Liquid-state food material 3D printing device

A 3D printing and food material technology, applied in the field of 3D printing, can solve the problems of high requirements on printing raw materials (such as only using food materials in a certain state, bulky printing mechanism, single printing function, etc.), achieving low cost and high printing accuracy. , The effect of uniform delivery of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

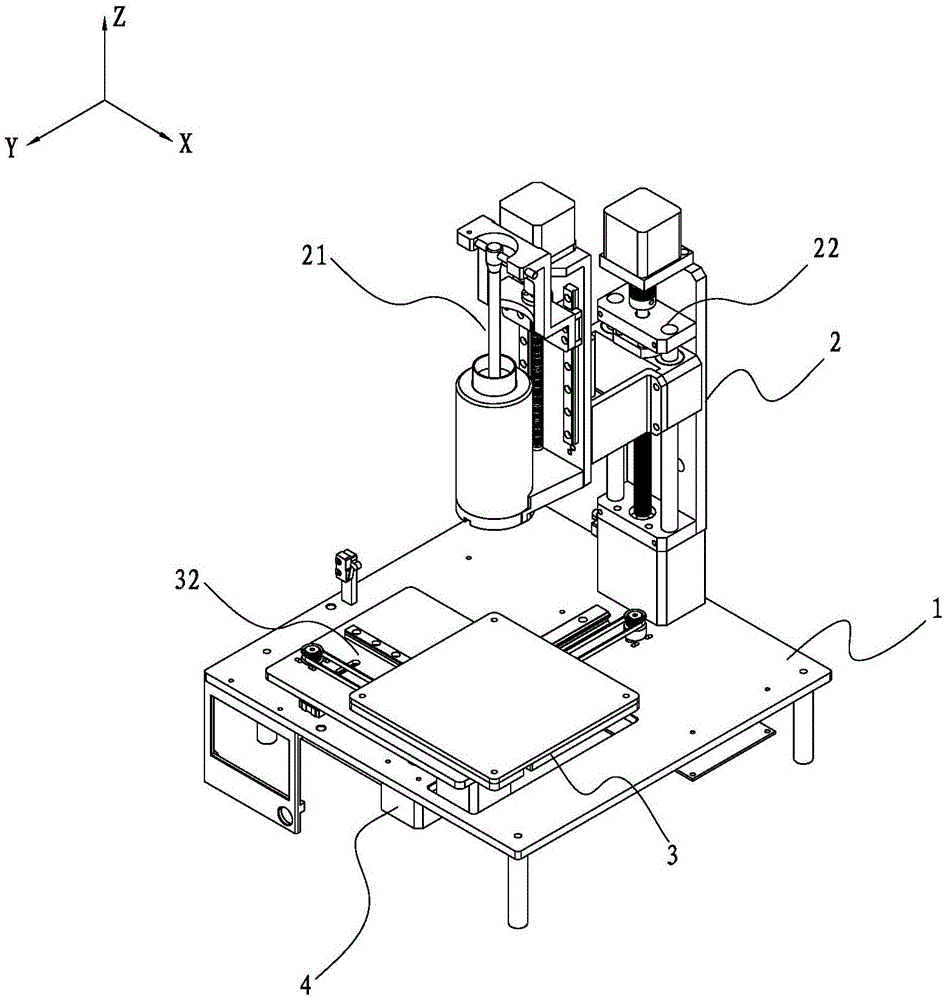

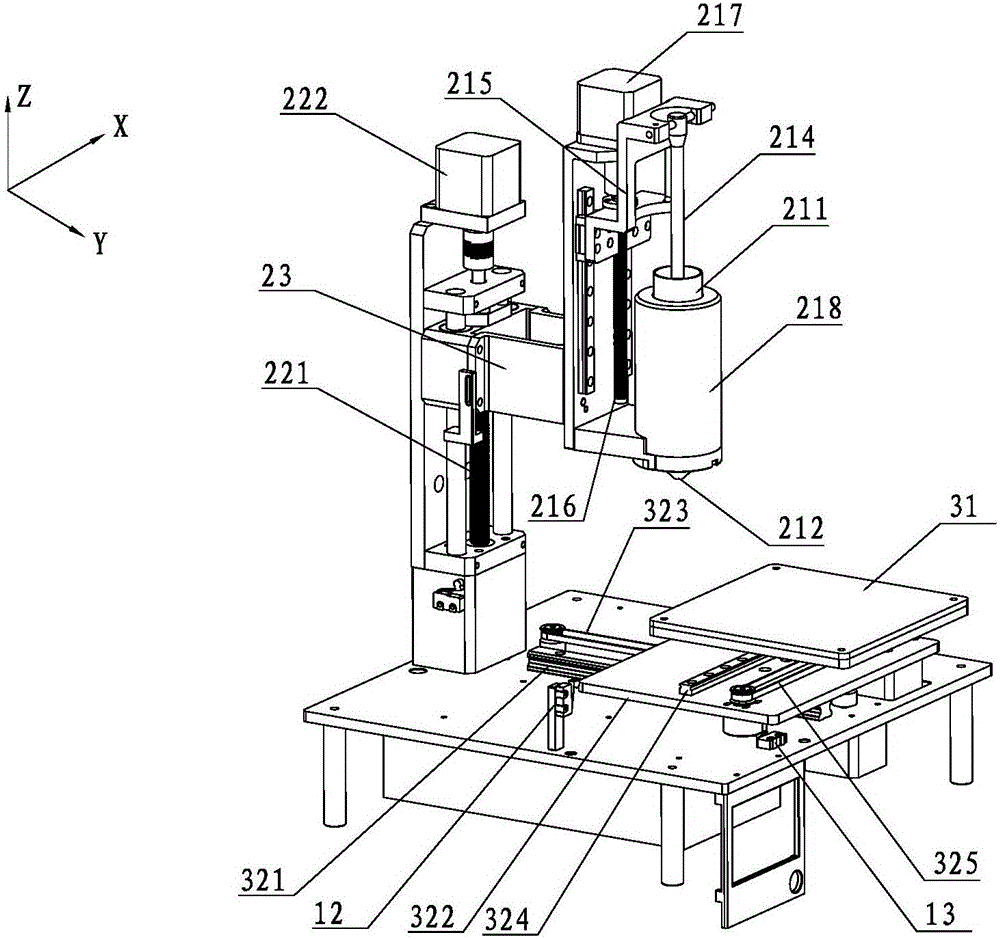

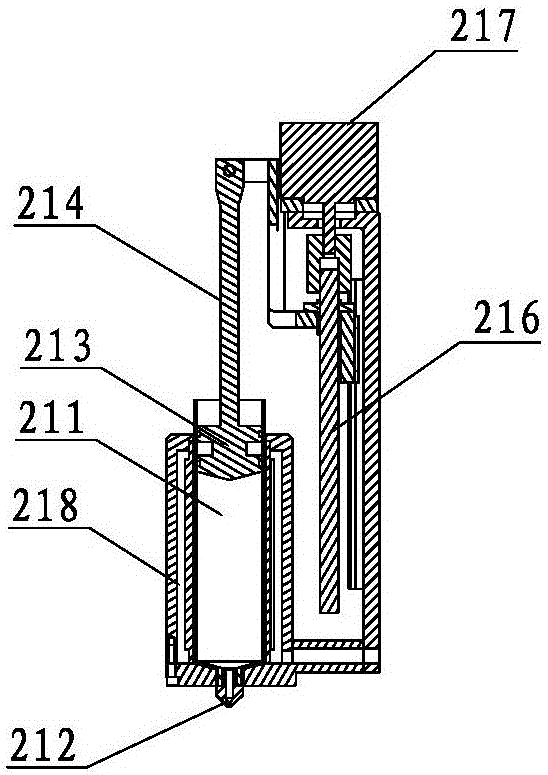

[0019] Such as Figure 1~3 As shown, a liquid food material 3D printing device includes a machine base 1 , and a printing mechanism 2 , a translation mechanism 3 and a control mechanism 4 arranged on the machine base 1 . Wherein, the printing mechanism 2 includes a printing head assembly 21, and a driving assembly 22 that drives the printing head assembly 21 to move on a vertical plane, and the driving assembly 22 of the printing mechanism 2 includes a vertically arranged first lead screw 221, which is connected to the first The first drive motor 222 connected to the lead screw 221, the print head assembly 21 is connected to the first lead screw 221 through the connector 23, and the print head assembly 21 is driven up and down in the Z-axis direction by the first drive motor 222 and the first lead screw 221 Movement; the print head assembly 21 includes a raw material barrel 211 for holding printing materials, the bottom of the raw material barrel 211 is provided with a print h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com