3D-printing thermoplastic polyurethane material and preparation method of same

A thermoplastic polyurethane and 3D printing technology, applied in the field of polymer materials and 3D printing polymer preparation, can solve the problems of low melting temperature, large dimensional shrinkage and high price, and achieve the effects of low surface energy, stable size and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of 3D printing thermoplastic polyurethane material comprising the following steps:

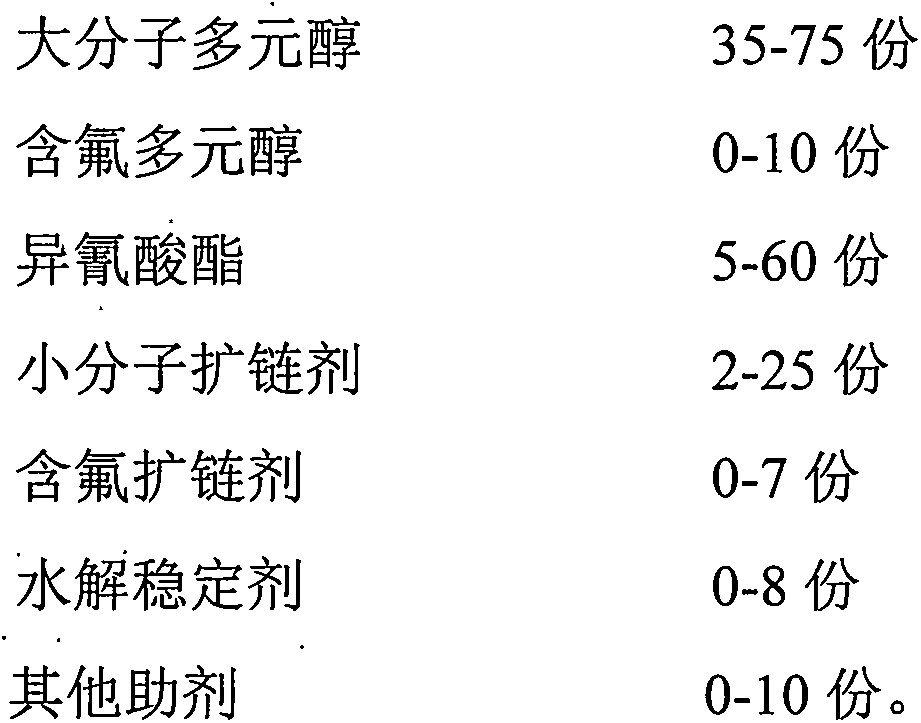

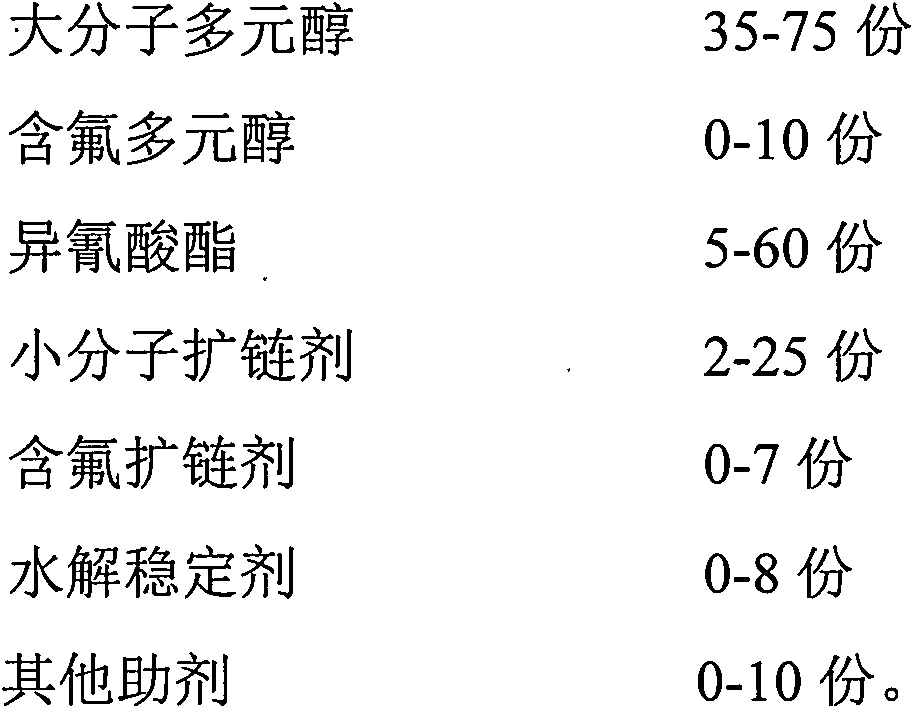

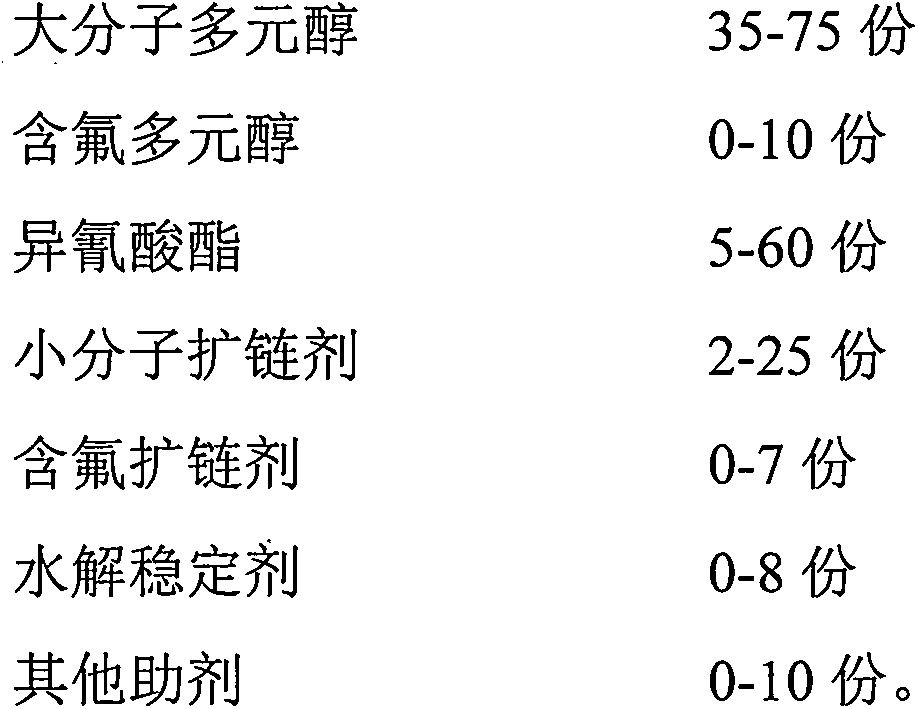

[0025] Step 1: Weigh 35-75 parts of macromolecular polyol, 0-10 parts of fluorine-containing polyol, 2-25 parts of small molecule chain extender, 0-7 parts of fluorine-containing chain extender, and 0-8 parts of hydrolysis stabilizer , 0-10 parts of other additives, placed at 30-150°C for melting and dehydration for 2-4 hours;

[0026] Step 2: Add the melted and dehydrated macromolecular polyol, fluorine-containing polyol, small molecule chain extender, hydrolysis stabilizer and other additives, and 5-60 parts of isocyanate melted at 50-120°C to the twin-screw reactive extrusion at the same time. The reaction is carried out in the machine, and the extrusion temperature is 130-250 ° C to obtain thermoplastic polyurethane composite material particles through underwater pelletizing;

[0027] Step 3: Put the obtained thermoplastic po...

Embodiment 1

