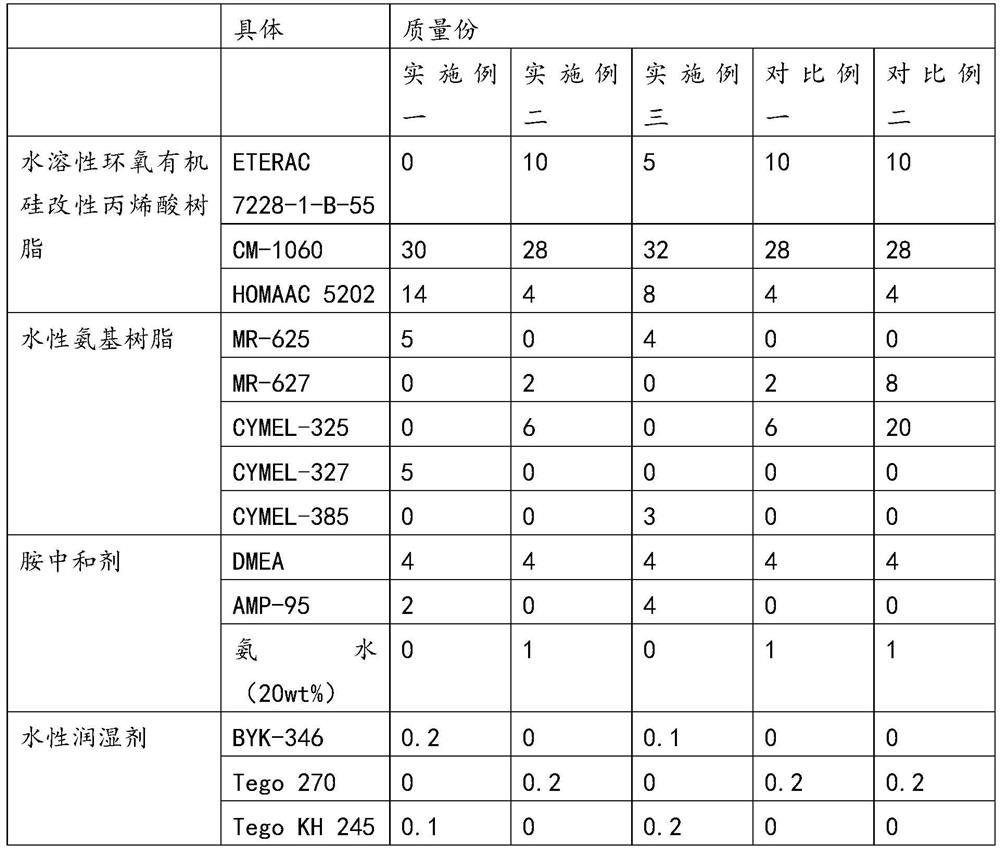

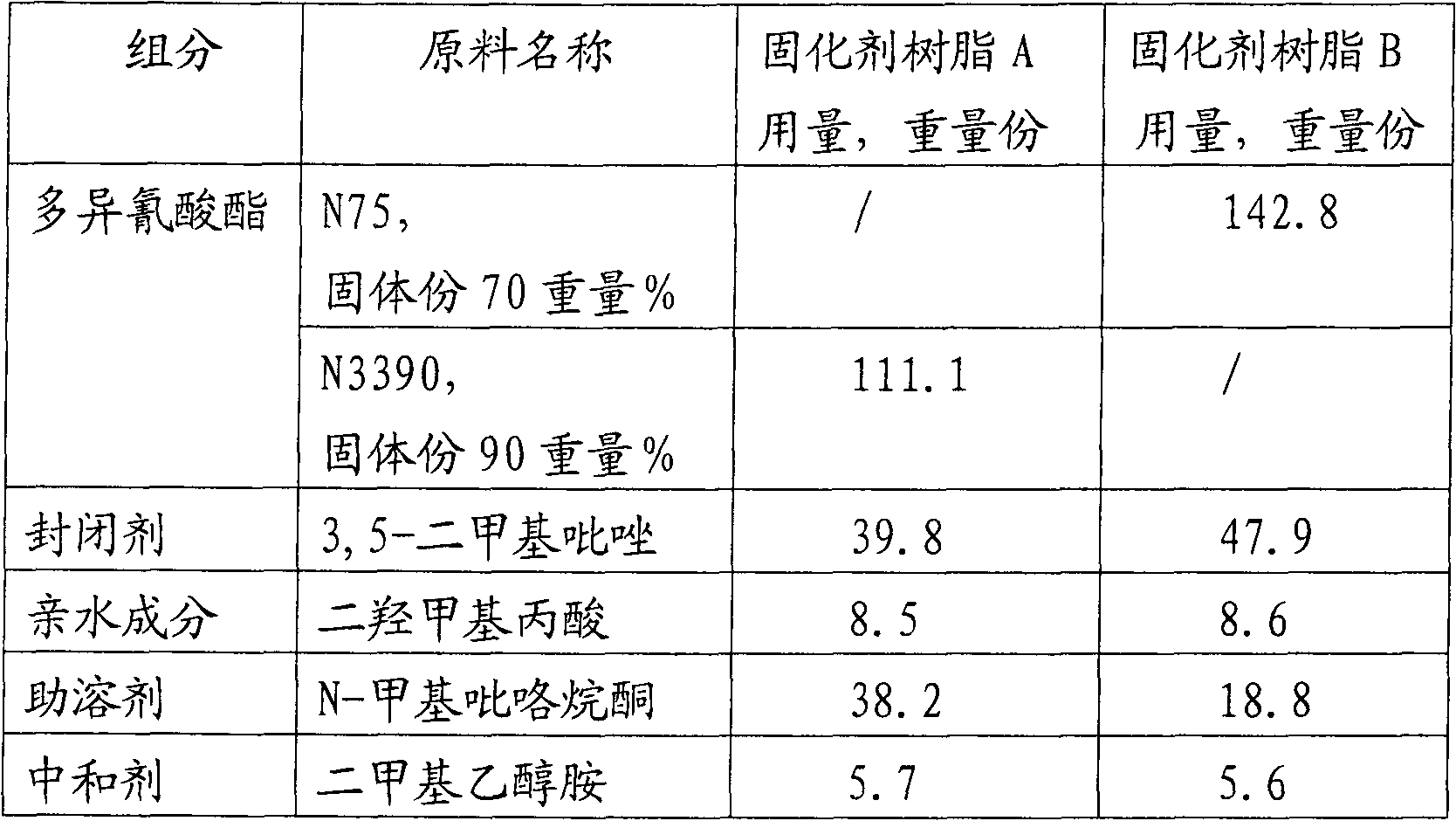

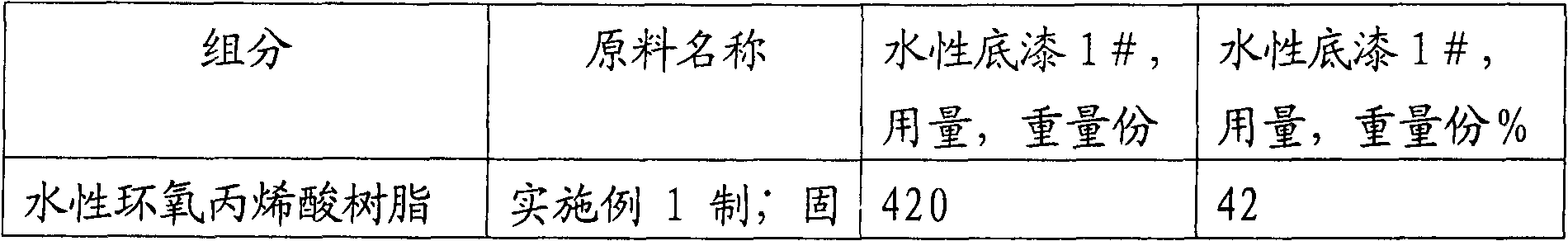

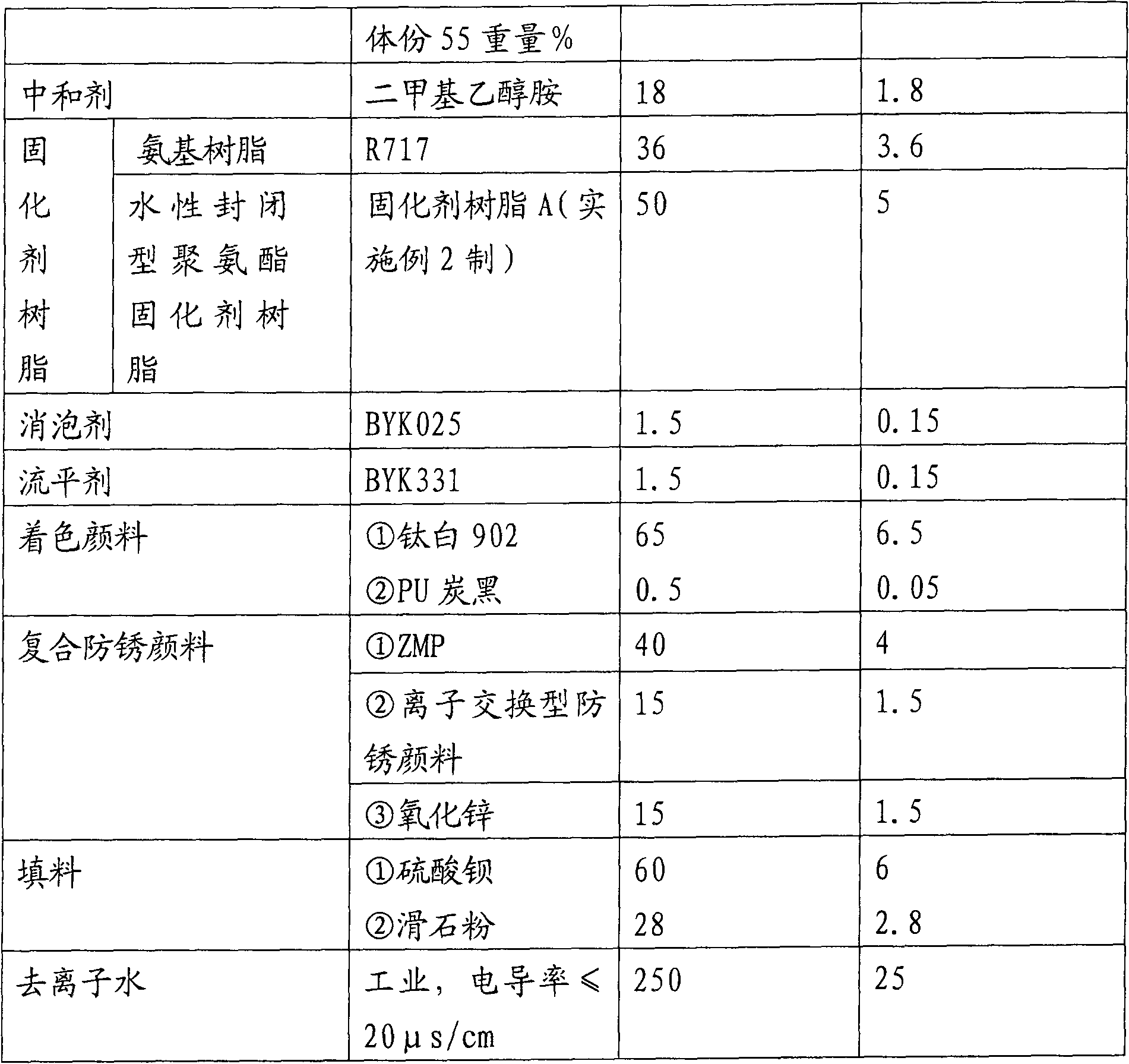

Aqueous primer used for bicycles

The invention relates to an aqueous primer used for bicycles, which comprises the following components in percentage by weight: 25-45% of aqueous epoxy acrylate resin, 2-10% of curing agent resin, 1-3% of neutralizing agent dimethylethanolamine, 2-10% of compound anticorrosive pigment, 5-20% of tinting pigment and filler, 0.1-0.5% of antifoaming agent, 0.1-0.5% of flatting agent and 20-40% of deionized water, wherein the sum of the content of all components is 100%. The aqueous epoxy acrylate resin accounts for 10-40% of the total mass of epoxy resin; the curing agent resin comprises aqueous closed-type polyurethane curing agent resin and amino curing agent resin, wherein the mass ratio of the aqueous closed-type polyurethane curing agent resin to the amino curing agent resin is 1:5-5:1; the aqueous closed-type polyurethane curing agent resin is decapsulated and solidified at the temperature of 130DEG C; the amino curing agent resin is carbinol or butylated amino melamine formaldehyderesin; and the compound anticorrosive pigment comprises modified zinc phosphate, zinc oxide and ion exchange type anticorrosive pigment. The aqueous primer disclosed by the invention is especially suitable for preventing rust and corrosion of structures, such as bicycles and the like.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Styrene modified polyvinyl acetate emulsion and preparation method

InactiveCN103131354AWith boiling water resistanceSystem stabilityMonocarboxylic acid ester polymer adhesivesAdhesiveCarvacryl acetate

The invention relates to a styrene modified polyvinyl acetate emulsion and a preparation method, and relates to the modified polyvinyl acetate emulsion and the preparation method. The styrene modified polyvinyl acetate emulsion comprises the following raw materials by weight: 58-62% of deionized water, 2-10% of polyving akohol, 20-35% of mixed monomer 1, 4-20% of mixed monomer 2, 0.6-2% of compound emulsifier, 0.1-0.5% of pH buffering agent and 0.1-1% of initiator. The preparation method employs a staging polymerization mode, in a first stage, vinyl acetate monomer is polymerized to form a polymer seed; in a second stage, a styrene monomer is polymerized in the polymer seed to form emulsion particles with a two-phase separation structure. According to the invention, the process is simple, the cost is low, the boiling water resistance performance of the polyvinyl acetate emulsion is increased, no environmental pollution is generated, and cold pressure curing at normal temperature, and the styrene modified polyvinyl acetate emulsion can be directly used as aqueous adhesives.

