Patents

Literature

78results about How to "Less moisture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

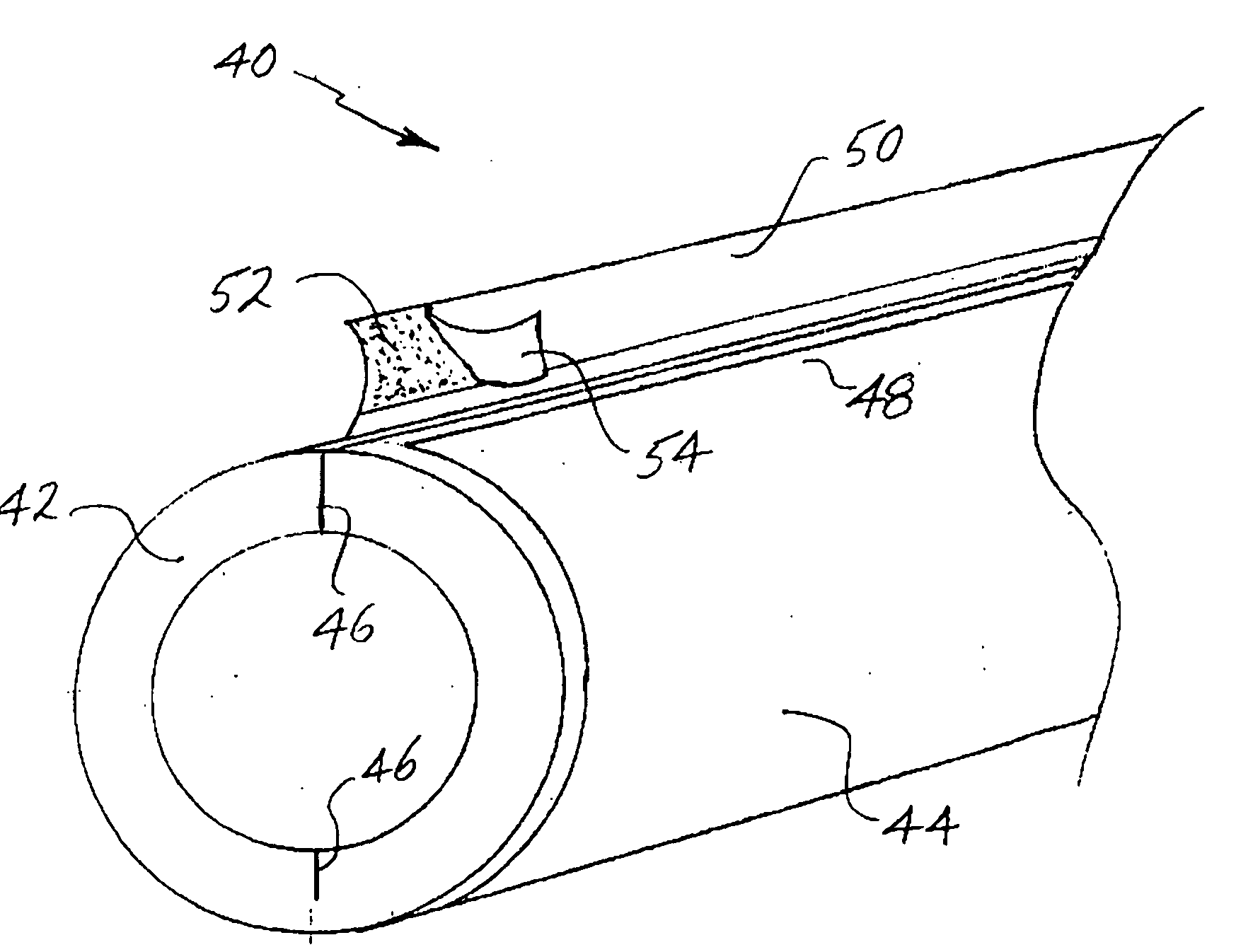

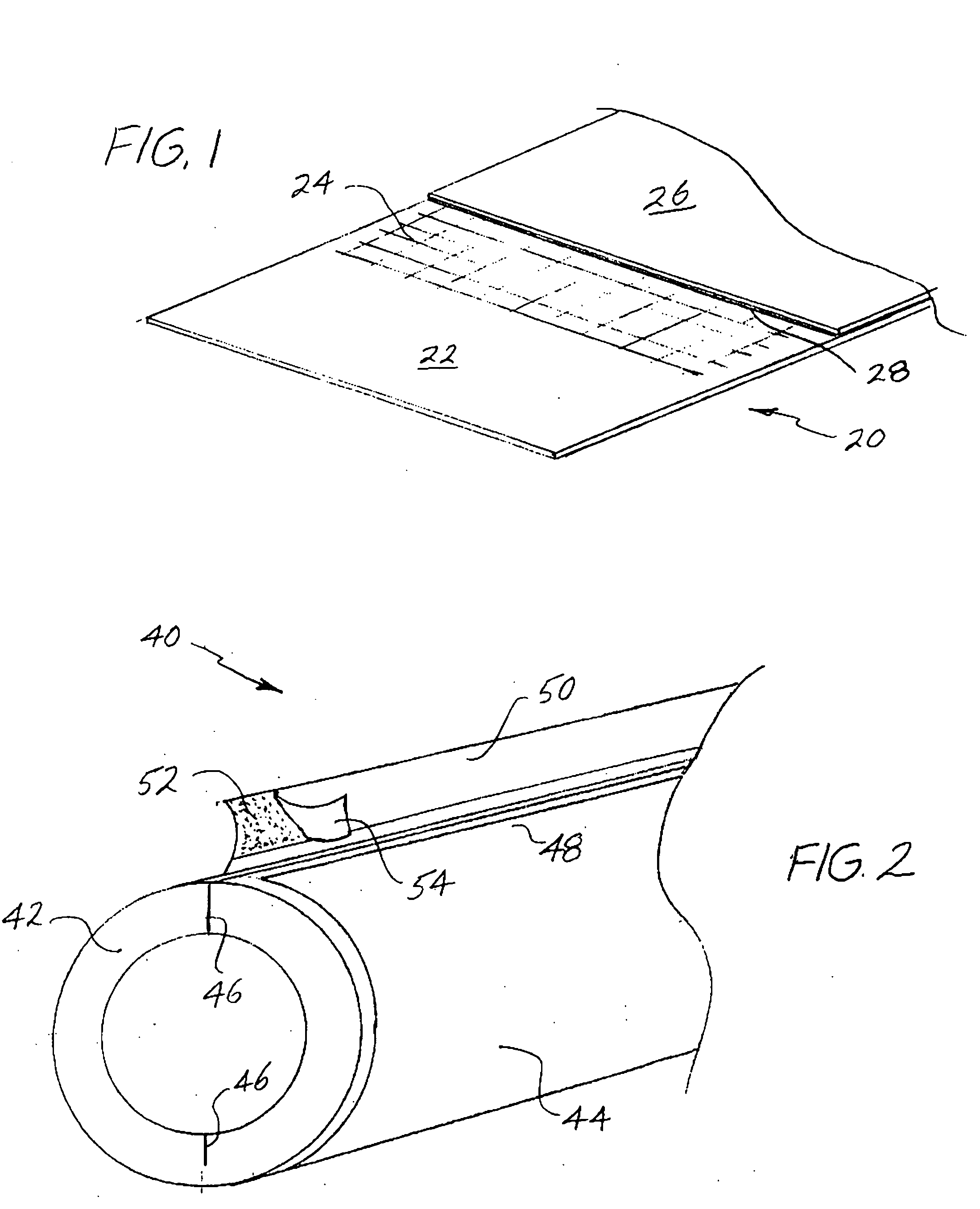

Facing and faced insulation products

ActiveUS20080081138A1Less moistureLess expansionPipe protection by thermal insulationGlass/slag layered productsWood veneerFiber

A facing laminate for insulation products includes: a foil or metallized polymeric film sheet layer forming an inner layer of the laminate that is adapted be bonded directly to a surface of an insulation product; a paper composite sheet layer, which may include synthetic and / or inorganic fibers, forming an outer exposed layer of the laminate; and a scrim intermediate and bonded to the foil or metallized polymeric film sheet and paper composite sheet layers. The facing laminate may include a humectant and / or a water, oil, and / or grease repellant component. The paper composite sheet layer of the laminate exhibits greater dimensional stability and reduced wrinkling when the laminate is exposed to conditions of high humidity. Insulation products to be faced with this facing laminate include pipe insulation, duct board, duct wrap insulation, metal building insulation, and other building insulation products.

