Patents

Literature

252results about How to "Print smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

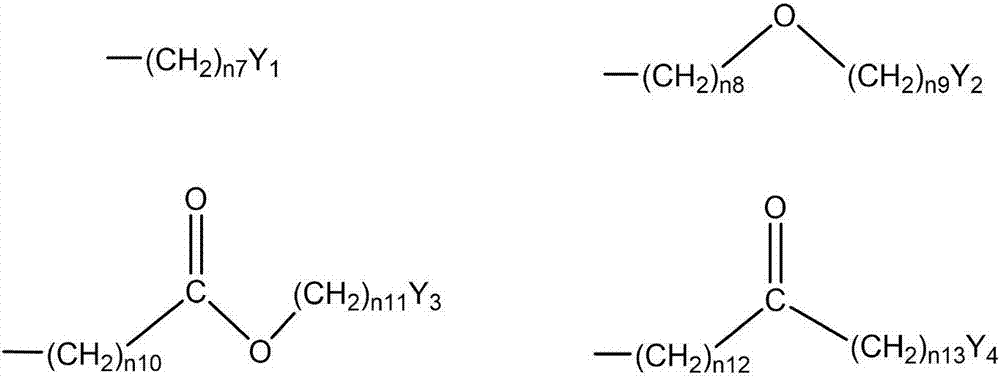

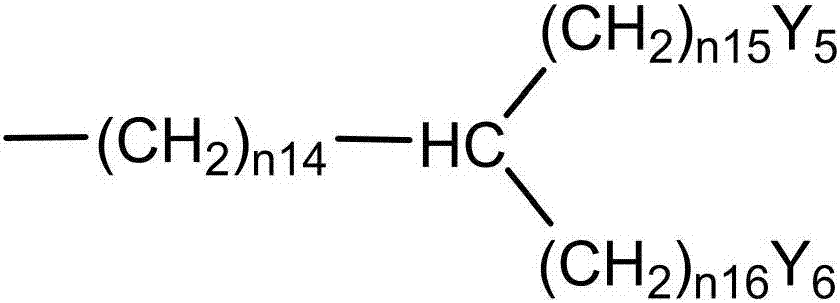

Water-base ink composition

InactiveUS20050235870A1Avoid problemsHighly stably ejectedMeasurement apparatus componentsDecorative surface effectsWater basedOrganic solvent

There is provided a water-base ink composition which has excellent ejection stability and can be evenly printed on recording media. The water-base ink composition comprises at least: a colorant component selected from dyes and pigments; a monovalent or divalent branched alcohol with C5 to C10 chain length; an acetylene glyco surfactant and / or a penetrating organic solvent; a humectant; and water. The monovalent or divalent branched alcohol with C5 to C10 chain length, the acetylene glycol surfactant and / or the penetrating organic solvent, and the humectant are selected from combinations of branched alcohols, acetylene glycol surfactants and / or penetrating organic solvents, and humectants which are miscible with one another.

Owner:SEIKO EPSON CORP

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

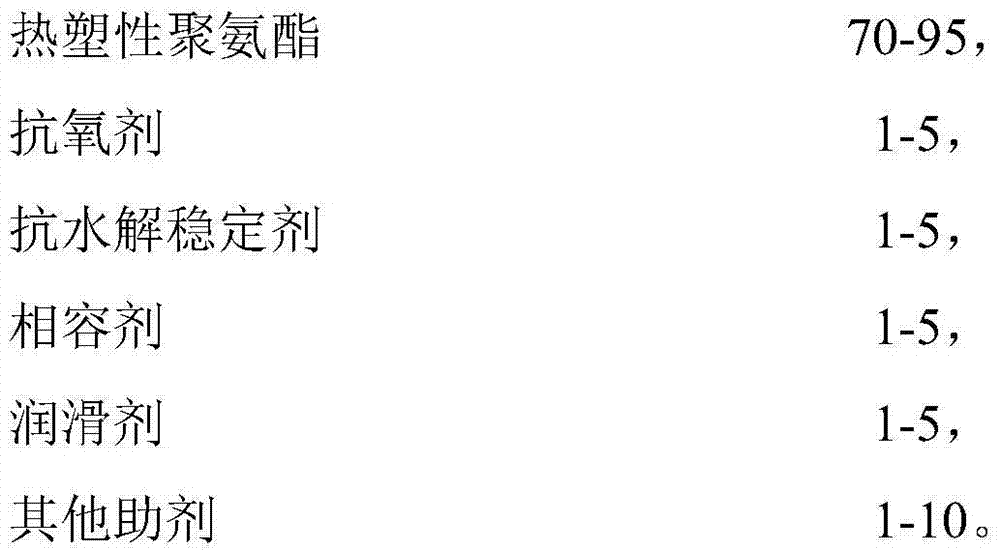

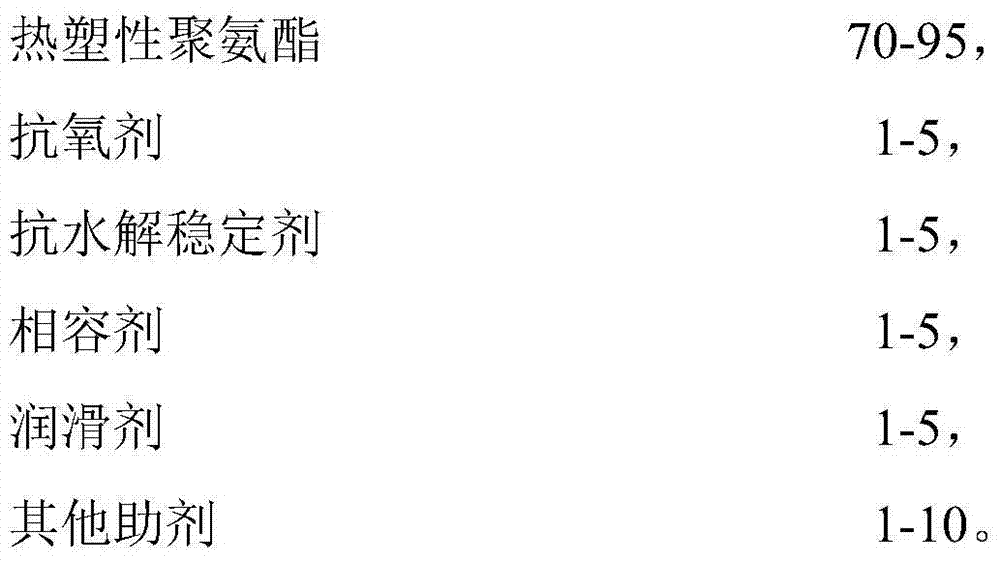

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Pure cocoa butter type chocolate for 3D printing and preparation method of palmin type chocolate

The invention discloses pure cocoa butter type chocolate for 3D printing. The chocolate is prepared from the following raw materials comprising the following components in percentage by weight: 50-60% of cocoa butter liquid blocks, 5-15% of dried skim milk powder, 15-35% of white granulated sugar, 10-15% of cocoa butter and 0.3-1.0% of an emulsifier. The chocolate is prepared by carrying out pre-treatment, mixing and precision grinding, refining, filling and temperature regulation on the raw materials. The chocolate disclosed by the invention has stable flowability, and the product is hard to grow dim and become white. The chocolate is suitable for 3D printing of medium-small target quantities, unnecessary waste is reduced, the cost is lowered, and the chocolate is convenient to use and operate.

Owner:天舜(杭州)食品股份有限公司

3D-printing thermoplastic polyurethane material and preparation method of same

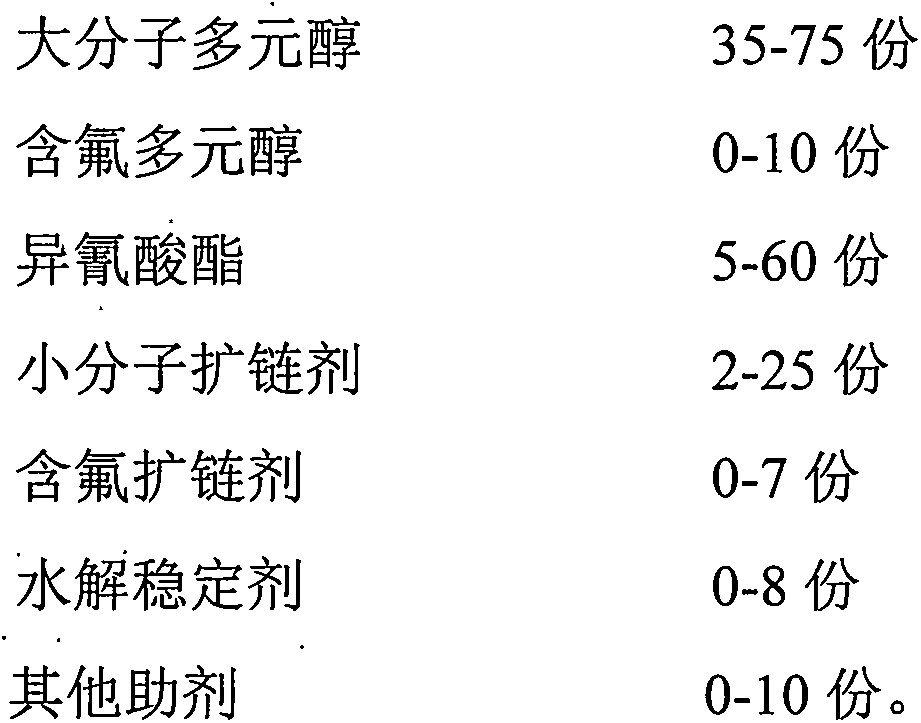

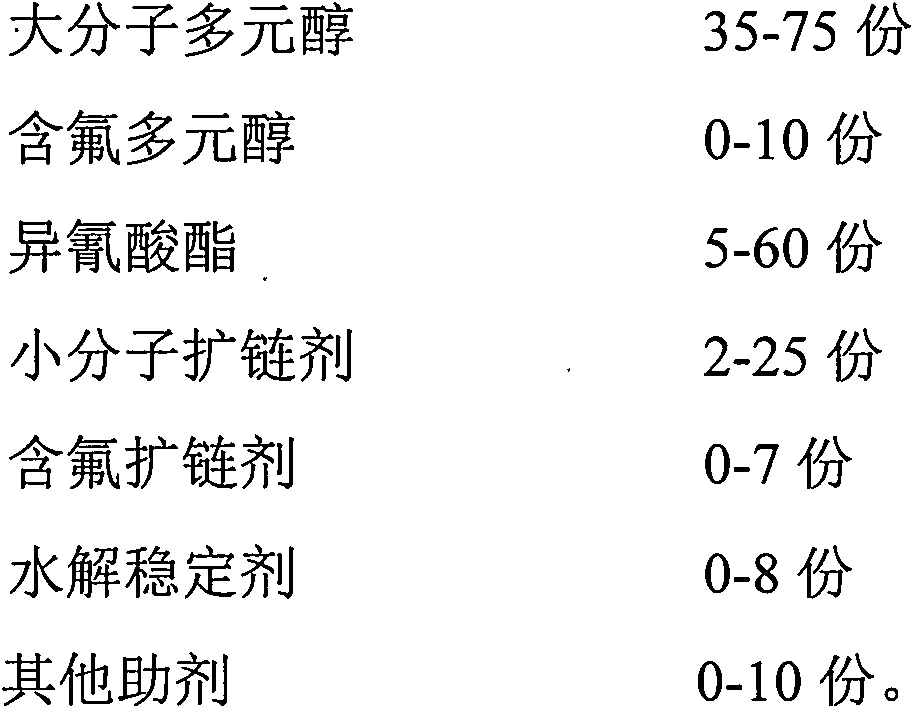

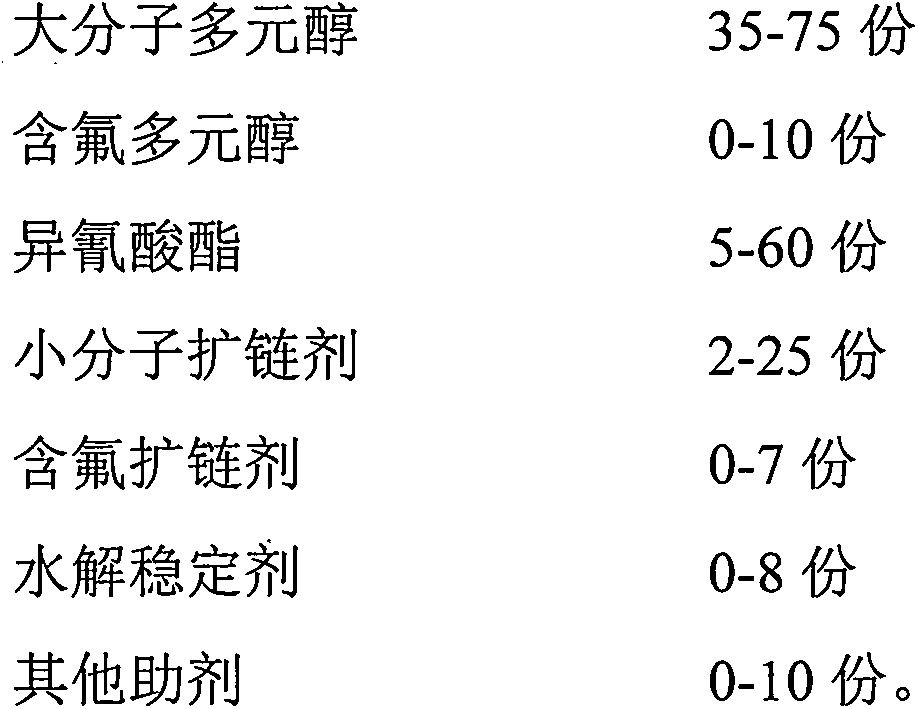

The invention discloses a 3D-printing thermoplastic polyurethane material and a preparation method of same. The 3D-printing thermoplastic polyurethane material includes, by weight, 35-75 parts of a macro-molecular polyol, 0-10 parts of a fluorine-containing polyol, 2-25 parts of a small-molecular chain extender, 0-7 parts of a fluorine-containing chain extender, 5-60 parts of isocyanate, 0-8 parts of a hydrolysis stabilizing agent, and 0-10 parts of other additives. Compared with a method in the prior art, an in-situ polymerization one-step method is employed in the preparation method. By means of one or more of the fluorine-containing polyol and the fluorine-containing chain extender, fluorine is introduced into the thermoplastic polyurethane material to prepare the 3D-printing thermoplastic polyurethane material which has the advantages of both the fluorine-containing compound and the TPU. The material is excellent in thermal-stability, is low in shrinking rate, is high in mechanical performance and is low in water absorption. A 3D-printing product prepared from the material is excellent in performance.

Owner:SHANGHAI HENGAN POLYURETHANE CO LTD

Conductive paste for solar cell and preparation method thereof

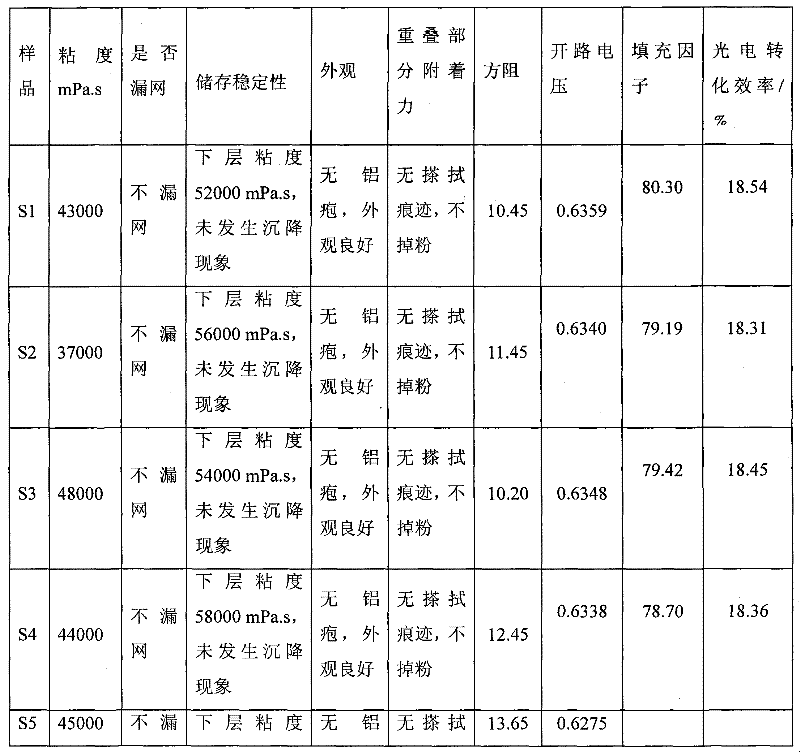

ActiveCN102479568AImprove rheologyEasy constructionNon-conductive material with dispersed conductive materialCable/conductor manufactureOpen-circuit voltageSedimentation

The invention provides a conductive paste and a preparation method thereof. The conductive paste comprises aluminum powder, an inorganic binding agent, an organic carrier and metal-glass composite powder, wherein the metal-glass composite powder is of nano-particles and a core-shell structure, glass is used as a core material, and metal is used as a shell material. The conductive paste disclosed by the invention is good in storage stability and less prone to sedimentation and agglomeration, and the conductive paste is less prone to leakage from a screen during screen printing; after sintering, an aluminum film is smooth in surface and grey white, and has no aluminum vesicles or aluminum beads; and furthermore, the part in contact and superimposition with a back silver electrode, of the aluminum film is wiped by a non-dust cloth, and wiping traces and powder dropping can be avoided. The series resistance of the produced solar cell is reduced obviously, a filling factor is increased obviously, and the average photoelectric conversion efficiency of a monocrystalline silicon cell piece can be above 18.20%. Simultaneously, the conductive paste disclosed by the invention is good in construction performance, a film layer formed after sintering is compact, the sintering thickness is uniform, the bending of a silicon chip is small, the sheet resistance is small and the open circuit voltage (Voc) of the formed cell is high.