Owner:NORTHEAST FORESTRY UNIVERSITY

UV anaerobic double curing coating

The invention relates to ultraviolet anaerobic dual-cured paint, containing an anaerobic curing agent combination. The paint consists of oxide initiator accounting for 30 to 60 percent, catalysts accounting for 10 to 35 percent and reduced matter accounting for 5 to 40 percent. The percentages of the components in the gross weight of the paint are as follows: acrylic ester active oligomer accounts for 30 to 60 percent; in active diluent, a compound with one olefinic unsaturated double bond, a compound with two olefinic unsaturated double bonds and a compound with three olefinic unsaturated double bonds respectively account for 5 to 30 percent, 0 to 20 percent and 5 to 20 percent; solvent accounts for 0 to 30 percent; photoinitiator accounts for 1-10 percent; additive accounts for 0 to 1 percent; and the anaerobic curing agent combination accounts for 0.1 to 5 percent. A paint film formed by the paint is level in exterior appearance, obviously increased in adhesive force, flexibility, hardness and boiling water resistance, and has no residual odor. The paint is especially applicable to the protection of wood, density boards, paper and other porous base materials.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

Ceramic sol modified polyether-ether-ketone paint and preparation method thereof

The invention discloses ceramic sol modified polyether-ether-ketone paint and a preparation method thereof. The invention aims at providing safe, environment-friendly, oleophobic and hydrophobic water-based paint and manufacturing and spray coating methods thereof. The ceramic sol modified polyether-ether-ketone paint is prepared from prime coat paint, floating coat paint and surface coat paint, wherein the prime coat paint is prepared from all the following ingredients in mass fraction: 5 to 30 parts of ceramic sol, 5 to 15 parts of alkoxy silane, 5 to 30 parts of polyether-ether-ketone matter, 2 to 20 parts of fluroresin, 5 to 20 parts of powder filler, 1 to 15 parts of pigment filler and 10 to 40 parts of solvent; the floating coat paint is prepared from all the following ingredients inmass fraction: 5 to 30 parts of ceramic sol, 5 to 15 parts of alkoxy silane, 10 to 40 parts of fluroresin, 2 to 15 parts of powder filler, 1 to 15 parts of pigment filler and 20 to 50 parts of solvent; the surface coat paint is prepared from all the following ingredients in mass fraction: 40 to 60 parts of fluroresin, 30 to 50 parts of solvent, 0.2 to 2 parts of pearl powder and 1 to 5 parts of aid. The ceramic sol modified polyether-ether-ketone paint disclosed by the invention is mainly applied to paint production.

Owner:GUANGDONG FRUTO NEW MATERIALS CO LTD

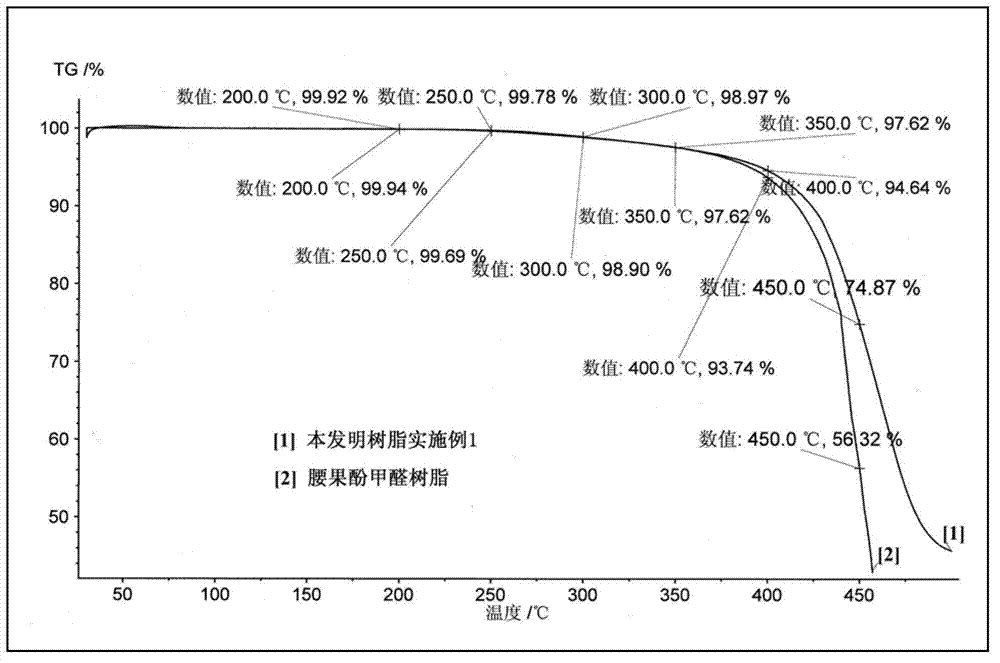

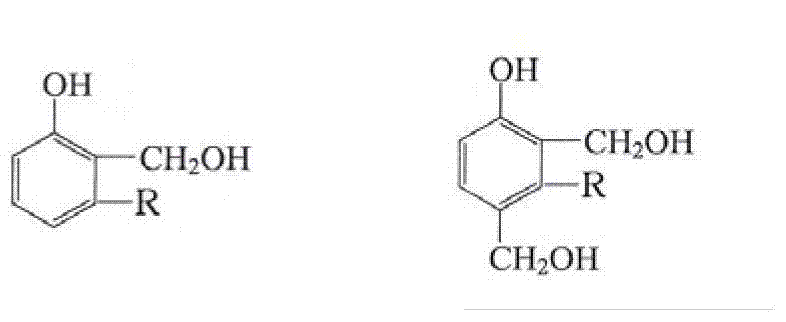

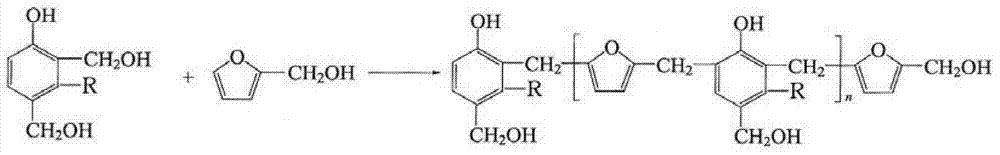

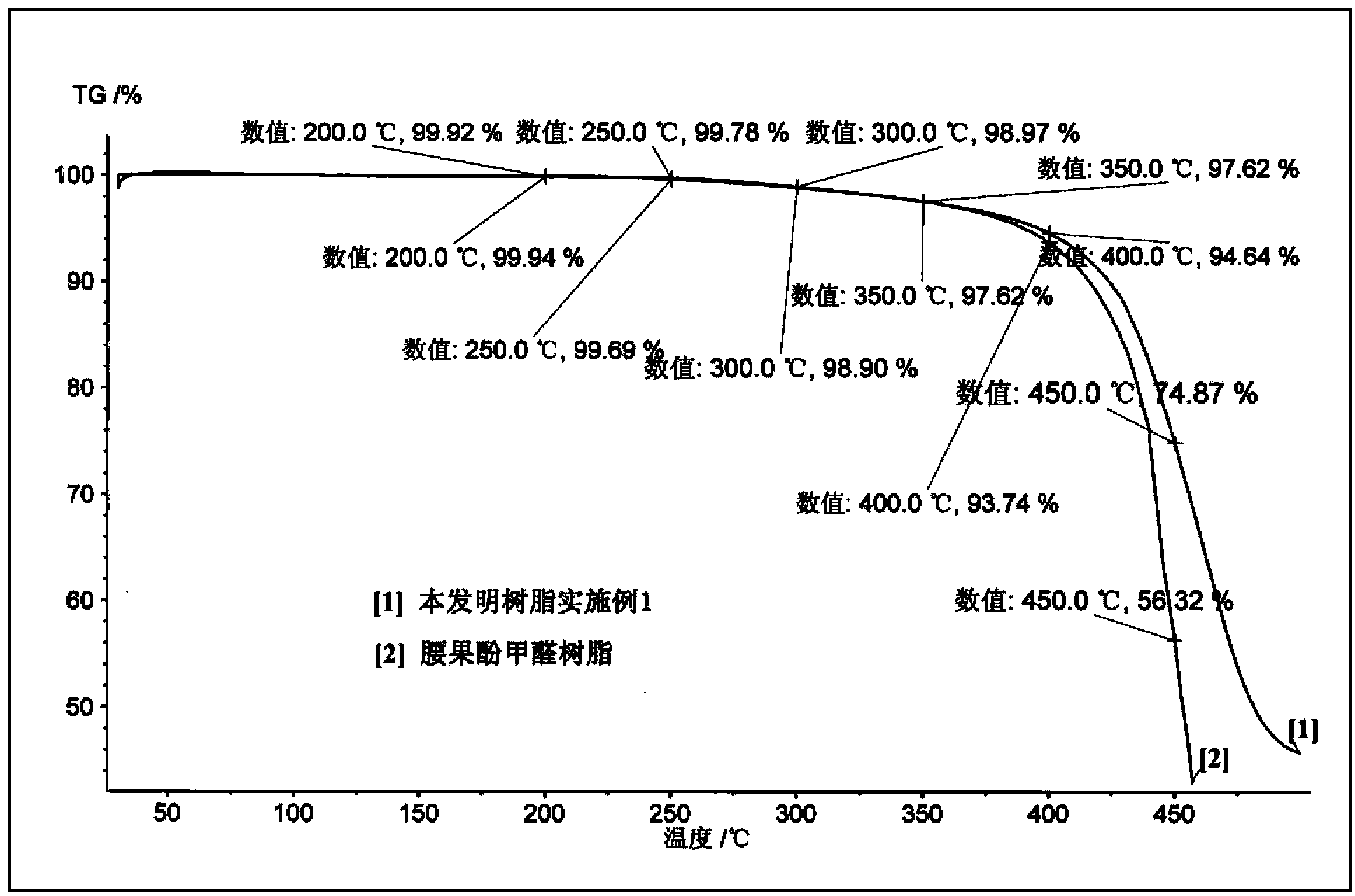

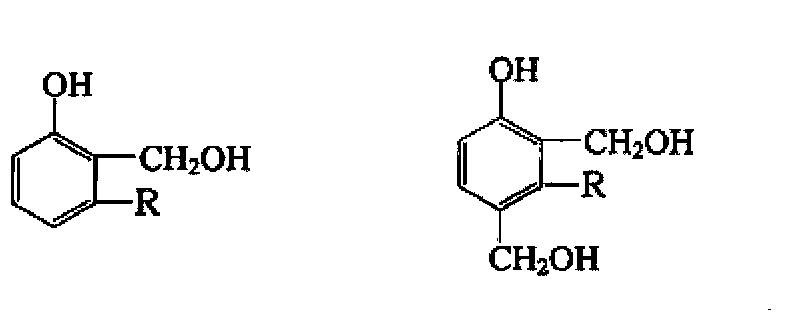

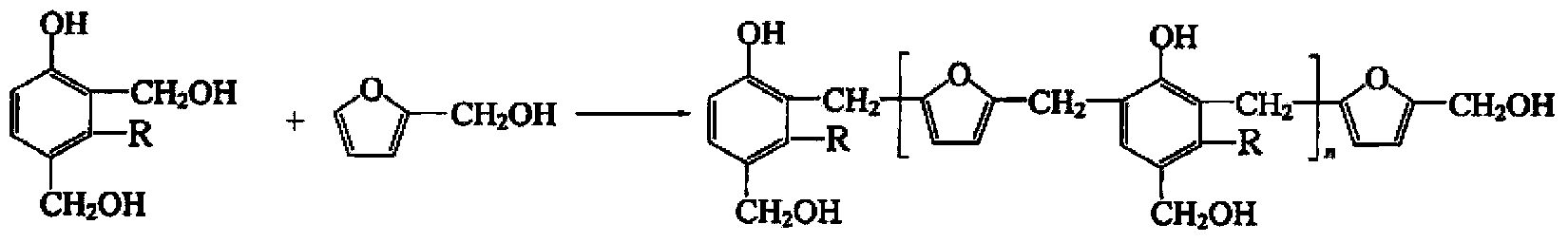

Preparation method of furan-modified cashew phenolic resin

ActiveCN103289035AImprove boiling water resistanceExcellent resistance to boiling waterHeat transfer tubeSeawater

The invention provides a preparation method of furan-modified cashew phenolic resin. The preparation method comprises the following steps of: selecting the following raw materials in parts by weight: 100-140 parts of cardanol, 32-54 parts of formaldehyde, 10-23 parts of furfuryl alcohol, 80-120 parts of dimethyl benzene and 8-10 parts of catalyst; adding the cardanol, the formaldehyde and the catalyst into a reaction kettle in proportion, reacting for 1 hour to 2 hours at 70 DEG C-80 DEG C; adding the furfuryl alcohol, and reacting for 1 hour to 2 hours at 90 DEG C-100 DEG C; adding the 80-120 parts of dimethyl benzene, heating up, separating the water by adopting an oil-water separating device until the temperature reaches 155 DEG C-160 DEG C, and performing heat preservation for 1 hour to 2 hours to obtain the furan-modified cashew phenolic resin. The preparation method of the furan-modified cashew phenolic resin has the beneficial effects of remarkably improving boiling water resistance and heat resistance of the resin, having a practical application meaning in corrosion resistance and scaling prevention of a distillation-process seawater desalting heat transfer tube as well as steam blowing resistance of a heat exchanger tube bundle of a petrifaction system, and being applicable to paint base preparation of industrial heavy-duty anticorrosive coating.