Owner:JOHNS MANVILLE CORP

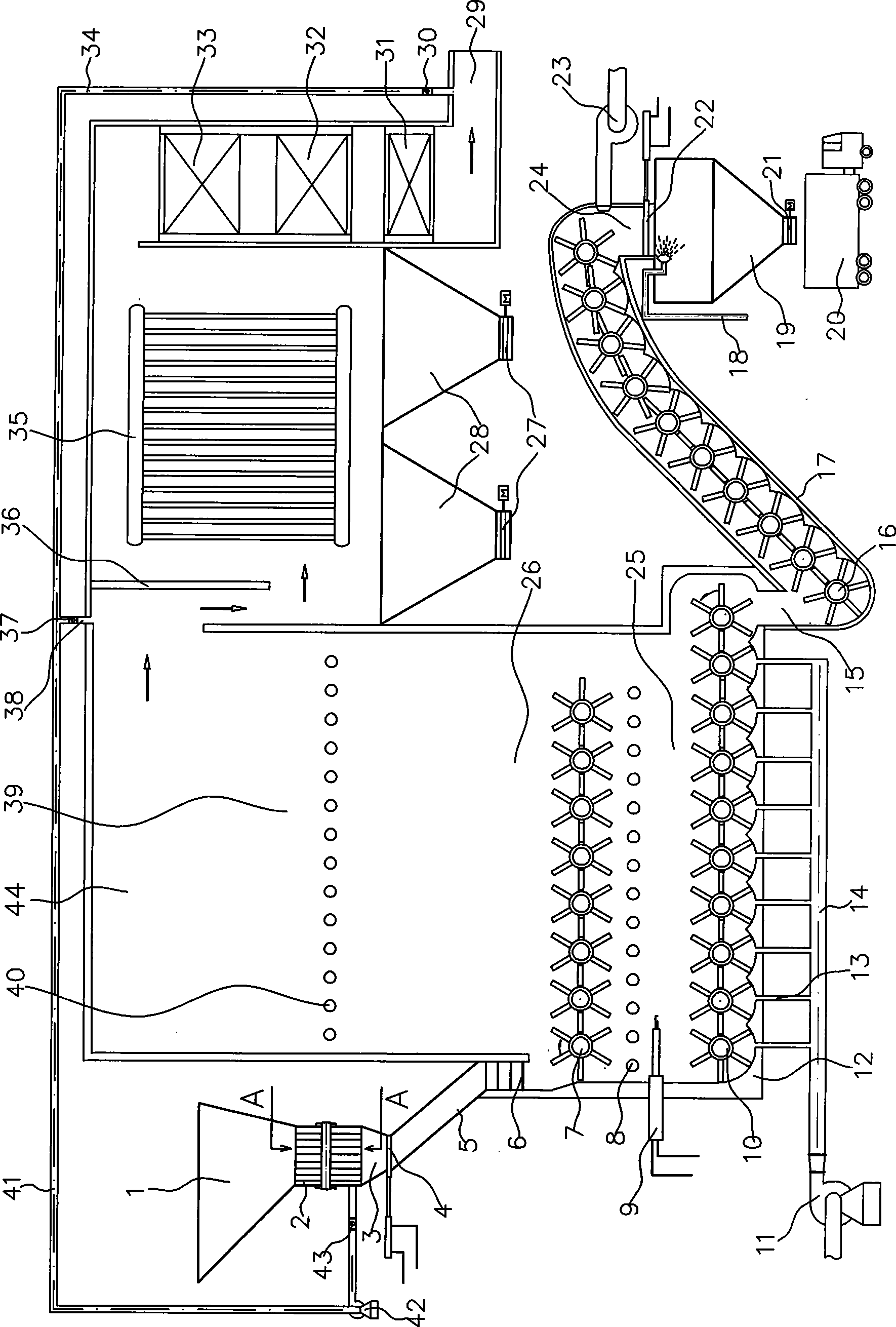

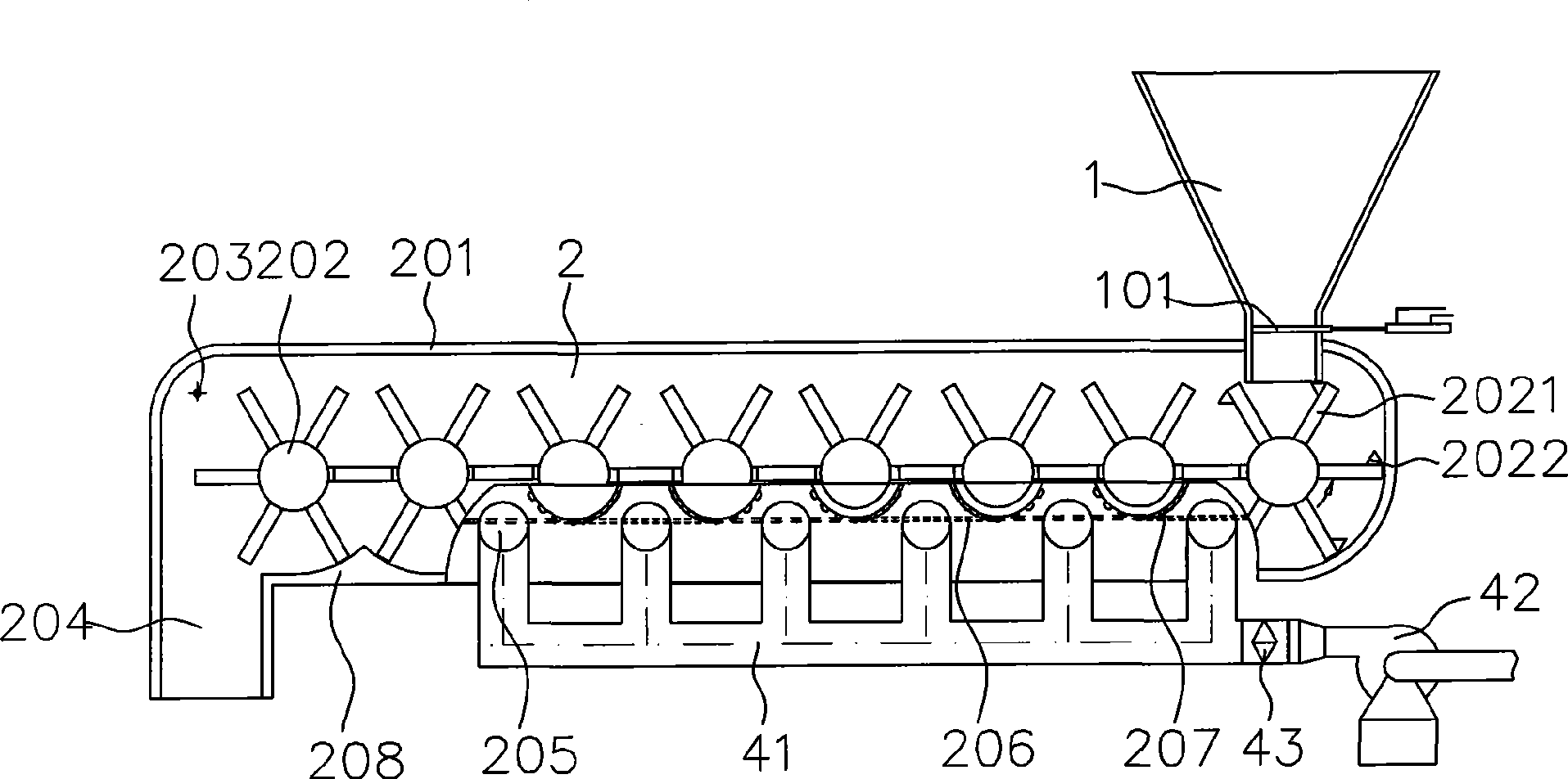

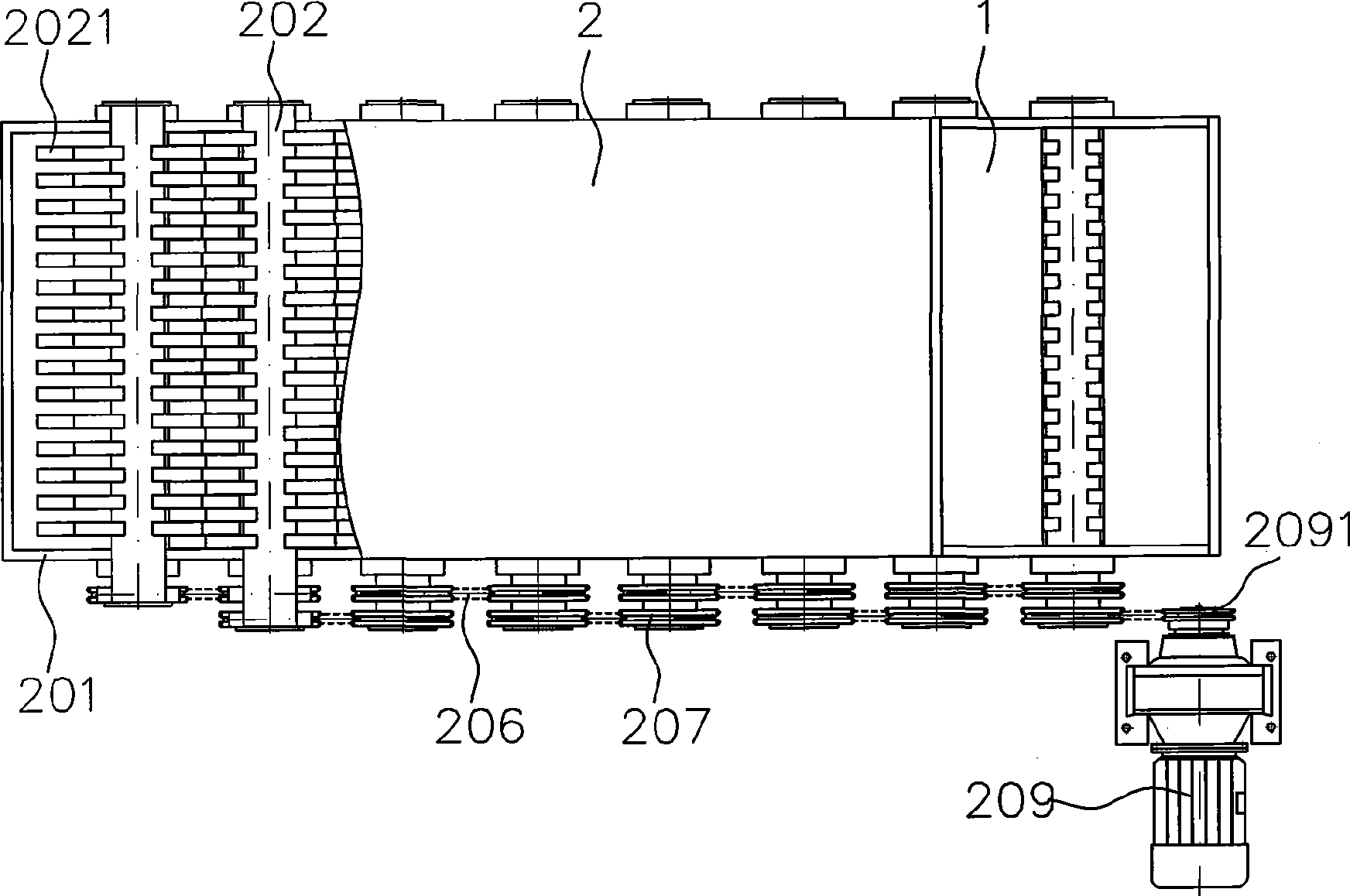

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

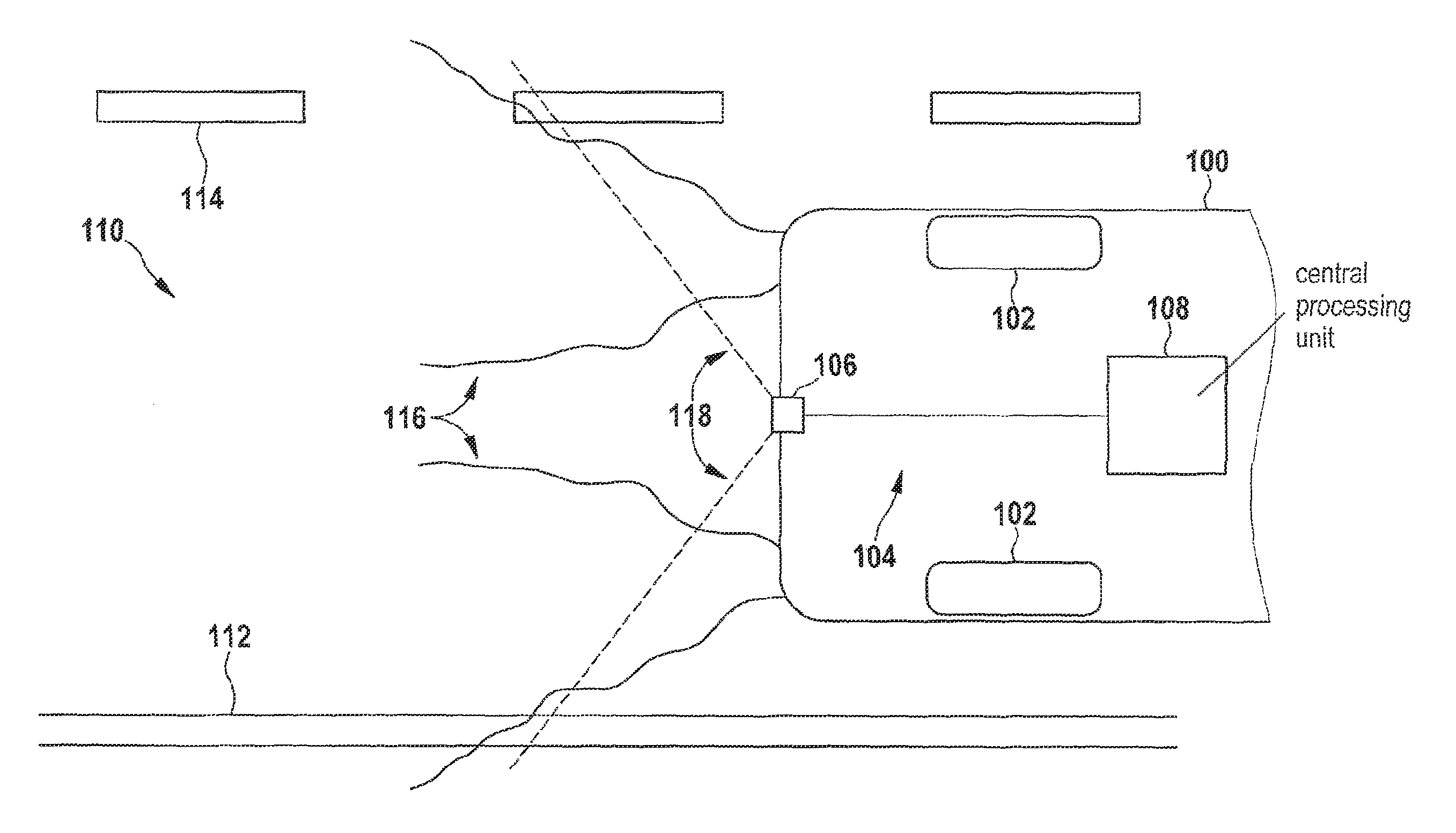

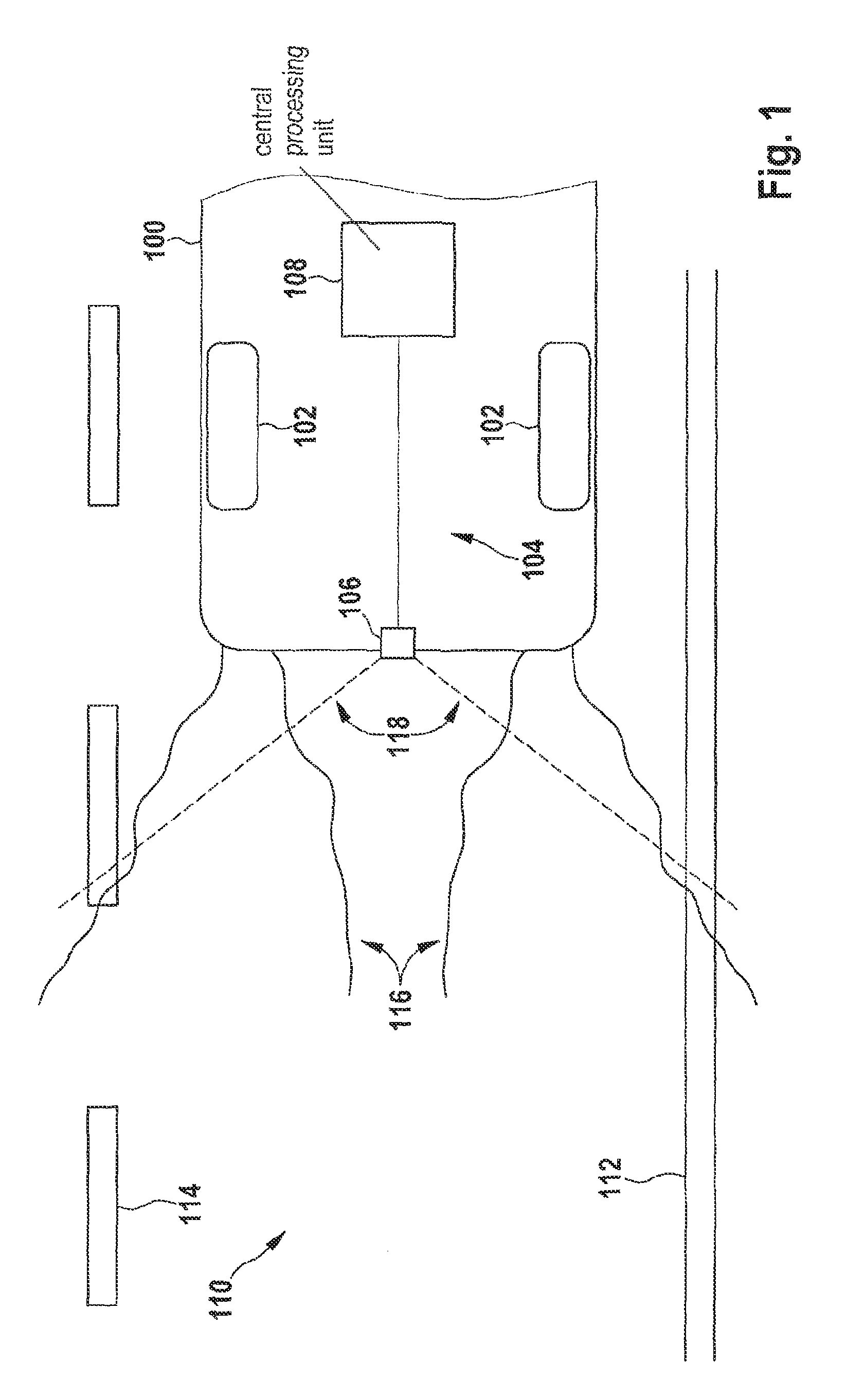

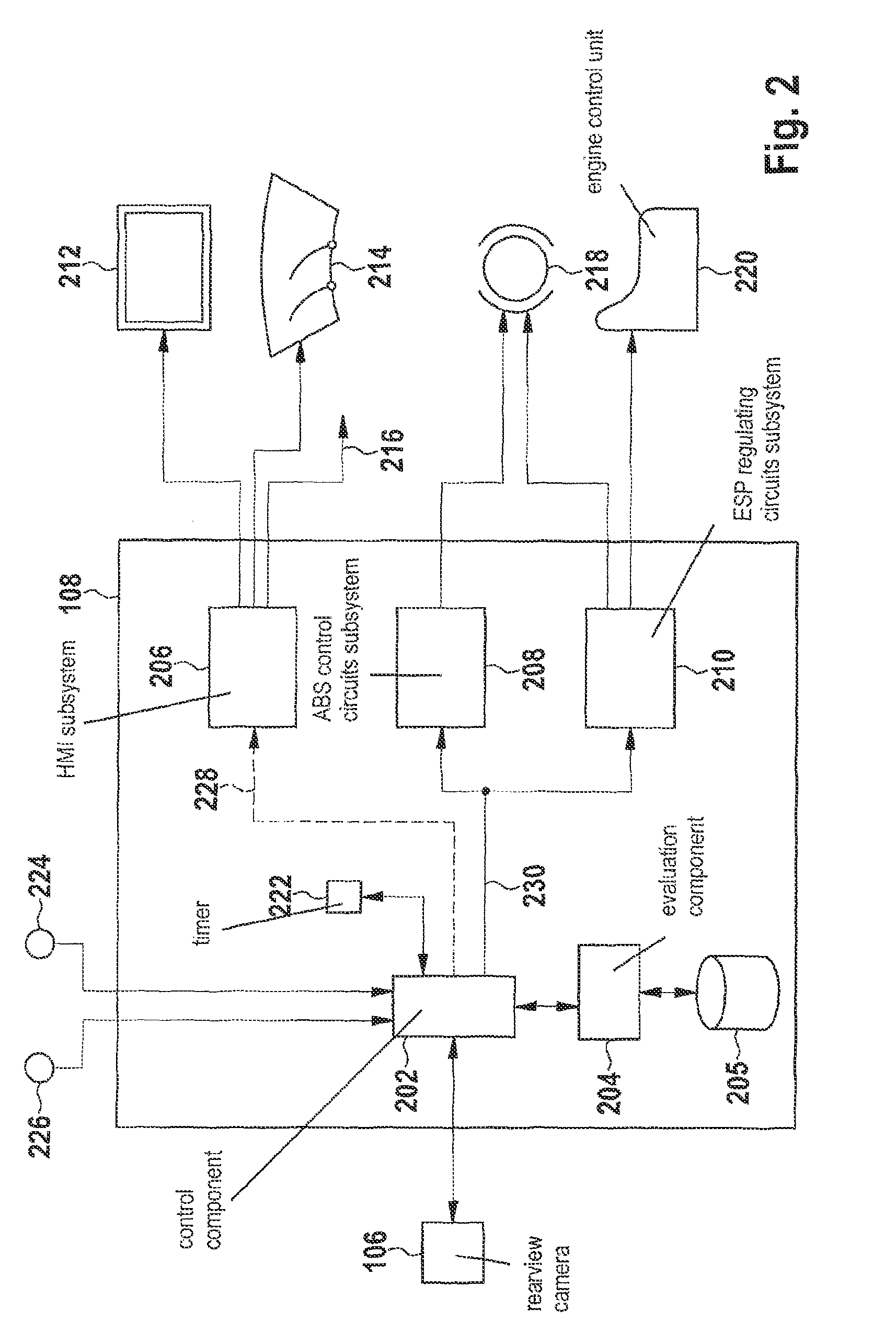

Method for detecting a wet road

ActiveUS9272676B2Eliminate needLess moistureVehicle headlampsAnalogue computers for trafficDriver/operatorEngineering

Methods in a driver assistance system of a vehicle for detecting wetness on a road surface as well as a corresponding driver assistance system having a rearview camera are described. The method may include the following: recording an image of an area located behind the rear end of the vehicle, using the rearview camera; evaluating the recorded image for the presence of a spray trail caused by the vehicle; and selectively outputting, based on the evaluation, a wetness signal for triggering an automatic response by the driver assistance system to the wet road surface.