Owner:BYD CO LTD

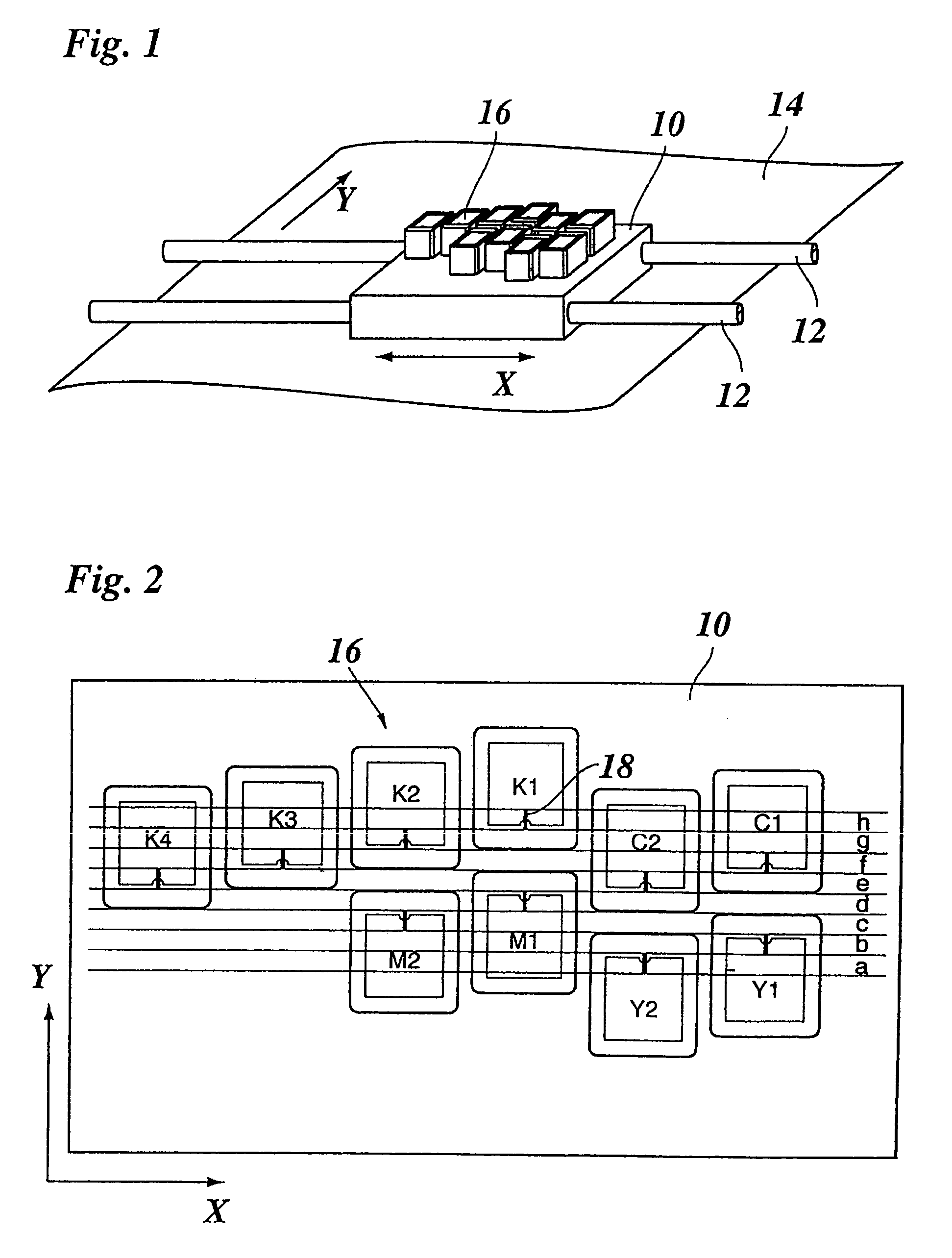

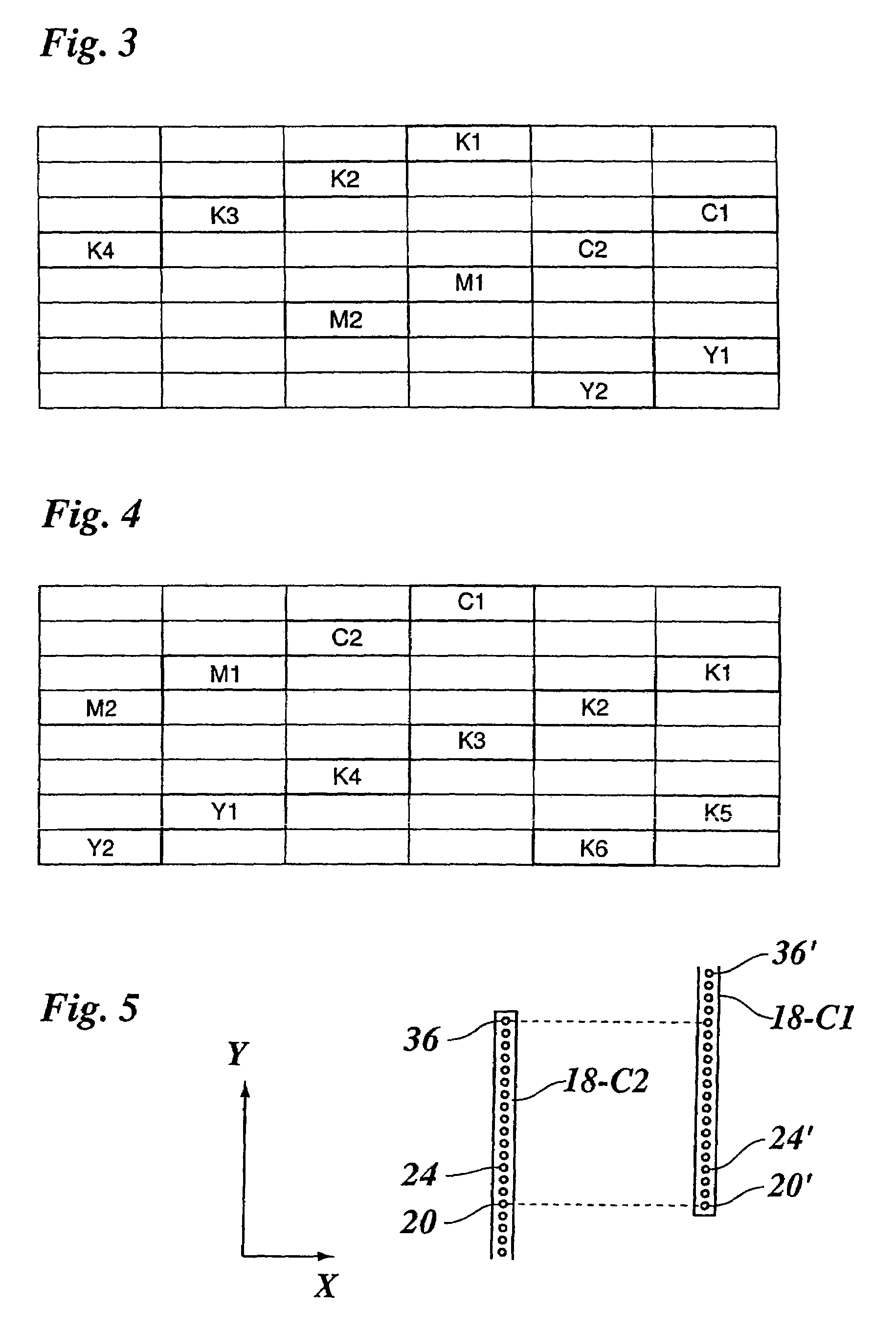

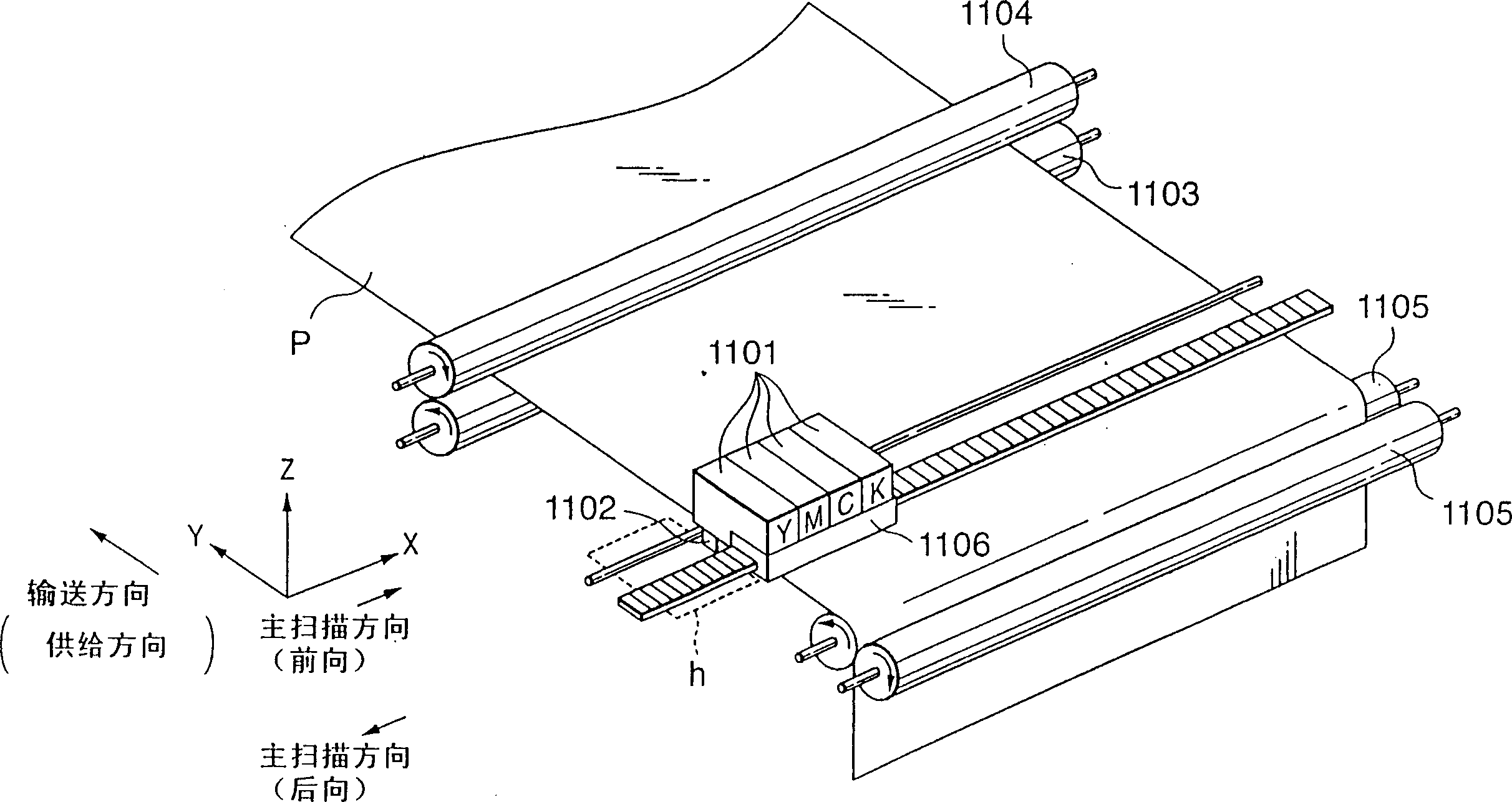

Multicolor ink jet printing method and printer

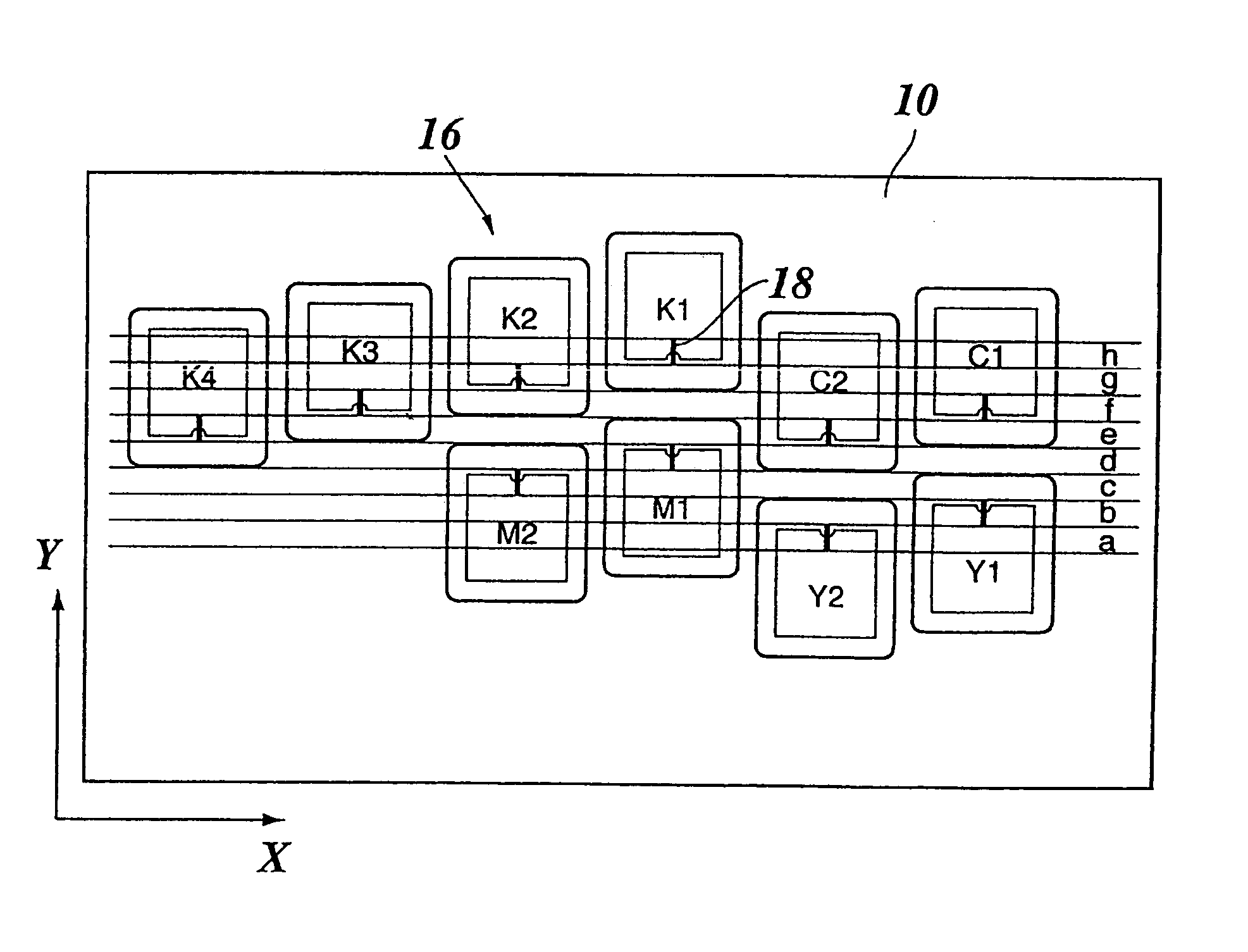

A multicolor ink jet printing method which includes the steps of moving a carriage is moved relative to a recording medium in a main scanning direction and a subscanning direction orthogonal to the main scanning direction, printing each color with a different group of nozzle heads mounted on the carriage, wherein at least one color is printed with a larger number of nozzle heads than the other colors, and printing the at least one color with a larger printing resolution in the main scanning direction than the other colors.

Owner:OCE TECH

Inkjet printing process of cotton fabric

ActiveCN103469642AEnhanced wash resistance and sorptionSmooth printingDry-cleaning apparatus for textilesDyeing processPre treatmentSizing

The invention discloses an inkjet printing process of a cotton fabric. A technological process which comprises the processes of sizing pre-treatment, drying, inkjet printing, steaming and colour fixing, after treatment, washing and drying is adopted, preshrinking process treatment is carried out firstly before the sizing pre-treatment, so that the phenomenon that printed flowers are irregular owning to shrinkage of the cotton fabric in the inkjet printing process is effectively avoided; besides, idiosyncratic inkjet printing pigment ink is adopted for carrying out inkjet printing, cold water and hot water are alternate for multiple times in a washing process, chemical tolerance of a pigment is stimulated, and washing resistance and adsorption rate of the cotton fabric are improved. The inkjet printing process of the cotton fabric has the advantages of smooth printing, appropriate colouring depth, difficulty in colour fading and simple technology.

Owner:溆浦县顺成服装有限公司

Chocolate for 3D printing and preparation method thereof

The invention discloses chocolate for 3D printing and a preparation method thereof. Based on the total weight of the chocolate, the chocolate comprises the following raw materials in percentage by weight: cocoa mass 18-30%, cocoa butter 6-12%, ultrafine microcrystalline cellulose 0.5-5%, maltitol 35-45%, xylitol 6-10%, skimmed milk powder 8-15%, emulsifier 0.5-1.0% and essence 0.05-0.2%. The chocolate has stable liquidity, is suitable for 3D printing and does not cause hole plugging.

Owner:珠海市红旌发展有限公司

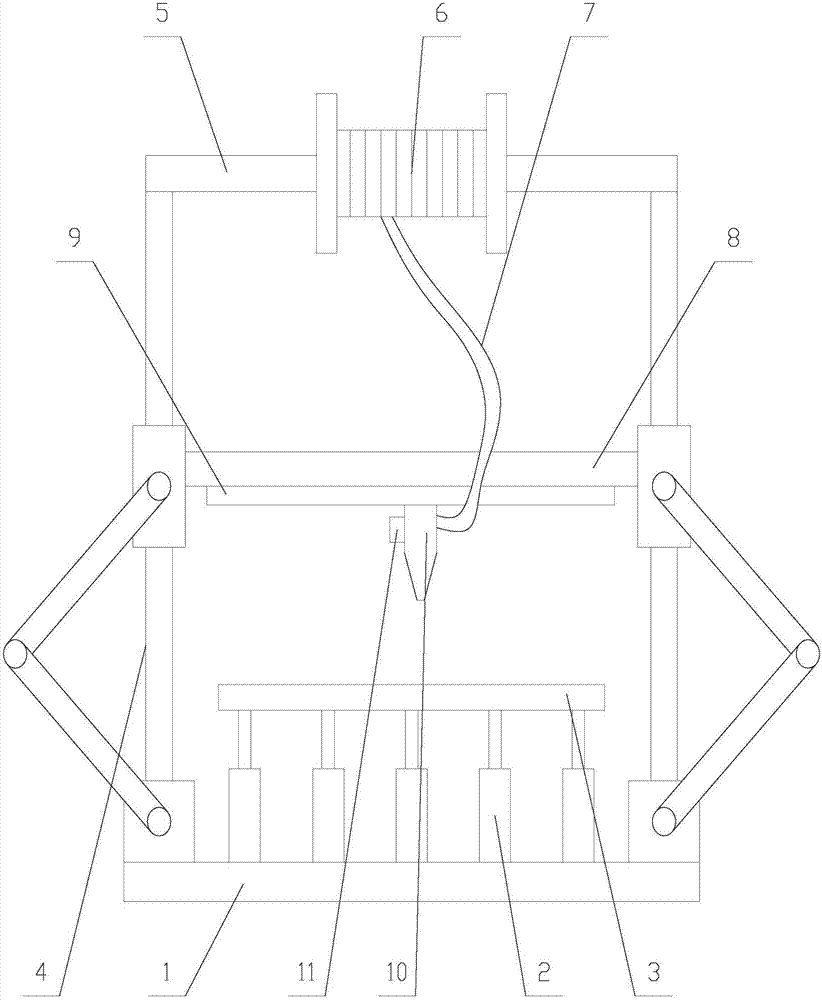

Three-dimensional printer with automatic clearing function

InactiveCN105128335AAchieve cleanupPrint smoothlyAdditive manufacturing apparatusExhaust valveEngineering

The invention provides a three-dimensional printer with an automatic clearing function. The three-dimensional printer comprises a base, a support frame, a print sprayer, a third driving mechanism, a fourth driving mechanism, a material storage box, a feeding pipe, a feeding device, an air blower and a controller, wherein the print sprayer is driven by the third driving mechanism and the fourth driving mechanism to respectively move in a transverse direction and a longitudinal direction; the first end of the feeding pipe is connected with the print sprayer, the second end of the feeding pipe is communicated with the material storage box, a vent valve is arranged on the material storage box, the feeding device comprises a material pushing plate and a cylinder, the material pushing plate is positioned in the material storage box, and the cylinder is connected with the material pushing plate; and a first air supply pipe is connected to the air blower, an air supply connecting part is arranged at the end part, far from the air blower, of the first air supply pipe, the air supply connecting part is fixed to the support frame through a connecting rod, and a heating device is connected to the position, close to the air blower, of the first air supply pipe. The three-dimensional printer can automatically clear material residues in the print sprayer and the feeding pipe, so that the print work is more smooth.

Owner:WUHU SIRUIDI THREE DIMENSIONAL TECH CO LTD

Method for manufacturing white-light LED fluorescent film based on 3D printing technology

InactiveCN104051599APrecise preparation made easyImprove uniformitySemiconductor devices3d patterningFluorescence

The invention discloses a method for manufacturing a white-light LED fluorescent film based on the 3D printing technology. The method for manufacturing the white-light LED fluorescent film based on the 3D printing technology comprises the following steps that (1) fluorescent powder slurry is prepared; (2) a 3D printer is introduced, and the fluorescent film is printed on an LED chip or on other transparent substrates under the control of a computer; (3) the printed film is cured simultaneously through hot wind scanning or ultraviolet light curing during printing; (4) integral curing is conducted according to an optimized heating technology or an optimized ultraviolet light curing method based on the property of colloid, and then the required fluorescent film is obtained. The method for manufacturing the white-light LED fluorescent film based on the 3D printing technology has the advantages that the printing precision is high, the automation degree is high, material waste is small, 3D patterns in various shapes and with various thicknesses can be printed on various substrates or various objects freely, the method is an advanced manufacturing technology, a complete 3D printer is available at present, automatic production can be achieved, and the method is quite suitable for manufacturing the white-light LED fluorescent film.