Owner:天津市中海科技有限公司

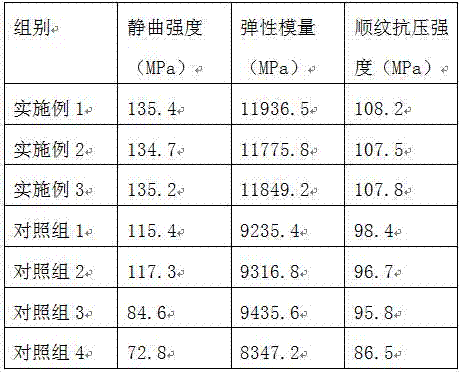

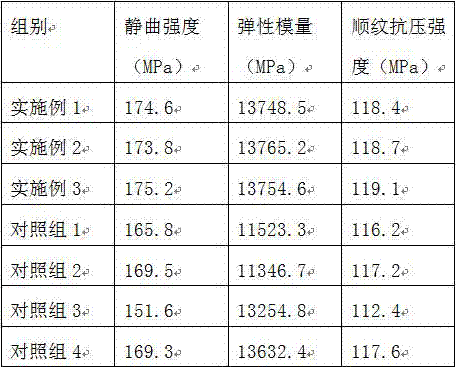

Processing method for enhancing ageing resistance of bamboo battens

InactiveCN107116637AImproved stability of surface structure changesImprove boiling water resistanceWood treatment detailsPlant material mechanical workingFiberPaulownia

The invention belongs to the technical field of materials made of bamboo and particularly relates to a processing method for enhancing the ageing resistance of a bamboo batten. According to the specific content of boiling and pretreatment, Chinese pepper straws, paulownia wood and the bamboo battens are placed in a sodium hydroxide solution to be boiled for 6-8 hours; as to the primary drying condition, the low-power microwave condition is adopted, and then hot air drying is conducted; as to impregnation, the carbonized bamboo battens are placed in a dipping tank to be dipped; and as the secondary drying condition, the water content is lowered to be lower than 7% through hot air drying. Compared with the prior art, the processing method for enhancing the ageing resistance of the bamboo battens has the advantages that boiling, pretreatment, primary drying, impregnation and secondary drying of the bamboo battens are improved, the pore structure, the pore diameter distribution and the like of surface fiber of the bamboo battens are changed because the Chinese pepper straws are added during boiling, through cooperation of primary drying and impregnation process, the surface structure of the bamboo battens is improved, and the boiling water resistance and the ageing resistance of the bamboo battens are improved; and the retention capacity of bending strength and rigidity of the bamboo battens is good in a humid and stuffy environment.

Owner:阜南县宏达工艺品厂

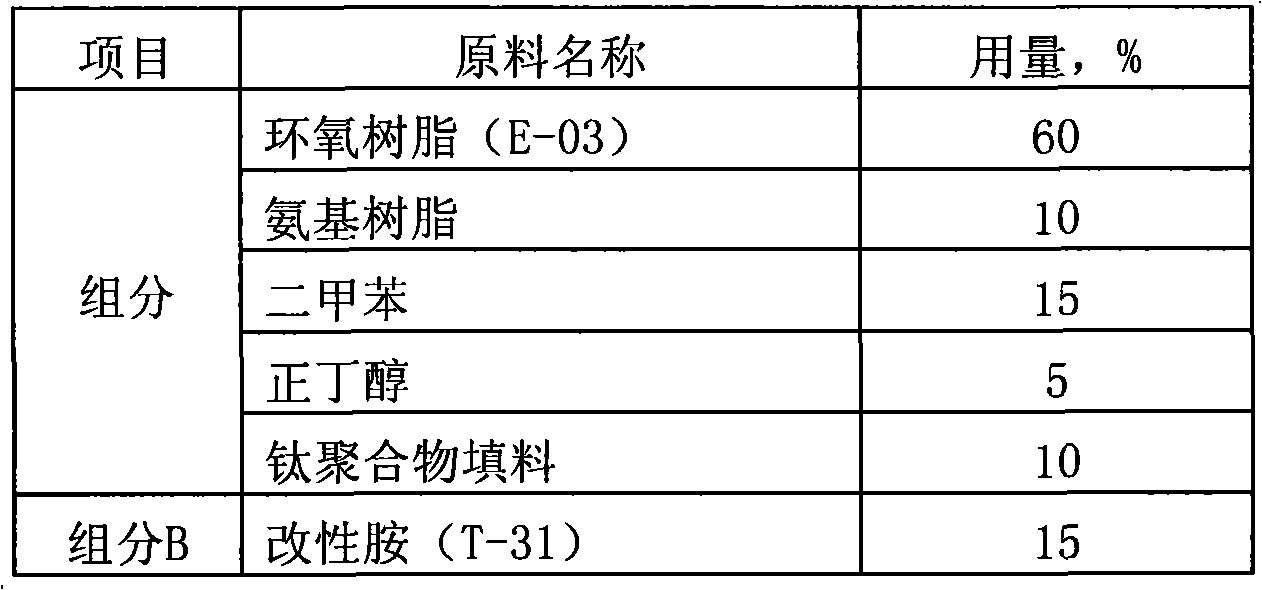

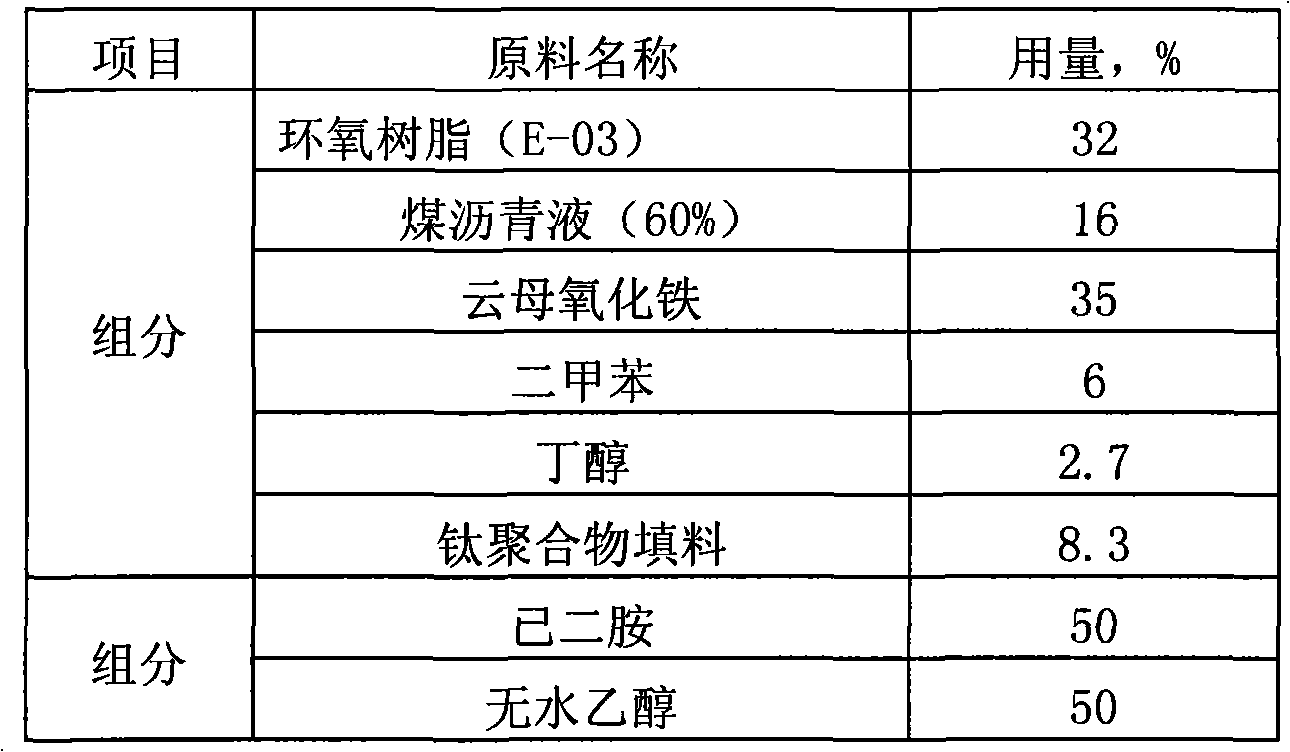

Method for producing titanium polymer resin anti-dirty corrosion-resistant oil pipe for oil field

InactiveCN101270845AIncrease resistanceStrong penetration resistanceCorrosion preventionPipe protection against corrosion/incrustationPolymer resinSpray coating

A preparation method for a titanium polymer resin, scale inhibition and anti-corrosion tube which is used in the oil field is disclosed. The preparation method for the titanium polymer resin, scale inhibition and anti-corrosion tube which is used in the oil field has the following procedures that the external and internal walls of the tube are coated with paint after the pre-treatment for the tube surface; the paint is produced that 7 percent to 20 percent titanium polymer fillings are added in the routine epoxy resin paint; the internal wall of the tube applies the high pressure, airless and stereo spray coating way; the external wall of the tube applies the stereo spray coating way with compressed air and three spray guns; the coating layers of the external and internal walls of the tube are adjusted and cured through an adjusting and curing furnace after the spray coating; the power of the furnace is 200KW, the temperature of the furnace is 50 degrees to 180 degrees and the curing time is 60 minutes; the tube rotates and moves forward in the adjusting and curing furnace; and the self-rotating speed of the tube is 30r / min to 80r / min. The preparation method solves the scaling and corrosion problem of the underground tube in the oil field under complex industrial and mining conditions, which protects the tube, prolongs the using life of the tube and saves the oil extraction cost.

Owner:DAQING PETROLEUM ADMINISTRATION

High-performance flame-retardant antistatic powder coating and preparation method thereof

ActiveCN114250027APerformance is not affectedAvoid General Performance IssuesFireproof paintsAnti-corrosive paintsEpoxyTin dioxide

The invention relates to a high-performance flame-retardant antistatic powder coating and a preparation method thereof, and belongs to the technical field of coatings, the coating is composed of epoxy resin, antistatic hyperbranched polyester, a high-flame-retardant curing agent, a curing accelerator, a leveling agent, a degassing agent and a pigment filler; the preparation method of the antistatic hyperbranched polyester comprises the following steps: modifying antimony-doped tin dioxide powder, and synthesizing the antistatic hyperbranched polyester. The high-flame-retardant curing agent contains two elements of phosphorus and bromine, the curing agent is finally crosslinked and cured into matrix resin of the coating in a chemical bonding manner, various properties of the coating are not influenced, and the problem that the conventional properties of the coating are seriously influenced by an additive flame retardant is avoided; the oxygen index of the powder coating is 48-51, the fire resistance is 0.95-1.15 hours according to the standard GB14907-2018, and the surface inherent resistance value is 1.14-1.35 * 10 < 4 > omega.

Owner:山东信科新材料有限公司

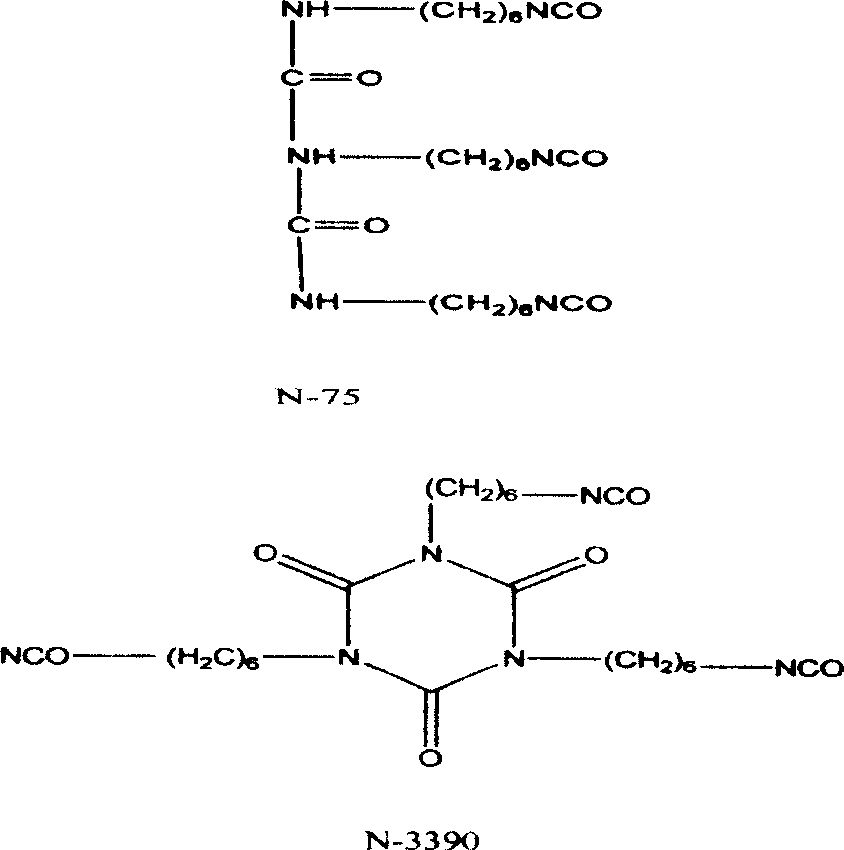

Transparent polyurethane primer and preparation method thereof

InactiveCN103740254AHigh tensile strengthImprove wear resistancePolyurea/polyurethane coatingsPolymer sciencePolyurethane coating

The invention discloses transparent polyurethane paint. The polyurethane aliphatic crosslinking type resin one-component paint, compared with linear polyurethane coating, is better than other series of coatings on aspects of paint film hardness, boiling water resistance, solvent resistance, light and color retention, resistance to firing of cigarette butts, infusion resistance and the like. Moreover, the solid component is high, the construction procedures are reduced, the transparent polyurethane paint can be rapidly dried at normal temperature, and a paint film is flat and full.