Owner:ROBERT BOSCH GMBH

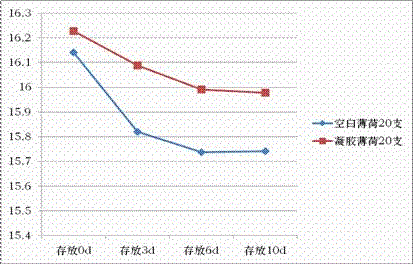

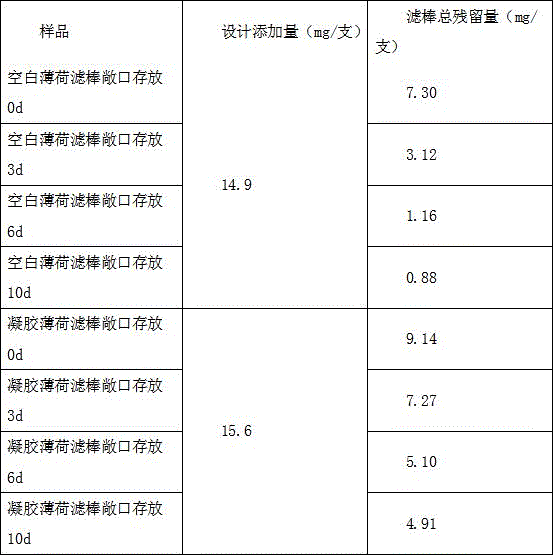

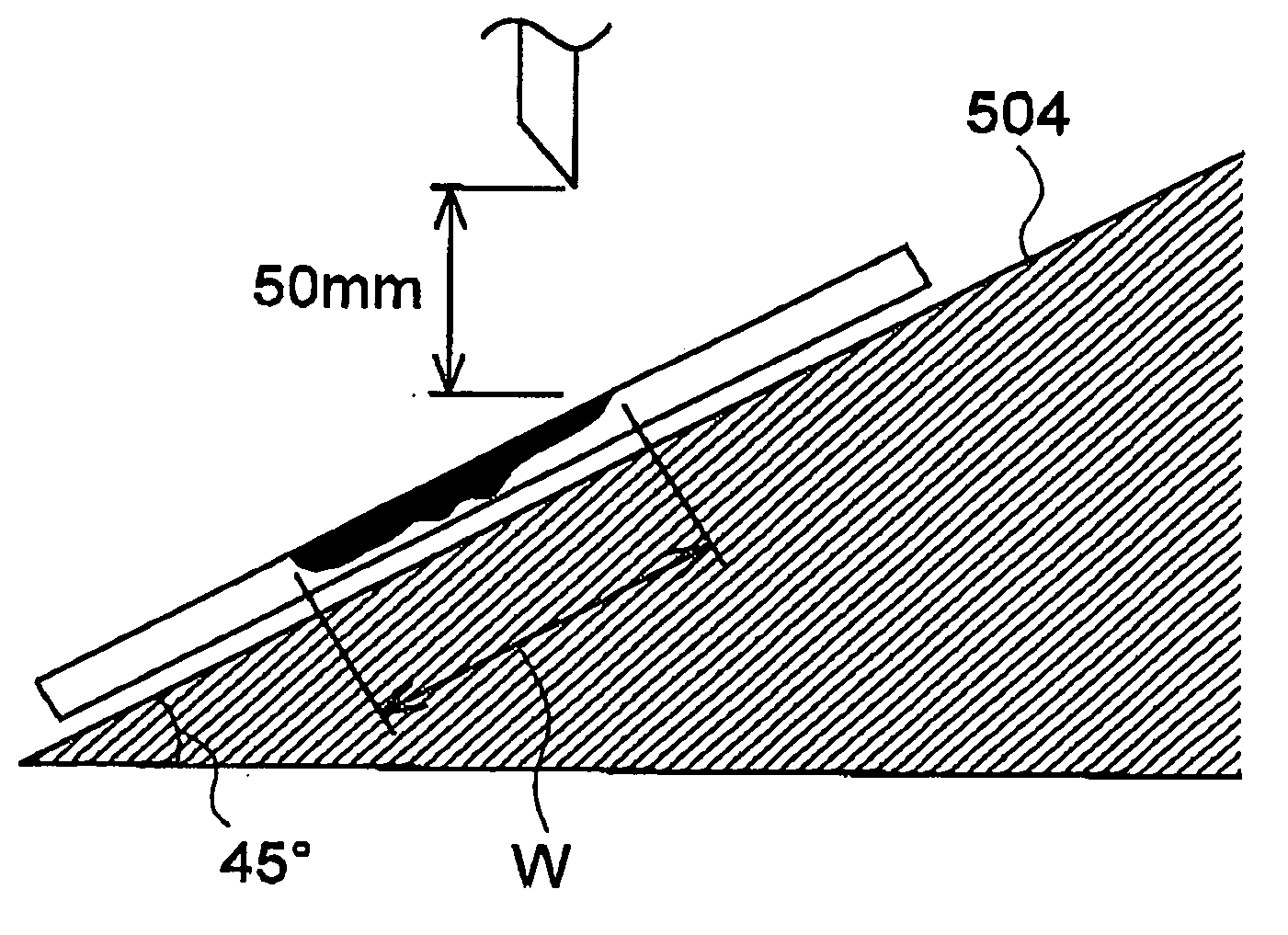

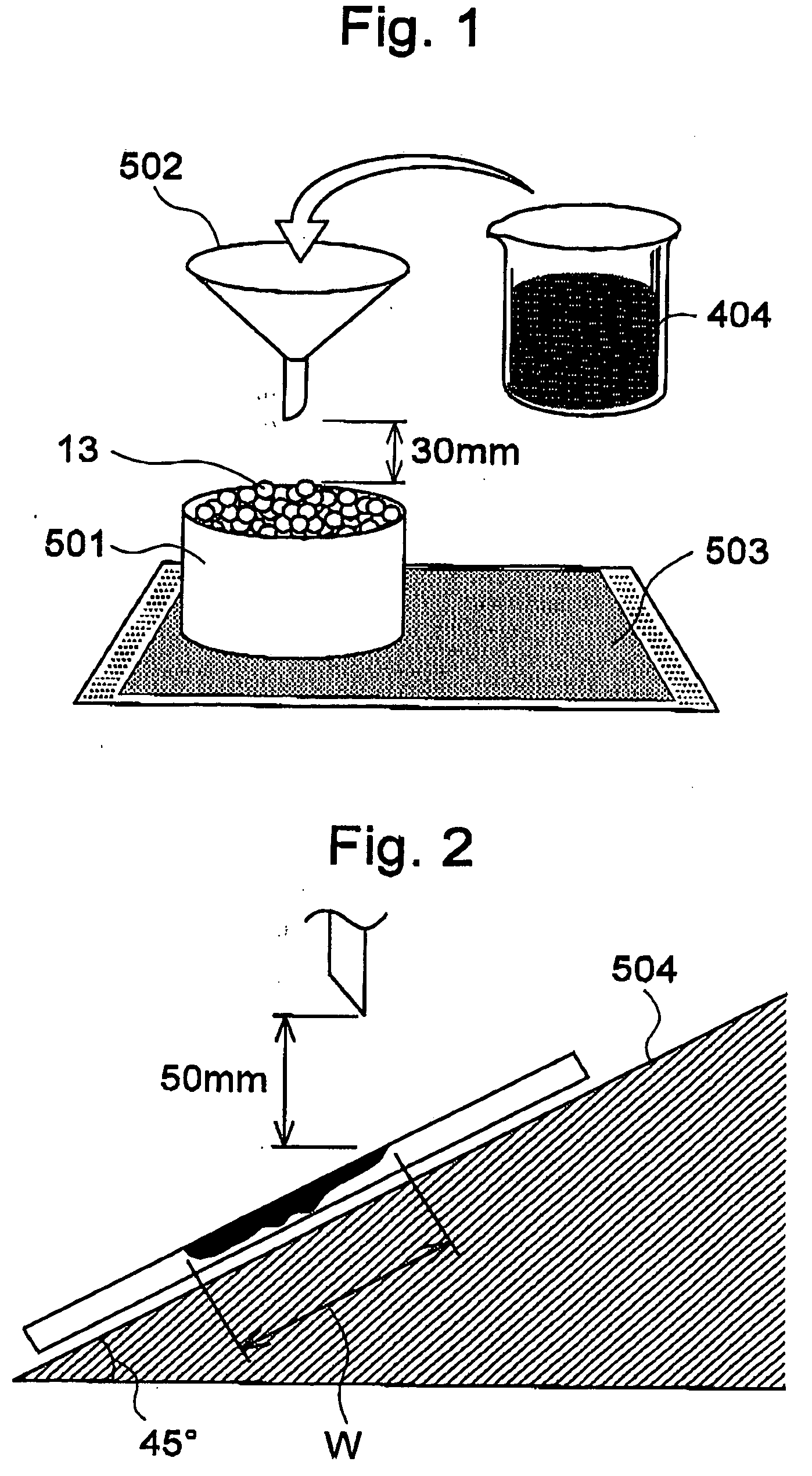

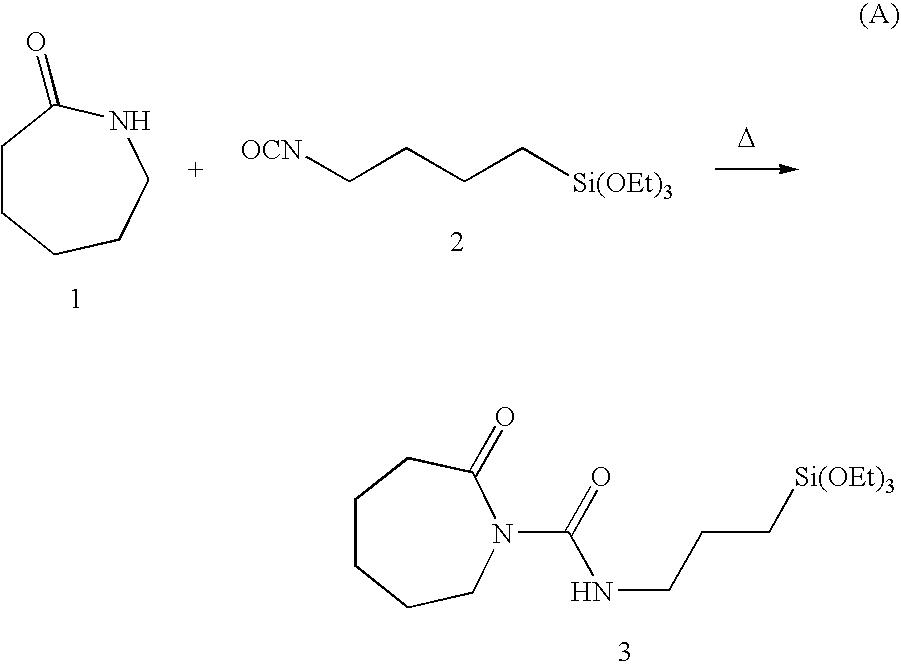

Temperature-variable controlled-release gel composite material and application thereof in cigarette filter stick

InactiveCN107173848ANo obvious smellImprove smellTobacco smoke filtersManufacturing technologyControl release

The invention provides a temperature-variable controlled-release gel composite material and application thereof in a cigarette filter stick, and belongs to the technical field of preparation of cigarette holders. A preparation method comprises the steps that gel is heated and melted; then the gel is conveyed into an infiltration tank with a heat preservation function; a common aroma-increasing core wire is wound through an unwinding mechanism and then guided to the infiltration tank, the core wire is immersed into the liquid gel, and the concentration of the liquid gel is adjusted so that the thickness of a gel layer attached to the surface of the aroma-increasing core wire can be larger than or equal to the diameter of the aroma-increasing core wire; then cooling and drying are conducted on the infiltrated aroma-increasing core wire, the gel is solidified into a solid which is attached to the surface of the aroma-increasing core wire, and accordingly the temperature-variable controlled-release gel composite material is obtained. According to the composite material prepared from the gel and the prepared filter stick, the forming degree and the aroma locking effect are good, production arrangement of the filter stick is facilitated, obtained products are relatively rich, and quick volatilization of the gel which is simply applied to the filter stick during smoking can be slowed down, so that a whole cigarette has a relatively balanced mouth feel.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