Owner:GUILIN UNIV OF ELECTRONIC TECH

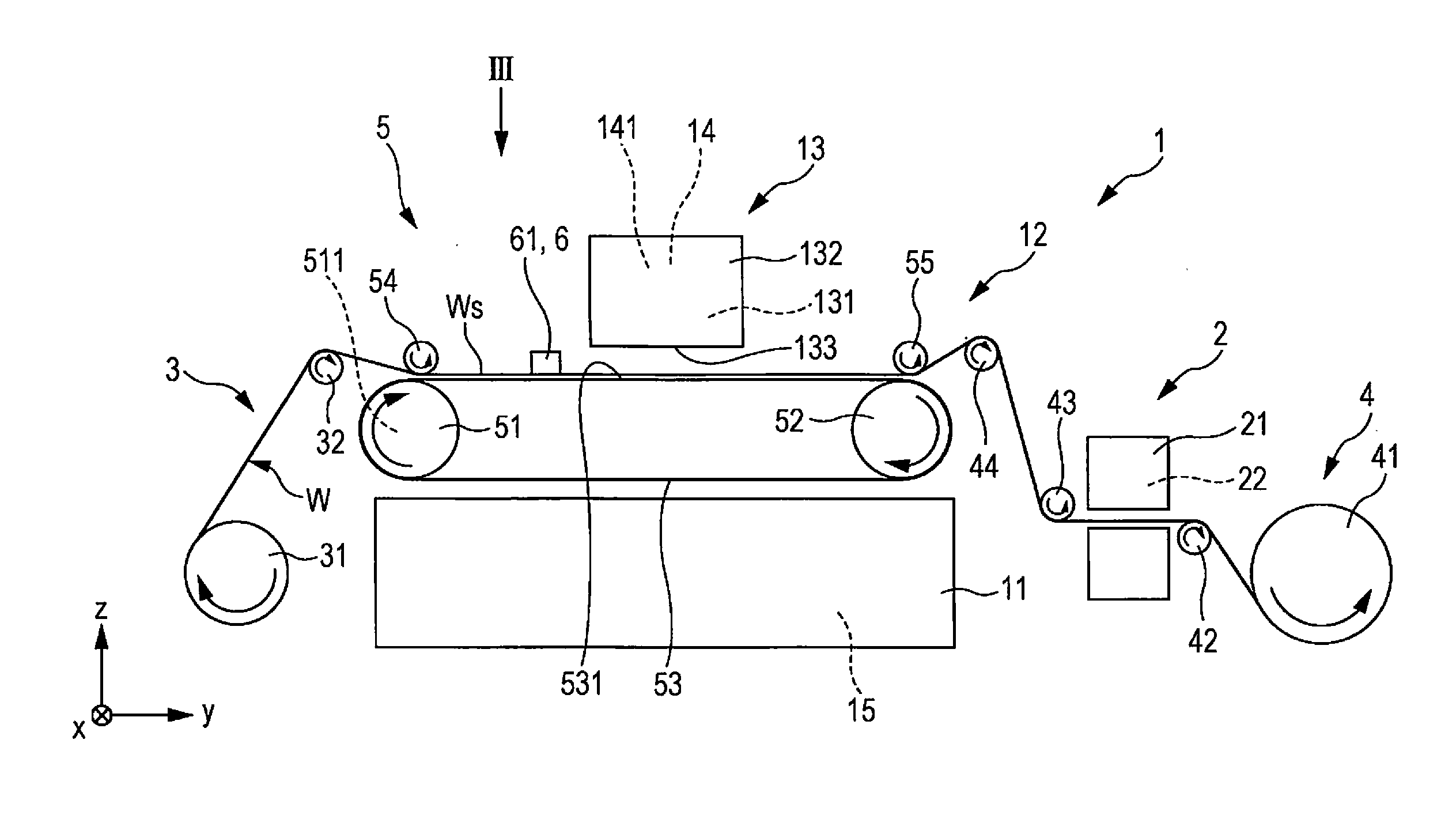

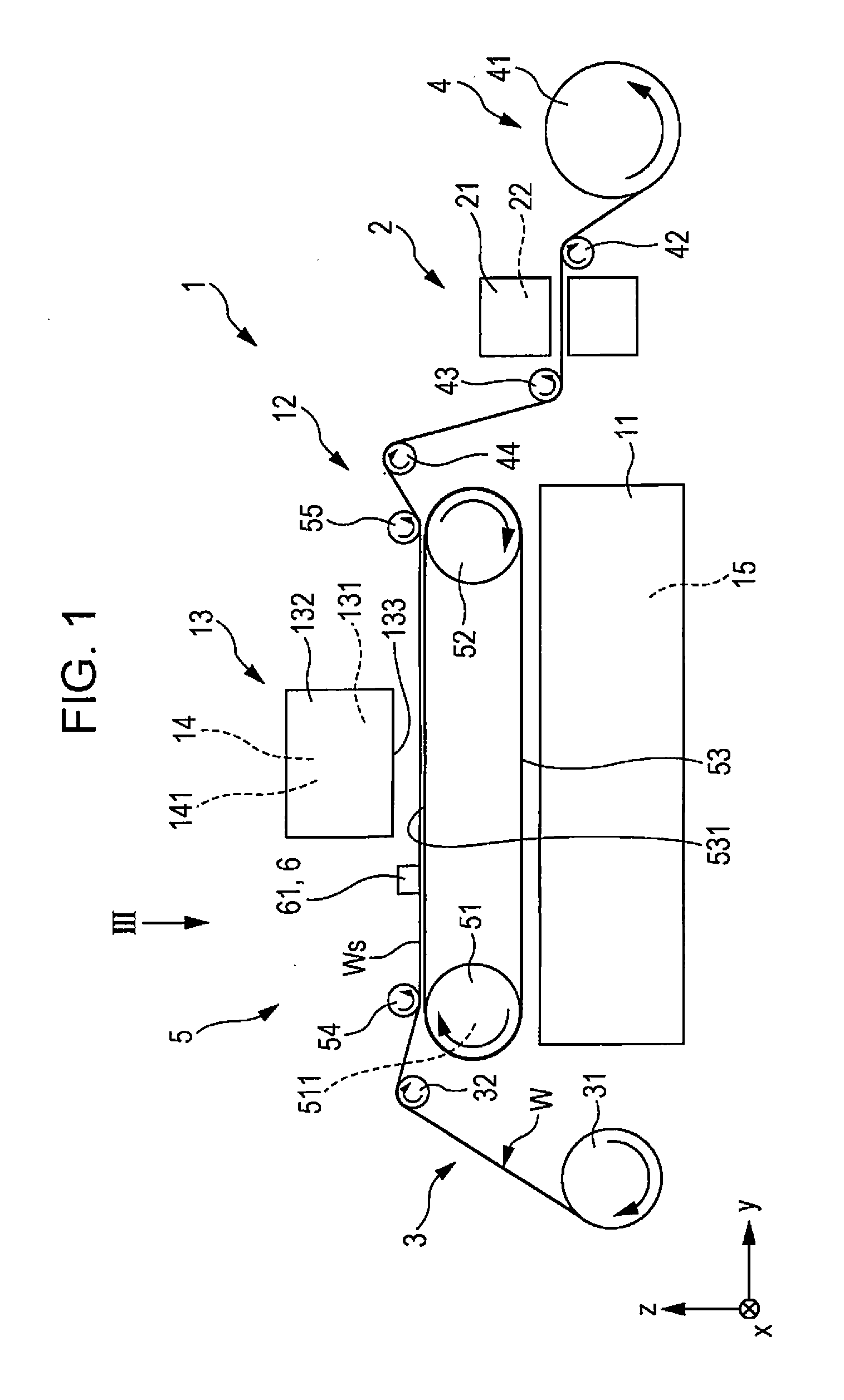

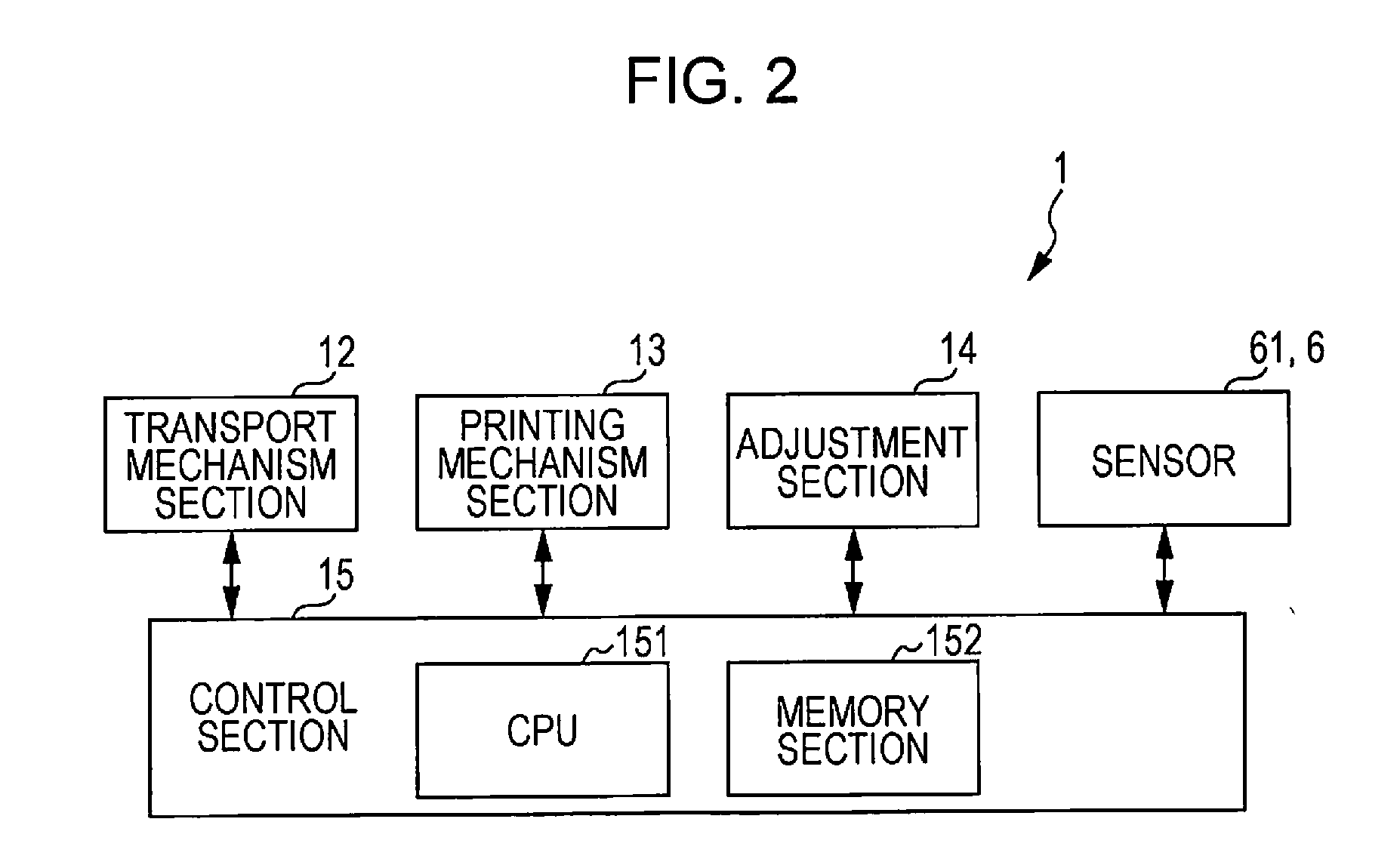

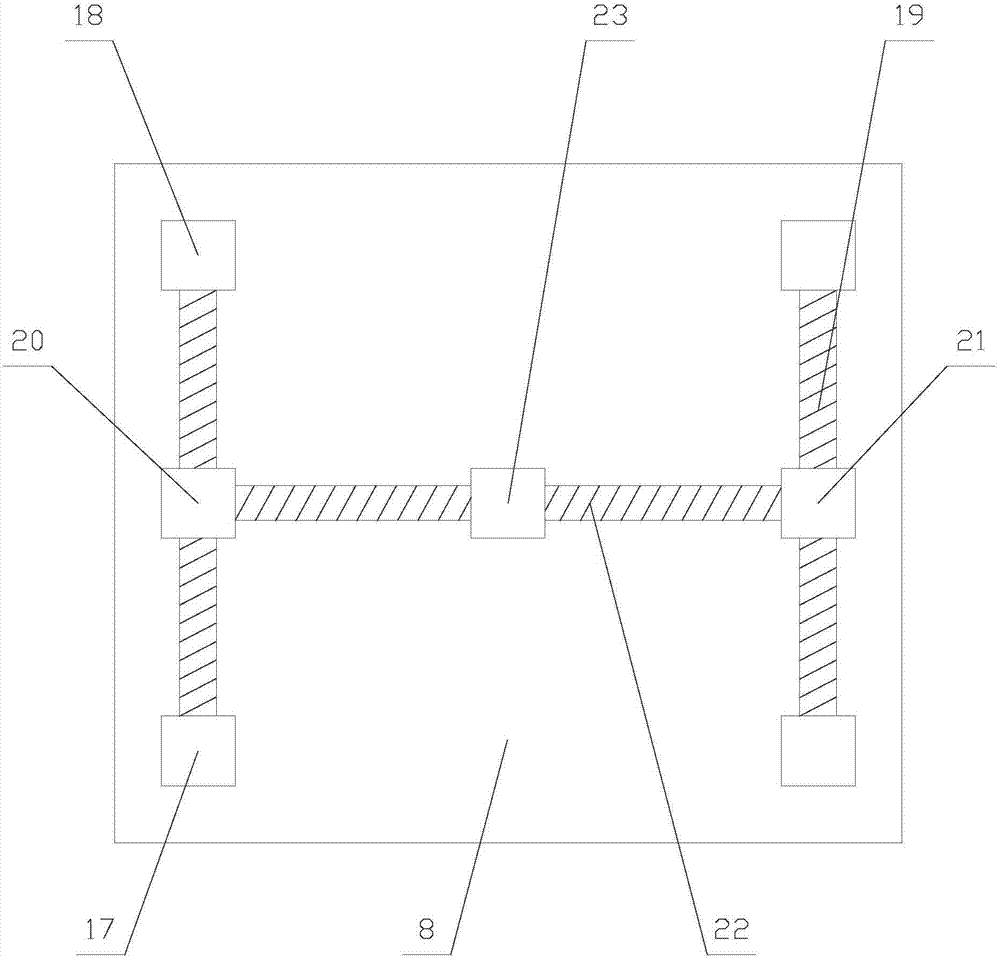

Printing apparatus

ActiveUS20160136949A1Reduce the burden onPrint smoothlyTypewritersPower drive mechanismsEngineeringSupport surface

A printing apparatus includes a transport mechanism section which has a support surface that supports and transports a workpiece, a printing mechanism section which has an ink jet head that executes printing on the workpiece that is transported by the transport mechanism section, a detecting section which is provided further on the upstream side in the transport direction than the ink jet head and detects an upper surface position of the workpiece, an adjustment section which adjusts a separation distance between the support surface and the ink jet head, and a control section. In addition, the control section selects a first mode for printing and a second mode for stopping printing by adjusting the separation distance by operating the adjustment section based on a detection result of the detecting section.

Owner:SEIKO EPSON CORP

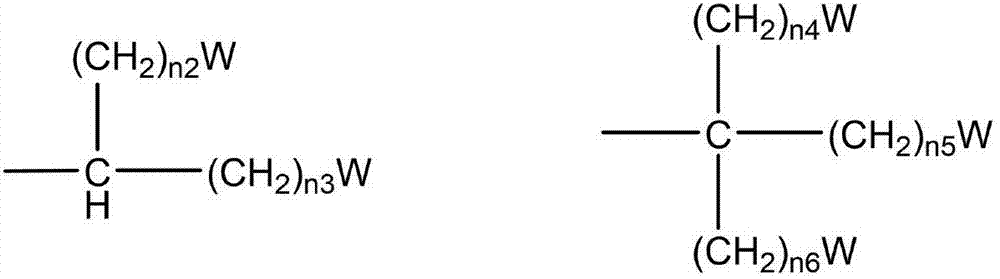

Water-base ink composition

InactiveUS7442244B2Highly stably ejectedPrint smoothlyMeasurement apparatus componentsDecorative surface effectsWater basedOrganic solvent

There is provided a water-base ink composition which has excellent ejection stability and can be evenly printed on recording media. The water-base ink composition comprises at least: a colorant component selected from dyes and pigments; a monovalent or divalent branched alcohol with C5 to C10 chain length; an acetylene glycol surfactant and / or a penetrating organic solvent; a humectant; and water. The monovalent or divalent branched alcohol with C5 to C10 chain length, the acetylene glycol surfactant and / or the penetrating organic solvent, and the humectant are selected from combinations of branched alcohols, acetylene glycol surfactants and / or penetrating organic solvents, and humectants which are miscible with one another.

Owner:SEIKO EPSON CORP

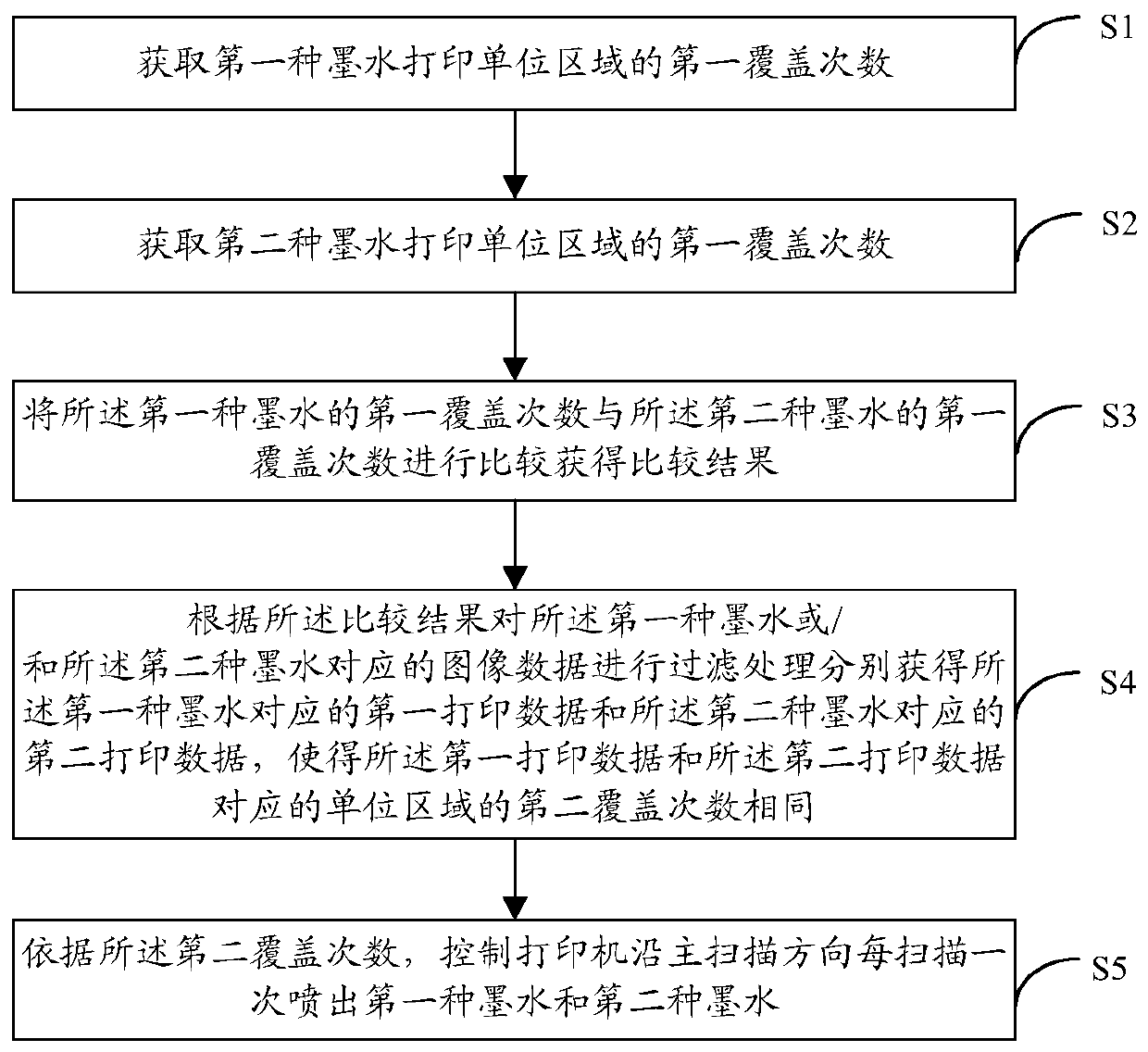

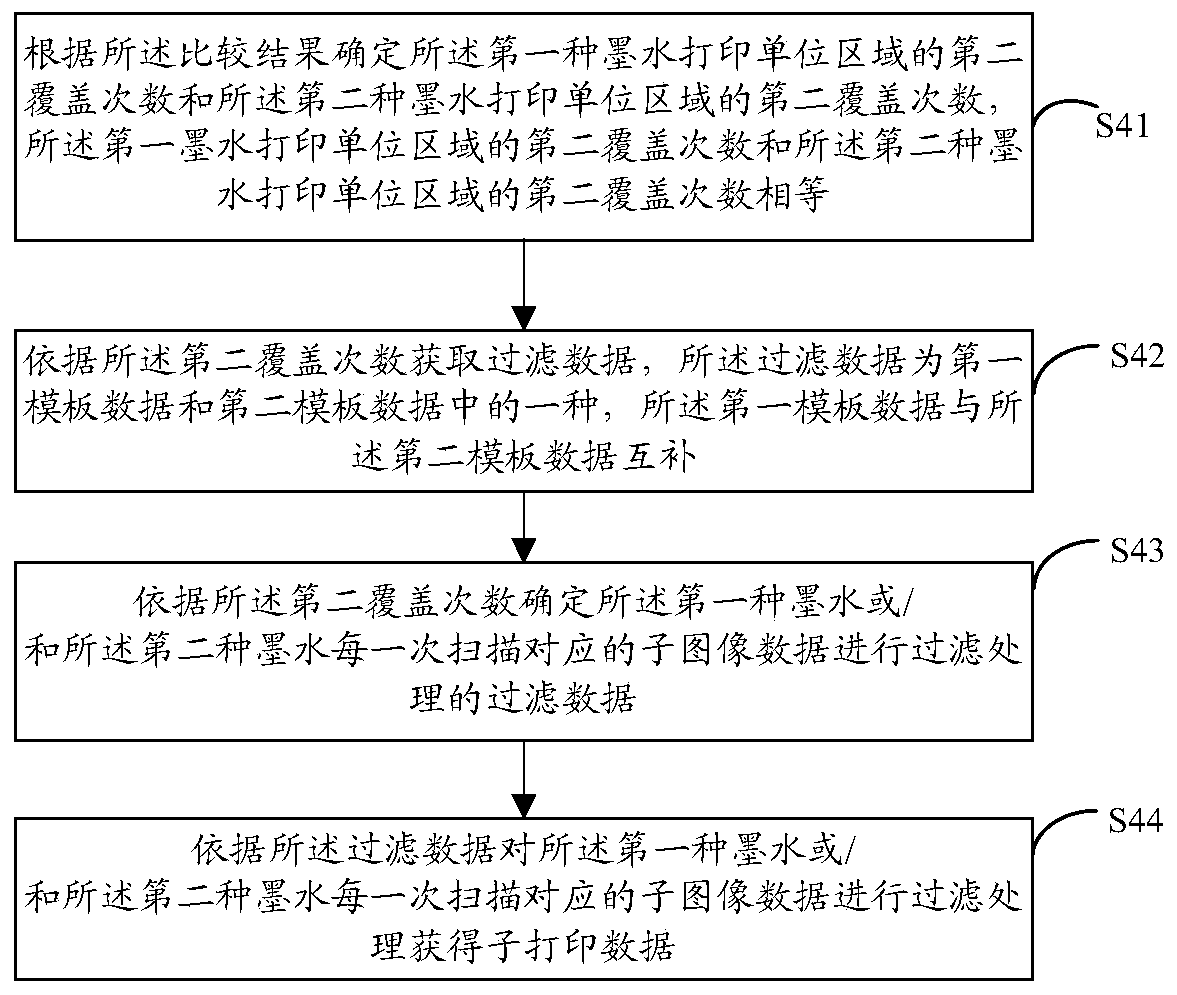

Printing control method, apparatus and device and printer

The invention discloses a printing control method, a printing control apparatus, a printing control device and a printer. The printing control method comprises the steps of obtaining a first coveringnumber of times in a printing unit area of first ink; obtaining a first covering number of times in a printing unit area of second ink; comparing the first covering number of times of the first ink with the first covering number of times of the second ink to obtain a comparison result; performing filtering processing on image data corresponding to the first ink or / and the second ink according to the comparison result to respectively obtain first printing data corresponding to the first ink and second printing data corresponding to the second ink, wherein a second number of times of the unit area corresponding to the first printing data is the same as a second number of times of the unit area corresponding to the second printing data; according to the first printing data and the second printing data, controlling the printer to jet the first ink and the second ink each time when the printer scans in the main scanning direction. The printing control method, the printing control apparatus,the printing control device and the printer have the advantage of being capable of efficiently and quickly printing images having three-dimensional effect.