Owner:广西宾阳县荣良农业科技有限公司

Adhesive composition and application thereof

ActiveCN110184021ASimple manufacturing processReduce manufacturing costNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesOligomerAdhesive

The invention relates to a glass UV (Ultraviolet) transfer printing adhesive with high hardness, water-boiling resistance and strong adhesive force and application thereof. The UV transfer printing adhesive comprises the following components in parts by weight: 1-5 parts of a fluorine-containing polyurethane acrylate oligomer, 30-50 parts of a polyurethane acrylate oligomer, 1-10 parts of a fluorine-containing acrylate monomer, 40-60 parts of an acrylate monomer, 3-5 parts of a photoinitiator and 1-5 parts of an additive. The UV transfer printing adhesive provided by the invention has high hardness, high adhesive force to glass and excellent water-boiling resistance and is particularly suitable for glass UV transfer printing in a GDM (Glass Direct Molding) process.

Owner:上海昀通电子科技有限公司

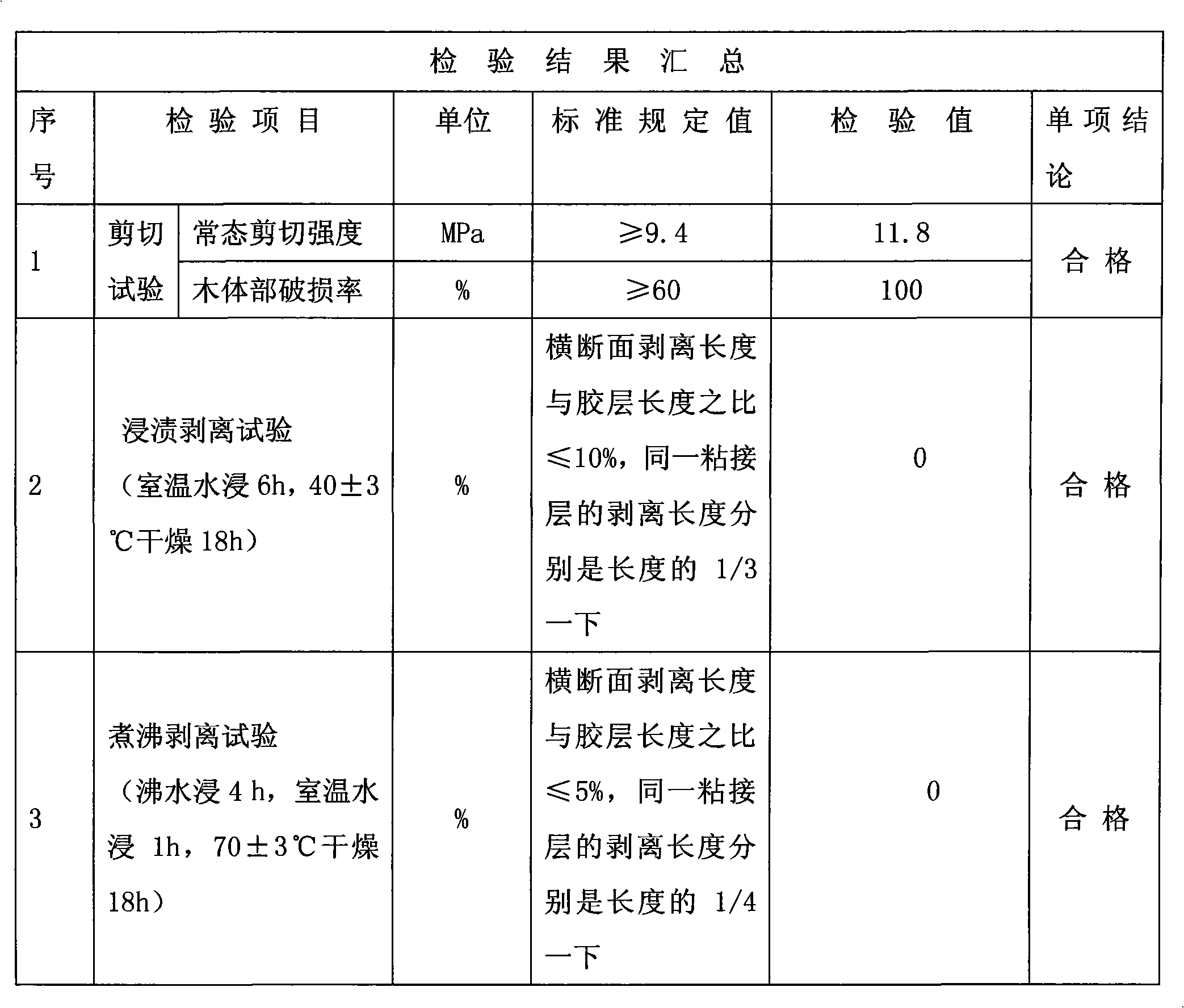

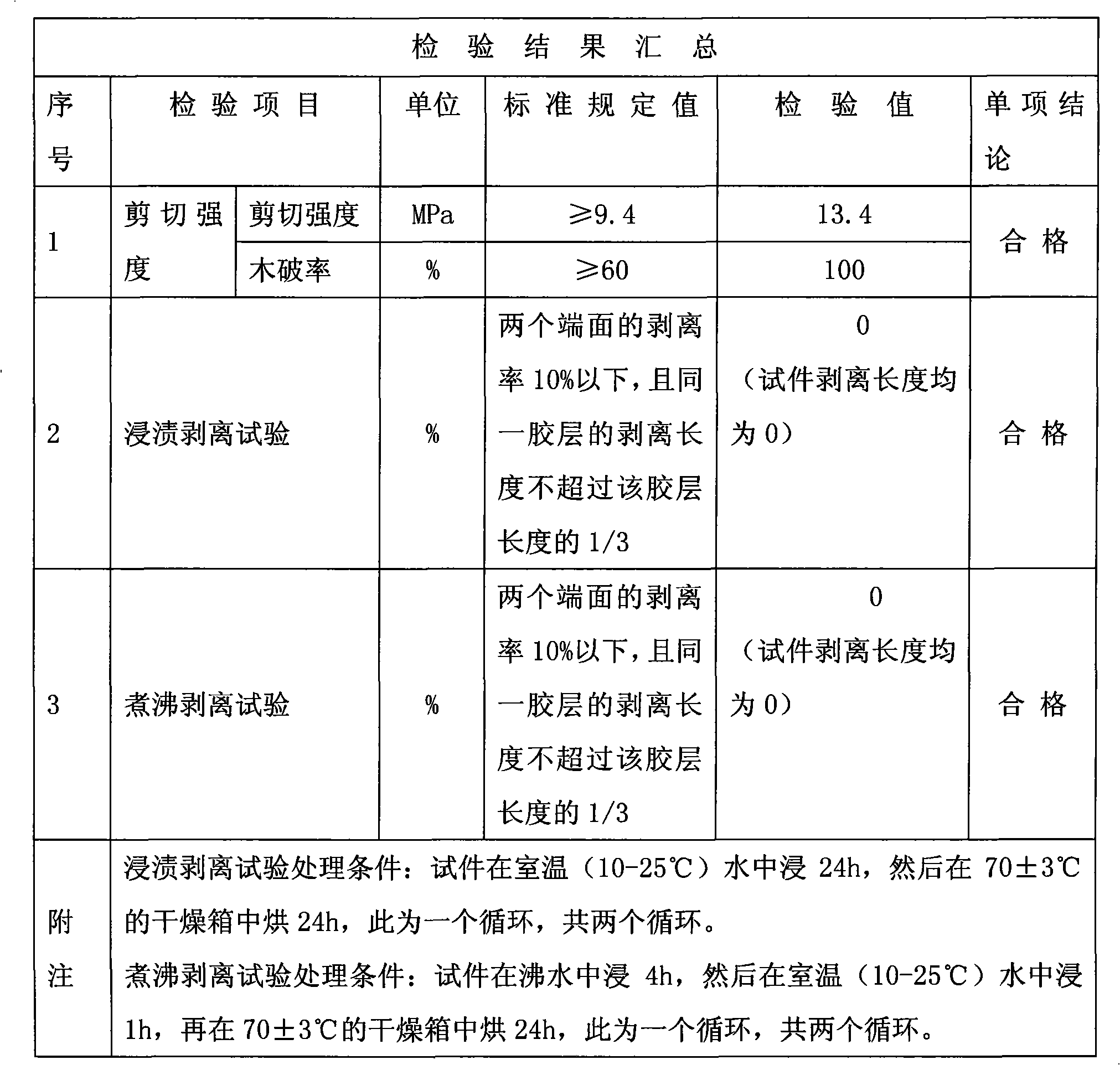

Integrated material wood-splicing adhesive and preparation method thereof

ActiveCN101565593BAdequate responseHigh hardnessMonocarboxylic acid ester polymer adhesivesPolymer scienceAdhesive

The invention provides an integrated material wood-splicing adhesive, which is characterized in that the integrated material wood-splicing adhesive is prepared by the following components by weight portions: 100 weight portions of main agent and 13-17 weight portions of cross linking agent modified polyisocyanate, wherein the main agent is prepared by the following raw materials by weight: 3-5% ofpolyvinyl alcohol, 21.4-38.92% of vinyl acetate, 1-3% of crylic acid, 5-10% of butyl acrylate, 1-3% of methacrylic acid, 0.9-1.1% of 2-hydroxyethyl acrylate, 1-2% of emulsifier OP-10, 1-2% of sodiumdodecyl sulfate, 0.08-0.2% of ammonium persulfate, 0.1-0.3% of pH regulator and 48-52% of deionized water. The integrated material wood-splicing adhesive has the advantages of high adhesion strength,good water resistance, and no organic solvent and formaldehyde.

Owner:顶立新材料科技股份有限公司

Boiling-water-resistant waterborne ink applied to PVC printing

The invention relates to boiling-water-resistant waterborne ink applied to PVC printing, which includes, by mass, 38-46 parts of an aqueous polyurethane-acrylic resin emulsion, 35-45 parts of deionized water, 5-8 parts of a styrene-acrylic emulsion, 7-17 parts of a pigment, 1-2 parts of ammonia water, 1-2 parts of a defoamer, 2-3 parts of an additive, and 2-5 parts of nano-fluorescent powder. The pigment is a modified pigment which is modified through the steps of: mixing a common pigment, potassium hexatitanate whiskers, glass flakes, titanium dioxide, barium sulfate and ethanol, adding the mixture to a container with a stirring unit, and stirring the mixture for 15-25 min; and then adding sodium m-carboxylbenzenesulfonate, and uniformly stirring the mixture to prepare a micro-emulsion; moving the micro-emulsion into a vacuum ball milling tank, and placing the ball milling tank in a ball mill to perform planetary vacuum ball milling; and relieving pressure, discharging the materials, and drying the materials to prepare the modified pigment. The boiling-water-resistant waterborne ink is high in color fastness to light, has high adhesion force, is low in viscosity and is good in water resistance.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Glass fiber toughened polycarbonate/polypropylene alloy material and preparation method thereof

The invention discloses a glass fiber toughened polycarbonate / polypropylene alloy material which is characterized by comprising the following components in percentage by weight: 100g of polycarbonate resin, 10-5g of polycarbonate resin, 5-20g of a polycarbonate grafted glycidyl methacrylate copolymer, 5-20g of an ethylene-methyl acrylate glycidyl methacrylate random copolymer, 0.1-1g of an antioxidant and 1-2g of a lubricant. The material disclosed by the invention has the advantages of better toughness and higher strength.