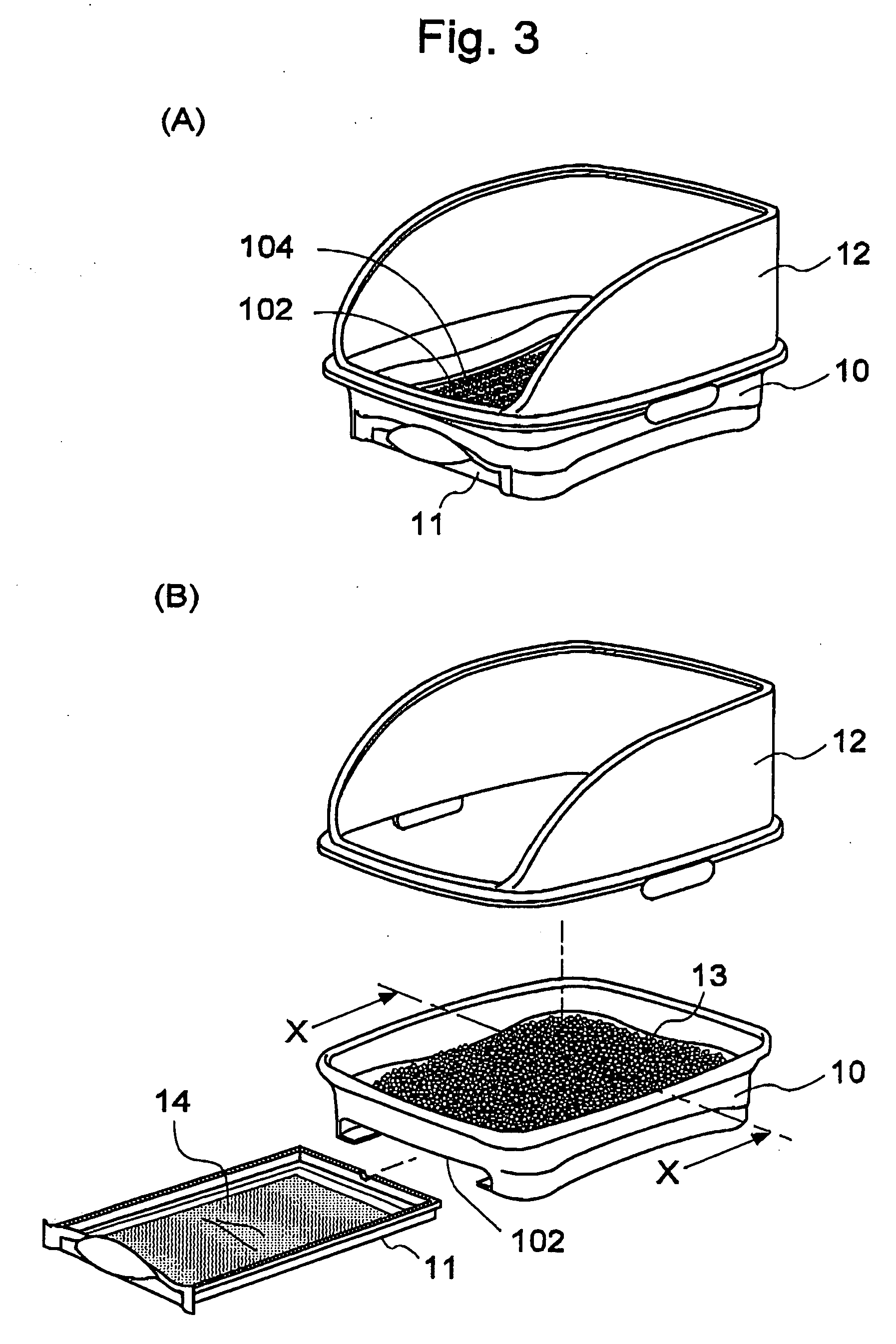

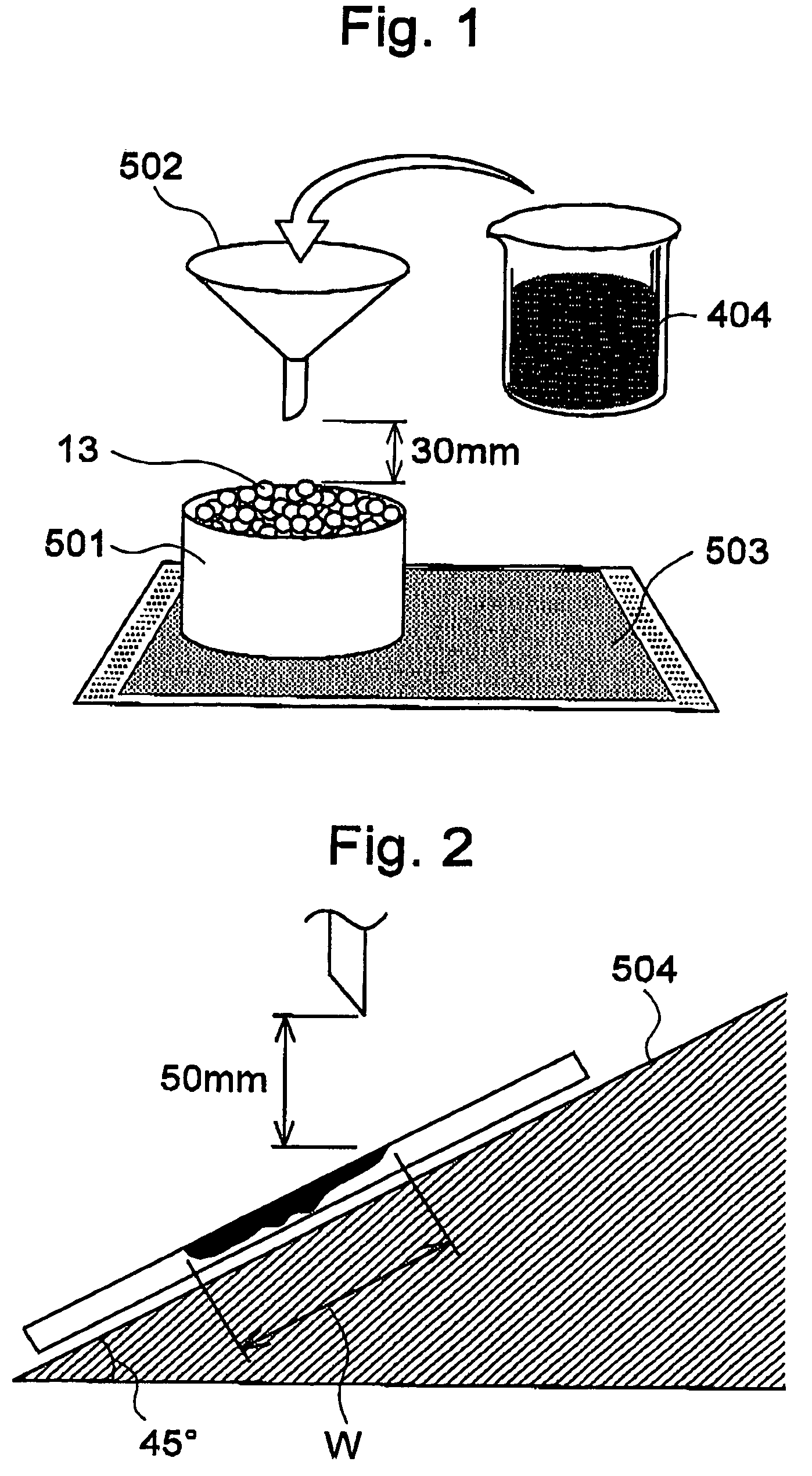

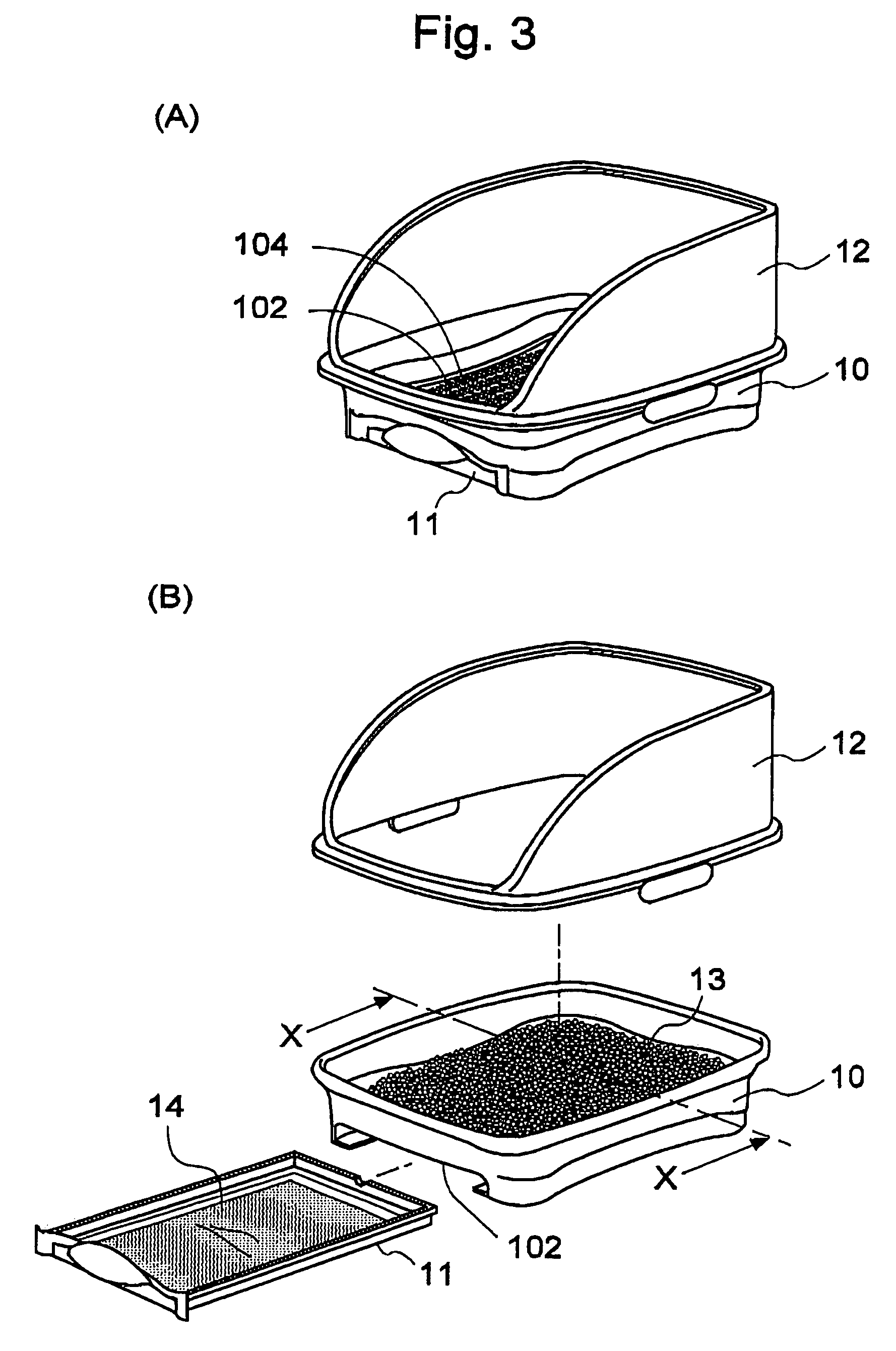

Animal litter

ActiveUS20060112894A1Absorption speed can be suppressedDry stateAnimal housingOther apparatusAnimal scienceGranular material

Provided is a litter, related to litter used for animal litter, which suppresses odors due to excretory substances remaining in litter and litter container using thereof. This animal litter comprises a plurality of granular materials, one part of a surface thereof comprising first granular material having water-shedding properties and second granular material having liquid-absorbing properties.

Owner:UNI CHARM CORP

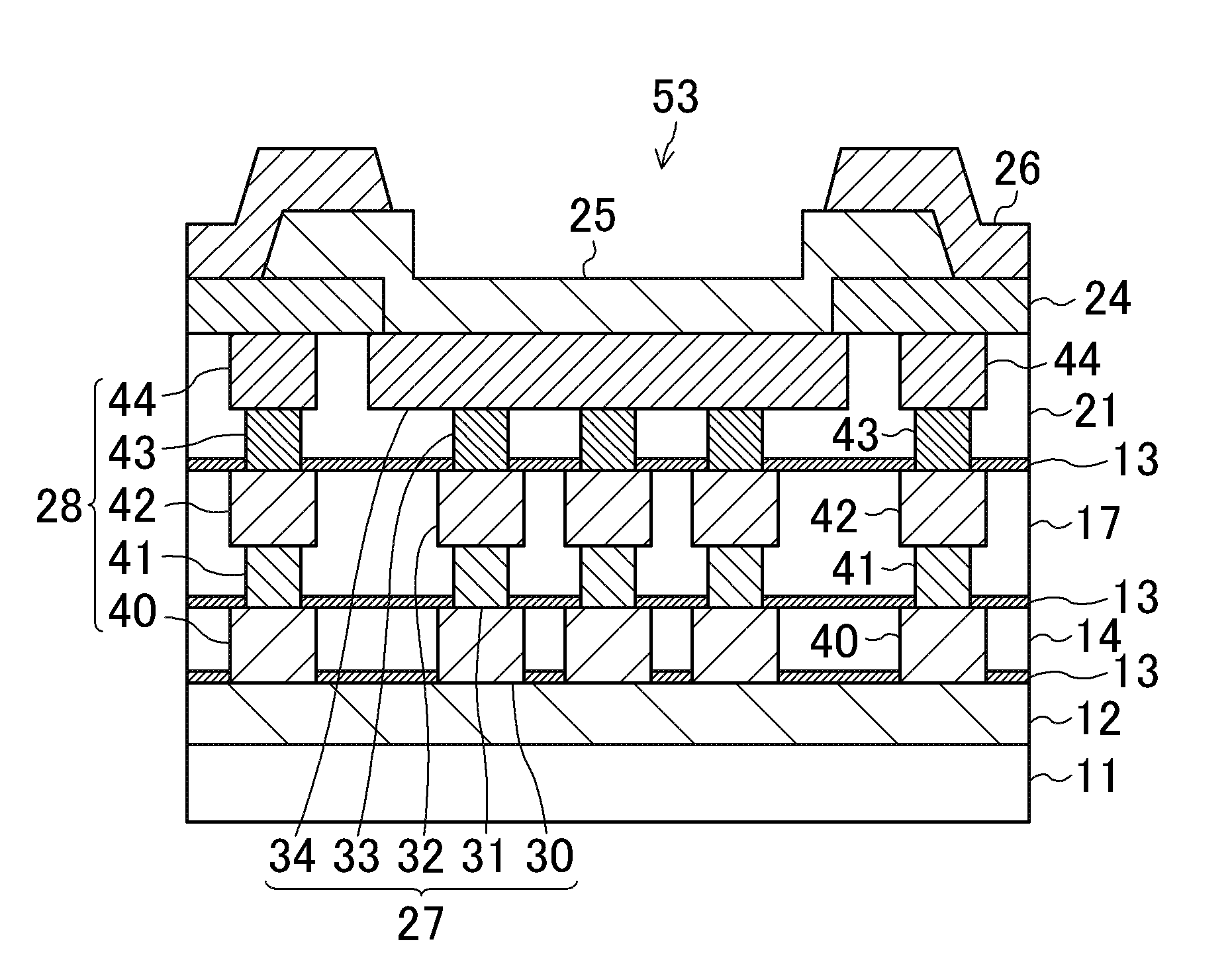

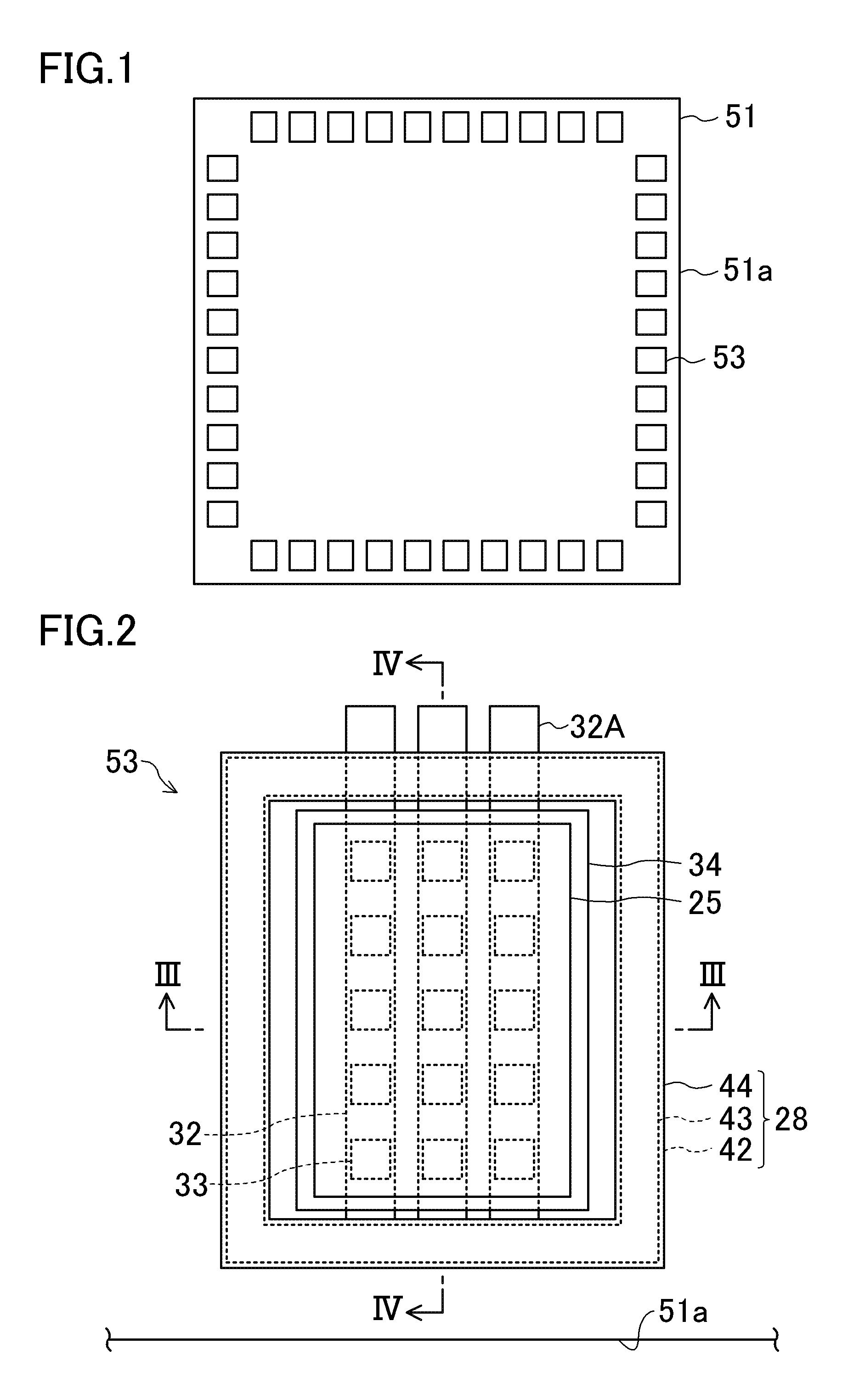

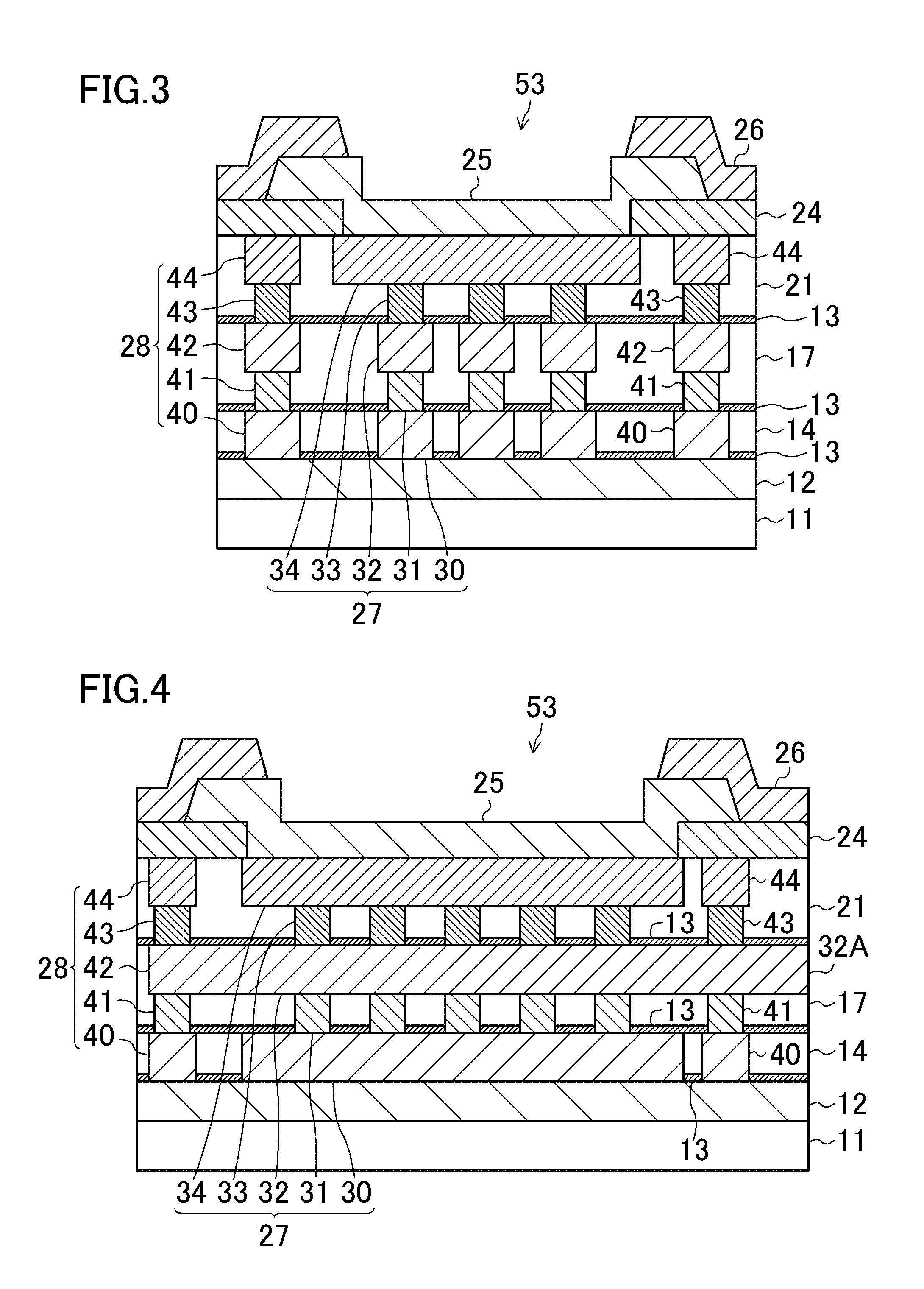

Semiconductor device

ActiveUS20110175232A1Reduce diffusion of moistureReinforcing electrode padSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceElectrical connection