Owner:SHENZHEN HOSONSOFT CO LTD

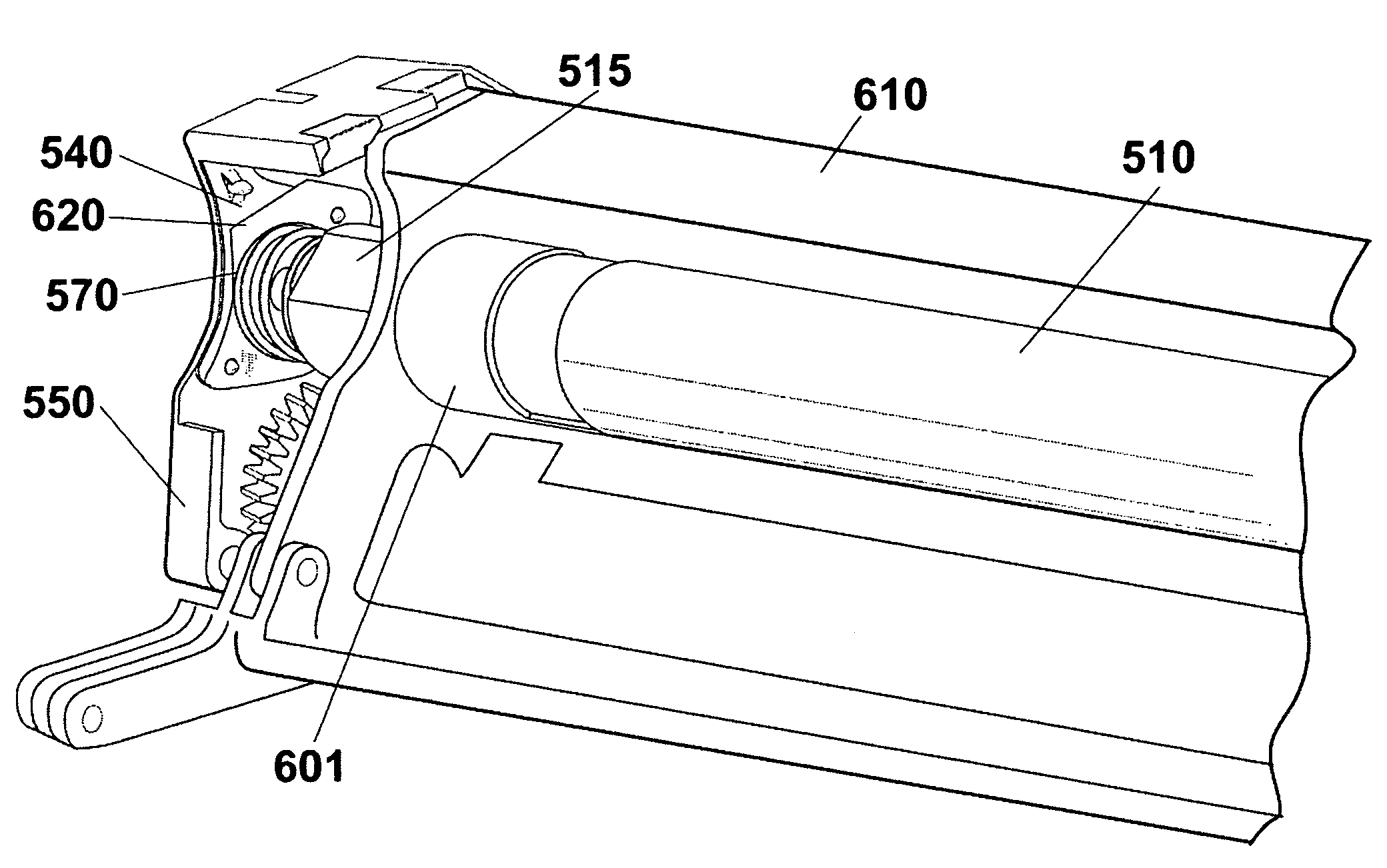

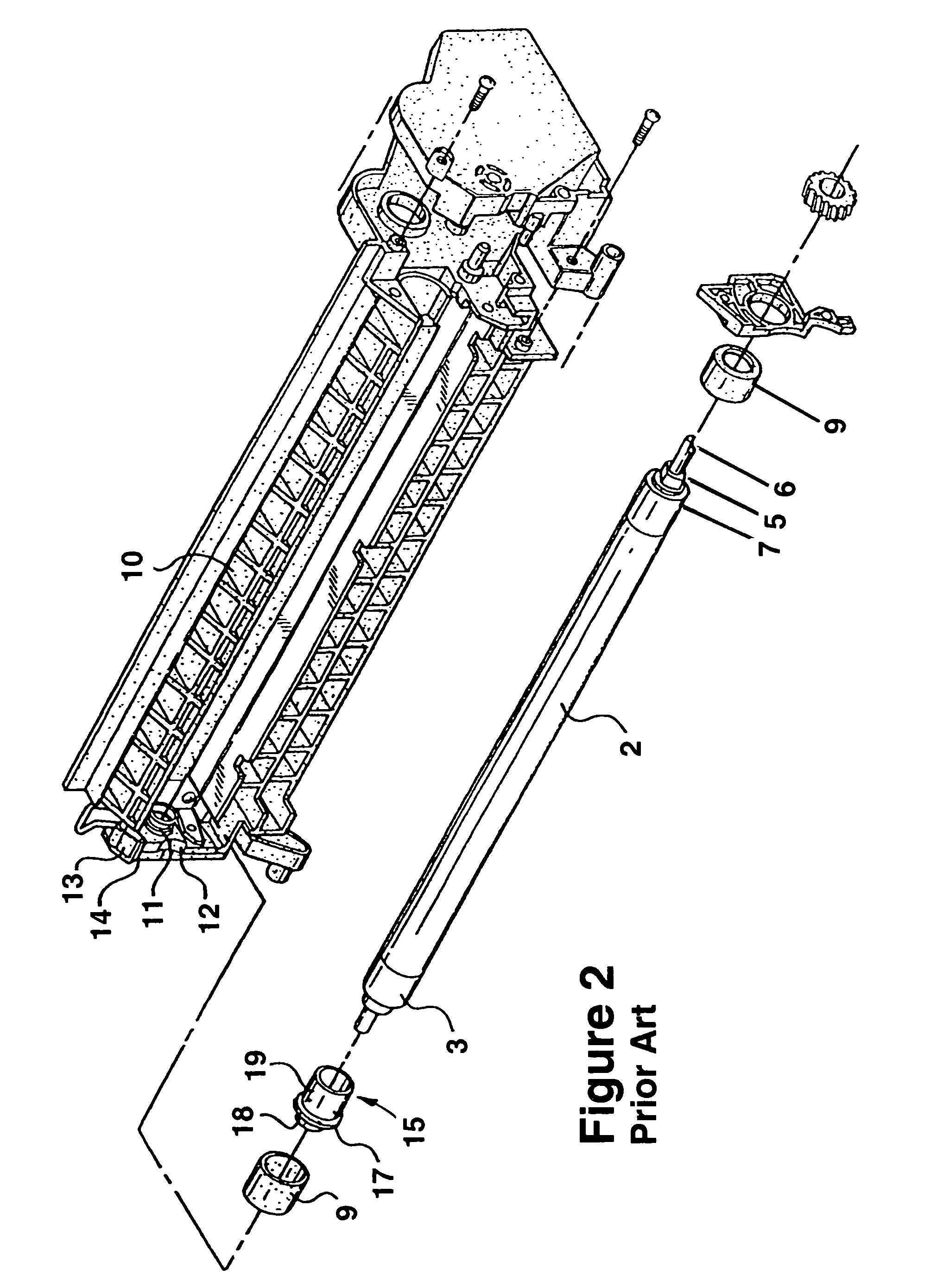

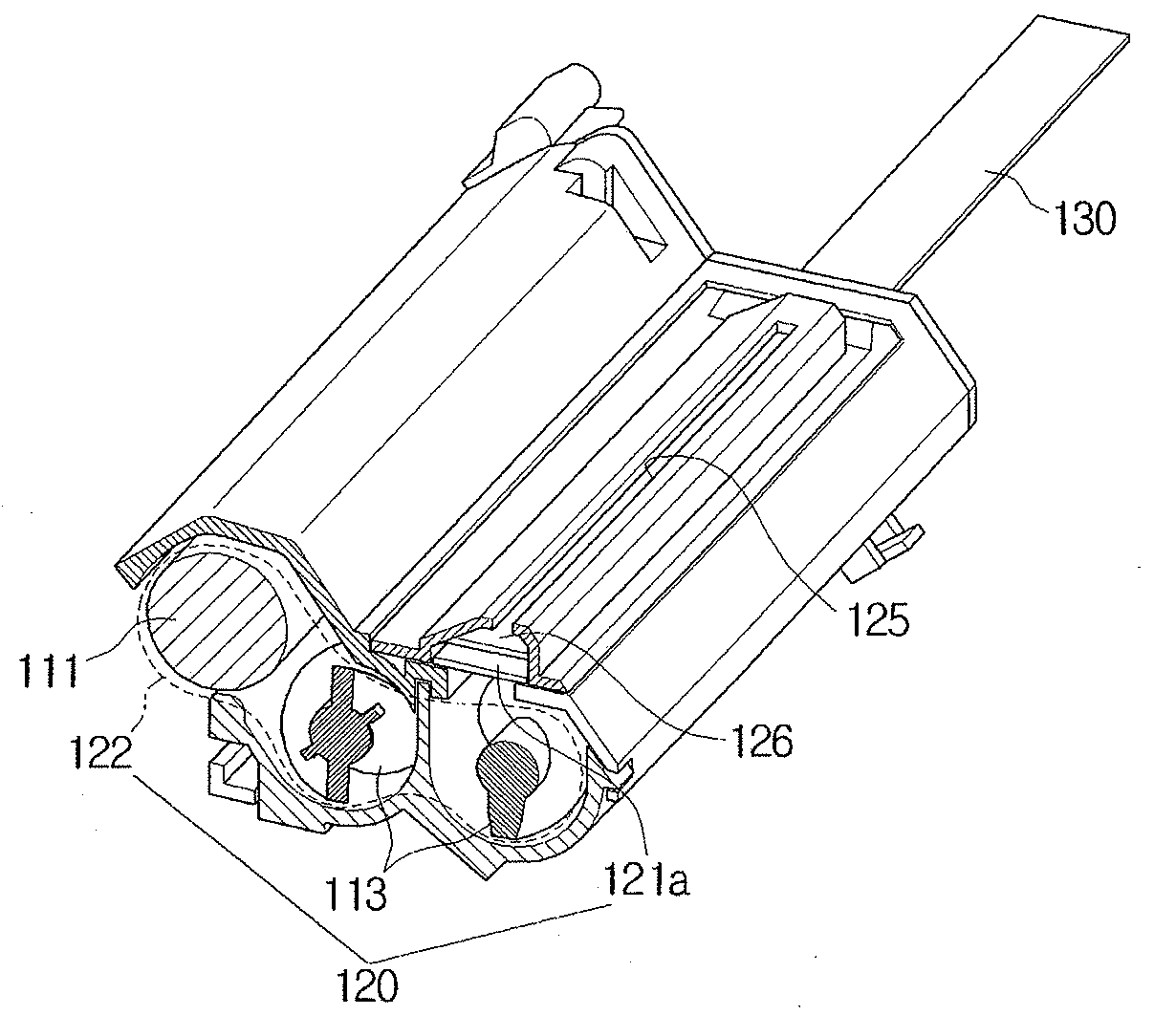

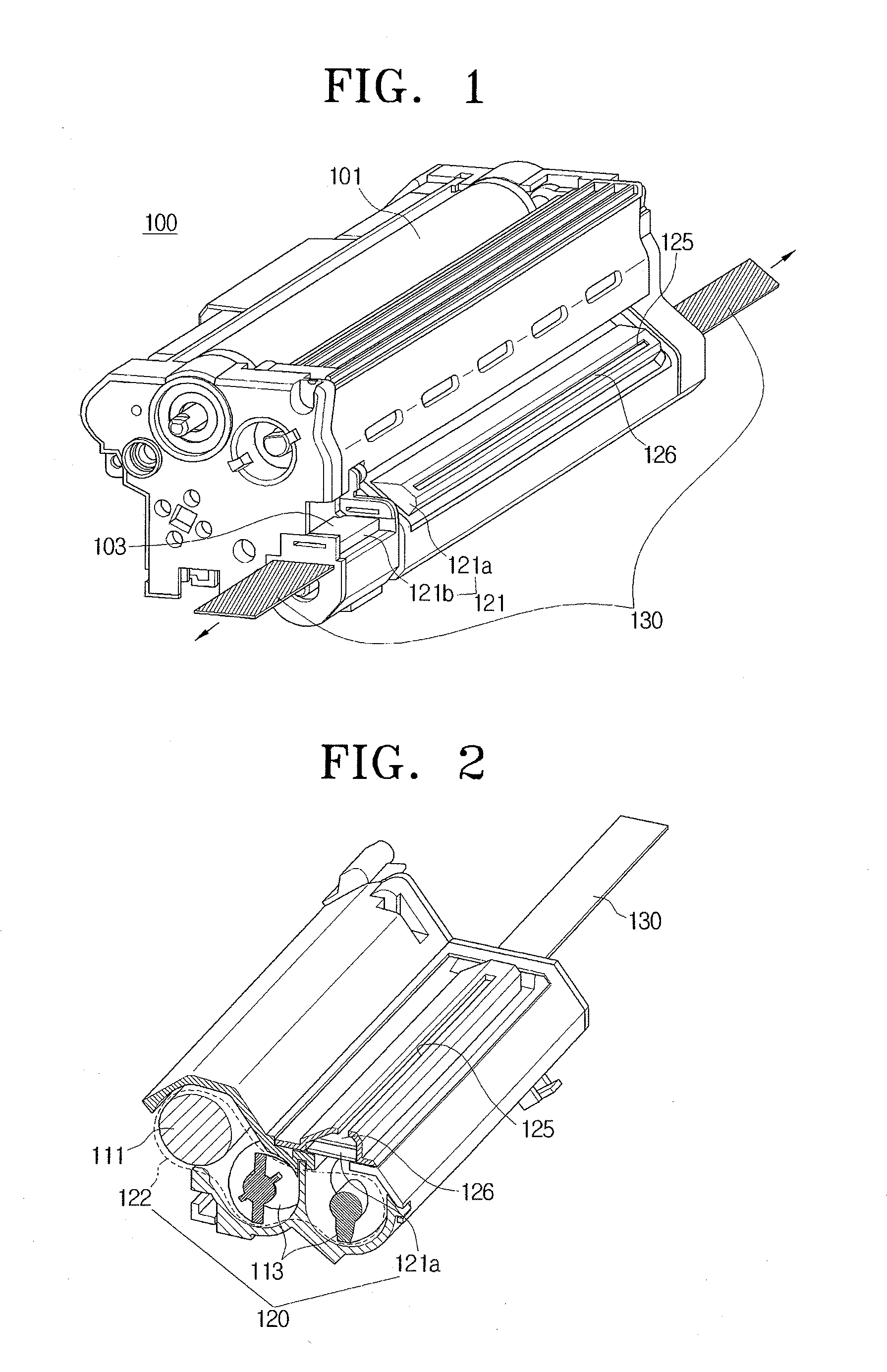

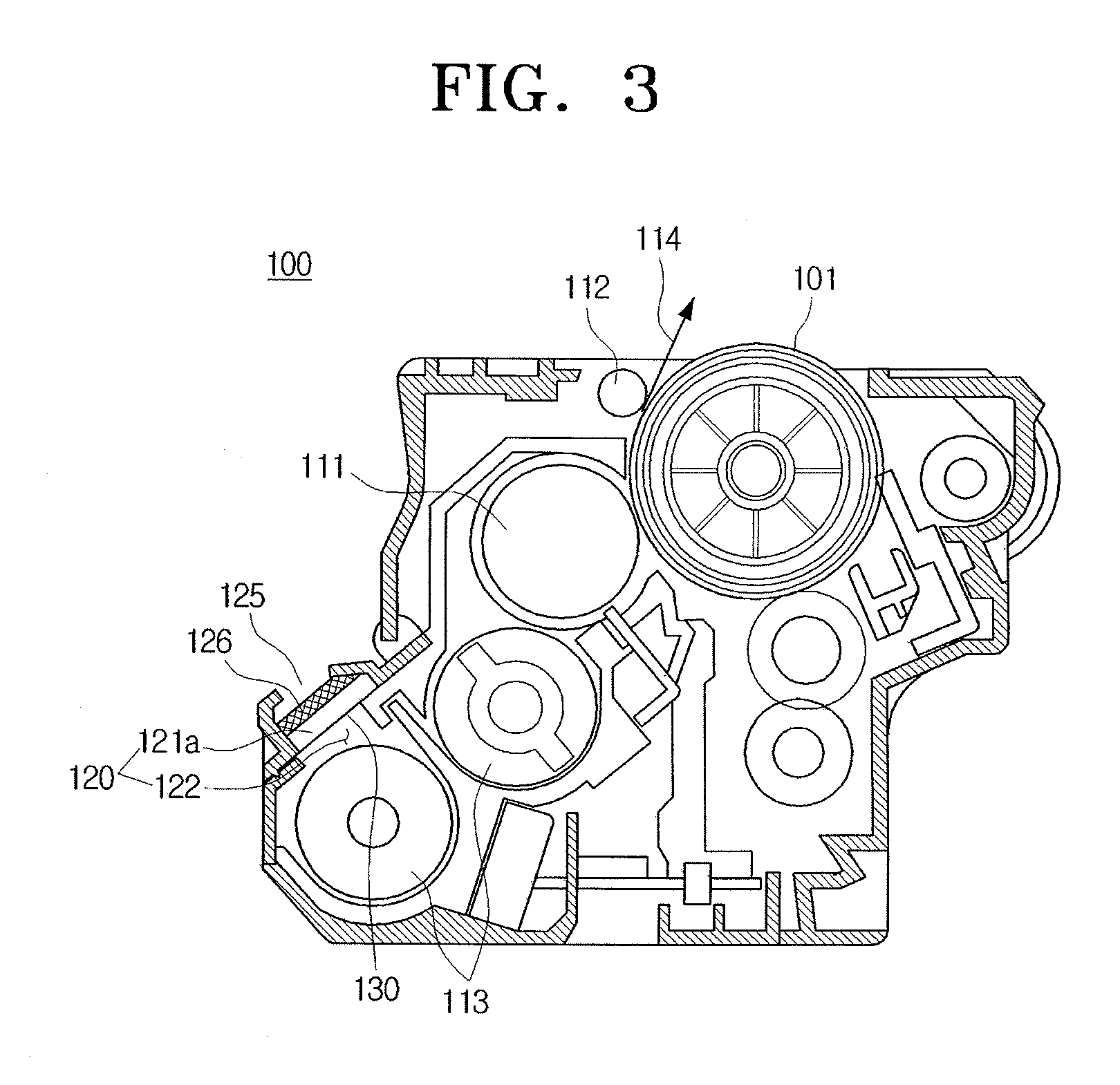

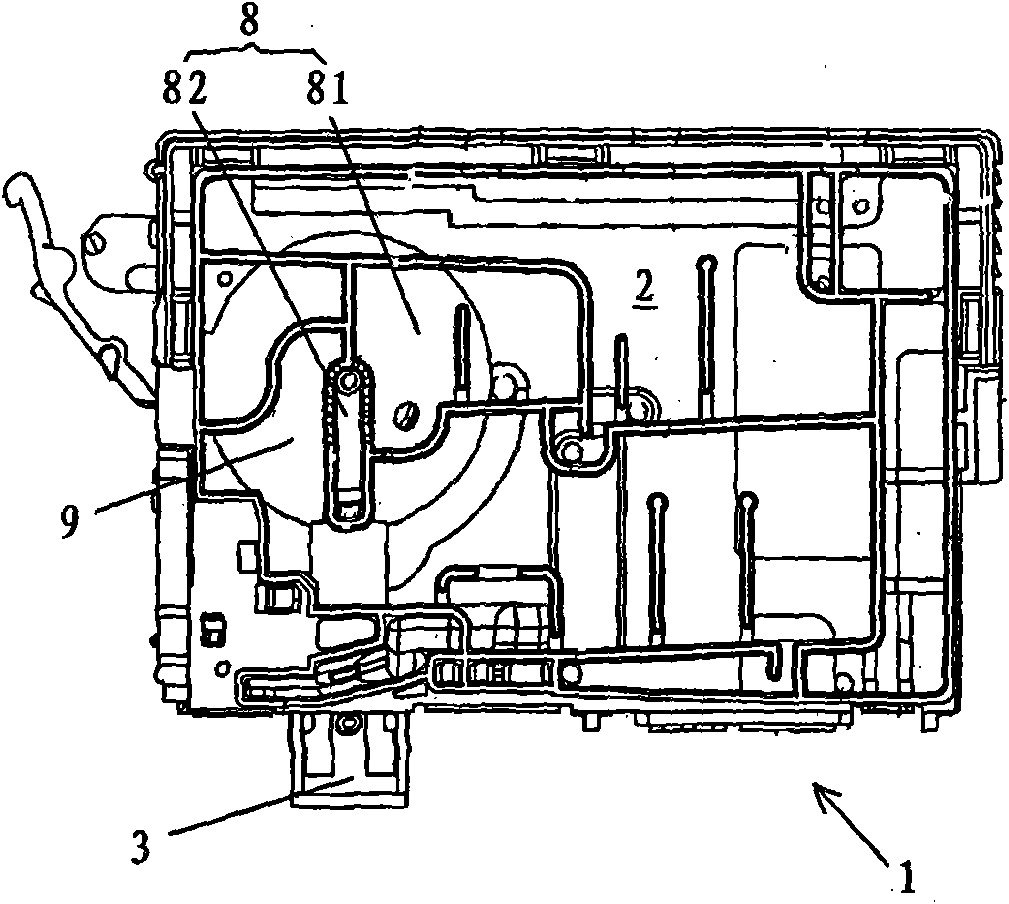

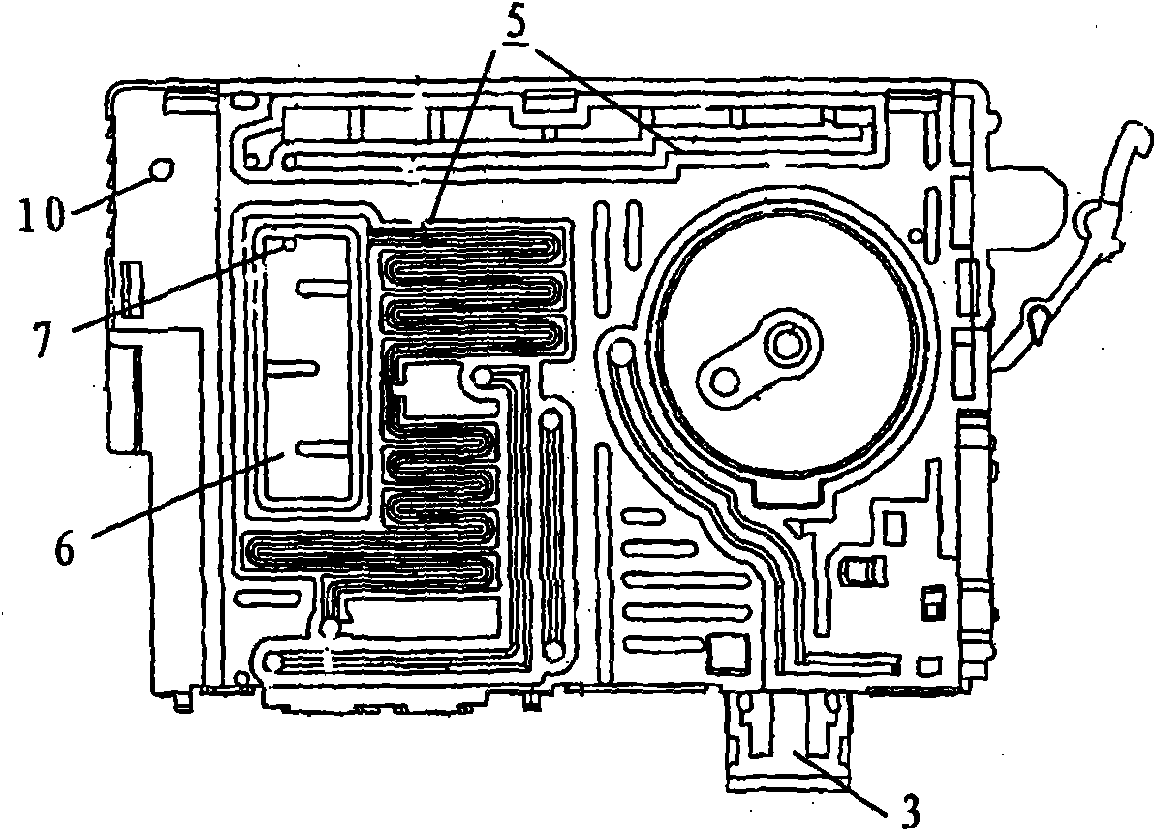

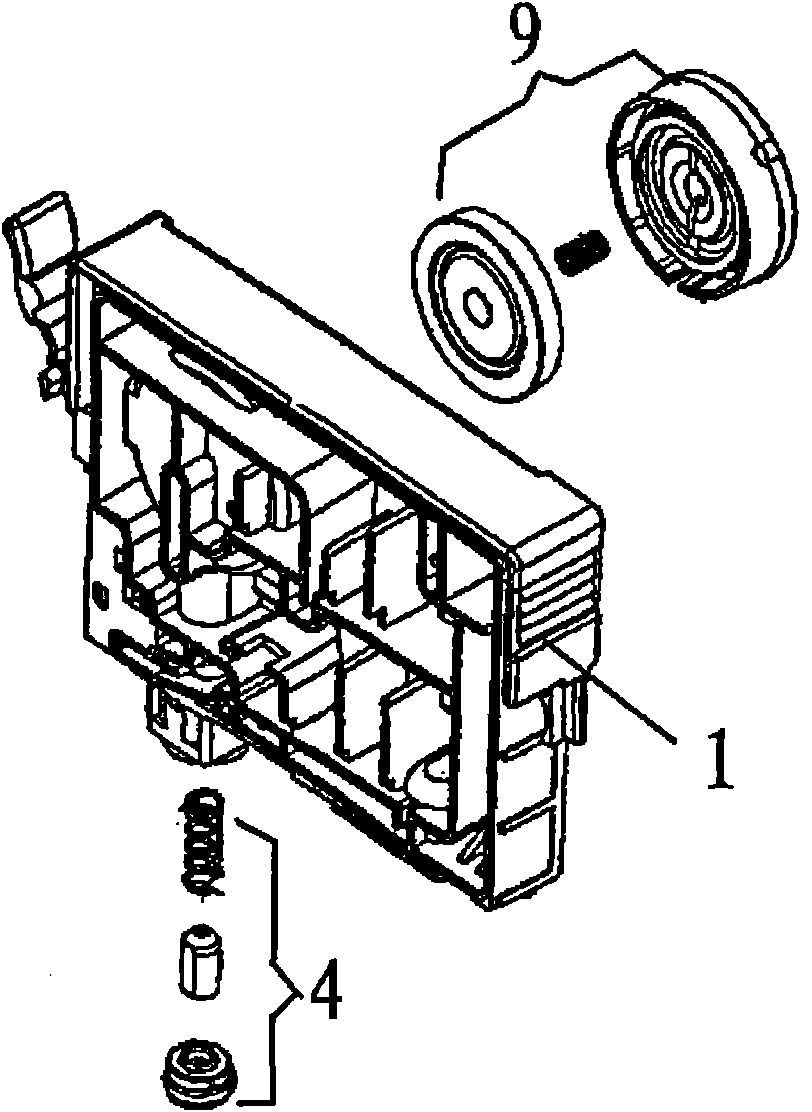

Electrical contact adapter and toner cartridge using electrical contact adapter and method

InactiveUS7110693B1Increase maximum allowable part lengthSave moneyElectrographic process apparatusCoil springBiomedical engineering

A type 2 IP-5000 toner cartridge is converted to a type 1 HP-5000 toner cartridge. The device and method are utilized by placing a repair contact over-plate over a double-spring contact subassembly to make a flat surface for the coil-spring contactor to engage while it rotates so that there will be electrical communication between the double-spring contact subassembly, the repair contact over-plate, the coil-spring contactor, the flange and the developer roller. The repair contact over-plate has at least two attachment-alignment holes used to lock into posts of the gear housing. Various forms of locking, removable locking or non-locking may be implemented into the repair contact over-plate. Installation of the repair contact over-plate may be facilitated by using a tool. The tool may consist of one plate, bar or flat srewdriver with at least one attachment-alignment hole to press the repair contact over-plate over the posts.

Owner:MICHLIN STEVEN BRUCE +1

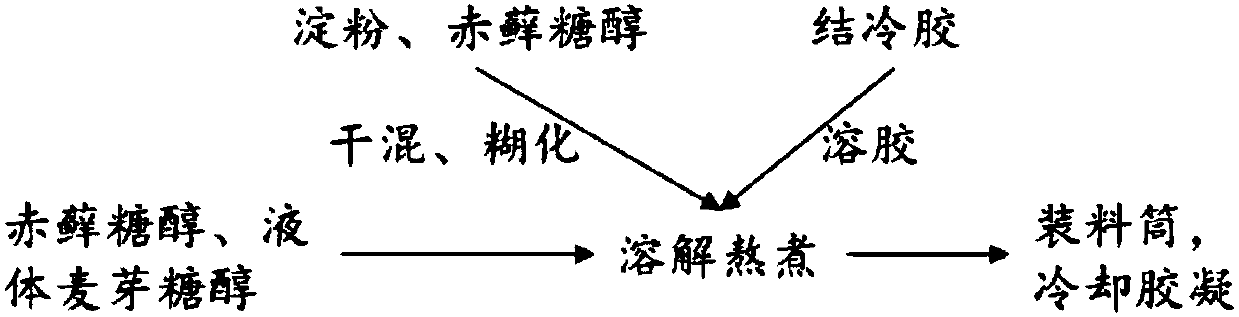

3D printing material for gelatinized confections and preparation method of 3D printing material

InactiveCN107668306AFlexible textureThe group ratio is reasonableConfectioneryFood preservationGellan gumRoom temperature

The invention relates to the technical field of food, in particular to a 3D printing material for gelatinized confections and a preparation method of the 3D printing material. Starch and low-acyl gellan gum in the 3D printing material are taken as gel, remelting is facilitated, rapid gelling at room temperature can be realized, smooth discharge can be guaranteed during 3D printing, stability of the printing material can be improved with application of plant extract, so that the printed confections can be stored for a long time, and sugar crystals are avoided. Experiments prove that the 3D printing material can be printed successfully, sensory evaluation of the obtained products is good, and sugar crystals or sugar dissolution does not occur when the products are placed at room temperaturefor 60 d.

