Water-based two-component wood lacquer and preparation method thereof

A water-based two-component, wood lacquer technology, applied in the field of wood lacquer, can solve the problems of poor water resistance, poor low-temperature film-forming performance, low hardness, etc., and achieve the effect of improving mechanical properties, good pollution resistance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Correspondingly, the present invention also discloses a preparation method of the above-mentioned water-based two-component wood lacquer, which comprises the following steps:

[0054] (1) Put 20-25 parts of water and 1.2-2.5 parts of emulsifier in an emulsification tank, stir rapidly for 10-15 minutes, then add soft monomer, hard monomer, fluorine-containing functional monomer, methacrylic acid, methyl Hydroxyethyl acrylate, cross-linking monomer and dodecyl mercaptan, high-speed emulsification for 20-30 minutes to obtain a pre-emulsion;

[0055] (2) Put the remaining water and emulsifier into the reaction tank, heat up to 80-90°C while stirring, initially add 5-6% of the pre-emulsion, stir for 1-5min, then add 0.04-0.05 parts of initiator, stir React for 25 to 35 minutes. When the emulsion in the reaction tank is blue and transparent, add the remaining pre-emulsion and the remaining initiator dropwise at the same time. The dropping time is controlled within 4-5 hours,...

Embodiment 1

[0062] The present embodiment provides a kind of water-based two-component wood lacquer, and it comprises matrix emulsion and curing agent, matrix emulsion: curing agent=100:14, and curing agent selects toluene diisocyanate for use;

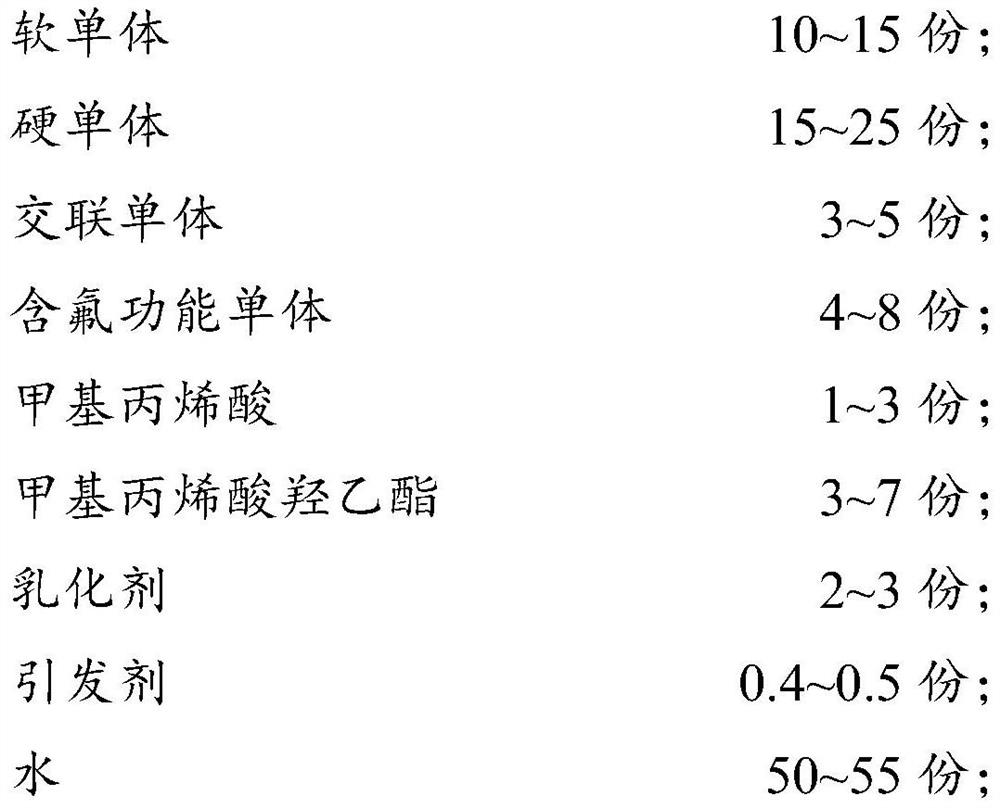

[0063] The formulation of the base emulsion is as follows:

[0064]

[0065] Among them, the soft monomer is isooctyl acrylate, the hard monomer is methyl methacrylate, the crosslinking monomer is glycidyl methacrylate, the fluorine-containing functional monomer is hexafluoroisopropyl methacrylate, and the emulsifier is Nonylphenol polyoxyethylene ether is selected, and potassium persulfate is selected as the initiator.

