A kind of method that muf-mdi glue prepares fiberboard for outdoor use

A fiberboard and fiber technology, which is applied in the field of outdoor fiberboard prepared by MUF-MDI glue, can solve the problems of inability to meet high moisture resistance and high water resistance, limit large-scale production and application, different structure and reaction mechanism, etc., and achieve superior bonding strength, The effect of constant production capacity and widening application fields

Active Publication Date: 2022-05-31

DARE WOOD BASED PANEL GRP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, ordinary melamine-modified urea-formaldehyde resin (MUF) cannot meet the requirements for high moisture-proof and high water-resistant performance of outdoor medium-density fiberboard; using isocyanate (MDI) instead of MUF, although the performance of fiberboard can meet the requirements for outdoor use, but the production process High requirements, expensive production costs, and reduced production capacity limit large-scale production applications

Some manufacturers in the industry also proposed to use MUF and MDI glues to produce fiberboard at the same time, but the structures and reaction mechanisms of these two glues are completely different, so how to develop a new type of MUF that matches MDI and determine the addition of the two glues Proportion and hot pressing process are currently facing difficulties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The MUF-MDI glue of the present invention is described in further detail for preparing the method for outdoor medium density fiberboard.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Login to View More

Abstract

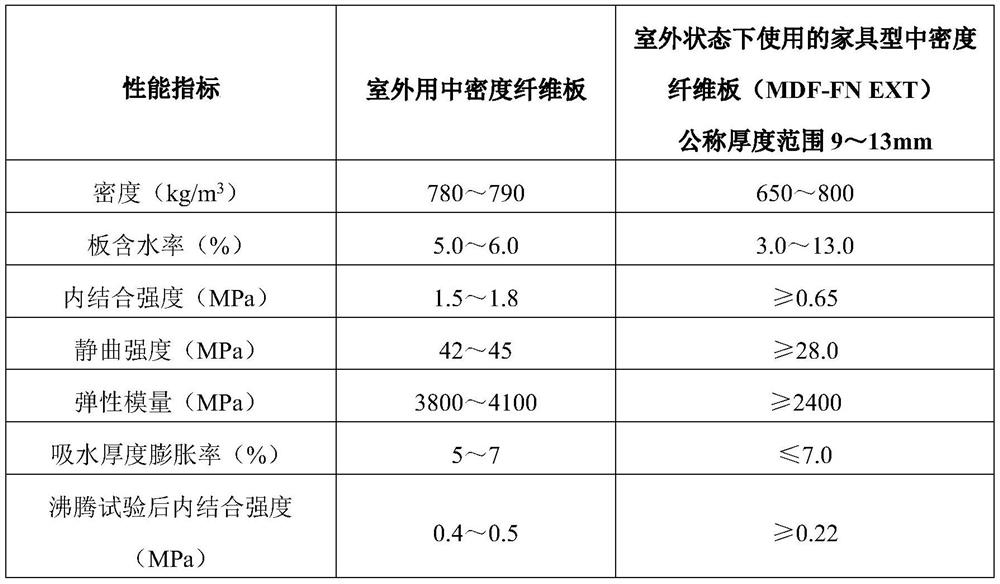

The invention belongs to the technical field of fiberboard production, and relates to a method for preparing outdoor fiberboards with MUF-MDI glue. The production steps include: glue preparation, fiber preparation, glue mixing and drying, pavement pre-pressing, slab hot-pressing and post-treatment. The "medium-medium-alkali" synthesis process is used to prepare MUF that matches MDI, including one feeding of formaldehyde, two feedings of urea, and one feeding of melamine. The whole preparation process is divided into neutral addition reaction and neutral polycondensation reaction and alkaline post-treatment in three stages; then use MDI and the prepared MUF to determine the addition ratio of the two glues and the hot-pressing process to produce outdoor fiberboard. The method disclosed in the present invention significantly reduces the production cost compared with only using MDI glue, the production capacity is basically unchanged, the production is stable, and it is suitable for large-scale continuous production; the board has superior bonding strength, moisture resistance and water resistance, and can be applied to sunlight In the outdoor environment of , rain and air pollution, it broadens the application field of fiberboard.

Description

A method for preparing outdoor fiberboard with MUF-MDI glue technical field The invention belongs to fiberboard production technical field, relate to the production method of medium density fiberboard, relate in particular to a kind of Method for preparing fiberboard for outdoor use with MUF‑MDI glue. Background technique Fiberboard takes wood fiber or other plant fiber as raw material, prepares through fiber, applies synthetic resin, and heats Sheets pressed under pressure. Fiberboard for outdoor use, generally used for decoration panels, outdoor hanging panels, building door and window panels, etc. combine. Due to the long-term exposure to sunlight, rain and air pollution in the outdoor environment, the fiberboard is resistant to moisture, water and aging, etc. performance demands higher. Traditional fiberboard industry uses urea-formaldehyde resin as adhesive, but urea-formaldehyde resin is subject to its own molecular structure characteristics Limited and r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B27N1/00B27N1/02B27N3/10B27N3/20C08K5/29C08L61/30C08G12/38

CPCB27N1/00B27N1/0209B27N1/029B27N3/10B27N3/203C08G12/38C08K5/29C08L61/30

Inventor 孙旺赵金良朱光华

Owner DARE WOOD BASED PANEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com