Owner:深圳市奥晶科技有限公司

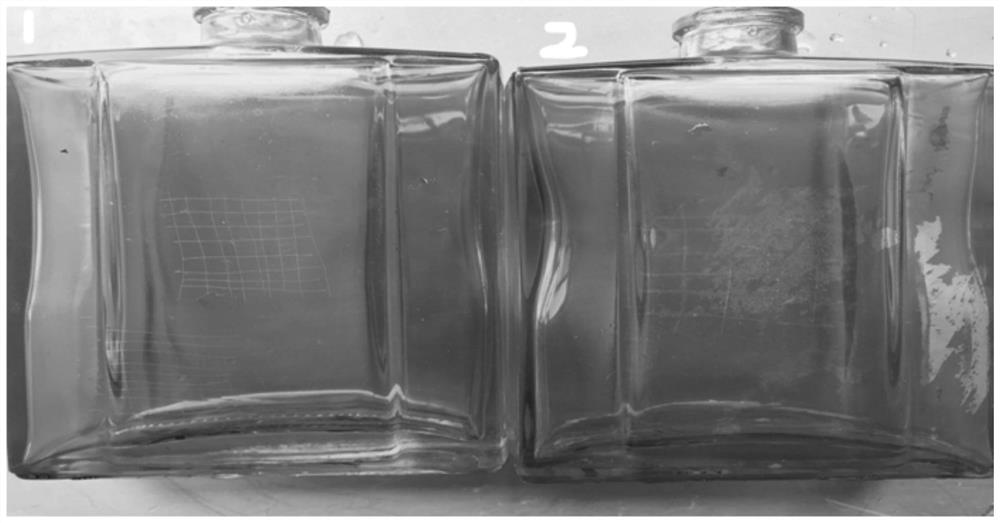

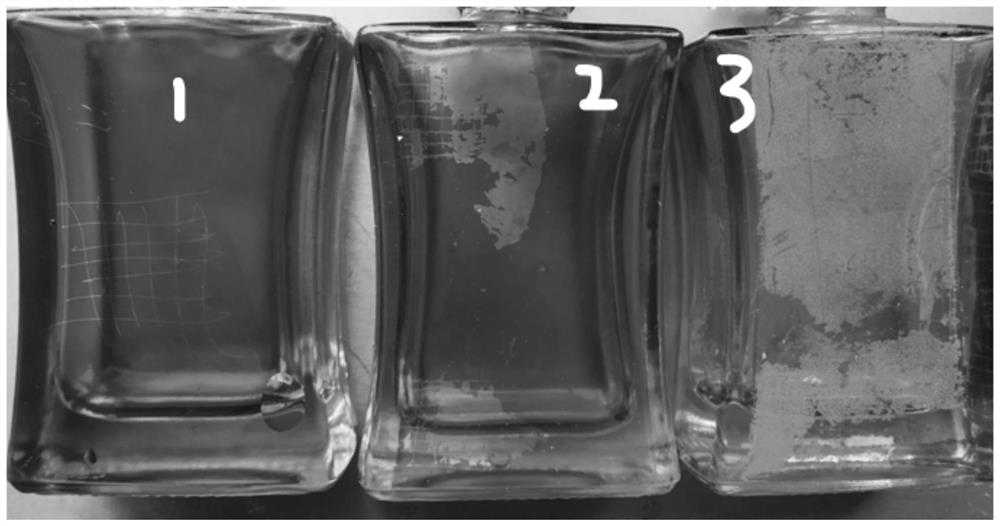

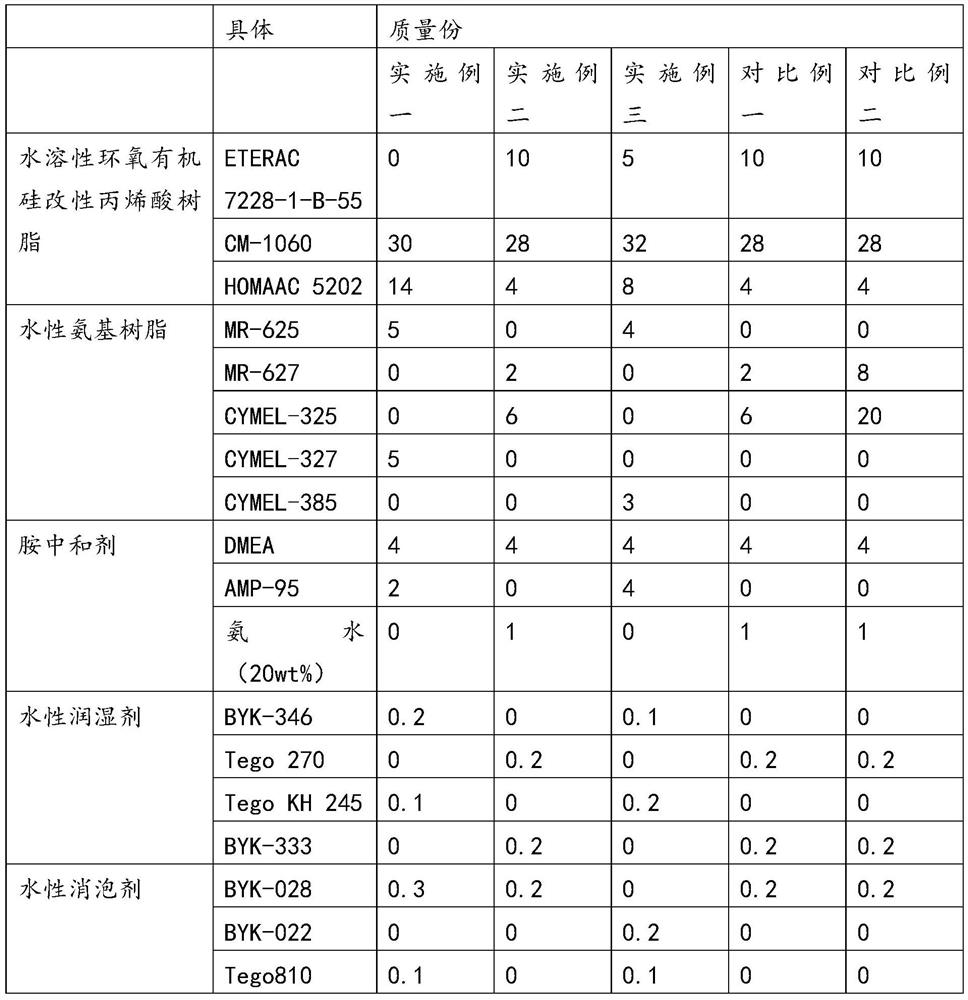

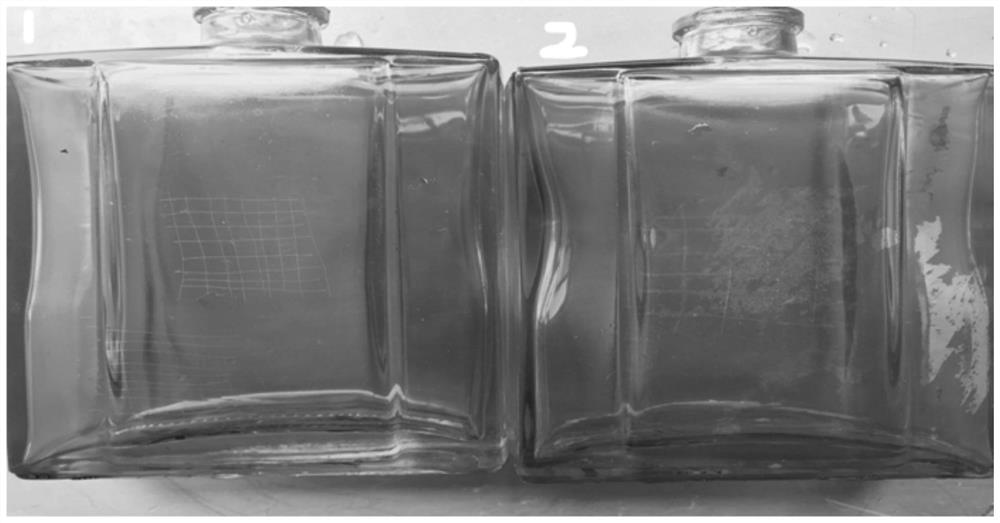

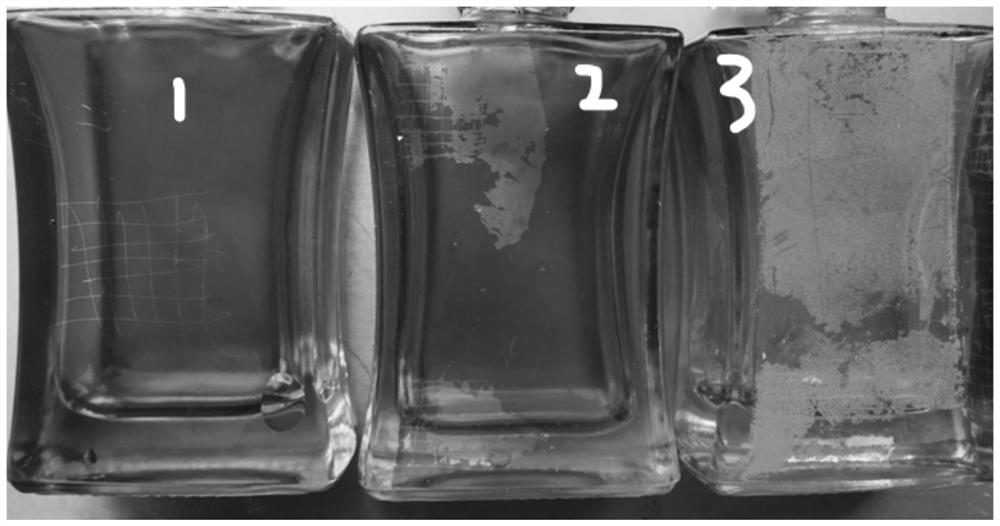

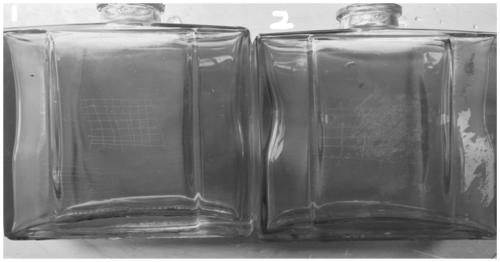

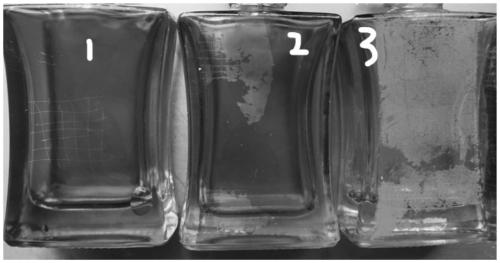

Boiling-water-resistant water-based glass coating material and preparation method thereof

InactiveCN111732861AImprove boiling water resistanceImprove the use environmentCoatingsEpoxyAcrylic resin

The invention discloses a boiling-water-resistant water-based glass coating material and a preparation method thereof. The preparation method comprises the following steps: stirring and dispersing water-soluble epoxy modified acrylic resin for the first time; stirring and dispersing the component again, then adding the cosolvent, continuously stirring and dispersing the component, then adding thewater-based defoaming agent; stirring and dispersing the components, and then adding the water-based wetting agent; continuously stirring and dispersing the components, then adding the deionized water; finally stirring and dispersing the component and then adding the water-based amino resin, and uniformly stirring the mixture to obtain a component A; mixing the component A, the component B, waterand a coloring agent to obtain the boiling-water-resistant water-based glass coating material, wherein the component B is a silane coupling agent. According to the invention, the water-soluble resin can be better dissolved in water by virtue of the feeding sequence and process parameters, so that the use of a cosolvent is reduced, and meanwhile, the assistants are more uniformly and stably dispersed in a coating system, so that the product quality is ensured. Color paste or color concentrate can be added into the water-based glass coating, the water-based glass coating has good color development performance and vividness, the coating is resistant to boiling water boiling for 2 h after being dried and has no abnormity, and particularly the problems that existing water-based glass coatings on the market have no adhesion and are not resistant to boiling water boiling after sky blue color concentrate is added are solved.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

Boiling-water-boiling-resistant water-based glass coating and preparation method thereof

InactiveCN111718626AImprove boiling water resistanceImprove the use environmentCoatingsEpoxyAcrylic resin

The invention discloses a boiling-water-boiling-resistant water-based glass coating and a preparation method thereof. The preparation method comprises the following steps: adding an amine neutralizerafter water-soluble epoxy modified acrylic resin is stirred and dispersed for the first time; stirring and dispersing again, then adding a cosolvent, continuously stirring and dispersing, then addinga water-based defoaming agent, then stirring and dispersing, then adding a water-based wetting agent, continuously stirring and dispersing, then adding deionized water, finally stirring and dispersing, then adding water-based amino resin, and uniformly stirring to obtain a component A; combining the component A with a component B to obtain boiling-water-boiling-resistant water-based glass coating;mixing the boiling-water-resistant water-based glass coating with water to obtain a boiling-water-resistant water-based glass coating material, or mixing the boiling-water-resistant water-based glasscoating with water and a coloring agent to obtain a boiling-water-resistant water-based glass coating material; and then coating glass with the coating material, and drying to obtain the boiling-water-boiling-resistant water-based glass coating. Color paste or color concentrate can be added into the water-based glass coating so that the water-based glass coating has good color development performance and vividness, the coating is resistant to boiling water boiling for 2 h without abnormity after the coating is dried, and particularly the problems that existing water-based glass coating on themarket has no adhesion and is not resistant to boiling water boiling after sky blue color concentrate is added are solved.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