Owner:INFINITUS (CHINA) CO LTD

Quantum dot ink and electroluminescent device

ActiveCN107400414AGood dispersionImprove solubilitySolid-state devicesSemiconductor/solid-state device manufacturingDispersitySolubility

The invention provides quantum dot ink. The quantum dot ink is characterized by being prepared from components in percentage by weight as follows: 0.01%-50.00% of quantum dots, 30.00%-99.98% of a solvent and 0.01%-40.00% of a cosolvent, wherein the cosolvent contains mutually linked groups R1 and groups R2, the groups R1 contain at least one oxygen-containing functional group, the groups R2 contain at least one coordination functional group W capable of being bonded with the quantum dots, and the cosolvent totally contains 2-25 carbon atoms. The problems of lower solubility and poorer dispersity of quantum dots of the conventional quantum dot ink can be solved effectively.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

Ink box

ActiveCN104723690AImprove smooth performanceEasy to usePrintingMechanical engineeringMaterials science

The invention relates to an ink box, and belongs to the technical field of printing. The ink box comprises an ink box body, an ink storage cavity, a sponge groove, an ink injection pipe, an ink discharge pipe, an air intake and an ink discharge opening. The ink storage cavity is located in the ink box body. The air intake is connected with the ink injection pipe and located in the top of the ink box body. The ink discharge opening is connected with the ink discharge pipe. The sponge groove is located in the bottom of the ink storage cavity. The sponge groove is of a closed structure with the two ends provided with a first air hole and a second air hole respectively, and a sponge is arranged in the sponge groove. The sponge groove is connected with the ink storage cavity through the first air hole and connected with the ink injection pipe through the second air hole. The ink box is simple in structure, easy to machine, convenient to use, smooth in printing, capable of saving ink, not prone to leakage and reliable in performance.

Owner:南京绿旗喷墨技术有限公司

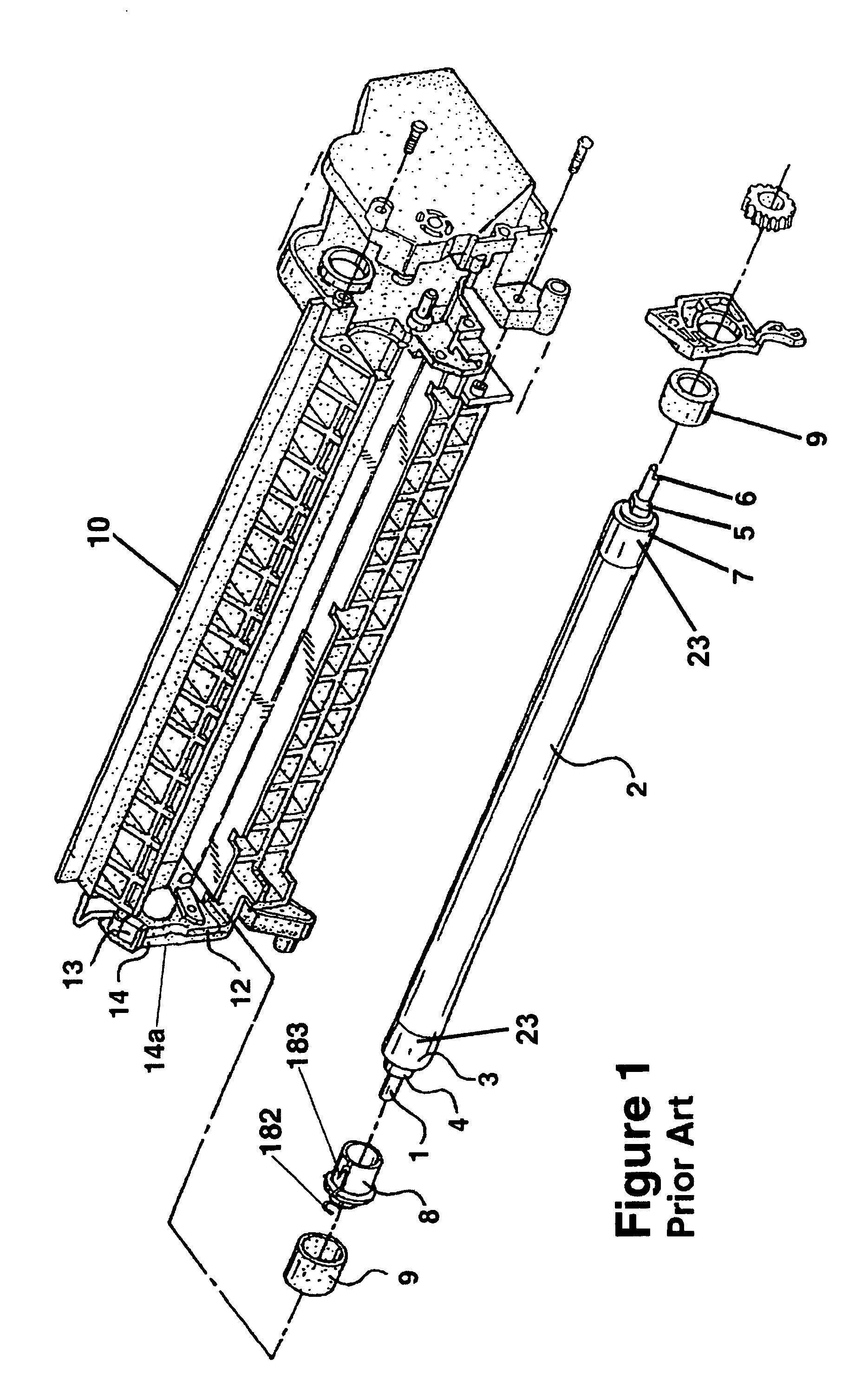

Developing unit and image forming apparatus having the same

ActiveUS20090074466A1Simple structureApply evenlyElectrographic process apparatusImage formationElectrical and Electronics engineering