[0029] Weigh and weigh 35 parts of polytetrahydrofuran ether diol, 2 parts of 1,4-butanediol, 7 parts of 2,2,3,3,4,4,5,5-octafluoro-1,6-hexanediol , respectively placed at 70°C for melting and dehydration for 3 hours (hours). Melt dehydrated polytetrahydrofuran ether diol, 2,2,3,3,4,4,5,5-octafluoro-1,6-hexanediol, 1,4-butanediol and melt at 80°C 5 parts of diphenylmethane diisocyanate were simultaneously added into a twin-screw reaction extruder for reaction, and the extrusion temperature was 130°C. The thermoplastic polyurethane composite material pellets are obtained through underwater pelletizing. The obtained thermoplastic polyurethane composite material particles were dried and aged in a vacuum oven at 150°C for 9 hours to obtain the required 3D printing thermoplastic polyurethane material.

[0030] The obtained 3D printing thermoplastic polyurethane material has a tensile strength of 33MPa and an elongation at break of 649%.

Embodiment 2

[0032]Weigh 51 parts of polyoxypropylene glycol, 6 parts of hexafluorobenzenehexafluoropentanediol, and 15 parts of 1,3-propanediol, and place them at 30° C. for melting and dehydration for 4 hours. Polyoxypropylene glycol, hexafluorobenzenehexafluoropentanediol, 1,3-propanediol, 2 parts of carbodiimide, 5 parts of montmorillonite and 30 parts of toluene diisocyanate melted at 50°C were melted and dehydrated at the same time. Add it to a twin-screw reaction extruder for reaction, and the extrusion temperature is 200°C. The thermoplastic polyurethane composite material pellets are obtained through underwater pelletizing. The obtained thermoplastic polyurethane composite material particles were dried and aged in a vacuum oven at 100°C for 50 hours to obtain the desired 3D printing thermoplastic polyurethane material.

[0033] The obtained 3D printing thermoplastic polyurethane material has a tensile strength of 27MPa and an elongation at break of 549%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com