A semiconductor device includes an electrode pad formed above a semiconductor substrate, and being a connecting portion for an external electrical connection; a multilayer body including a plurality of first interconnect layers formed in a plurality of insulating films stacked between the semiconductor substrate and the connecting portion and including an upper interconnect connected to the connecting portion, and a via configured to connect the first interconnect layers; a ring body formed in the plurality of insulating films to surround the multilayer body without interposing space, and including a plurality of second interconnect layers and at least one line via linearly connecting the second interconnect layers; and a lead line electrically connecting the connecting portion to an internal circuit. The multilayer body is connected to the ring body by at least one of the plurality of first interconnect layers. The lead line is connected to the ring body.

Owner:PANNOVA SEMIC

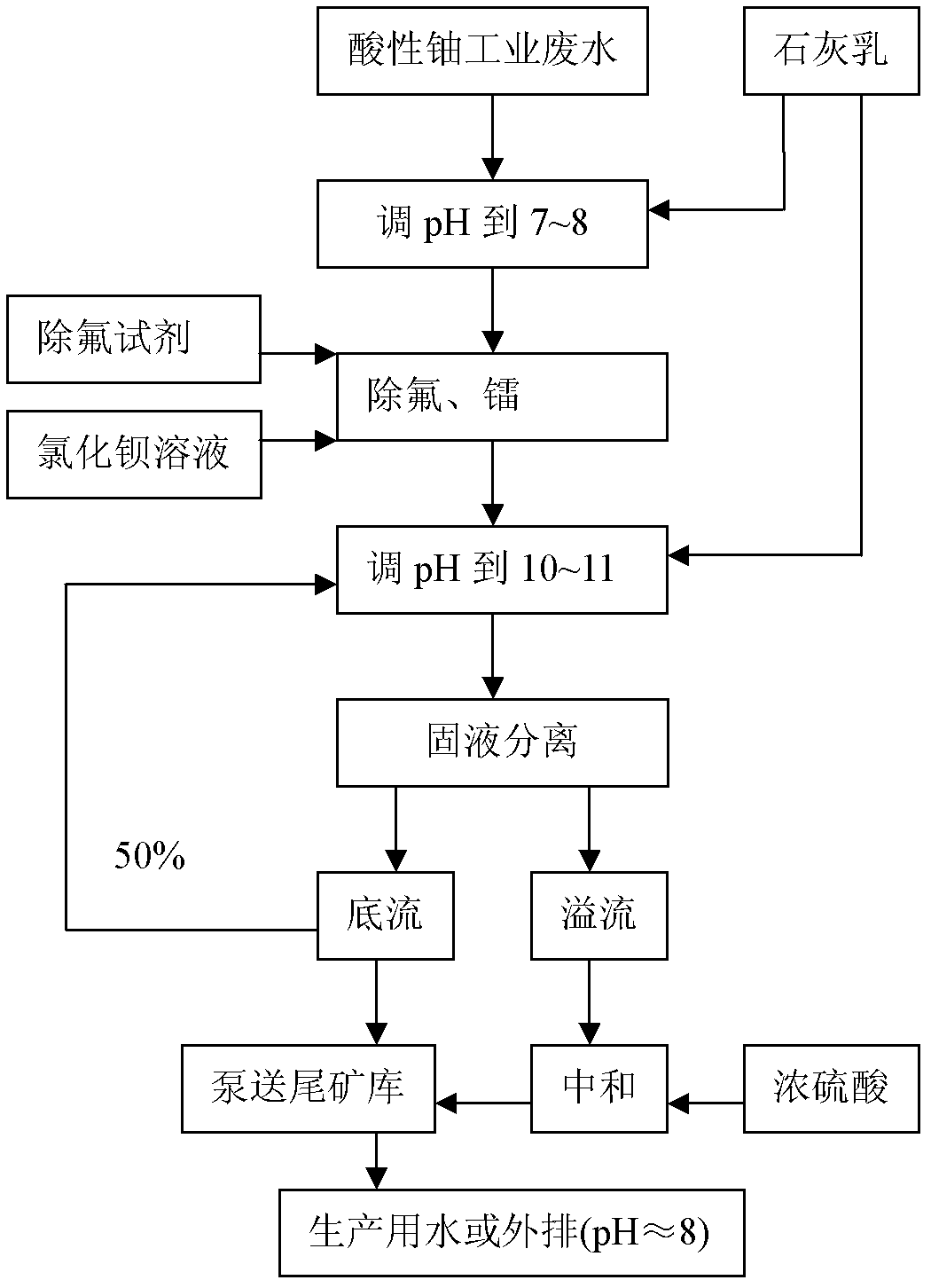

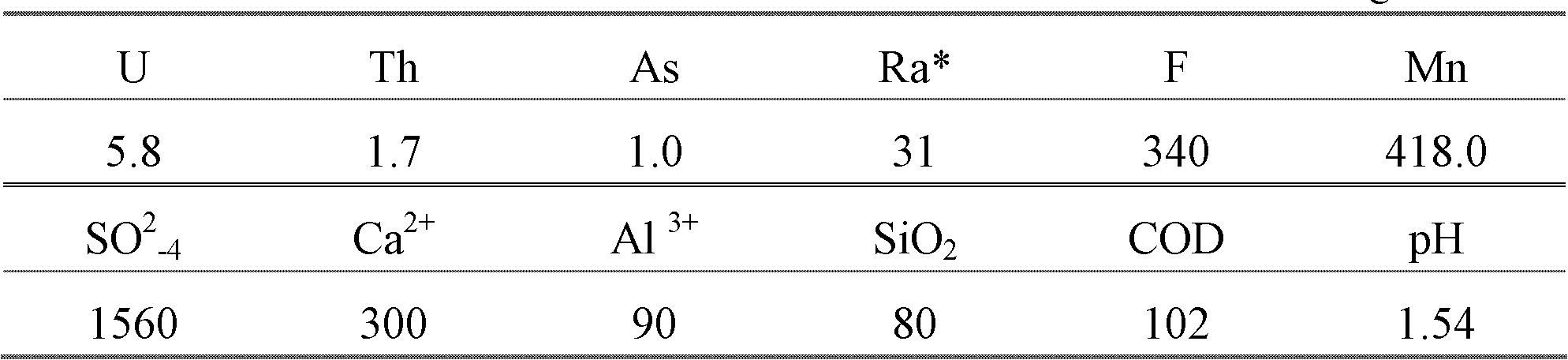

Method for removing fluorine in acid uranium process wastewater

InactiveCN102491555ALess moistureEfficient removalWater contaminantsMultistage water/sewage treatmentSulfate radicalsWater content

The invention provides a method for removing fluorine in acid uranium process wastewater, which comprises the following steps: (1) adding Ca(OH)2 into the acid uranium process wastewater for neutralization, (2) adding BaCl2 to remove radium and adding a fluorine-removing reagent to remove fluorine under the condition of solution sulfate radical concentration rho (SO2-4) >= 250mg / l, (3) adding Ca(OH)2 for neutralization, and (4) performing solid-liquid separation to obtained solution. Cycling operation is performed to 40-60 wt% of obtained lower-portion underflow after the separation according to the step (3) for 10-20 times, and the rest of the underflow is stored in a tailing pond. Obtained upper-portion underflow after the separation is neutralized by concentrated sulphuric acid, and a potential of hydrogen (pH) value is approximately equal to 8, namely neutralized upper-portion underflow after the separation is industrial wastewater meeting discharge standards. By means of the method, radioactive nuclides including the uranium, thorium and the radium in the acid uranium process wastewater are removed, hazardous elements including the fluorine, manganese and other irons are removed effectively, and uranium industrial wastewater after treatment reaches the discharge standards. The method is simple and convenient to operate, saved in reagents, little in water content in residues and quick in sedimentation velocity.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