Owner:HEWLETT PACKARD DEV CO LP

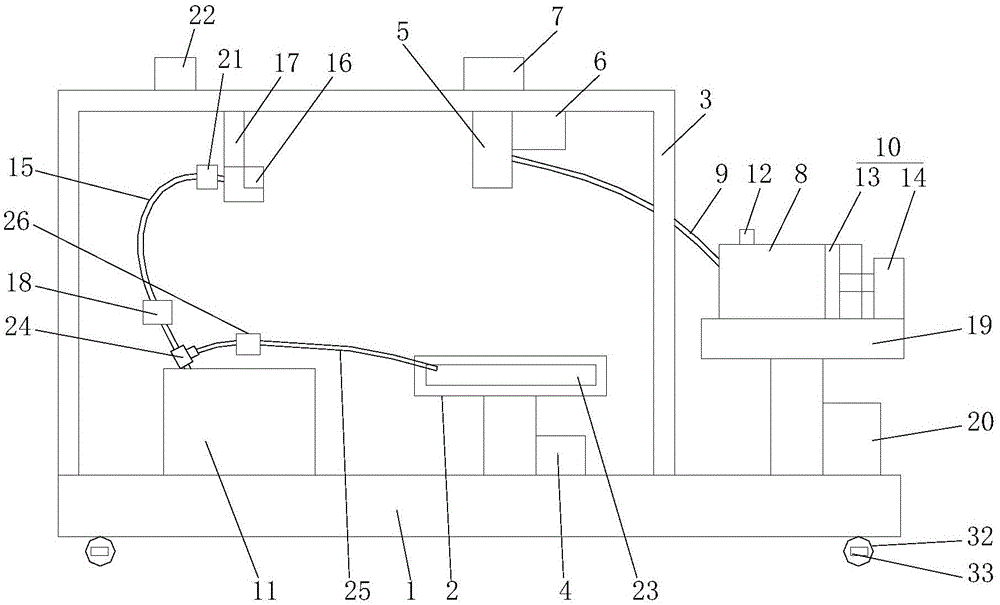

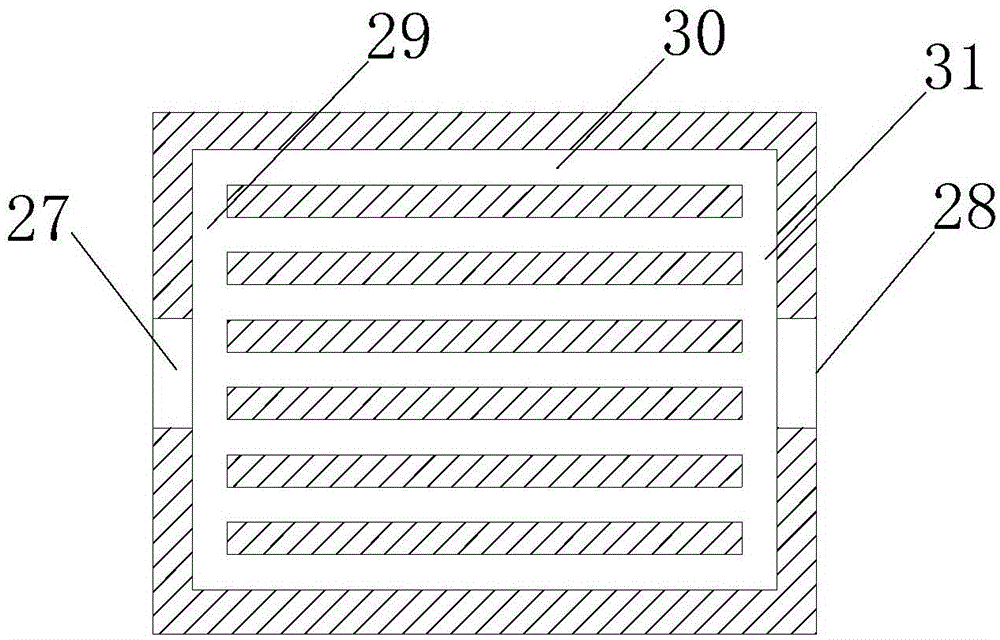

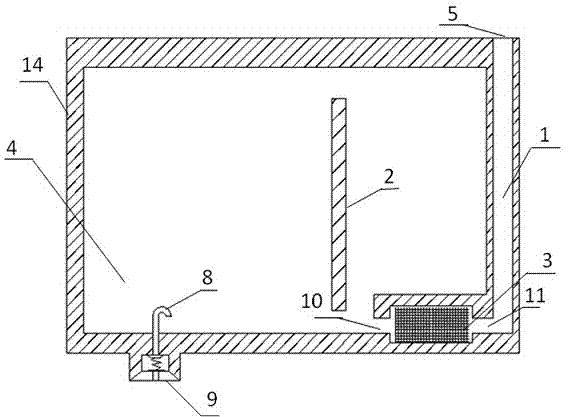

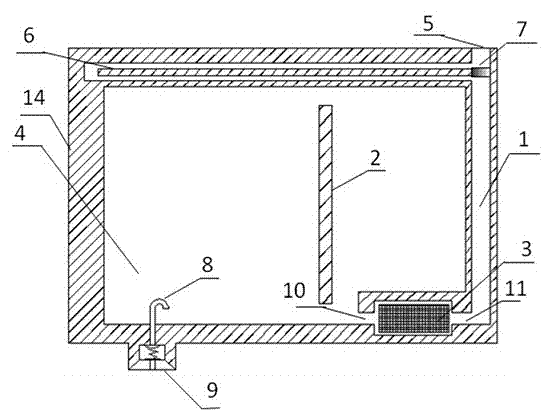

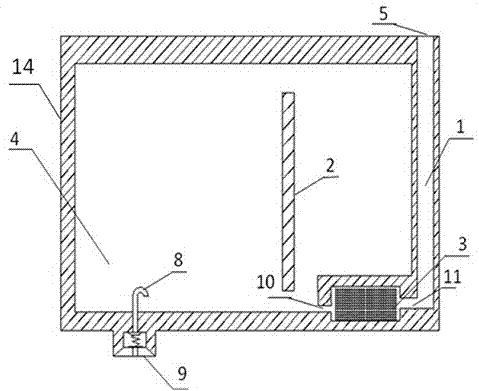

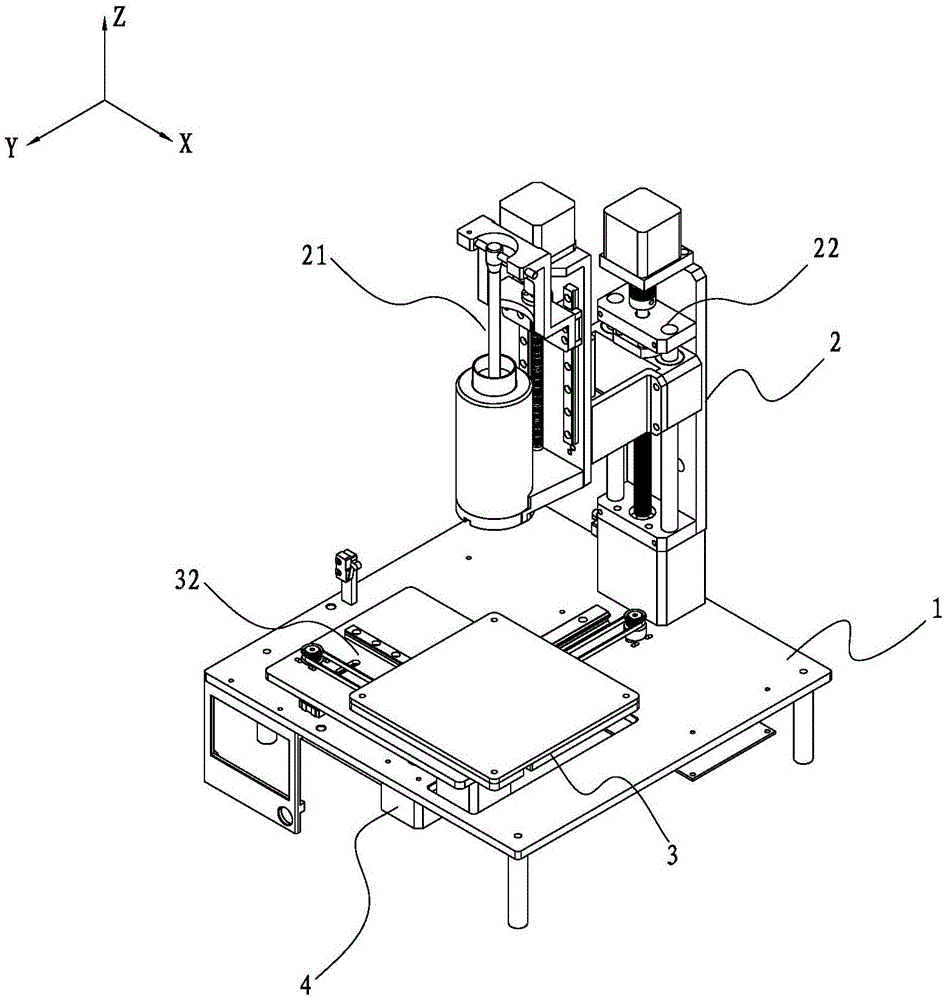

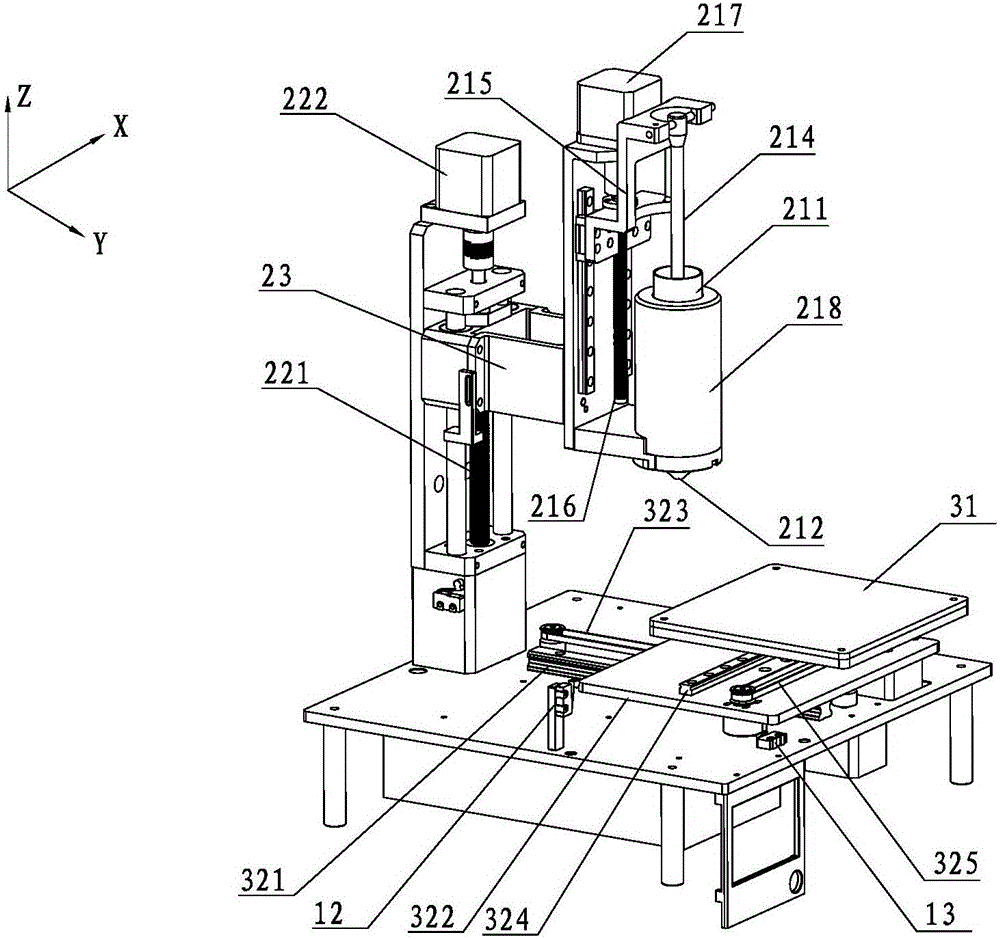

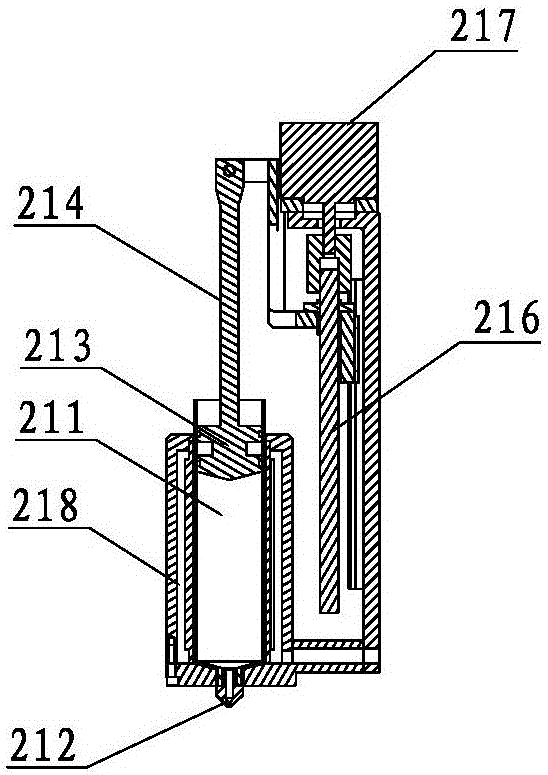

Liquid-state food material 3D printing device

InactiveCN106262994APrint smoothlyConvey evenlyAdditive manufacturing apparatusConfectioneryLinear motionVertical plane

The invention discloses a liquid-state food material 3D printing device. The device comprises a base and a printing mechanism, a translation mechanism and a control mechanism which are arranged on the base; the printing mechanism comprises a printing head assembly and a driving assembly used for driving the printing head assembly to move in the vertical plane; the translation mechanism comprises a printing platform and a driving assembly used for driving the printing platform to move in the horizontal plane; the printing head assembly comprises a raw material barrel used for containing printing raw materials, a printing head is arranged at the bottom of the raw material barrel, a pressing block used for pressing the raw materials towards the printing head is arranged in the raw material barrel, the pressing block is connected with a second screw through a piston rod and a connecting block sequentially, the second screw is driven by a motor, linear motion of the second screw drives linear motion of the piston rod, and then the pressing block continuously pushes the raw materials towards the printing head. The liquid-state food material 3D printing device can achieve printing of multiple liquid-state food materials and is high in practicability and printing precision, good in stability, convenient to operate and low in cost.

Owner:SHAOXING FAST REAL ELECTRONICS TECH CO LTD

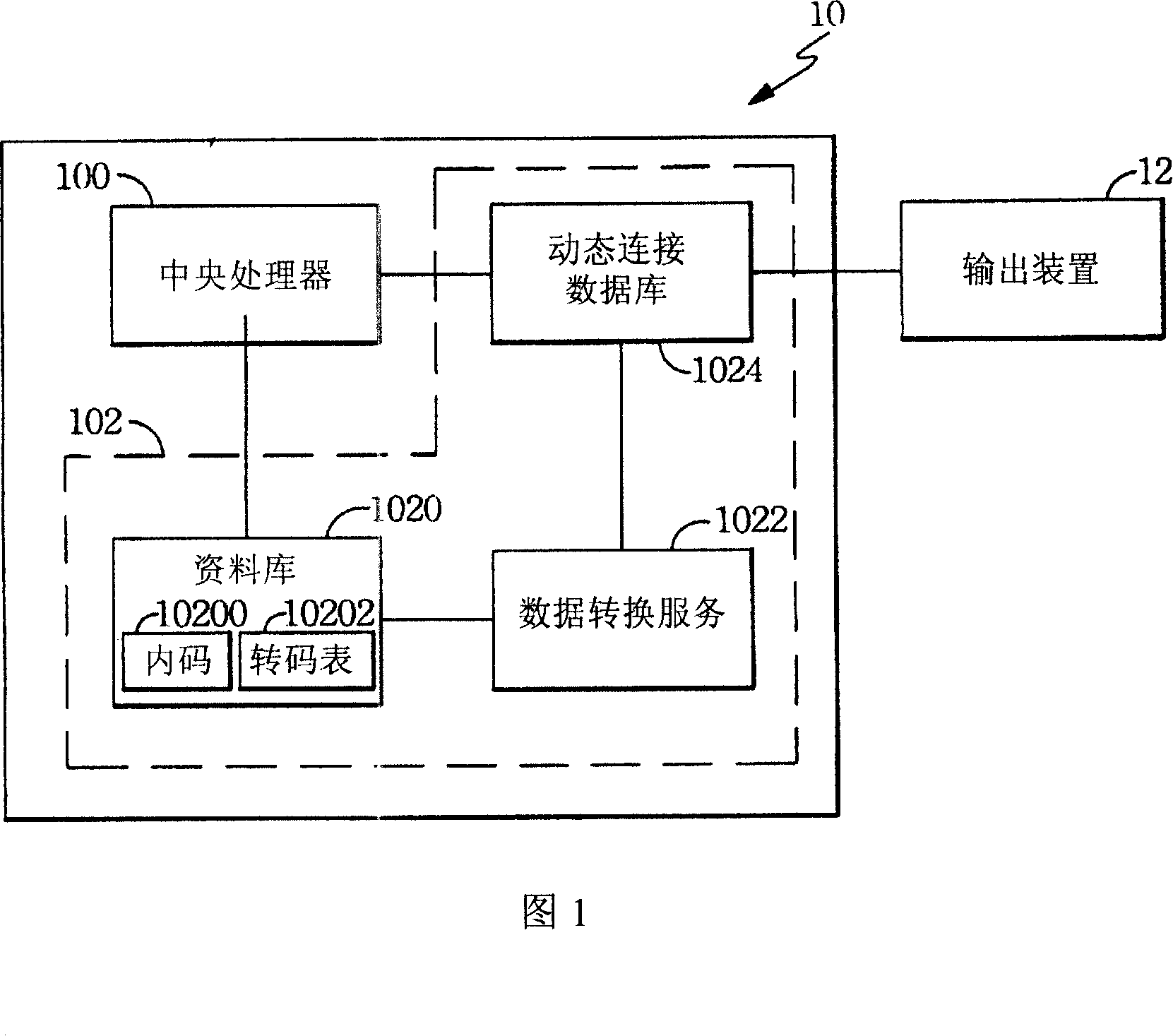

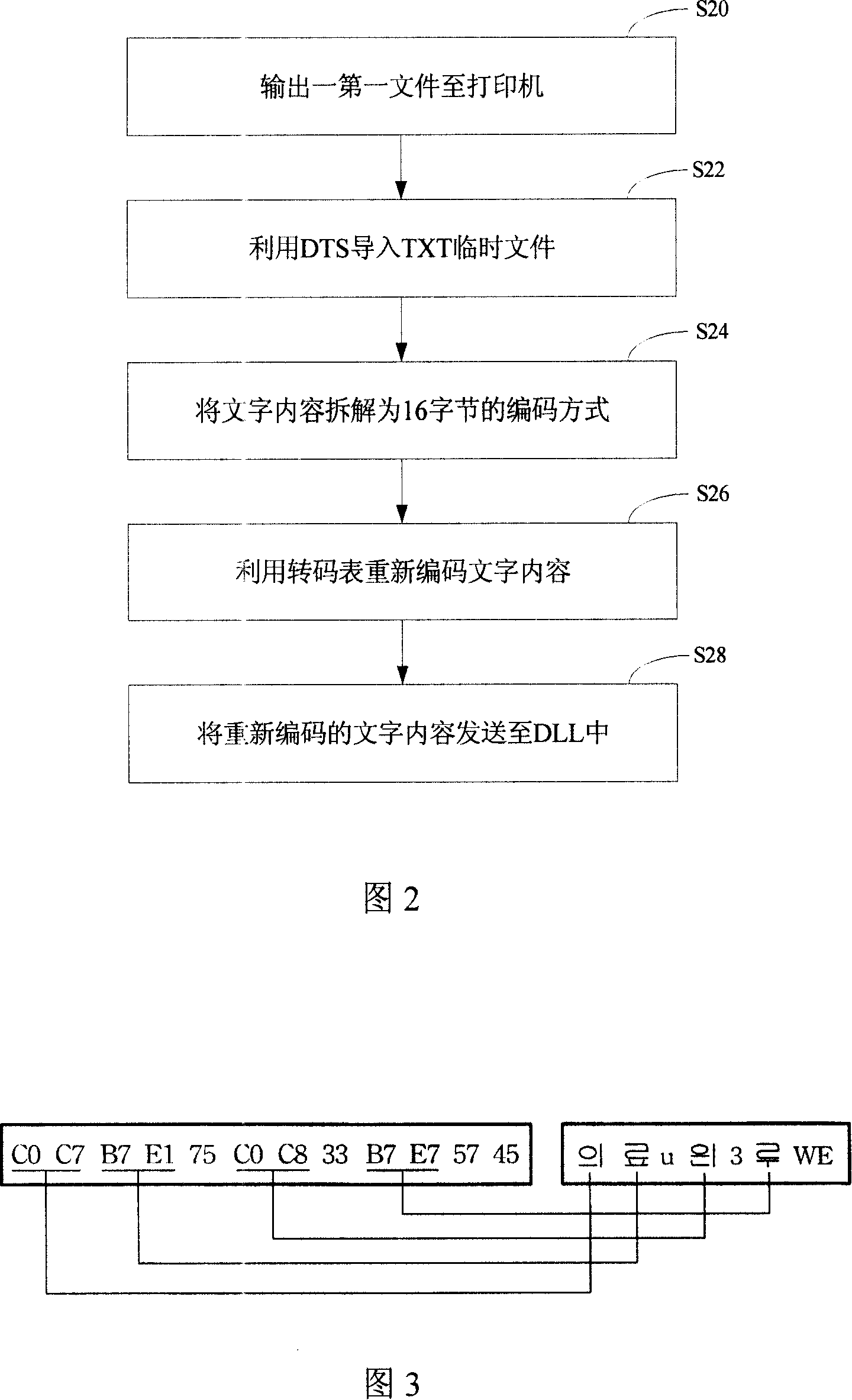

Words coded conversion method

InactiveCN101149669APrint smoothlySmooth displaySpecial data processing applicationsDigital output to print unitsProgramming languageTransformation of text

This invention discloses a method for transforming literal code, it uses the computer encoding construction with existing system and writing inside, and transforms the code of the other country writing for printing; Then encodes codes again with encoding method of the printer receiving, it is a method could print various countries' writing row successfully with printer.

Owner:INVENTECSHANGHAI TECH

Knotless screen printing front side silver paste for crystalline silicon solar cells

InactiveCN106448808AImprove screen printing qualitySmooth printingNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSolventPolyamide

The invention relates to the technical field of solar cells, in particular to a knotless screen printing front side silver paste for crystalline silicon solar cells. The knotless screen printing front side silver paste is characterized by being prepared from, by weight, 75-90% of silver powder, 1-8% of glass powder, 5-15% of organic carriers, 0-3% of addition agents and the balance solvent, wherein organic resin in the organic carriers refers to one or more of rosin, ethyl cellulose, thermoplastic resin and acrylic resin, and the thermoplastic resin refers to one or more of PE-polyethylene, PVC-polyvinyl chloride, PS-polystyrene, PA-polyamide, POM-polyformaldehyde, PC-polycarbonate, PVB-polyvinyl butyral, polyphenyl ether, polysulfone and polyester. The knotless screen printing front side silver paste for the crystalline silicon solar cells has the advantages that several kinds of resins are selected to prepare the organic carriers, and a nonionic surface active agent is adopted to disperse the silver powder, so that knot-less silk-screen printing quality of the paste is improved, smooth printing is guaranteed, and EL (electroluminescence) of the crystalline silicon solar cells can meet related requirements.

