Method for preparing nano-phase reinforced nickel-based superalloy by adopting micron ceramic particles

A nickel-based superalloy, ceramic particle technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problems of low cost, poor wettability, poor interface bonding between substrates, etc. The effect of fine grains, excellent mechanical properties and uniform phase distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

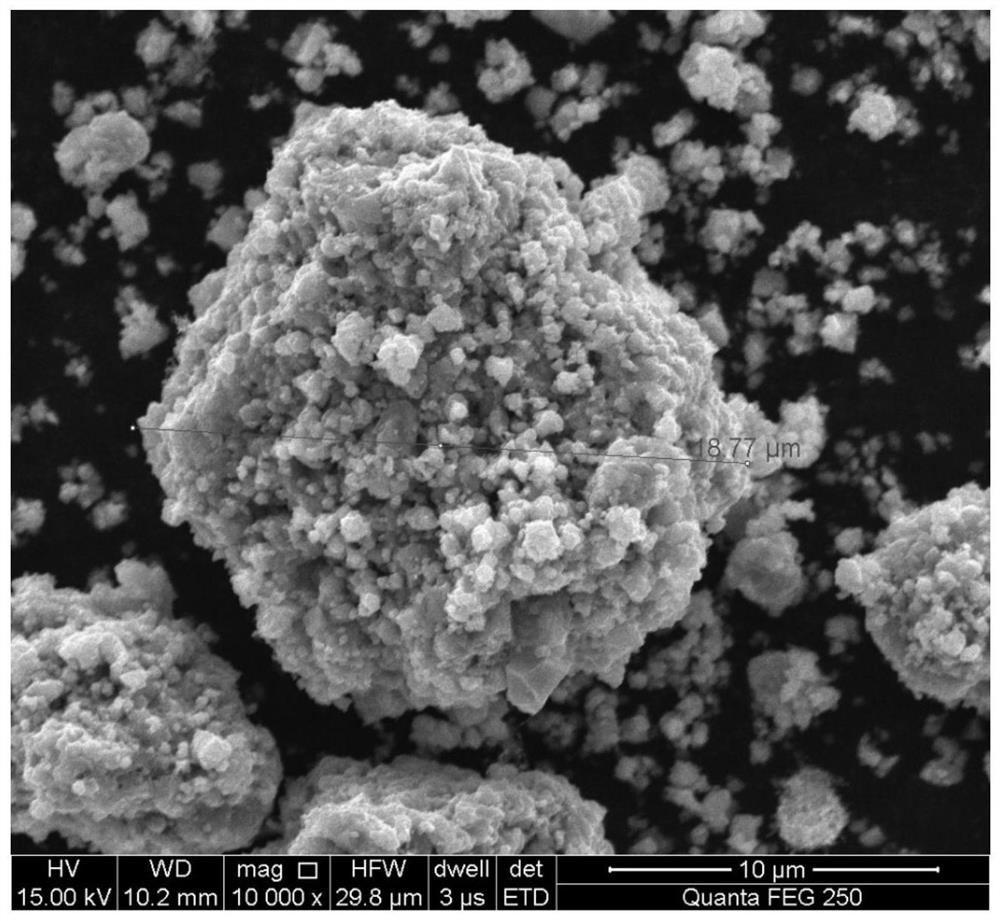

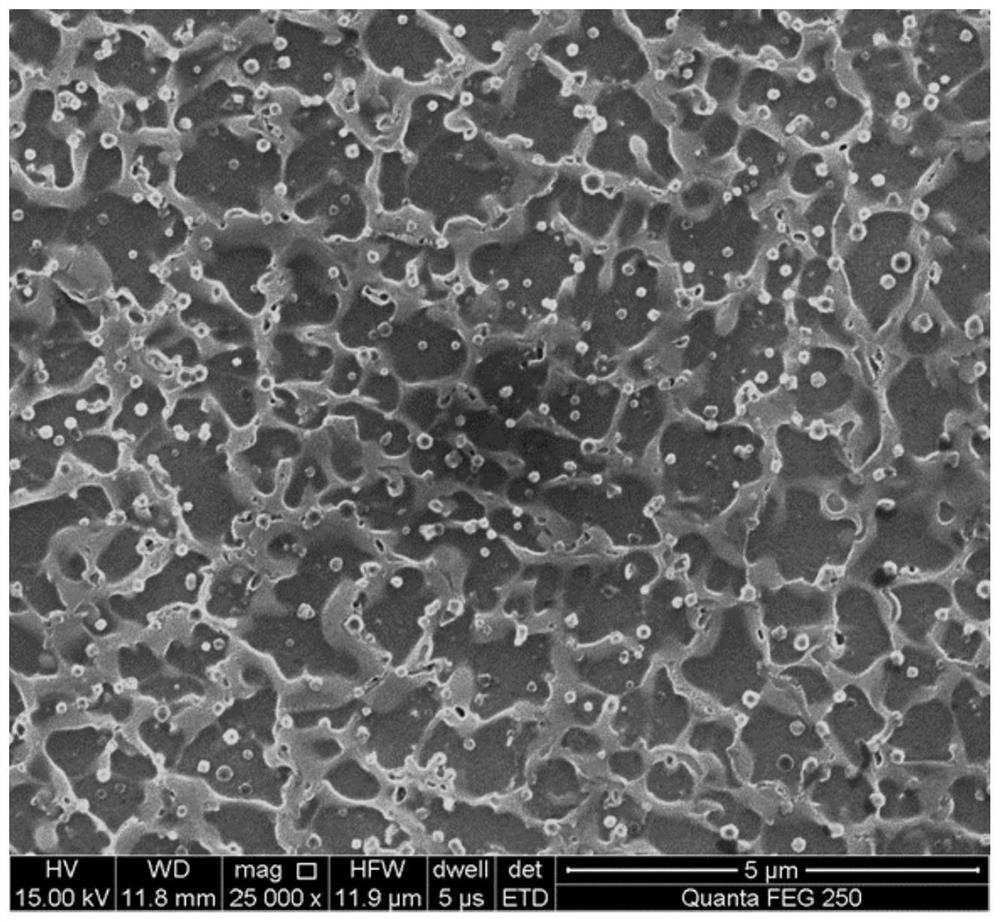

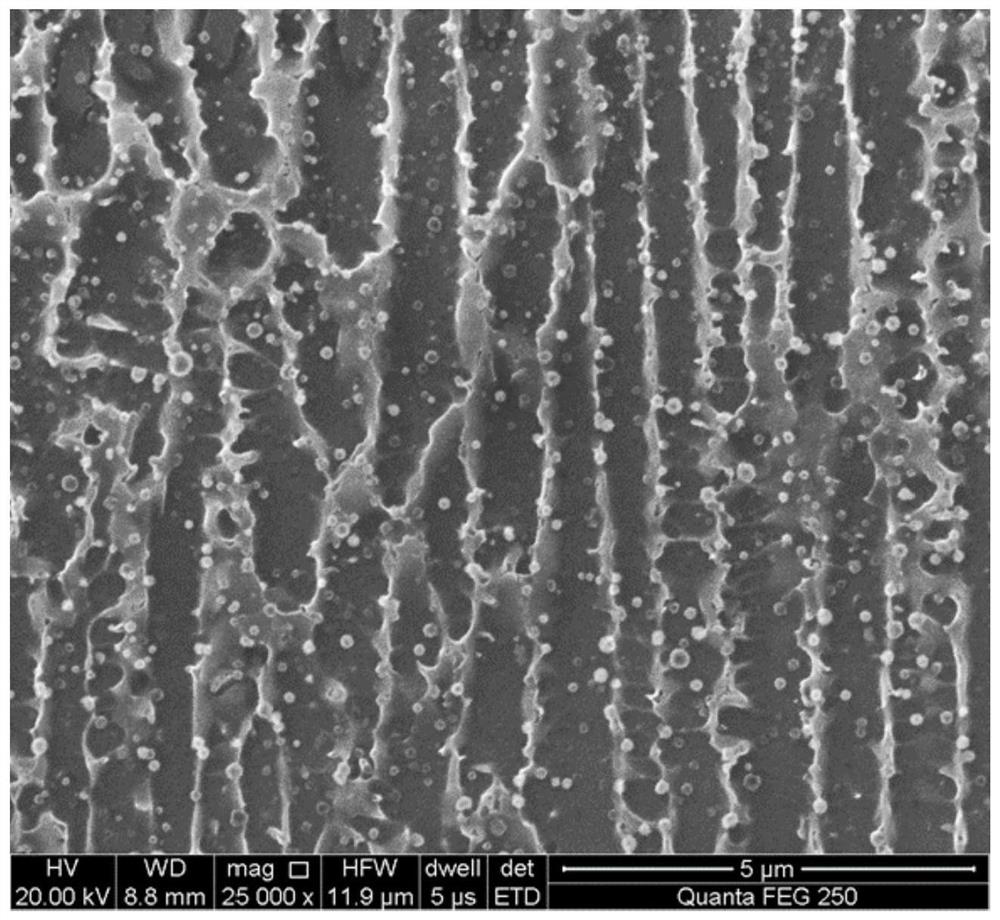

[0037] A method for preparing nano-phase reinforced nickel-based superalloys by using micron ceramic particles, using René 104 nickel-based superalloy as a matrix, using TiC ceramic particles with an average particle size of 1.5 μm as a reinforcing phase, and adding a mass percentage of 2.0%.

[0038] The matrix material is René104 nickel-based superalloy spherical powder with a particle size of 15-53 μm. The composition of René104 nickel-based superalloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9Nb ~0.05Zr~0.03B~0.04C~the balance is Ni.

[0039] The preparation steps of the nano-ceramic particle reinforced nickel-based superalloy composite material are as follows:

[0040] (1) First mix the TiC ceramic particles with an average particle size of 1.5 μm and part of the René104 nickel-based superalloy powder (the ratio is 2:3), and then use a high-energy ball mill to perform wet grinding and dry grinding on the mixed powder, Obtain a composite powder with uniform distribu...

Embodiment 2

[0052] A method for preparing nano-phase reinforced nickel-based superalloys by using micron ceramic particles, using René 104 nickel-based superalloy as the substrate, and A1 with an average particle size of 2.0 μm 2 o 3 The ceramic particles are the reinforcing phase, and the added mass percentage is 3.0%.

[0053] The matrix material is René104 nickel-based superalloy spherical powder with a particle size of 15-53 μm. The composition of René104 nickel-based superalloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9Nb ~0.05Zr~0.03B~0.04C~the balance is Ni.

[0054] The preparation steps of the nano-ceramic particle reinforced nickel-based superalloy composite material are as follows:

[0055] (1) First mix the TiC ceramic particles with an average particle size of 1.5 μm and part of the René104 nickel-based superalloy powder (the ratio is 1:2), and then use a high-energy ball mill to perform wet grinding and dry grinding on the mixed powder, Obtain a composite powder wit...

Embodiment 3

[0063] A method for preparing nano-phase reinforced nickel-based superalloys using micron ceramic particles, using René 104 nickel-based superalloy as a substrate, and using TiC ceramic particles with an average particle size of 1.5 μm and WC ceramic particles with an average particle size of 2.5 μm as reinforcement Phase, the added mass fraction is 1.5%.

[0064] The matrix material is René104 nickel-based superalloy spherical powder with a particle size of 15-53 μm. The composition of René104 nickel-based superalloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9Nb ~0.05Zr~0.03B~0.04C~the balance is Ni.

[0065] The preparation steps of the nano-ceramic particle reinforced nickel-based superalloy composite material are as follows:

[0066] (1) First mix the TiC ceramic particles with an average particle size of 1.5 μm and part of the René104 nickel-based superalloy powder (the ratio is 1:2), and then use a high-energy ball mill to perform wet grinding and dry grinding on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com