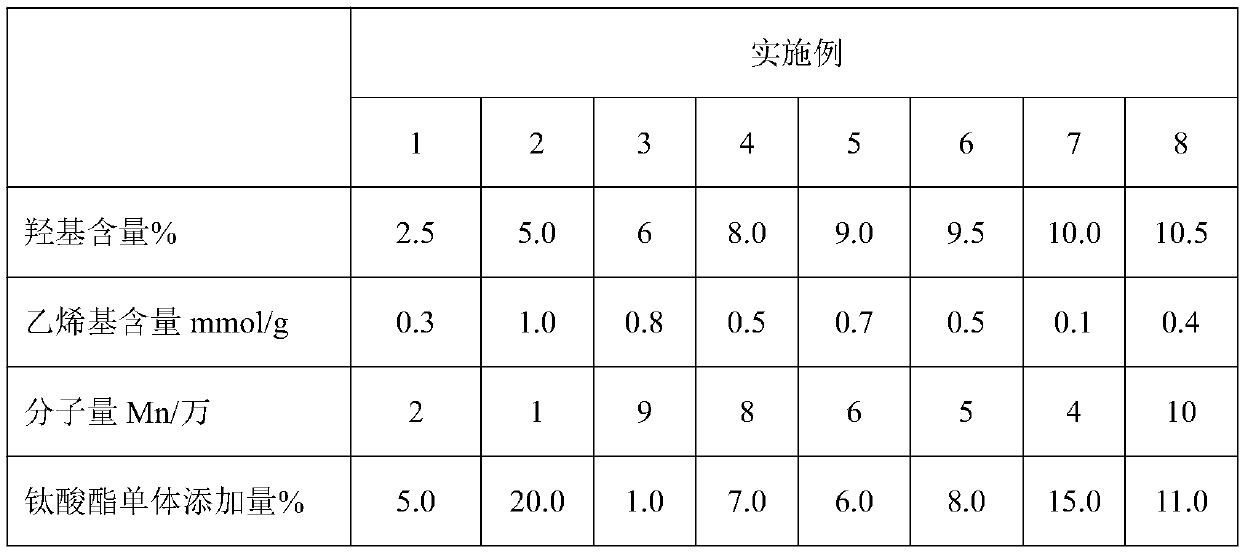

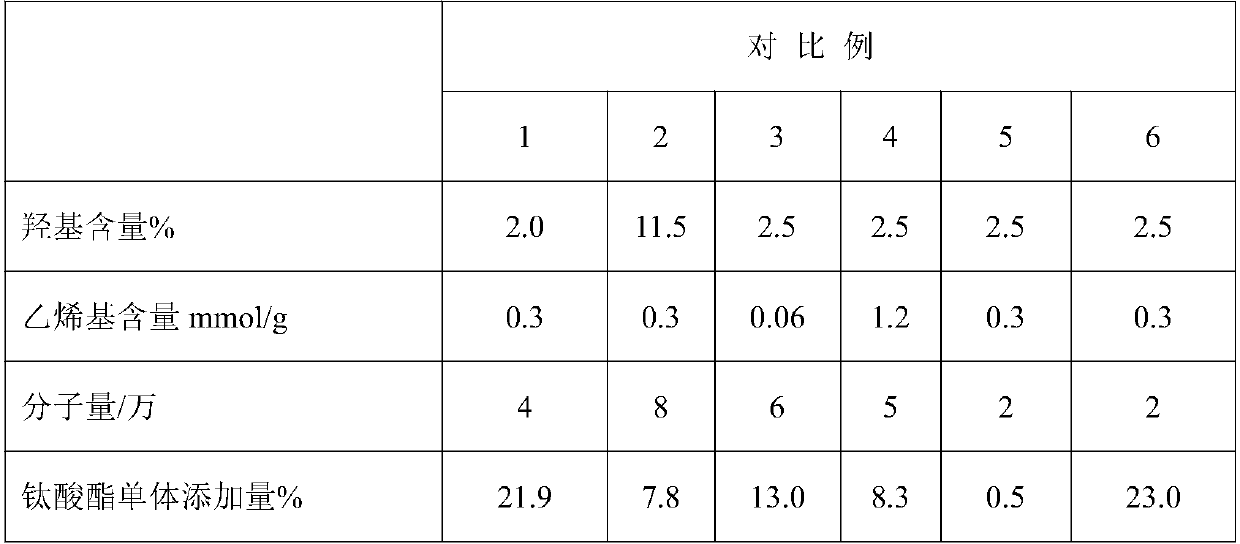

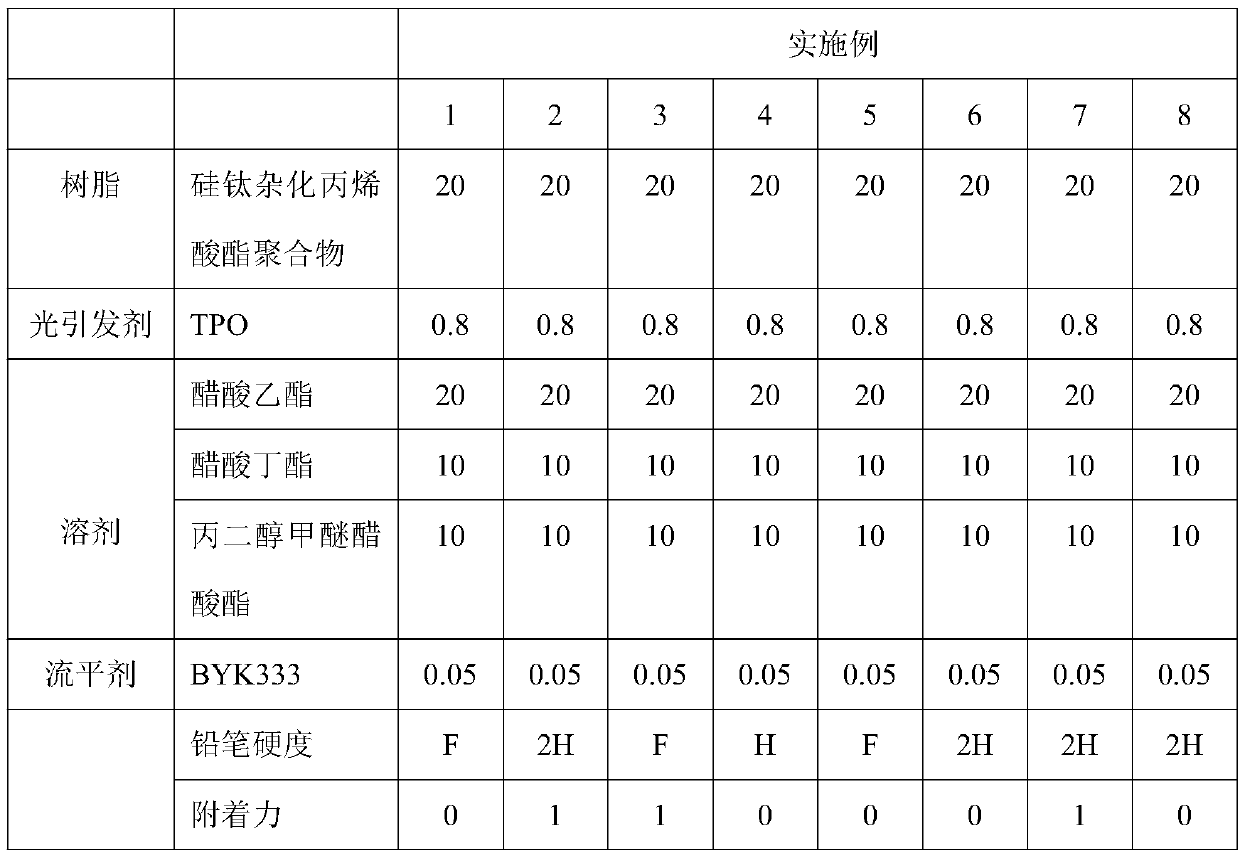

Silicon-titanium hybrid acrylate polymer and double-cured paint prepared therefrom

ActiveCN110003383AImprove hydrophilicityImprove adhesionCoatingsGlycidyl methacrylateHydroxybenzoate Ethers

The invention belongs to the technical field of polymer polymerization, and discloses a silicon-titanium hybrid acrylate polymer and double-cured paint prepared therefrom. The silicon-titanium hybridacrylate polymer is obtained by the following steps: adding an acrylate monomer, a silane coupling agent, a hydroxyl group-containing acrylate monomer and a carboxyl group-containing acrylate monomerinto an initiator for free radical polymerization to obtain a carboxyl group-containing prepolymer; then adding p-hydroxyanisole and triphenylphosphine, and using glycidyl methacrylate to react with acarboxyl group in the main chain of the carboxyl group-containing prepolymer to introduce a double bond and obtain an organosilicon hybrid acrylate prepolymer; and then adding a titanate monomer, andstirring at room temperature with humidity being not more than 30%. The invention provides silicon-titanium hybrid acrylate which is capable of double curing. The paint has both excellent continuousanti-fog property and boiling water resistance after being cured into a film.

Owner:广州五行材料科技有限公司

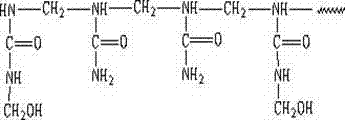

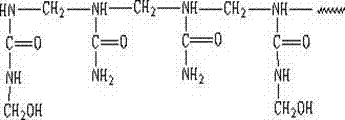

Waterproof reinforcing agent for urea-formaldehyde adhesive for boiling-resistant artificial board

ActiveCN103484036ASolve the waterproof problemLow costNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePtru catalyst

A waterproof reinforcing agent for a urea-formaldehyde adhesive for a boiling-resistant artificial board comprises the components as follows: 30% of aluminum sulfate, 20% of calcium hydroxide, 20% of stearic acid, 5% of potassium dichromate, 20% of aluminum silicate and 5% of 1,2,3-triphenyl cyclopropane. According to the waterproof reinforcing agent, in a condensation process of formaldehyde and urea, hydrophilic groups such as OH-, urea bonds and the like can be removed effectively and radically in a condensation process of the urea-formaldehyde adhesive under the action of the temperature and acid-base catalysts, the defect that application effects cannot be realized due to the fact that prepared traditional urea-formaldehyde adhesives are modified by melamine to be waterproof or become waterproof through paraffin is overcome, the waterproof performance is realized during production of the urea-formaldehyde adhesive, fm copolymers are produced through cross-linking reactions, effects of 3N heterocyclic rings in the urea bonds and MUF (melamine-urea-formaldehyde) copolymers are eliminated, and the dosage of the melamine of the traditional modified urea-formaldehyde adhesives can be saved by 60%.

Owner:SICHUAN LYUBEIER FINE CHEM SCI & TECH

Boiling-water-boiling-resistant water-based glass coating and preparation method thereof

InactiveCN111234635AImprove boiling water resistanceImprove the use environmentCoatingsEpoxyAcrylic resin

The preparation method comprises the following steps: combining a component A with a component B to obtain the boiling-water-resistant water-based glass coating, wherein the component A is prepared from water-soluble epoxy modified acrylic resin, water-based amino resin, an amine neutralizer, a water-based wetting agent, a water-based defoaming agent, a cosolvent and deionized water; and the component B is a silane coupling agent. According to the invention, the water-soluble resin can be better dissolved in water by virtue of the feeding sequence and process parameters, so that the use of a cosolvent is reduced, and meanwhile, the assistants are more uniformly and stably dispersed in a coating system, so that the product quality is ensured. Color paste or color concentrate can be added into the water-based glass coating, the water-based glass coating has good color development performance and vividness, the coating is resistant to boiling water boiling for 2 h after being dried and has no abnormity, and particularly the problems that existing water-based glass coatings on the market have no adhesion and are not resistant to boiling water boiling after sky blue color concentrate isadded are solved.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

Adhesive composition and use thereof

ActiveCN110184021BSimple manufacturing processReduce manufacturing costNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention relates to a glass UV transfer adhesive with high hardness and strong boiling resistance and strong adhesion and its application. The UV transfer adhesive, in parts by weight, includes the following components: 1-5 parts of fluorine-containing urethane acrylate oligomers, 30-50 parts of urethane acrylate oligomers, and 1-10 parts of fluorine-containing acrylate monomers parts, 40-60 parts of acrylate monomer, 3-5 parts of photoinitiator, and 1-5 parts of auxiliary. The UV transfer adhesive provided by the invention has high hardness, high adhesion to glass, and excellent resistance to boiling water, and is especially suitable for UV transfer of glass in GDM process.

Owner:上海昀通电子科技有限公司

Glulam glue and preparation method thereof

ActiveCN106867427BReduce dosageReduce layeringMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedBreaking strength

The invention discloses laminated material laminating glue and a preparation method thereof. The laminated material laminating glue comprises components A and B. The component A comprises, by mass, 17.7% to 25.4% of deionized water, 39% to 63% of a water-based emulsion, 1% to 5% of a plasticizer, 2% to 4% of polyvinyl alcohol, 0.1% to 0.2% of a chelating agent, 0.1% to 0.2 % of a dispersant, 0.05% to 0.1% of a defoamer, 16% to 26% of calcium carbonate and 0.05% to 0.1% of a bactericide. The component B comprises polyaryl polymethylene isocyanate. The preparation method comprises preparing a modified polyvinyl alcohol solution from deionized water, polyvinyl alcohol and the chelating agent, orderly adding the water-based emulsion, the plasticizer, the dispersant and the defoamer into a dispersion kettle, slowly adding calcium carbonate into the dispersion kettle, carrying out dispersion to obtain uniform glue slurry, adding a polyvinyl alcohol modification solution and a bactericide into the glue slurry to obtain the component A and mixing the component A and the component B. The laminated material laminating glue is used for splicing of various laminated materials, has high splicing strength, a long application period, excellent heat resistance and excellent water resistance, resists water boiling and can reach the wood breaking strength.