Owner:北京市合众创能光电技术有限公司

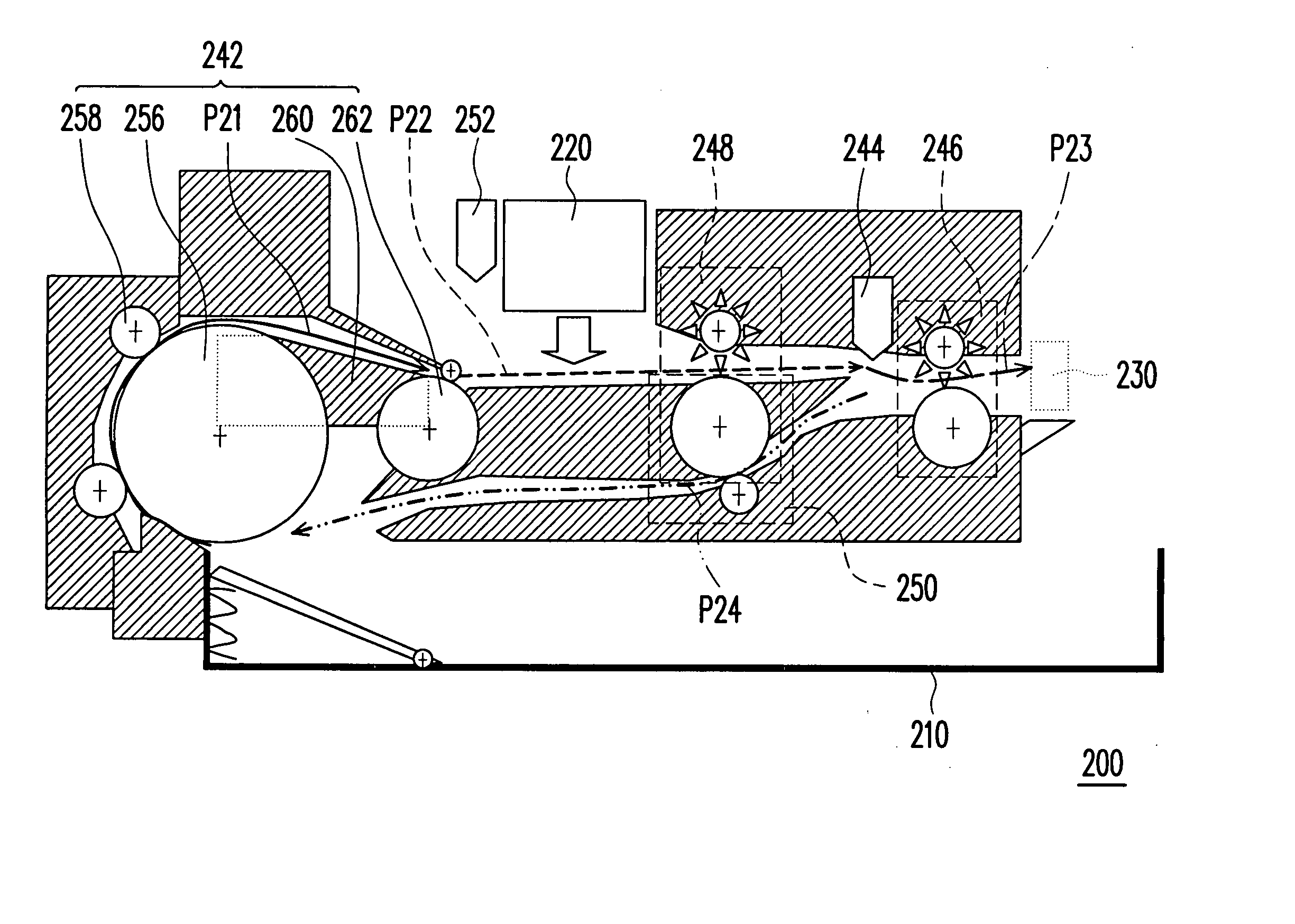

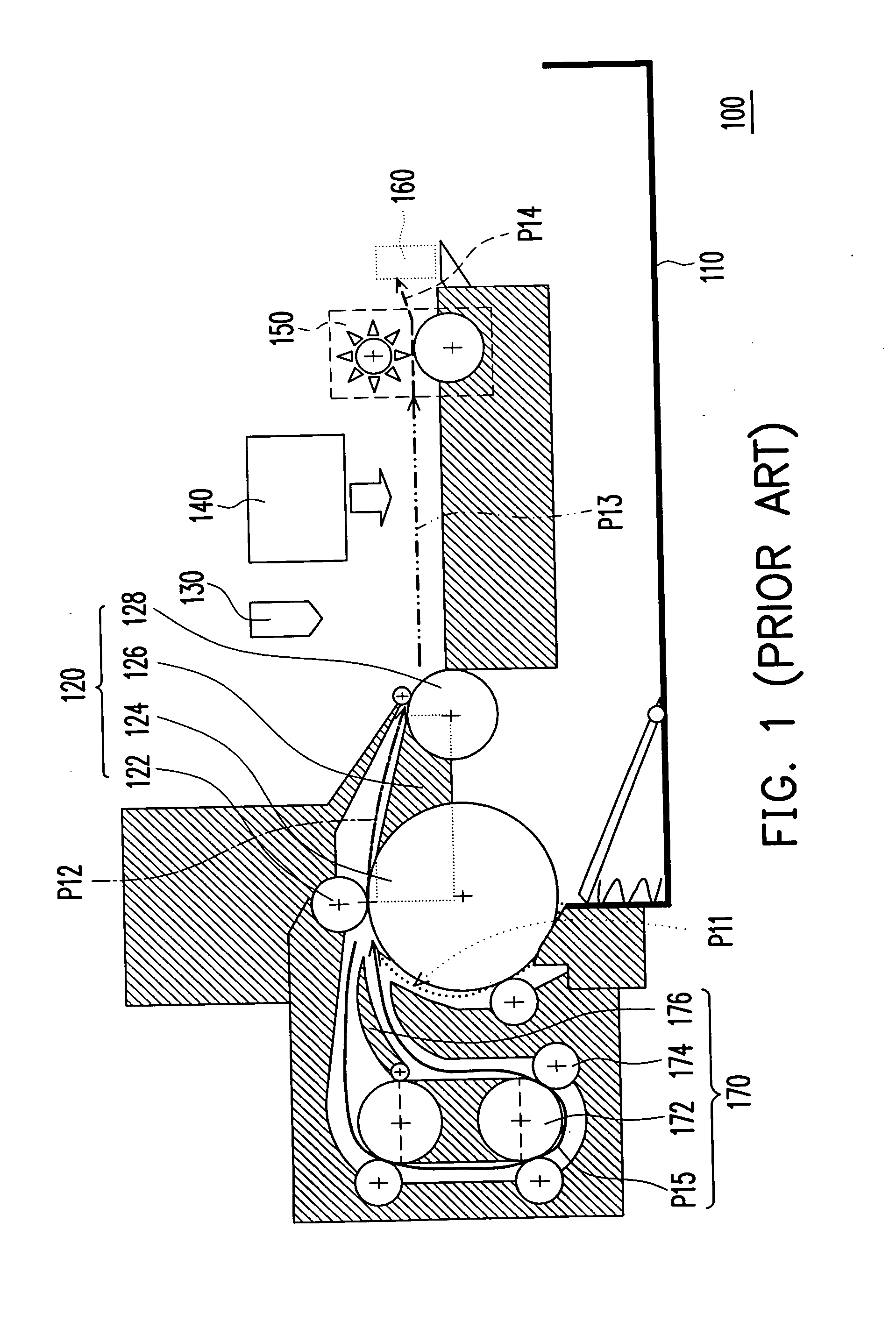

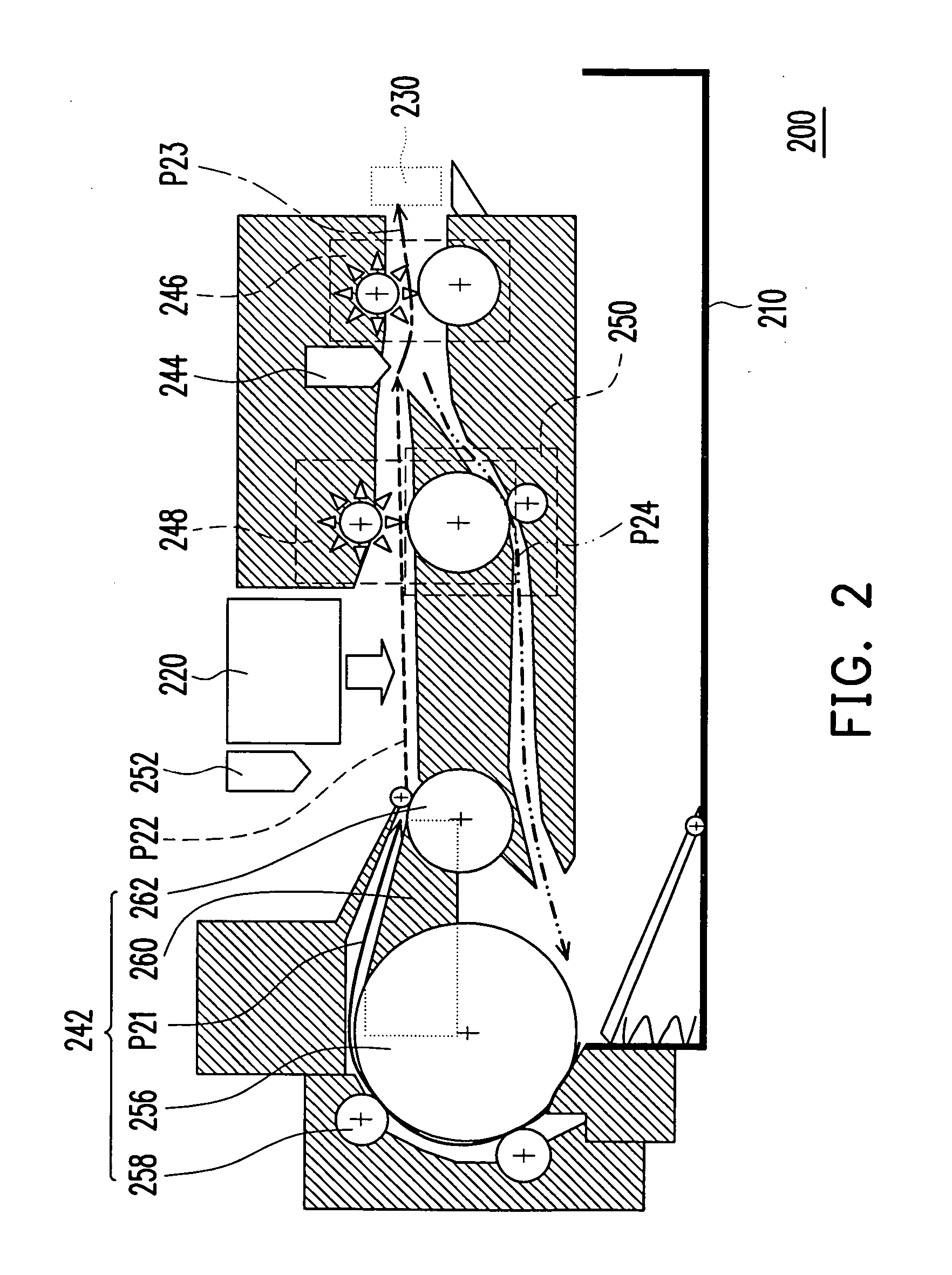

Sheet-feeding module for double-side printing and double-side printing method

InactiveUS20060279622A1Low costEnhance double-side printing efficiencyTypewritersOther printing apparatusEngineeringPaper sheet

Owner:KINPO ELECTRONICS

Method for recycling ink box with differential pressure valve and recycled ink box

ActiveCN101767486ASolve the technical problem of easy ink leakageReduce pollutionPrintingRecovery methodDifferential pressure

The invention relates to a method for recycling ink box with differential pressure valve. The method comprises the following steps: (1) removing gas-liquid separation membrane, sealing through holes, and opening a new small hole communicating with an ink storage chamber on the ink box; (2) injecting proper amount of ink through the small hole; (3) sealing the small hole and pumping proper amount of ink back through an ink supplying port. Ink is injected through the small hole when being recycled, and when the recycled ink box is used for printing, the small hole can be used as an air inlet hole to lead external air into the ink box, thus ensuring air inlet to be smooth and printing to be smooth, avoiding ink leakage when ink flows backwards, solving the technical problems that existing method for recycling ink box with differential pressure valve is complicated and that the recycled ink box is easy to leak. The invention also provides an ink box recycled by the above recycling method.

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

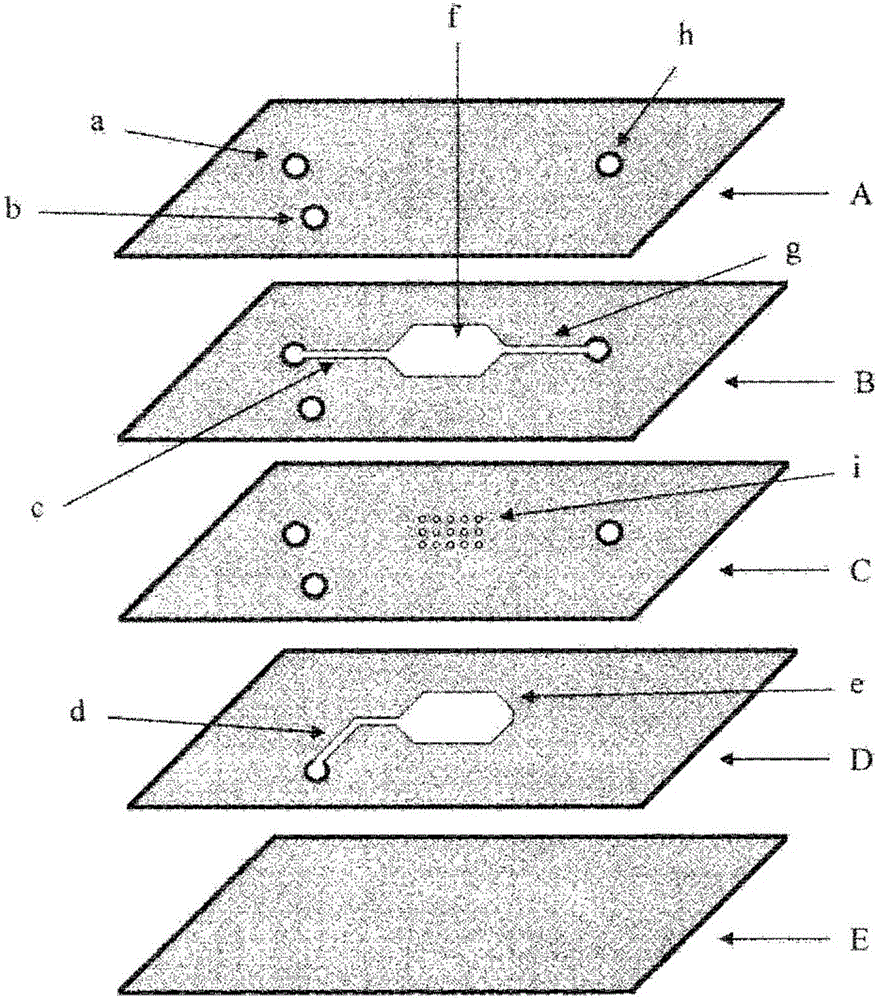

Microfluidic chip and droplet generation device applying same

The invention provides a microfluidic chip and a droplet generation device applying the same. The microfluidic chip of a T-shaped structure comprises a continuous-phase inlet portion, a dispersion-phase inlet portion and a droplet outlet portion, wherein the continuous-phase inlet portion is a straight-through portion of the T-shaped structure, and a continuous-phase passage is formed inside the straight-through portion; the dispersion-phase inlet portion is a bypass portion of the T-shaped structure, and a dispersion-phase passage is formed in the bypass portion; the droplet outlet portion is another straight-through portion of the T-shaped structure, and a droplet passage is formed in the droplet outlet portion; the continuous-phase passage, the dispersion-phase passage and the droplet passage converge in the microfluidic chip, and a conical passage is formed on one side, close to the droplet passage, of the convergence position. The microfluidic chip has the advantage that the small-scale conical passage exists on the lower downstream of a main passage, and when a continuous phase flows through the conical passage, more shear force can be generated, so that droplets with the diameters below 100 micrometers can be generated easily.

Owner:PEKING UNIV

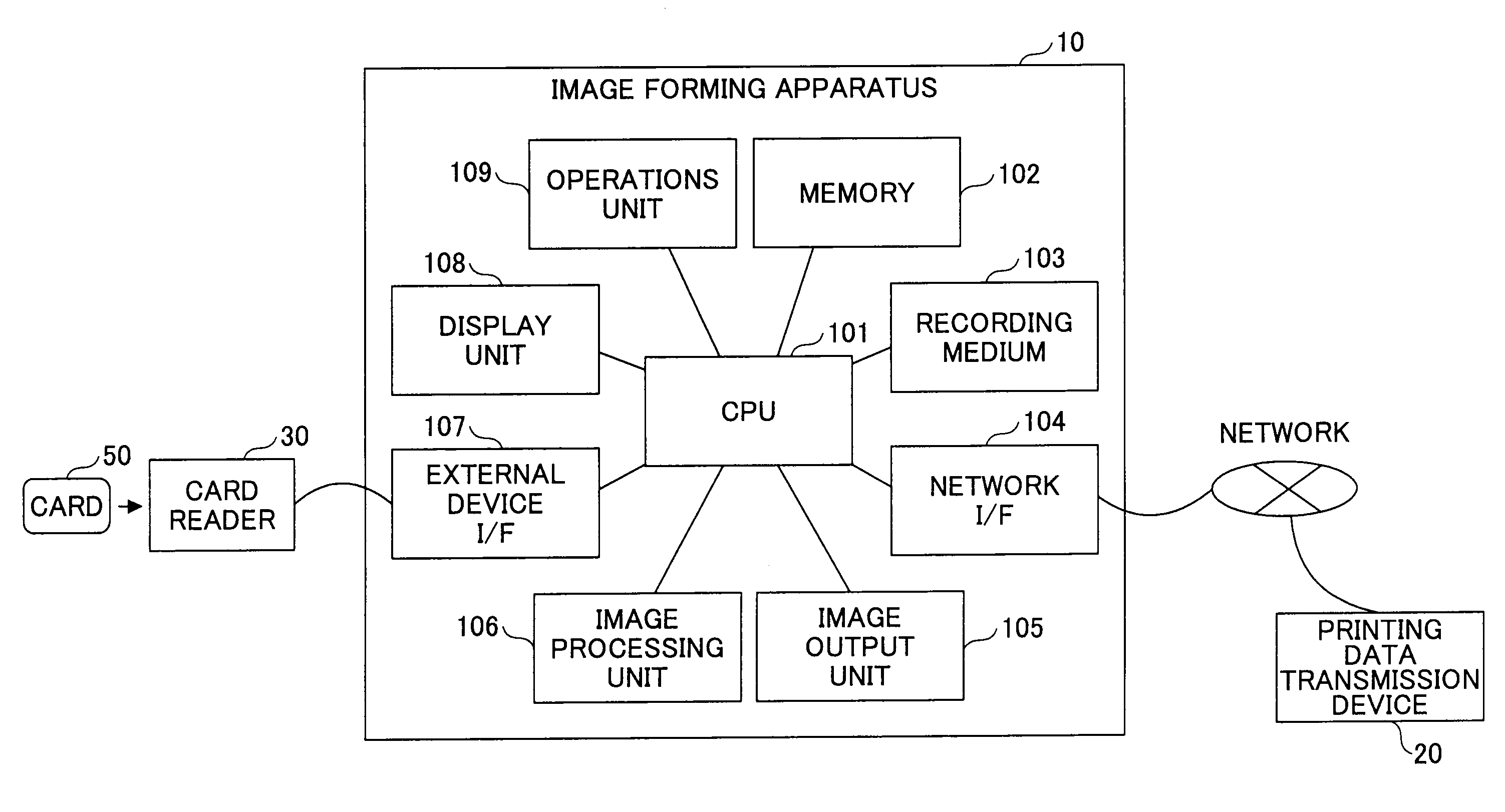

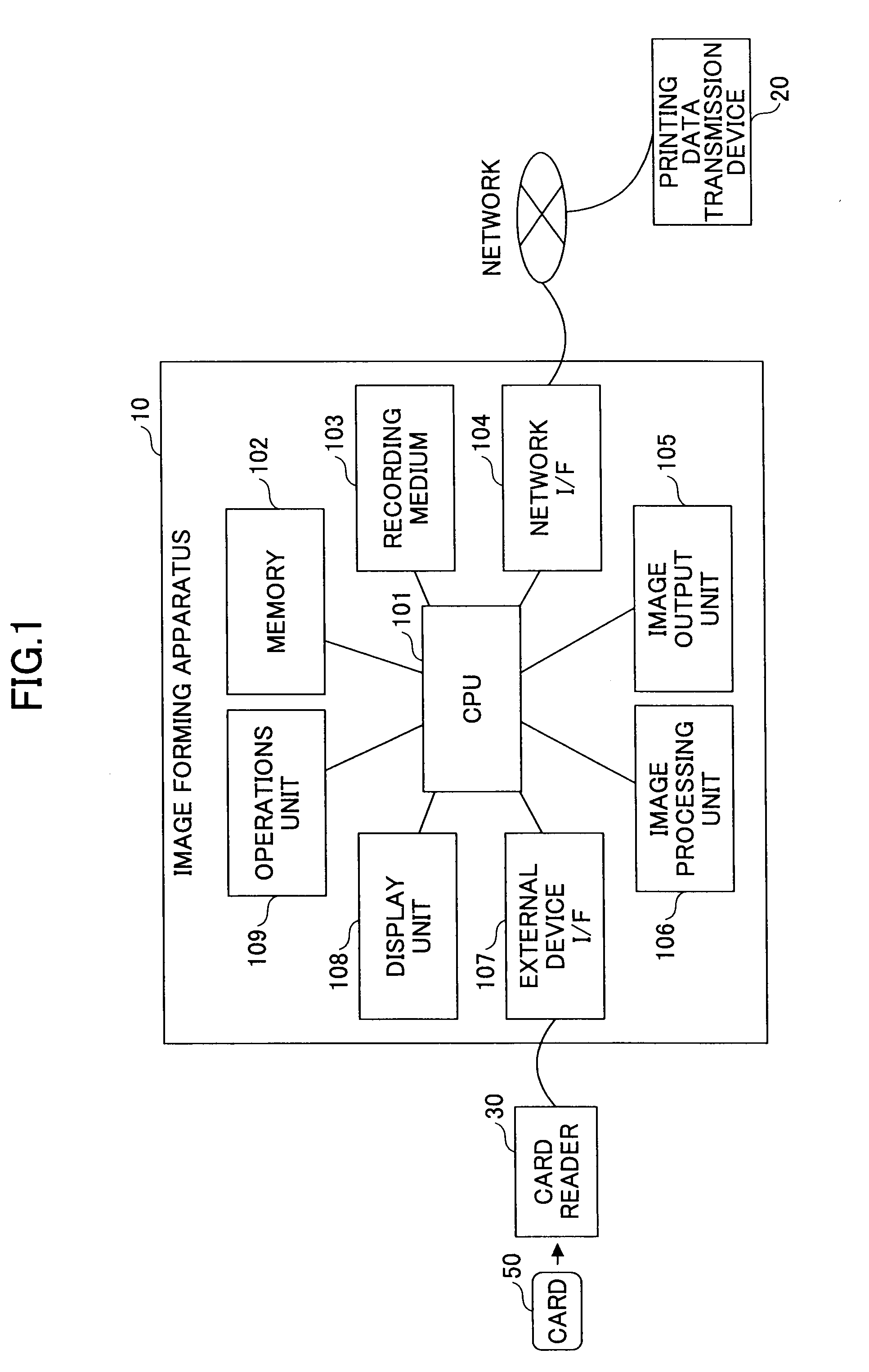

Image forming apparatus, print control method, recording medium

ActiveUS20100051681A1Eliminate disadvantagesPrint smoothlySpecial data processing applicationsVerifying markings correctnessManagement unitPassword

An image forming apparatus including a printing-data-receiving unit configured to receive a printing-data-item including a user identification information item and a password, and to save the printing-data-item in a storage device; a user-authentication unit configured to receive input information specifying a user identification information item of a user, and to authenticate the user based on a managing unit that manages association information associating user identification information items with passwords; a list-display unit configured to cause a display device to display a list of printing-data-items each including the same user identification information item as that of the user; and a printing-control unit configured to execute a printing job of a printing-data-item selected from the list, wherein in the event that there is a printing-data-item that cannot be printed, the printing-control unit does not cancel a printing job of another printing-data-item that can be printed.

Owner:RICOH KK

Reactive extrusion toughening carbon fiber reinforced polylactic acid 3D printing material and preparation method thereof

ActiveCN106867213AOvercome resilienceOvercoming the problem of low elongation at breakAdditive manufacturing apparatusFiberCarbon fibers

The invention discloses a reactive extrusion toughening carbon fiber reinforced polylactic acid 3D printing material and a preparation method thereof, and relates to the technical field of 3D printing materials. Raw materials are mixed according to the formula and then the mixed raw materials are put into a twin-screw extruder to be extruded after frit reaction and a reaction extrusion toughening modification carbon fiber reinforced polylactic acid 3D printing wire material is obtained after cooling. The reactive extrusion toughening technology overcomes the problems of poor toughness and low elongation at break of the wire material with high carbon fiber content, is beneficial to improvement of the interface compatibility between carbon fiber and polylactic acid, and effectively ensures that the printing process of the printed pieces is smooth. The processing time is short, the working process is environmentally friendly, the use of a large number of mixed acid is avoided, environmental pollution is reduced, the cost is low, and the reactive extrusion toughening carbon fiber reinforced polylactic acid 3D printing material and the preparation method thereof are suitable for industrial production.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

