Dual curing coating

A dual-curing and coating technology, applied in the coating and other directions, can solve the problems of insufficient radiation intensity, contradiction between coating hardness and toughness, and inability to guarantee toughness, to overcome the difficulty of taking into account the hardness and flexibility, and the shrinkage stress of the system. The effect of reducing and improving chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

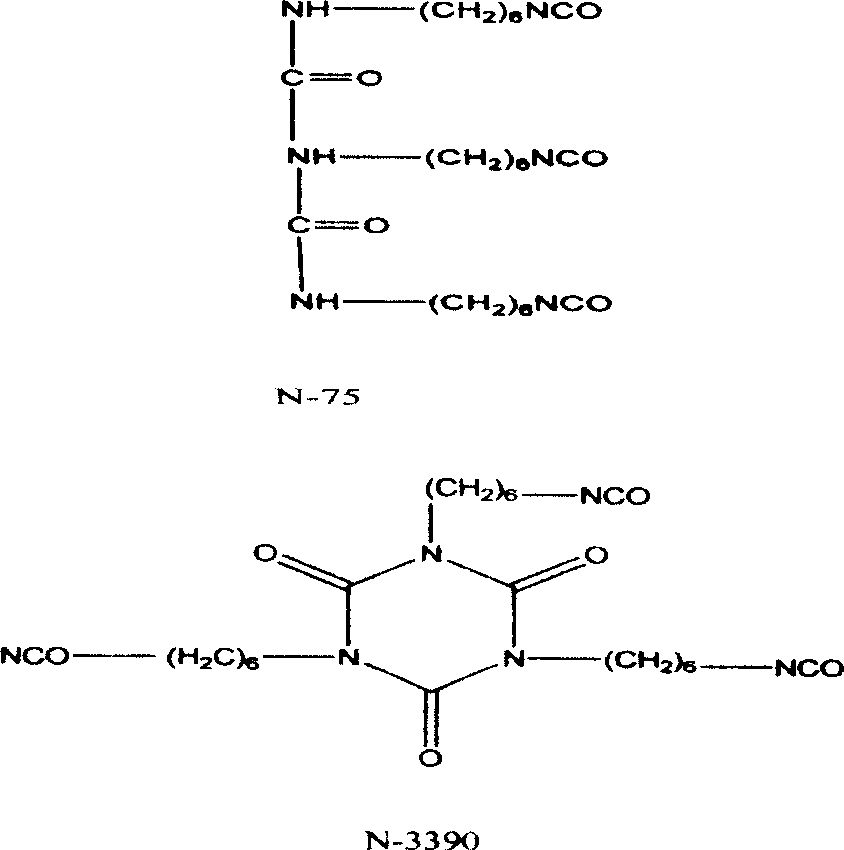

Method used

Image

Examples

Embodiment 1

[0027] In a four-necked bottle with a stirrer, condenser, thermometer and dropping funnel, add 100g of epoxy F-51, under stirring at 100°C, drop 37g of acrylic acid, 0.5 A mixture of g N,N-dimethylethanolamine and 0.2 g p-methoxyphenol. Stir the mixture at ≤100°C and keep it warm for reaction. When the acid value drops to 55 mgKOH / g, cool down to 70°C and discharge to obtain a reactive oligomer epoxy acrylate resin.

Embodiment 2

[0029] In a four-neck flask equipped with a stirrer, condenser, thermometer and dropping funnel, add 100g of polyether 210, and add 35g of 2,4-body TDI dropwise from the dropping funnel at a fixed speed within 30min under stirring at 40°C , kept at this temperature for three hours, and then a mixture of 28 g of hydroxypropyl acrylate, 0.014 g of dibutyltin dilaurate and 0.16 g of p-methoxyphenol was added. The mixture was stirred and kept at about 90°C for 6 hours, and when the NCO content was reduced to 0.5%, the temperature was lowered to 60°C, 5g of isopropanol was added and stirred evenly to obtain a reactive oligomer urethane acrylate resin.

Embodiment 3

[0031] In a four-necked flask with a stirrer, a condenser, a thermometer and a dropping funnel, add 150g of xylene, and add 35g of butyl acrylate and 41g of formazan at a fixed speed within 2 hours under stirring at 100°C. A mixture of methyl acrylate, 49g styrene, 15g acrylic acid, and 1.2g benzoyl peroxide, the mixture was stirred and kept at ≤110°C for 5 hours, cooled to 90°C, and 29g glycidyl methacrylate, 0.4g para Methoxyphenol, 0.7g of N,N-dimethylethanolamine, reacted for 6 hours under stirring at about 90°C to obtain an active oligomer acrylate resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com