Boiling-water-boiling-resistant water-based glass coating and preparation method thereof

A glass coating, water-based technology, applied in the direction of coating, can solve the problems of not bright enough color, low gloss coating, difficult to spray application, etc., to achieve excellent resin water dilution, reduce VOC content, excellent storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

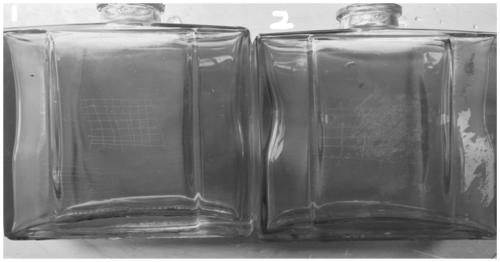

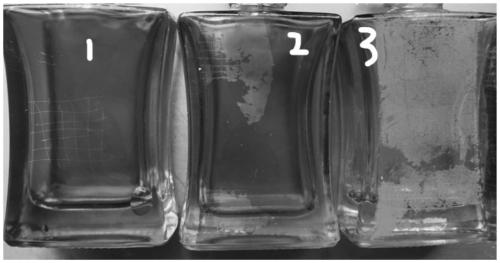

Image

Examples

Embodiment

[0027] Table 1 embodiment and comparative example formula, total 100 parts

[0028]

[0029]

[0030] Add the water-soluble epoxy-modified acrylic resin in Table 1 into the container and disperse for 2 minutes at a stirring rate of 800rpm; then add the amine neutralizer at a stirring rate of 800rpm and disperse for 4 minutes; then stir at 600rpm Add co-solvent at a stirring rate of 1000rpm and disperse for 4 minutes; then add a water-based defoamer at a stirring rate of 1000rpm and disperse for 20 minutes; then add a water-based wetting agent at a stirring rate of 1000rpm and disperse for 4 minutes; Ionized water, dispersed for 2 minutes; then added water-based amino resin at a stirring speed of 800rpm, dispersed for 8 minutes, respectively obtained the boiling-resistant water-based glass coating A component of embodiment 1 to embodiment 3 and the water-based glass coating of comparative example 1 and comparative example 2 Glass coating A component.

[0031] Combining t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com