[0066] Its preparation method is as follows:

[0067] (1) Put 25 parts of water and 1.3 parts of emulsifier in an emulsification tank, stir rapidly for 15 minutes, then add soft monomer, hard monomer, fluorine-containing functional monomer, methacrylic acid, hydroxyethyl methacrylate and Cross-linking monomers, high-speed e...

Embodiment 2

[0071] The present embodiment provides a water-based two-component wood paint, which includes a base emulsion and a curing agent, the base emulsion: curing agent=100:15, and the curing agent is selected from hexamethylene diisocyanate;

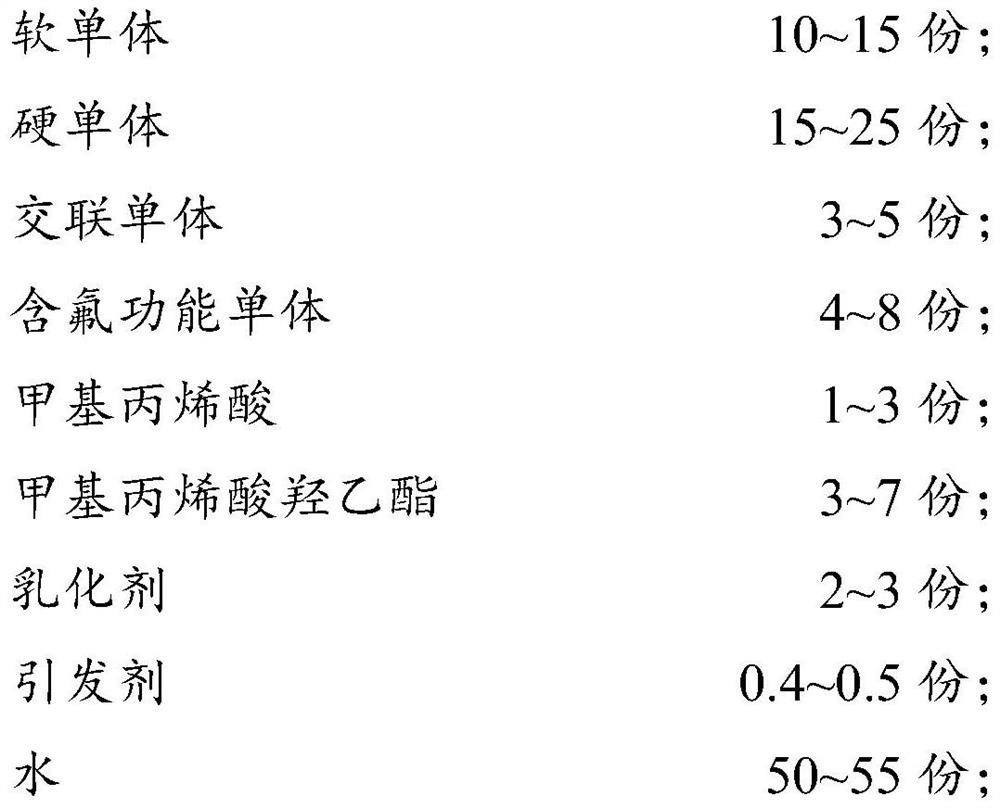

[0072] The formulation of the base emulsion is as follows:

[0073]

[0074] Among them, butyl acrylate is selected as the soft monomer, methyl methacrylate is selected as the hard monomer, octadecyl methacrylate is selected as the cross-linking monomer, tetrafluoropropanol methacrylate is selected as the fluorine-containing functional monomer, and tetrafluoropropanol methacrylate is selected as the emulsifier A mixture of ER-20 and sodium lauryl sulfate, and ER-20: sodium lauryl sulfate = 1:1, the initiator is ammonium persulfate.

[0075] Its preparation method is as follows:

[0076] (1) Put 23 parts of water and 2 parts of emulsifier in an emulsification tank, stir rapidly for 15 minutes, then add soft monomer, hard monomer, fluorine-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com