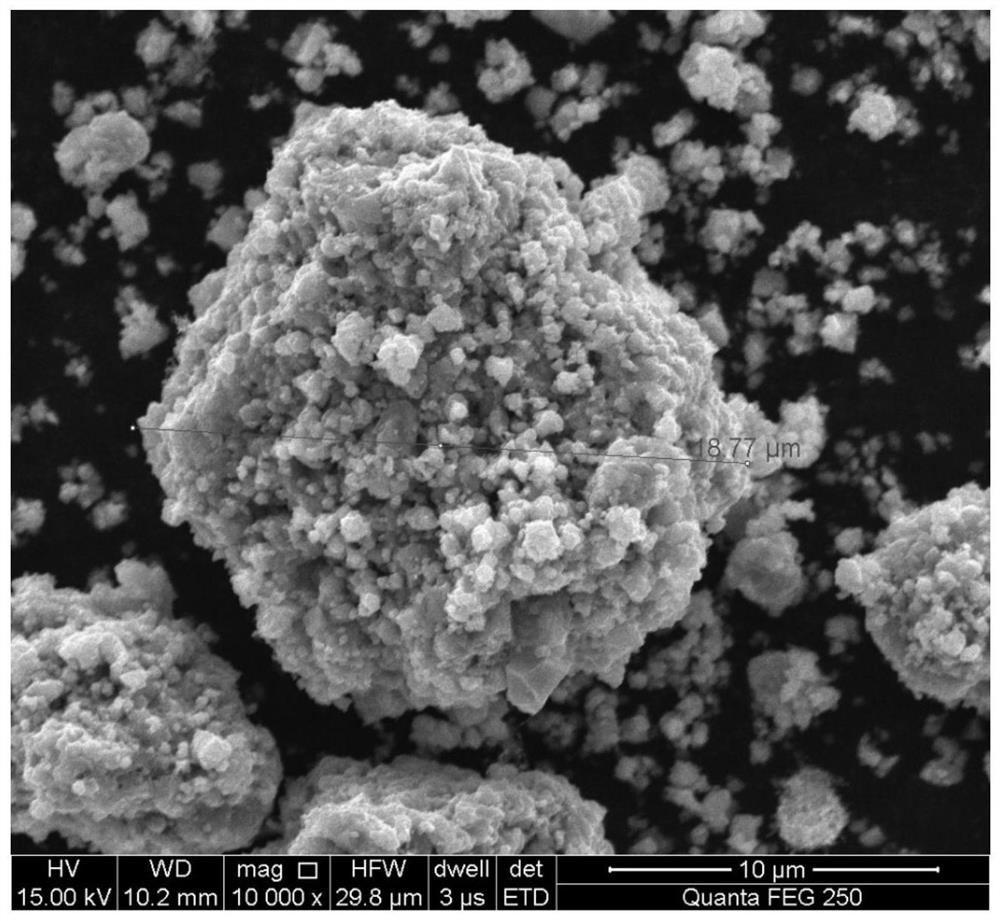

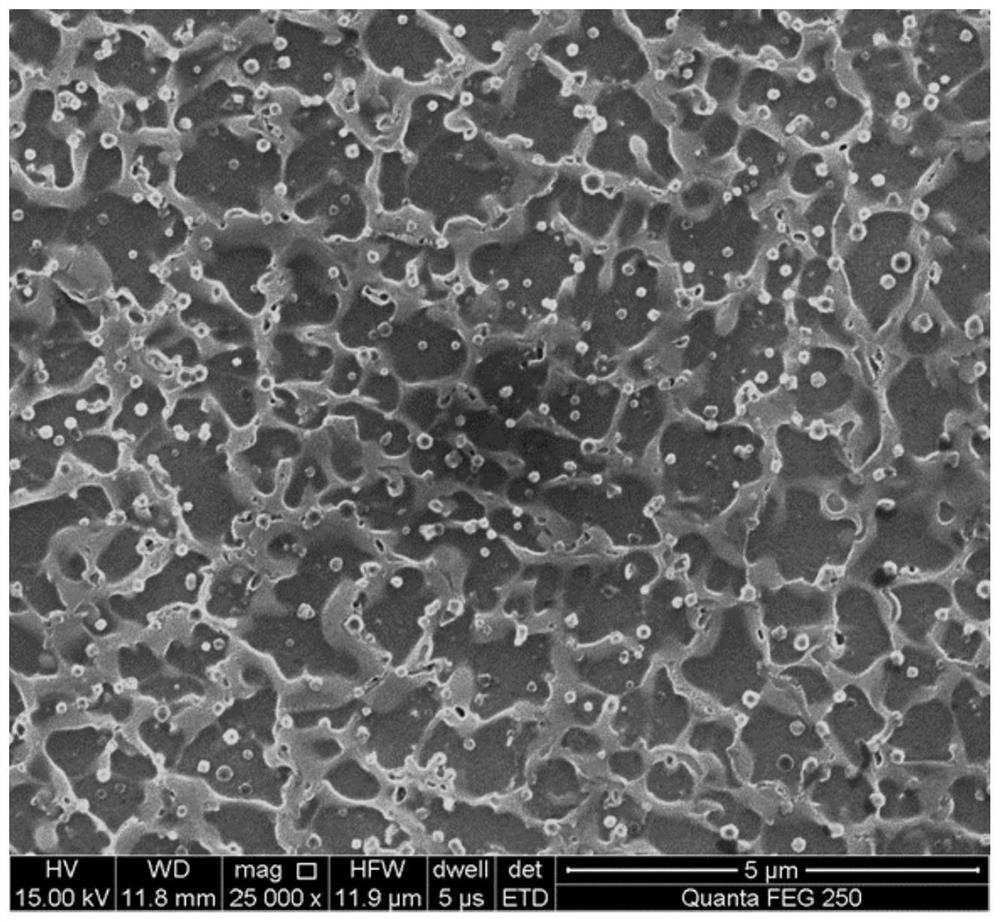

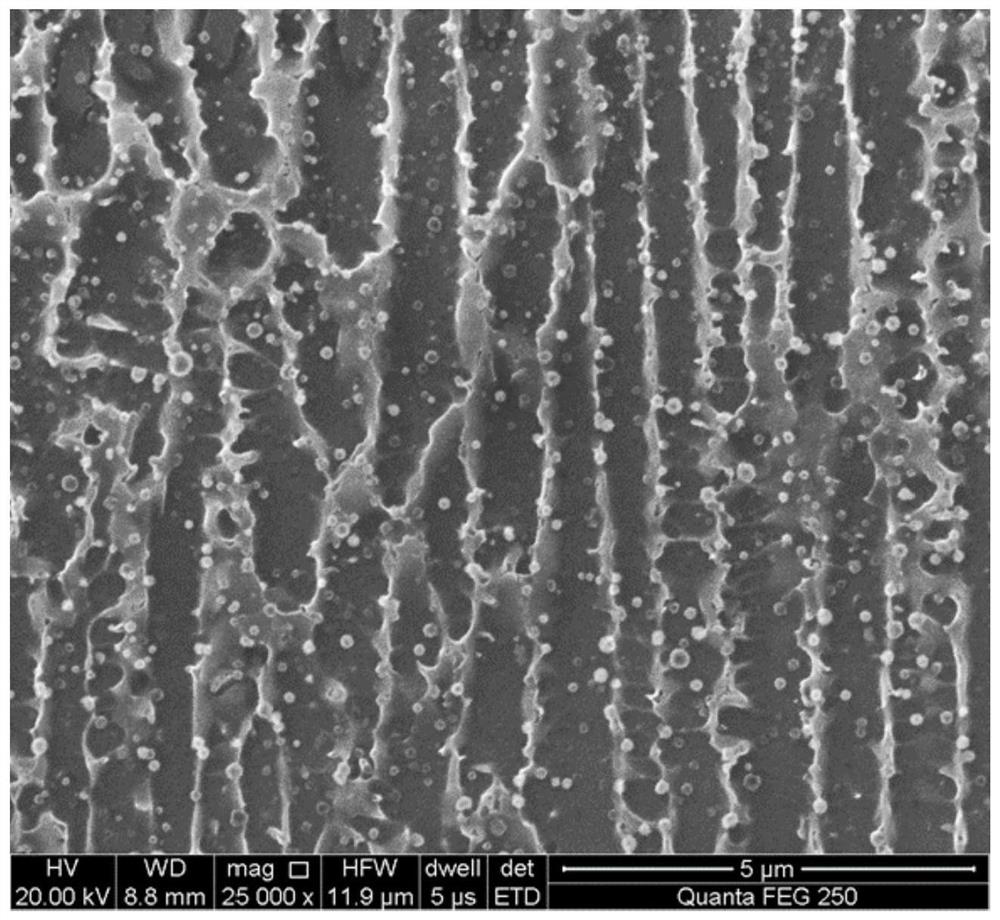

Method for preparing nano-phase reinforced nickel-based superalloy by adopting micron ceramic particles

ActiveCN112011702AFine grainGood mechanical propertiesMaterial nanotechnologyAdditive manufacturing apparatusMicron scaleNanoceramic

The invention provides a method for preparing a nano-phase reinforced nickel-based superalloy by adopting micron ceramic particles. In the nano-phase reinforced nickel-based superalloy, a nickel-basedsuperalloy is taken as a matrix, and one or more of TiC, TiB2, WC and Al2O3 are taken as a reinforcing phase. The particle size of a ceramic particle raw material as the reinforcing phase is 1-5 [mu]m; the adding amount of the ceramic particle raw material is 1 to 5 percent by weight; nickel-based superalloy composite powder with uniformly distributed nano-ceramics is prepared through a specificball milling process; the nano-ceramic phase reinforced nickel-based superalloy is prepared through a 3D printing technology; and the prepared material is uniform in nano-ceramic phase distribution and has excellent mechanical properties. Micron-sized ceramic particles are adopted, so that the cost is low; and parts in any complex shape can be integrally formed and prepared, so that the material utilization rate is increased.

Owner:CENT SOUTH UNIV

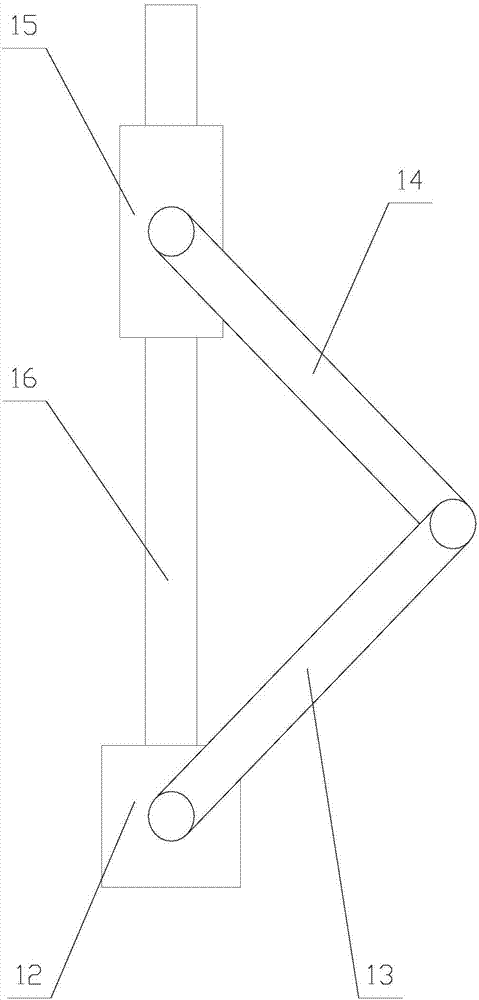

Intelligent 3D printing device capable of achieving smooth printing and free of faults

ActiveCN106938536AAvoid cloggingPrint smoothly3D object support structuresManufacturing data aquisition/processingDrive wheelSprayer

The invention relates to an intelligent 3D printing device capable of achieving smooth printing and free of faults. The intelligent 3D printing device comprises a printing sprayer and a plurality of supporting units. Each supporting unit comprises a casing pipe, a supporting rod, a buffer board, a spring and a pressure sensor. A material spraying mechanism, a material pipe, a heating ring and a throat pipe are arranged inside the printing sprayer. The material spraying mechanism comprises a slide bar and material spraying units arranged at the two sides of the slide bar. Each material spraying unit comprises a fourth driving motor, a driving wheel and a plurality of driving teeth. Bar-shaped teeth are arranged at the two sides of the slide bar. According to the intelligent 3D printing device capable of achieving smooth printing and free of faults, the pressure sensors in all the supporting units are used for detecting whether a printed sample moves or not, the printing sprayer is moved to a correct position through a camera and a plane moving mechanism and then printing continues, so that the fault problem happening in the printing process is avoided; and moreover, a liquefied material in the throat pipe can flow out of the printing sprayer through the material spraying mechanism, and therefore printing smoothness is guaranteed, nozzle blocking is avoided, and practicability of the printing device is improved.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

Inkjet printing technology for cotton and linen fiber fabric

InactiveCN106436349AImprove dark tone of dyeingEnhanced wash resistance and sorptionDry-cleaning apparatus for textilesDyeing processHot blastDyeing

The invention discloses an inkjet printing technology for a cotton and linen fiber fabric. The technological processes of low-temperature plasma modified pretreatment, sizing pretreatment, drying, inkjet printing, steaming fixation, after-treatment and washing and drying are adopted, low-temperature plasma modified pretreatment is performed at first before sizing pretreatment, modified treatment is performed on cotton and linen fiber, and then preshrinking technological treatment is performed; on one hand, the defect that the dyeing keynote of the cotton and linen fiber fabric is dark is overcome; on the other hand, the phenomenon that printing is irregular due to the fact that the cotton and linen fiber fabric is shrunk in the inkjet printing technology is effectively avoided; in addition, the special inkjet printing pigment ink is adopted for jet printing, the washing technology adopts warm water washing and hot-blast air drying, chemical tolerance of pigment is stimulated, and the wash resistance is enhanced and the absorption rate is increased; the technology has the advantages of being smooth in printing, bright in color, suitable for coloring depth, not prone to color fading, simple and the like.

Owner:苏州市恒信针织印染有限责任公司

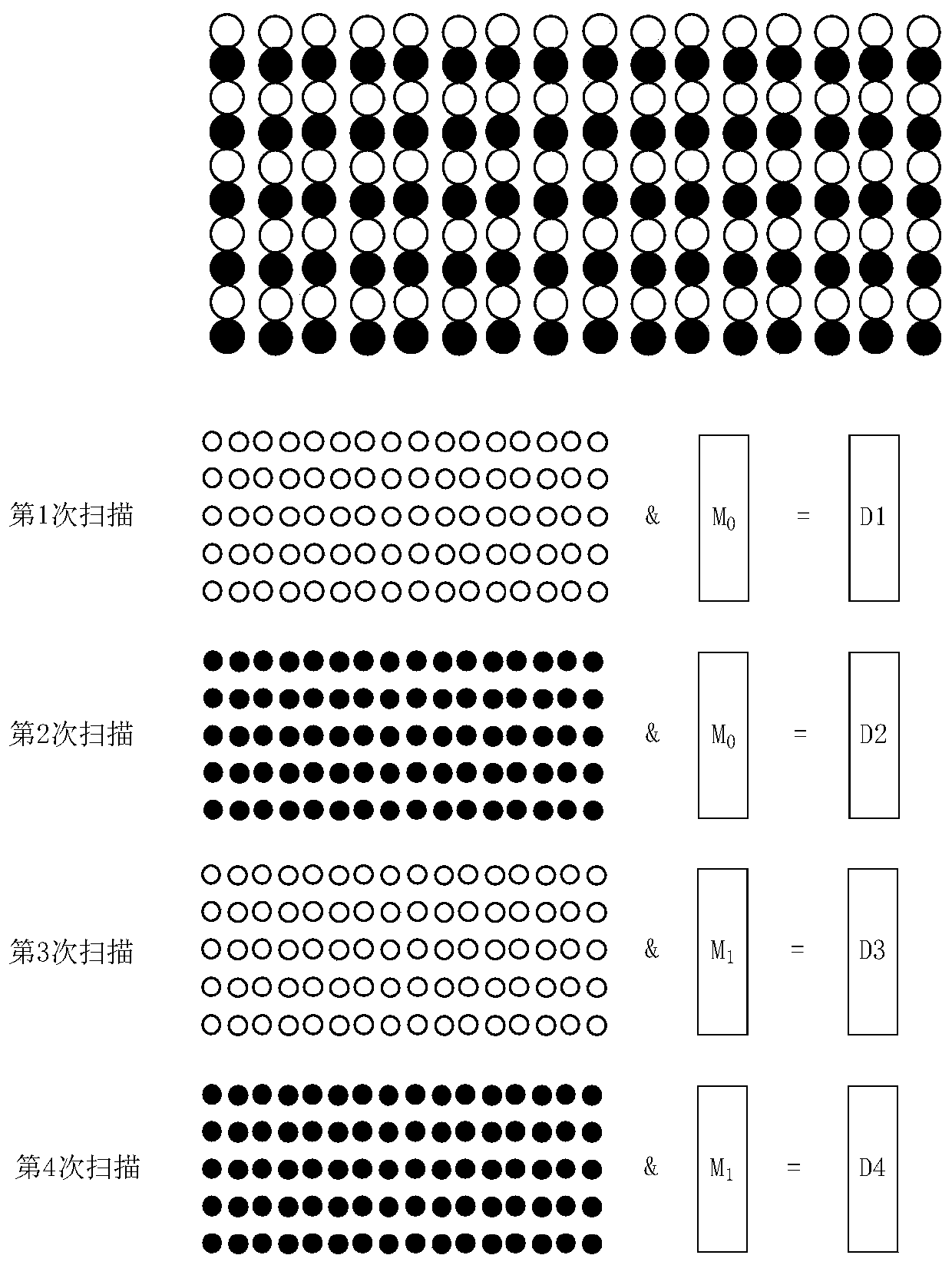

Image printing device, control method, storing medium and program

InactiveCN1390703APrint smoothlyQuality improvementProgram controlOther printing apparatusEngineeringPaper sheet

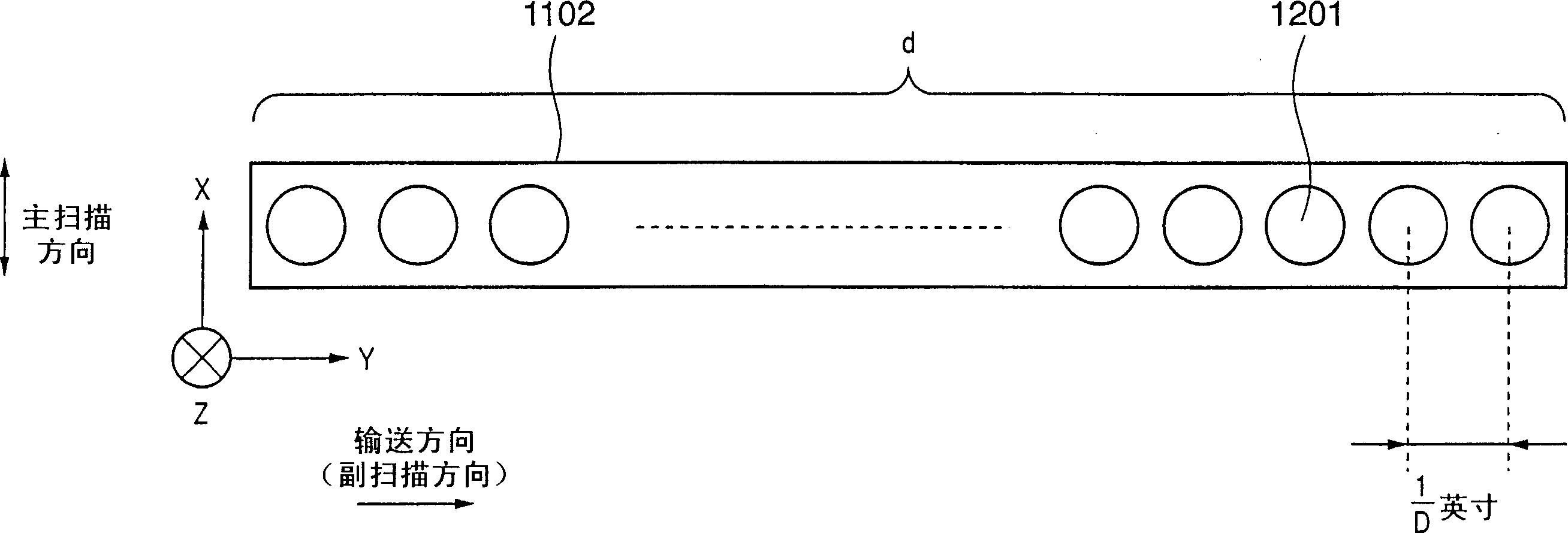

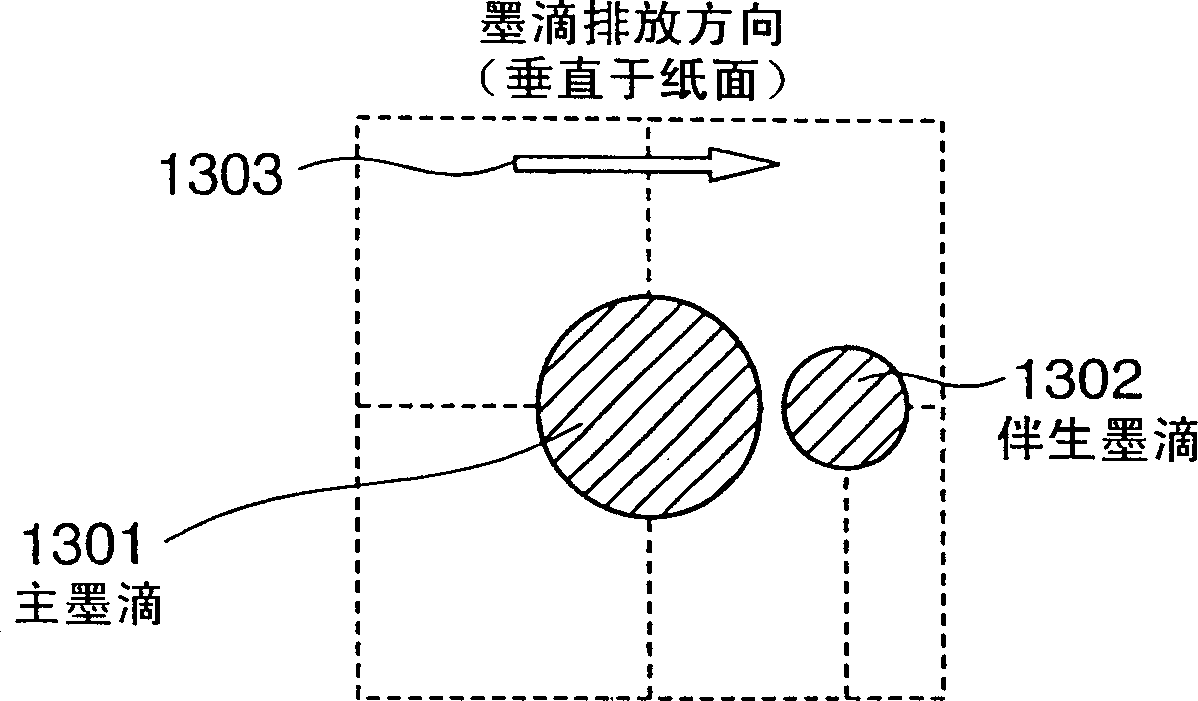

Printing of a unit pixel (1 / D = 1 / 600) in 4-pass printing (64 nozzles, and a total sheet supply amount of 62 / 600 in four operations) is exemplified in an image printing apparatus capable of printing a uniform, high-quality image while avoiding printing of a visually nonuniform image in multipass printing of two or more passes. A first pass printing dot (101) is printed using an Even nozzle by a sheet supply amount of 16 / 600 (even multiple of 1 / D) while a carriage moves in the main scanning direction (main droplet and satellite land apart from each other). A second pass printing dot (102) is printed using an Odd nozzle by a sheet supply amount is 15 / 600 (odd multiple of 1 / D) while the carriage moves in a direction opposite to the main scanning direction (main droplet and satellite land apart from each other). A third pass printing dot (103) is printed using an Odd nozzle by a sheet supply amount of 16 / 600 (even multiple of 1 / D) while the carriage moves in the main scanning direction (main droplet and satellite land close to each other). A fourth pass printing dot (104) is printed using an Odd nozzle while the carriage moves in a direction opposite to the main scanning direction (main droplet and satellite land close to each other). By repeating this operation, satellites can be uniformly printed on the right and left of a unit pixel.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com