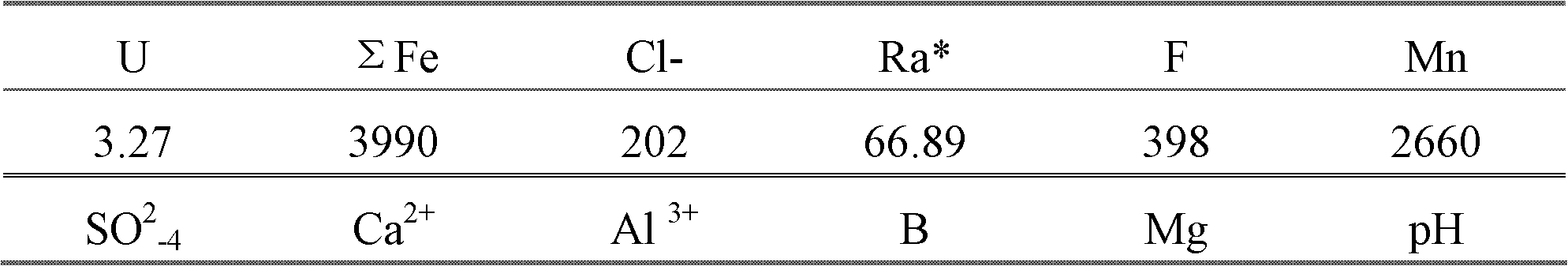

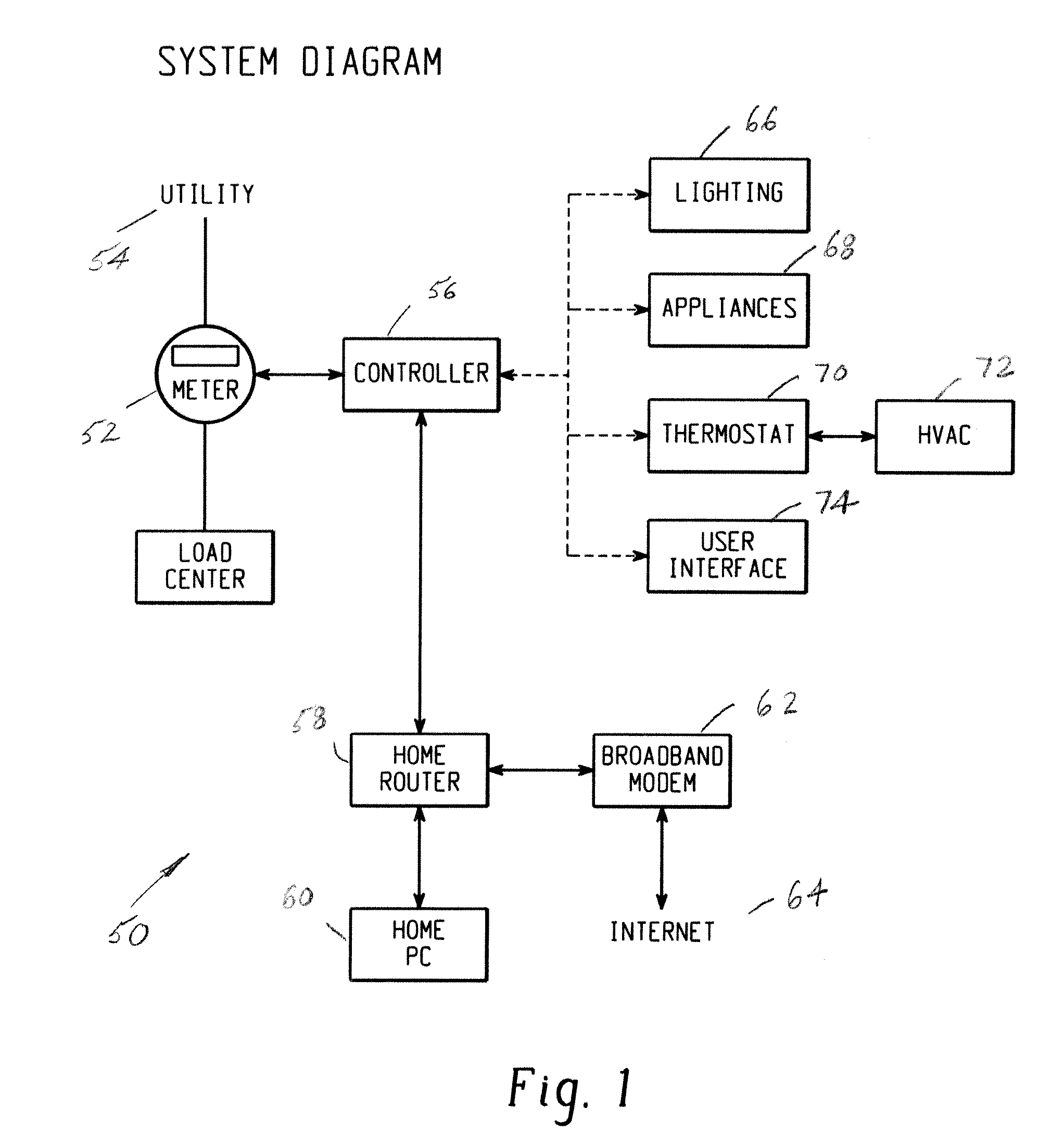

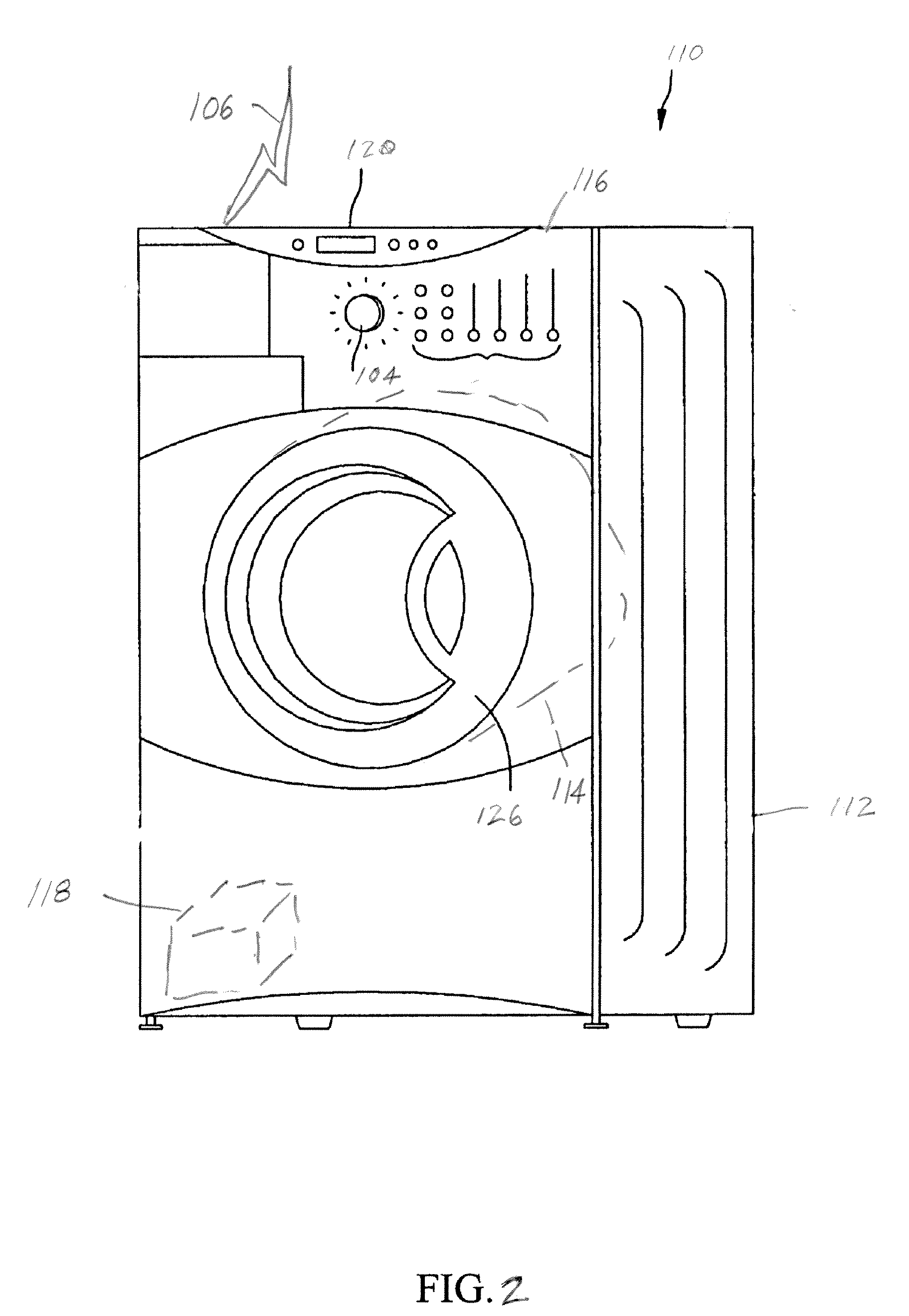

Clothes washer demand response with at least one additional spin cycle

ActiveUS20110061177A1Reduce power consumptionLow costOther washing machinesControl devices for washing apparatusSpinsProcess engineering

A clothes washer is provided comprising one or more power consuming functions and a controller in signal communication with an associated utility. The controller can receive and process a signal from the associated utility indicative of current state of an associated utility. The controller operates the clothes washer in one of a plurality of operating modes, including at least a normal operating mode and an energy savings mode in response to the received signal. The controller is configured to change the power consuming functions by modifying the spin cycle to achieve a lower remaining moisture content in the clothes load prior to going into a dryer, thus reducing overall total energy consumption to completely wash and dry a clothes load.

