Method for preparing lignin sulfonate by utilizing papermaking black liquid

A technology of sulfonated lignin and papermaking black liquor, which is applied in the field of papermaking, can solve the problems affecting the performance of sulfonated products and the low value of sulfonated degree, so as to achieve low content of total reducing substances, reduce the generation of by-products, effective response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

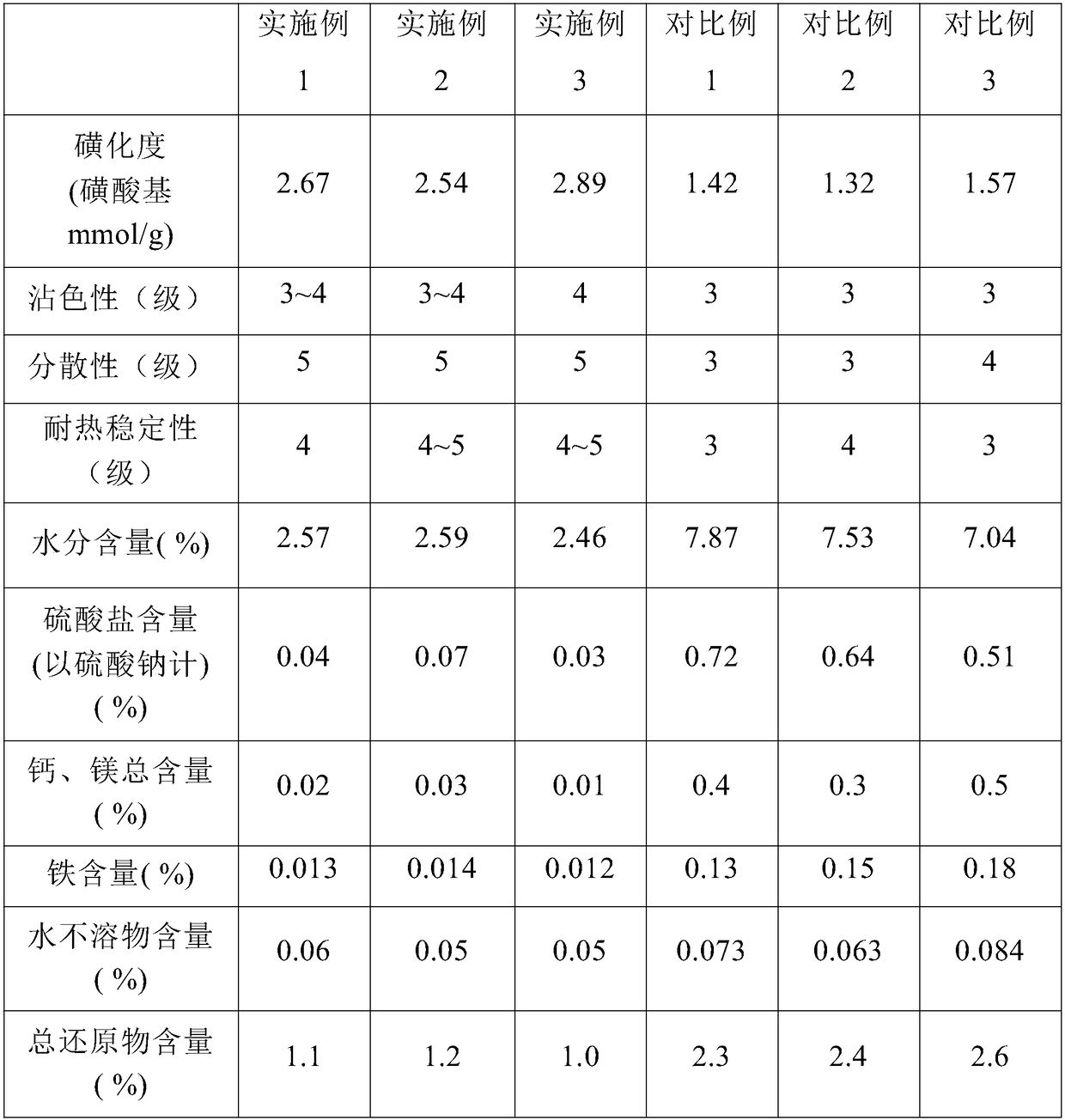

Examples

Embodiment 1

[0020] A method of utilizing papermaking black liquor to prepare sulfonated lignin, comprising the following steps:

[0021] S1, material preparation: prepare sulfate pulping black liquor, anhydrous sodium sulfite, formaldehyde raw materials, the amount of sodium sulfite is 2.9mmol / g lignin; the amount of formaldehyde is 0.8mmol / g lignin, and it is formulated into a mass concentration of 30% formaldehyde solution;

[0022] S2. Reaction: First, add sulfate pulping black liquor into the 3L stainless steel high-pressure reactor, then add sodium sulfite and formaldehyde solution, close the reactor, open the stirrer, set the stirring speed to 130r / min, and electrify to heat up, gradually heat up , when the reaction temperature reaches 105°C, open the vent valve for a small vent for 1min, then close the vent valve and continue heating until the temperature in the reactor reaches 158°C, and continue to stir the reaction at this temperature for 3.5h to control the pressure in the reac...

Embodiment 2

[0027] A method of utilizing papermaking black liquor to prepare sulfonated lignin, comprising the following steps:

[0028] S1, material preparation: prepare sulfate pulping black liquor, anhydrous sodium sulfite, formaldehyde raw materials, the amount of sodium sulfite is 3.2mmol / g lignin; the amount of formaldehyde is 1.2mmol / g lignin, and it is formulated into a mass concentration of 40% formaldehyde solution;

[0029] S2. Reaction: First, add sulfate pulping black liquor into the 250L stainless steel high-pressure reactor, then add sodium sulfite and formaldehyde solution, close the reactor, open the stirrer, set the stirring speed to 170r / min, and electrify to heat up, gradually heat up , when the reaction temperature reaches 110°C, open the vent valve for a small vent for 1min, then close the vent valve and continue heating until the temperature in the reactor reaches 165°C, and continue to stir the reaction at this temperature for 2.5h; control the pressure in the reac...

Embodiment 3

[0034] A method of utilizing papermaking black liquor to prepare sulfonated lignin, comprising the following steps:

[0035] S1, material preparation: prepare sulfate pulping black liquor, anhydrous sodium sulfite, formaldehyde raw materials, the amount of sodium sulfite is 3.0mmol / g lignin; the amount of formaldehyde is 1.0mmol / g lignin, and it is formulated into a mass concentration of 37% formaldehyde solution;

[0036] S2. Reaction: firstly add sulfate pulping black liquor into the 500L stainless steel autoclave, then add sodium sulfite and formaldehyde solution, close the reactor, open the stirrer, set the stirring speed to 150r / min, and electrify to heat up, gradually heat up , when the reaction temperature reaches 105 ℃, open the vent valve for a small vent for 1min, then close the vent valve and continue heating until the temperature in the reactor reaches 160 ℃, and continue to stir the reaction at this temperature for 3.0h; control the pressure in the reactor not mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com