Owner:北京市创新玮地科贸有限公司

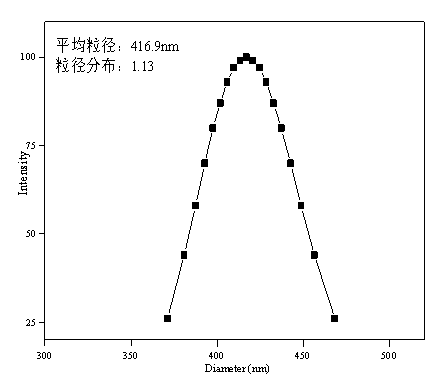

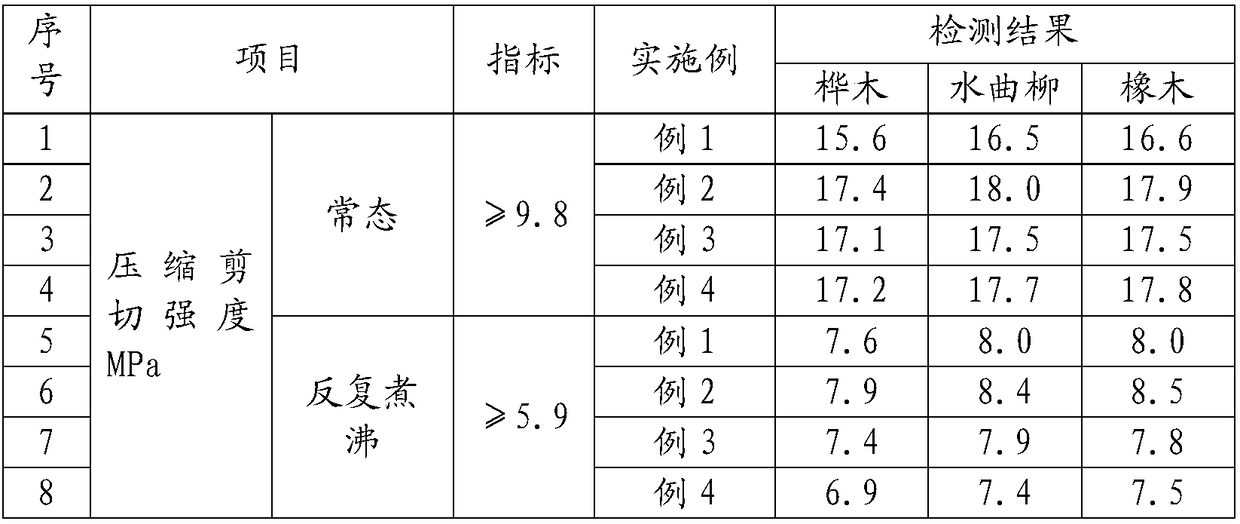

Preparation method of furan-modified cashew phenolic resin

The invention provides a preparation method of furan-modified cashew phenolic resin. The preparation method comprises the following steps of: selecting the following raw materials in parts by weight: 100-140 parts of cardanol, 32-54 parts of formaldehyde, 10-23 parts of furfuryl alcohol, 80-120 parts of dimethyl benzene and 8-10 parts of catalyst; adding the cardanol, the formaldehyde and the catalyst into a reaction kettle in proportion, reacting for 1 hour to 2 hours at 70 DEG C-80 DEG C; adding the furfuryl alcohol, and reacting for 1 hour to 2 hours at 90 DEG C-100 DEG C; adding the 80-120 parts of dimethyl benzene, heating up, separating the water by adopting an oil-water separating device until the temperature reaches 155 DEG C-160 DEG C, and performing heat preservation for 1 hour to 2 hours to obtain the furan-modified cashew phenolic resin. The preparation method of the furan-modified cashew phenolic resin has the beneficial effects of remarkably improving boiling water resistance and heat resistance of the resin, having a practical application meaning in corrosion resistance and scaling prevention of a distillation-process seawater desalting heat transfer tube as well as steam blowing resistance of a heat exchanger tube bundle of a petrifaction system, and being applicable to paint base preparation of industrial heavy-duty anticorrosive coating.

Owner:天津市中海科技有限公司

A kind of artificial colored sand adhesive and its application

The invention provides an artificial sintered colored sand adhesive and its application. The artificial colored sand adhesive includes the following components: sodium silicate, amphoteric oxide buffer, and phosphate; wherein, the sodium silicate The parts by weight are 80-120 parts, the parts by weight of the amphoteric oxide buffer solution are 5-10 parts, and the parts by weight of the phosphate are 4-6 parts of insoluble phosphate or 12 parts by weight. ‑16 parts of water-soluble phosphate; the present invention screens the active ingredients and proportions through experiments, uses amphoteric oxide buffer and phosphate to modify sodium water glass, and each component synergizes under a specific formula to finally optimize the preparation The artificial colored sand with excellent water resistance and boiling water resistance has broad application prospects and huge market value; the invention has simple technology, can realize industrialized large-scale production, can bring good economic benefits to enterprises, and has broad application prospects. prospect.

Owner:上海贝塔建筑科技有限公司

Aqueous primer used for bicycles

The invention relates to an aqueous primer used for bicycles, which comprises the following components in percentage by weight: 25-45% of aqueous epoxy acrylate resin, 2-10% of curing agent resin, 1-3% of neutralizing agent dimethylethanolamine, 2-10% of compound anticorrosive pigment, 5-20% of tinting pigment and filler, 0.1-0.5% of antifoaming agent, 0.1-0.5% of flatting agent and 20-40% of deionized water, wherein the sum of the content of all components is 100%. The aqueous epoxy acrylate resin accounts for 10-40% of the total mass of epoxy resin; the curing agent resin comprises aqueous closed-type polyurethane curing agent resin and amino curing agent resin, wherein the mass ratio of the aqueous closed-type polyurethane curing agent resin to the amino curing agent resin is 1:5-5:1; the aqueous closed-type polyurethane curing agent resin is decapsulated and solidified at the temperature of 130DEG C; the amino curing agent resin is carbinol or butylated amino melamine formaldehyde resin; and the compound anticorrosive pigment comprises modified zinc phosphate, zinc oxide and ion exchange type anticorrosive pigment. The aqueous primer disclosed by the invention is especially suitable for preventing rust and corrosion of structures, such as bicycles and the like.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

A kind of boiling-resistant water-based water-based ink applied to pvc printing

The invention relates to boiling-water-resistant waterborne ink applied to PVC printing, which includes, by mass, 38-46 parts of an aqueous polyurethane-acrylic resin emulsion, 35-45 parts of deionized water, 5-8 parts of a styrene-acrylic emulsion, 7-17 parts of a pigment, 1-2 parts of ammonia water, 1-2 parts of a defoamer, 2-3 parts of an additive, and 2-5 parts of nano-fluorescent powder. The pigment is a modified pigment which is modified through the steps of: mixing a common pigment, potassium hexatitanate whiskers, glass flakes, titanium dioxide, barium sulfate and ethanol, adding the mixture to a container with a stirring unit, and stirring the mixture for 15-25 min; and then adding sodium m-carboxylbenzenesulfonate, and uniformly stirring the mixture to prepare a micro-emulsion; moving the micro-emulsion into a vacuum ball milling tank, and placing the ball milling tank in a ball mill to perform planetary vacuum ball milling; and relieving pressure, discharging the materials, and drying the materials to prepare the modified pigment. The boiling-water-resistant waterborne ink is high in color fastness to light, has high adhesion force, is low in viscosity and is good in water resistance.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Styrene modified polyvinyl acetate emulsion and preparation method

InactiveCN103131354BWith boiling water resistanceSystem stabilityMonocarboxylic acid ester polymer adhesivesPolyvinyl acetatePolyvinyl alcohol

The invention relates to a styrene modified polyvinyl acetate emulsion and a preparation method, and relates to the modified polyvinyl acetate emulsion and the preparation method. The styrene modified polyvinyl acetate emulsion comprises the following raw materials by weight: 58-62% of deionized water, 2-10% of polyving akohol, 20-35% of mixed monomer 1, 4-20% of mixed monomer 2, 0.6-2% of compound emulsifier, 0.1-0.5% of pH buffering agent and 0.1-1% of initiator. The preparation method employs a staging polymerization mode, in a first stage, vinyl acetate monomer is polymerized to form a polymer seed; in a second stage, a styrene monomer is polymerized in the polymer seed to form emulsion particles with a two-phase separation structure. According to the invention, the process is simple, the cost is low, the boiling water resistance performance of the polyvinyl acetate emulsion is increased, no environmental pollution is generated, and cold pressure curing at normal temperature, and the styrene modified polyvinyl acetate emulsion can be directly used as aqueous adhesives.

Owner:NORTHEAST FORESTRY UNIVERSITY

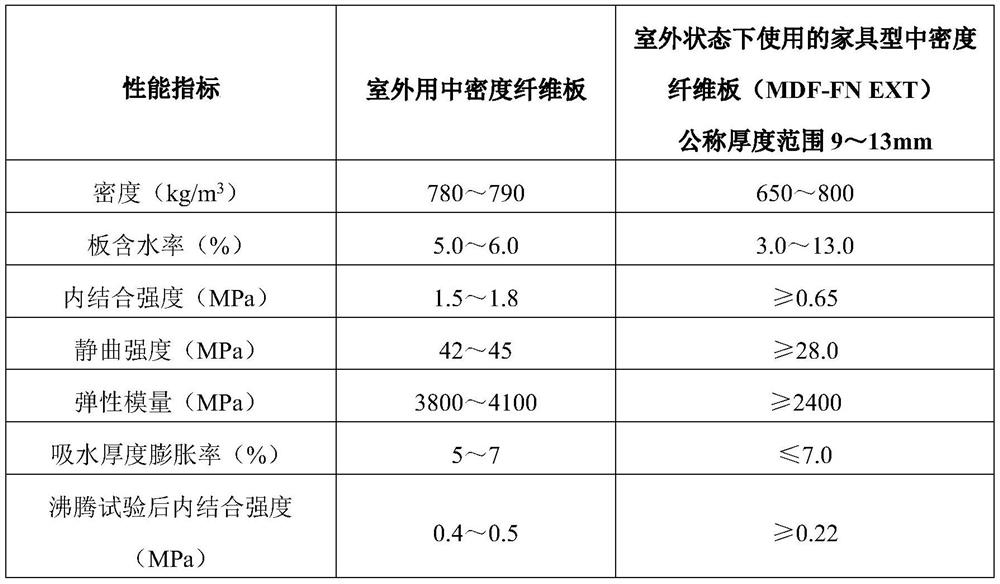

A kind of method that muf-mdi glue prepares fiberboard for outdoor use

ActiveCN112223480BStable generationImprove water resistanceDomestic articlesFlat articlesFiberAdhesive glue

The invention belongs to the technical field of fiberboard production, and relates to a method for preparing outdoor fiberboards with MUF-MDI glue. The production steps include: glue preparation, fiber preparation, glue mixing and drying, pavement pre-pressing, slab hot-pressing and post-treatment. The "medium-medium-alkali" synthesis process is used to prepare MUF that matches MDI, including one feeding of formaldehyde, two feedings of urea, and one feeding of melamine. The whole preparation process is divided into neutral addition reaction and neutral polycondensation reaction and alkaline post-treatment in three stages; then use MDI and the prepared MUF to determine the addition ratio of the two glues and the hot-pressing process to produce outdoor fiberboard. The method disclosed in the present invention significantly reduces the production cost compared with only using MDI glue, the production capacity is basically unchanged, the production is stable, and it is suitable for large-scale continuous production; the board has superior bonding strength, moisture resistance and water resistance, and can be applied to sunlight In the outdoor environment of , rain and air pollution, it broadens the application field of fiberboard.

Owner:DARE WOOD BASED PANEL GRP

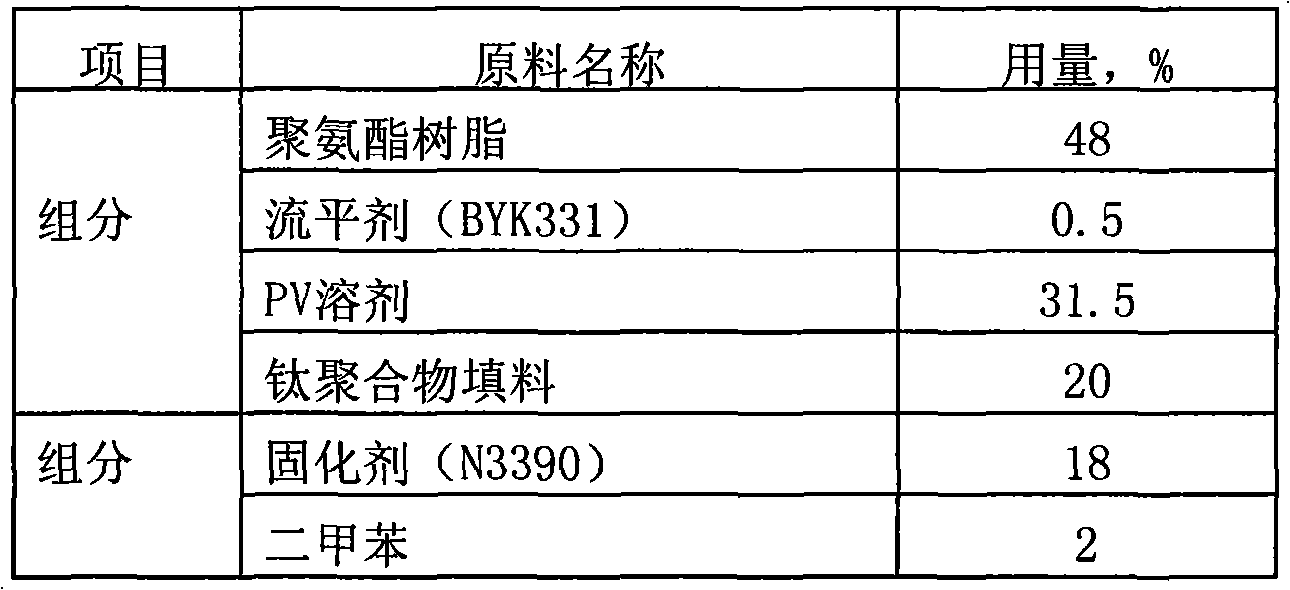

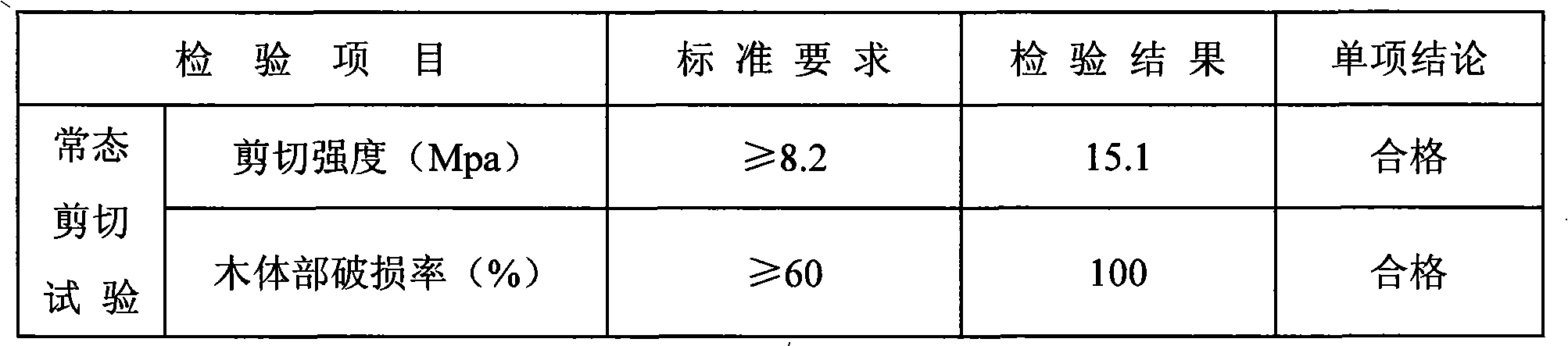

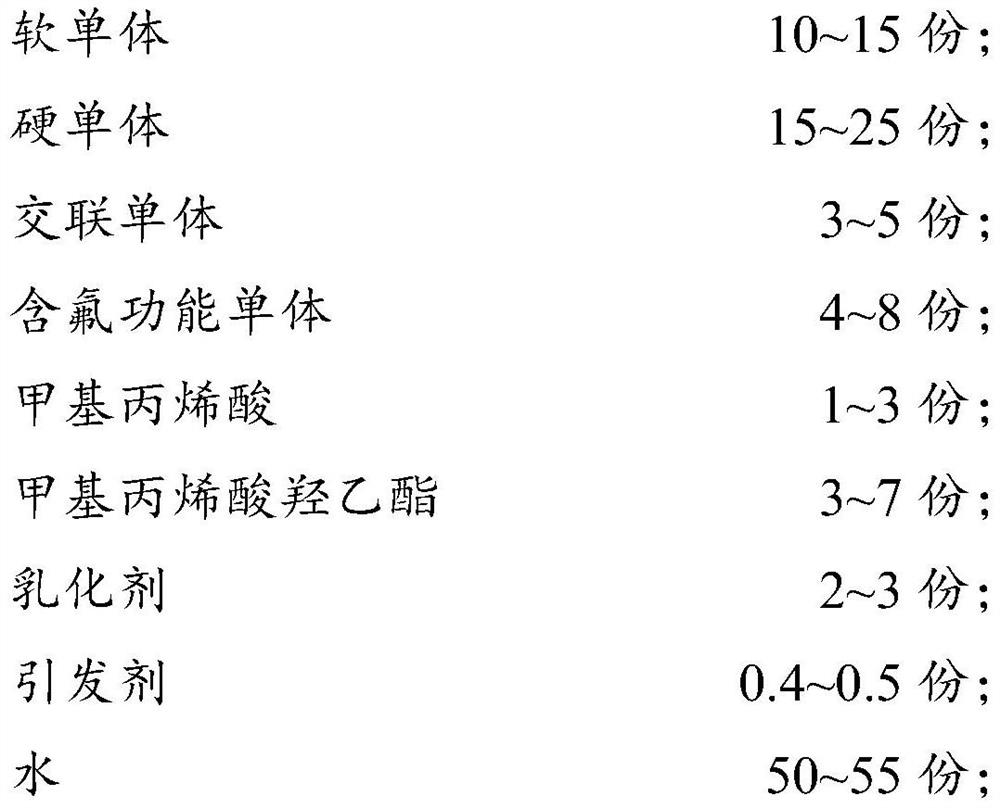

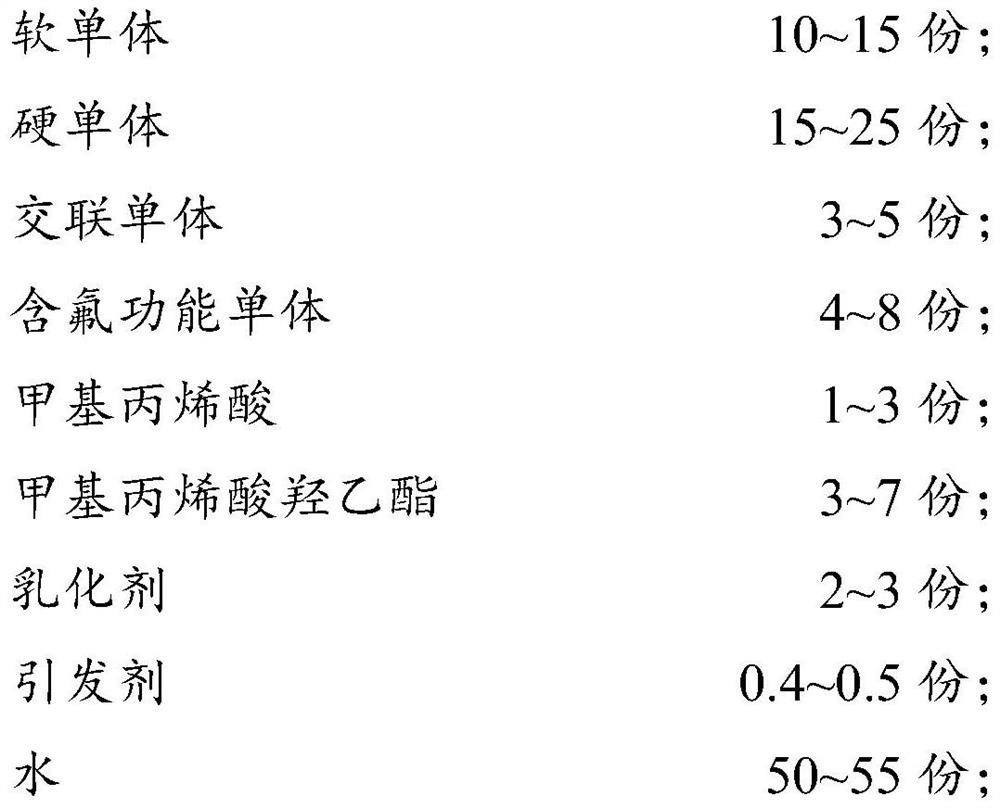

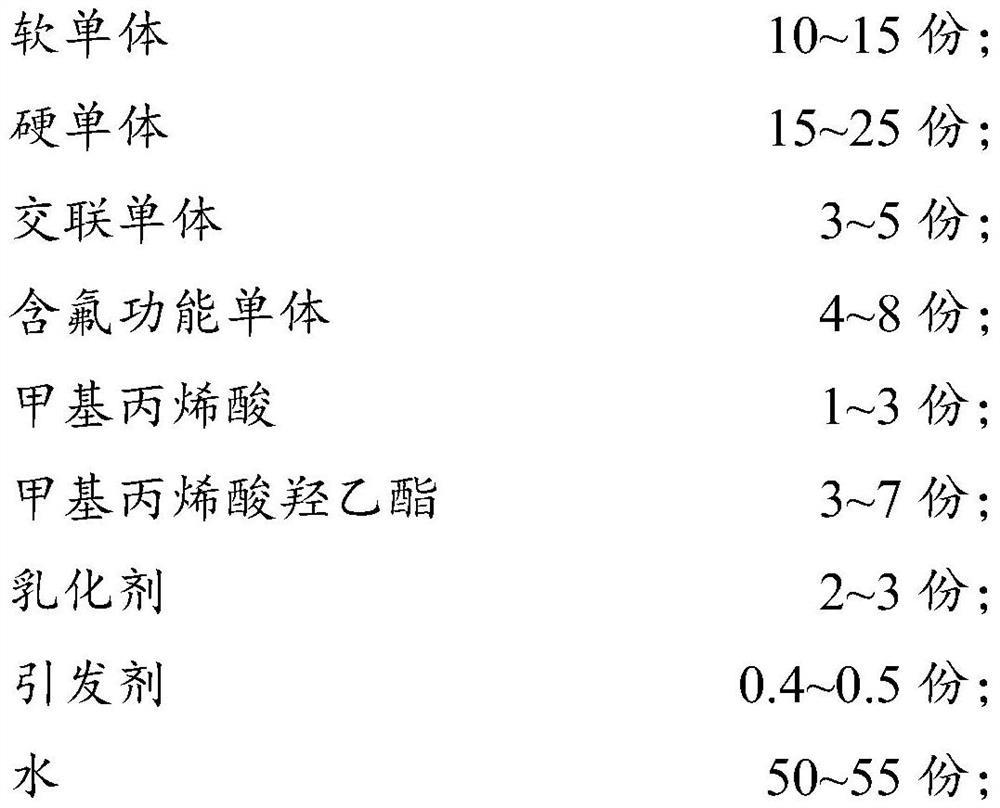

Water-based two-component wood lacquer and preparation method thereof

ActiveCN112063281AImprove mechanical propertiesImprove flexibilityAntifouling/underwater paintsPaints with biocidesFunctional monomerEmulsion

The invention discloses a water-based two-component wood lacquer, which comprises a matrix emulsion and a curing agent in a weight ratio of 100:(10-15), wherein the matrix component is mainly preparedfrom the following raw materials: a soft monomer, a hard monomer, a cross-linking monomer, a fluorine-containing functional monomer, methacrylic acid, hydroxyethyl methacrylate, an emulsifier, an initiator and water, wherein the glass-transition temperature of the soft monomer is less than or equal to 20 DEG C, and the glass-transition temperature of the hard monomer is more than or equal to 100DEG C. Correspondingly, the invention further discloses a preparation method of the water-based two-component wood lacquer. The wood lacquer disclosed by the invention has the characteristics of low cost and good film-forming property, and a formed coating film has the advantages of high hardness, good pollution resistance, good water resistance and good boiling water resistance.

Owner:FOSHAN HAITE CHEM TECH

Dual curing coating

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

A processing method for enhancing the aging resistance of bamboo strips

InactiveCN107116637BImproved stability of surface structure changesImprove boiling water resistanceWood treatment detailsPlant material mechanical workingFiberPaulownia

The invention belongs to the technical field of materials made of bamboo and particularly relates to a processing method for enhancing the ageing resistance of a bamboo batten. According to the specific content of boiling and pretreatment, Chinese pepper straws, paulownia wood and the bamboo battens are placed in a sodium hydroxide solution to be boiled for 6-8 hours; as to the primary drying condition, the low-power microwave condition is adopted, and then hot air drying is conducted; as to impregnation, the carbonized bamboo battens are placed in a dipping tank to be dipped; and as the secondary drying condition, the water content is lowered to be lower than 7% through hot air drying. Compared with the prior art, the processing method for enhancing the ageing resistance of the bamboo battens has the advantages that boiling, pretreatment, primary drying, impregnation and secondary drying of the bamboo battens are improved, the pore structure, the pore diameter distribution and the like of surface fiber of the bamboo battens are changed because the Chinese pepper straws are added during boiling, through cooperation of primary drying and impregnation process, the surface structure of the bamboo battens is improved, and the boiling water resistance and the ageing resistance of the bamboo battens are improved; and the retention capacity of bending strength and rigidity of the bamboo battens is good in a humid and stuffy environment.

Owner:阜南县宏达工艺品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com