Owner:HAIER US APPLIANCE SOLUTIONS INC

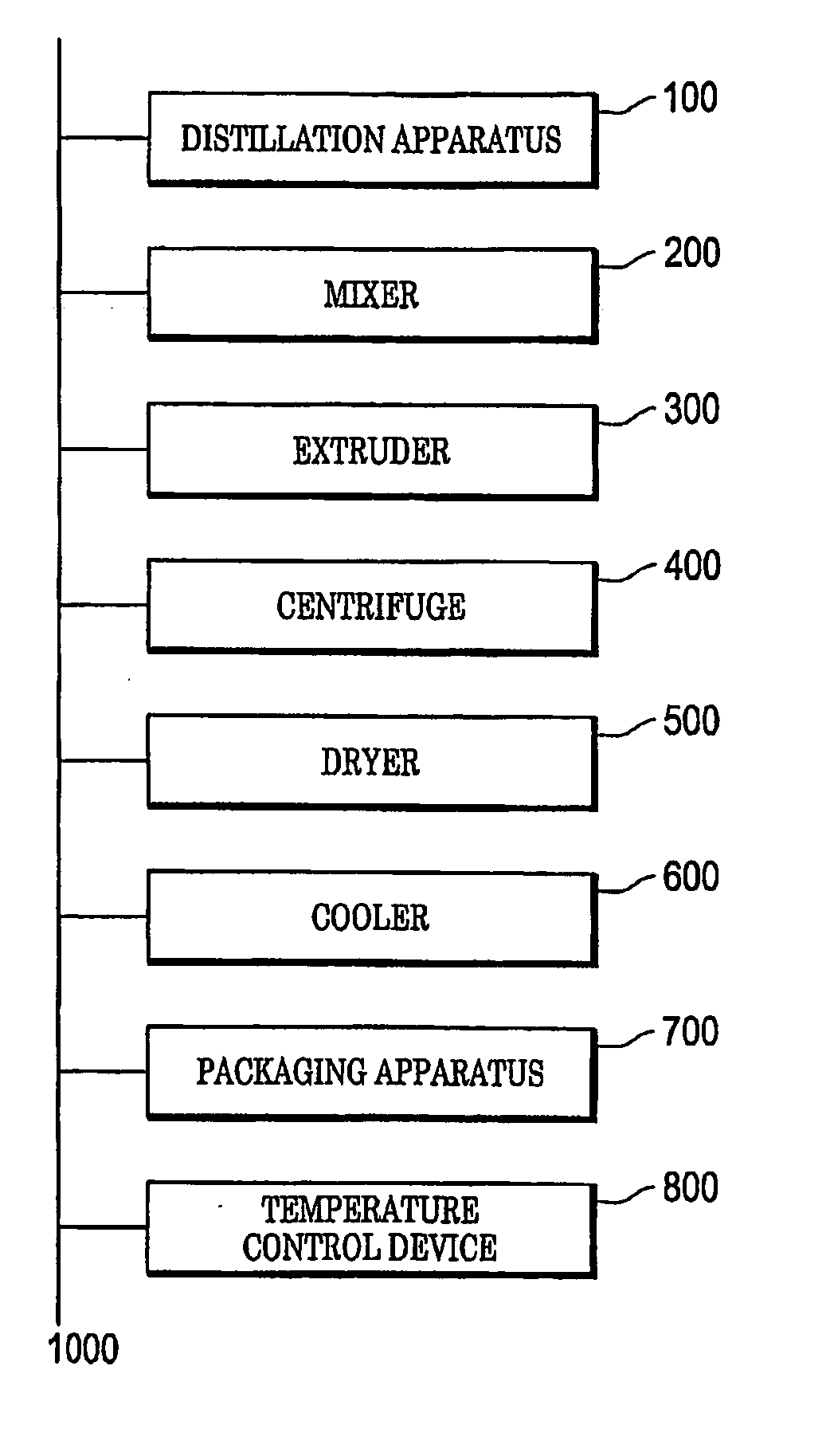

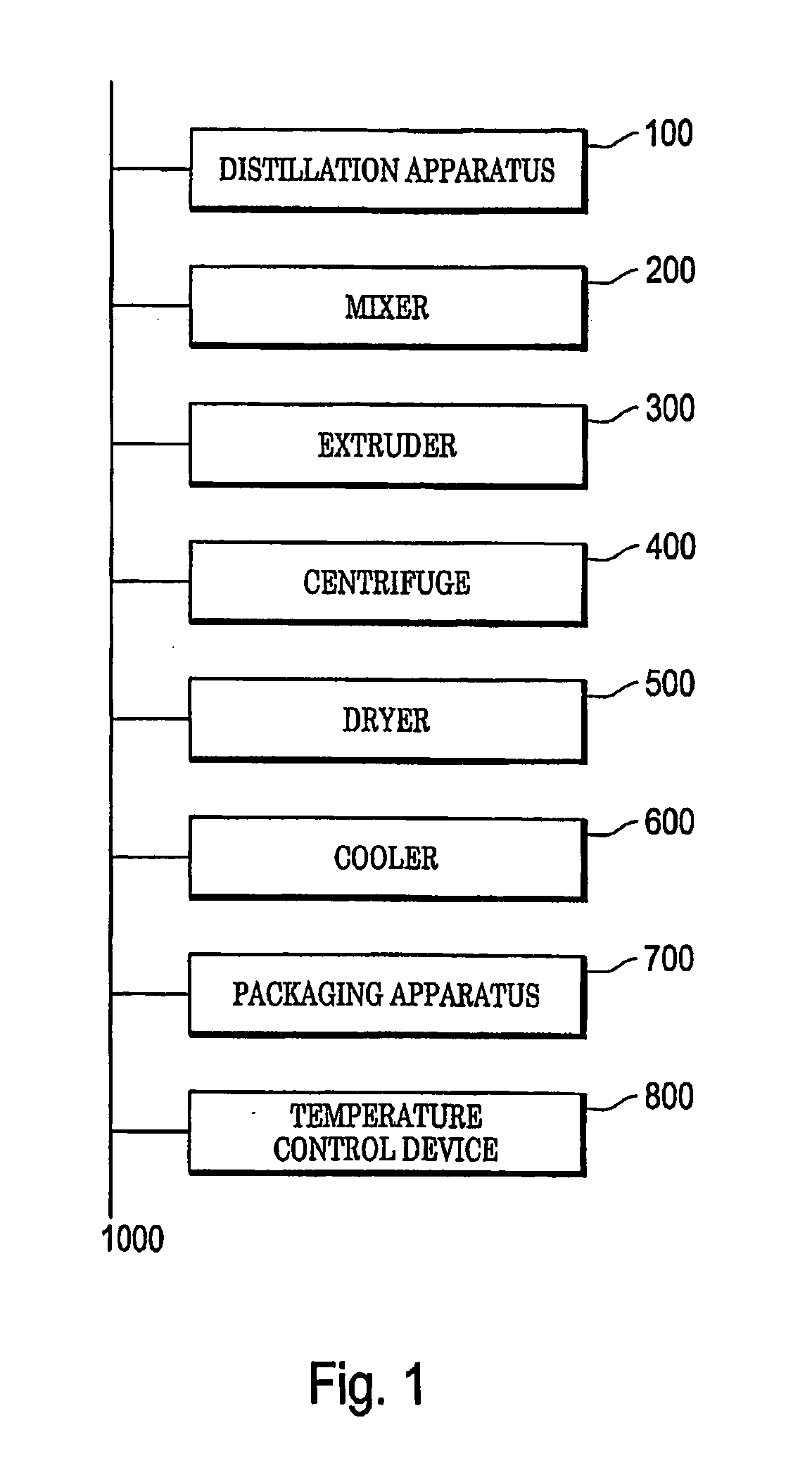

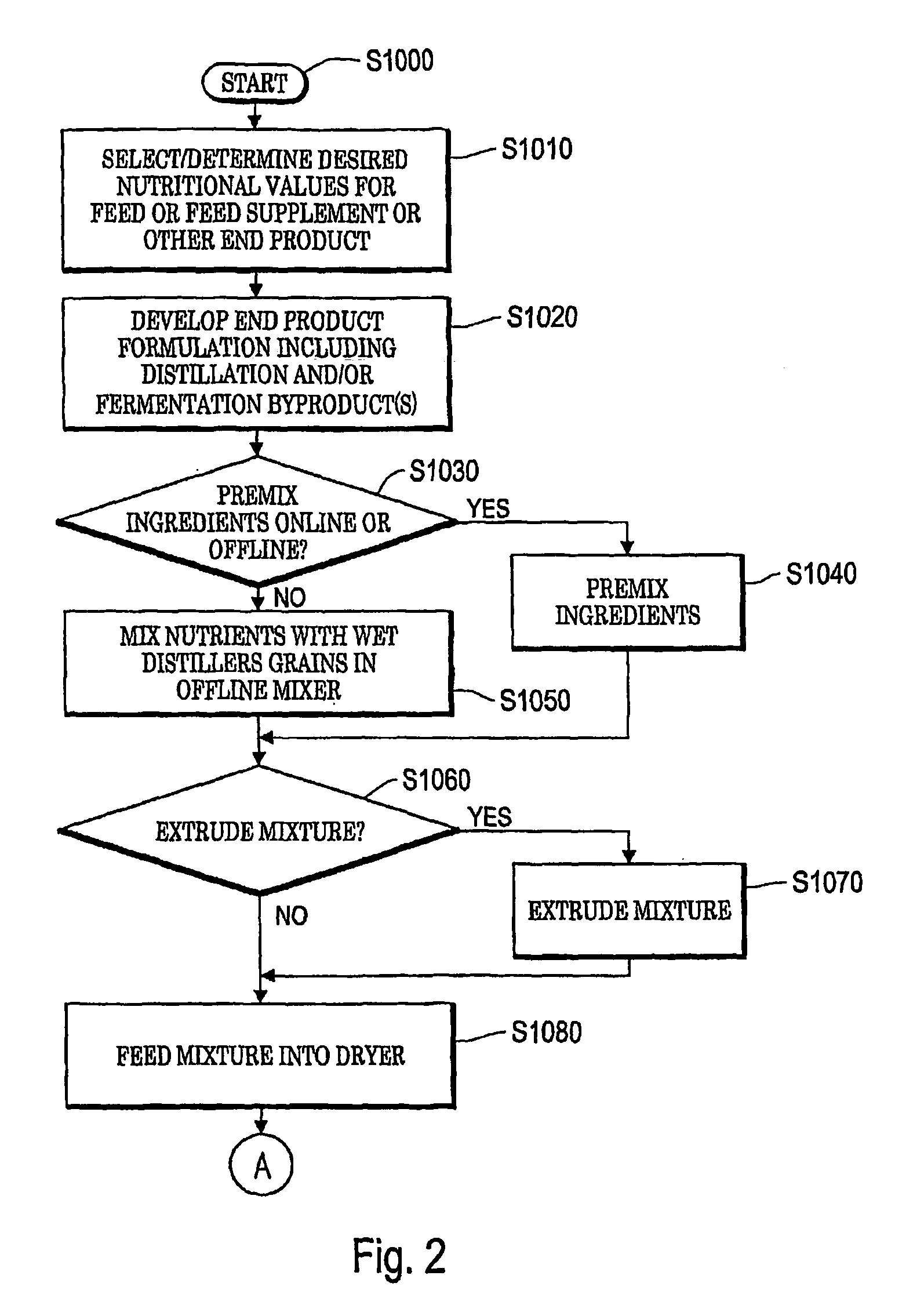

Fermentation byproduct feed formulation and processing

InactiveUS20050255220A1Increase valueHigh nutritional valueFood processingAnimal feeding stuffBiotechnologyFodder

The invention is to products for enhancing the nutrient value of distillers, brewers or fermenters grain byproducts using an injector or mixer to add predetermined amounts of nutrients to the grains. The byproduct nutrient obtained is heated, dried and / or extruded to increase the ruminant bypass protein of the nutrient product.

Owner:NOVERA INC

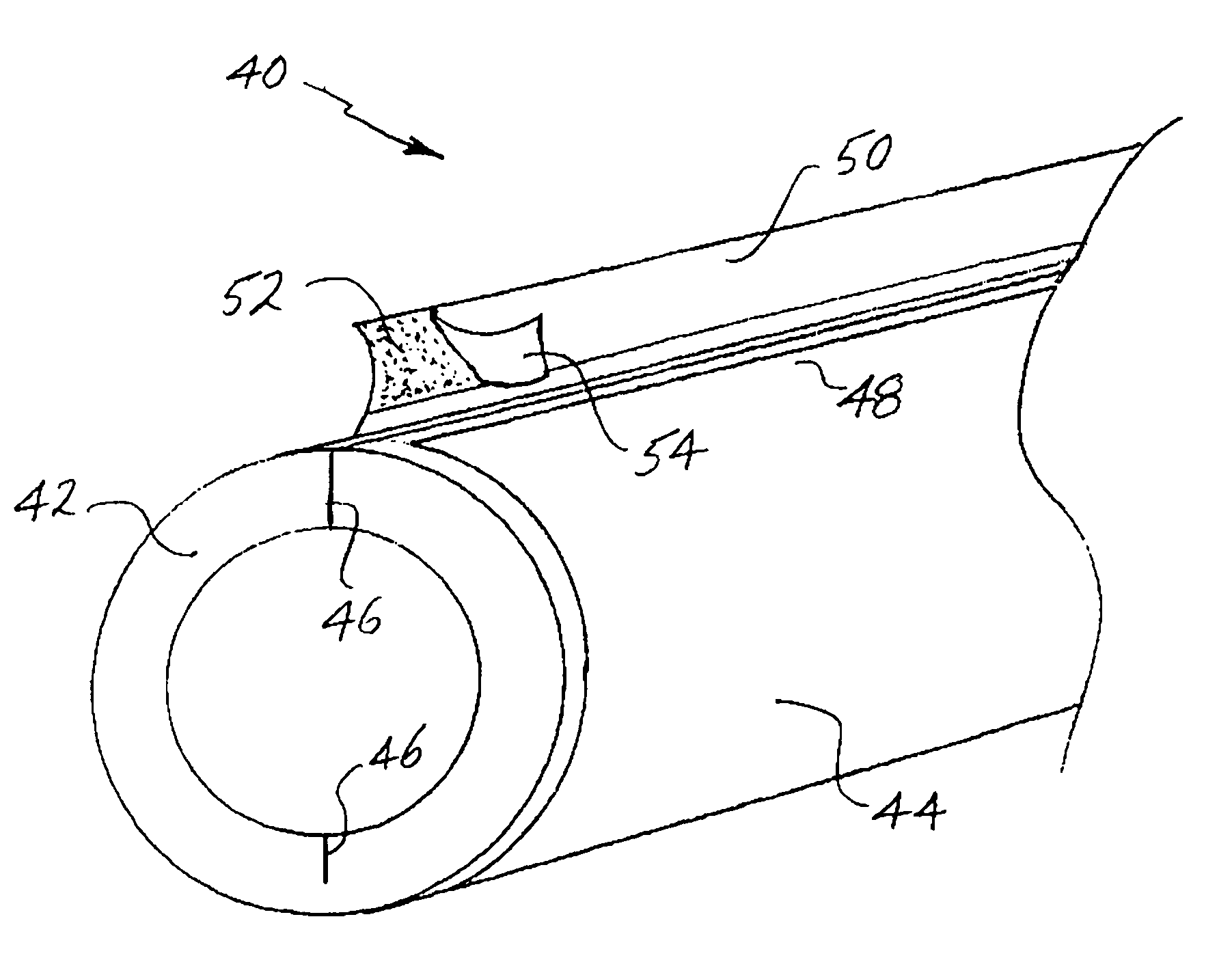

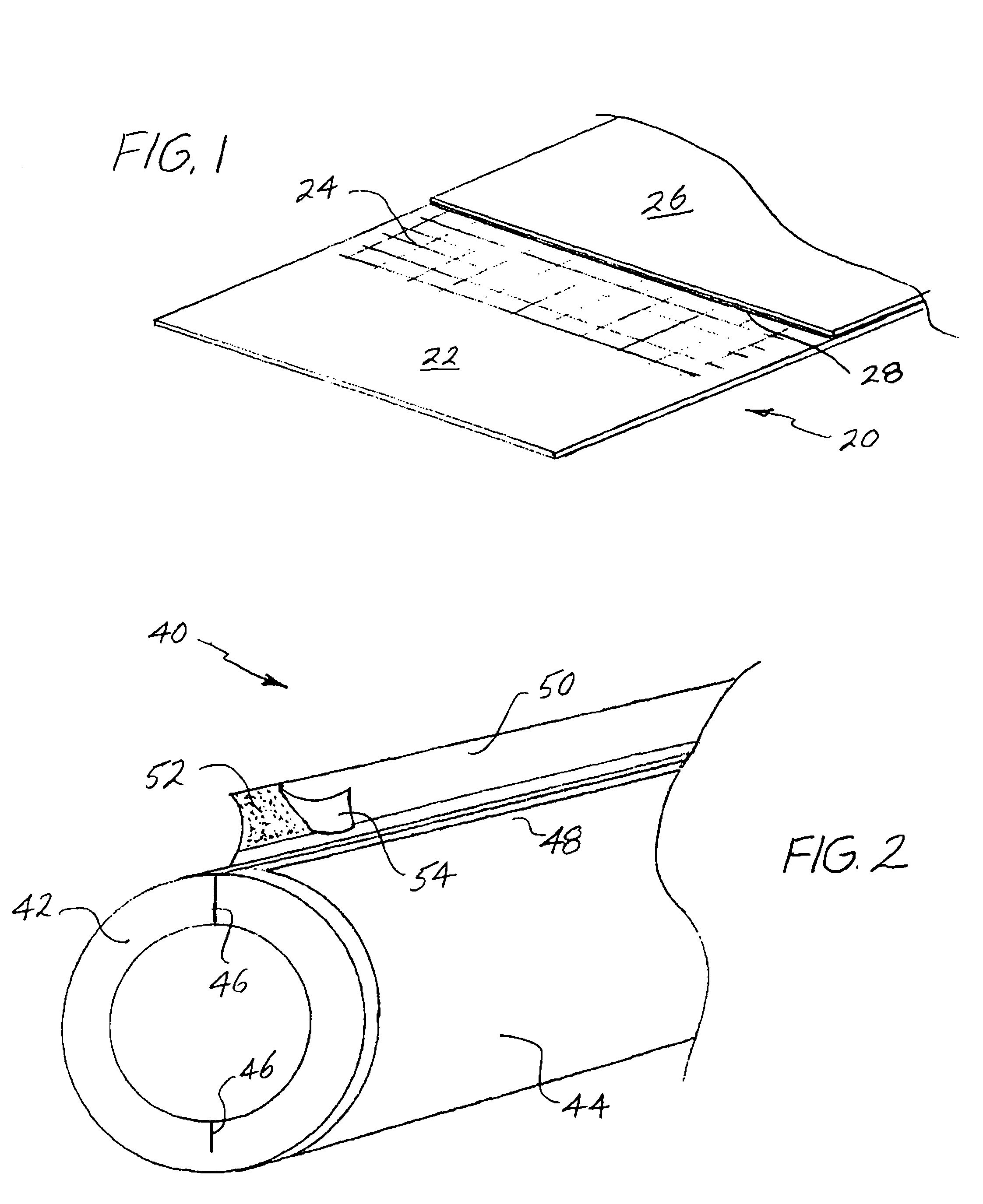

Facing and faced insulation products

ActiveUS7749923B2Less moistureLess expansionPipe protection by thermal insulationGlass/slag layered productsFiberWood veneer

A facing laminate for insulation products includes: a foil or metallized polymeric film sheet layer forming an inner layer of the laminate that is adapted be bonded directly to a surface of an insulation product; a paper composite sheet layer, which may include synthetic and / or inorganic fibers, forming an outer exposed layer of the laminate; and a scrim intermediate and bonded to the foil or metallized polymeric film sheet and paper composite sheet layers. The facing laminate may include a humectant and / or a water, oil, and / or grease repellant component. The paper composite sheet layer of the laminate exhibits greater dimensional stability and reduced wrinkling when the laminate is exposed to conditions of high humidity. Insulation products to be faced with this facing laminate include pipe insulation, duct board, duct wrap insulation, metal building insulation, and other building insulation products.

Owner:JOHNS MANVILLE CORP

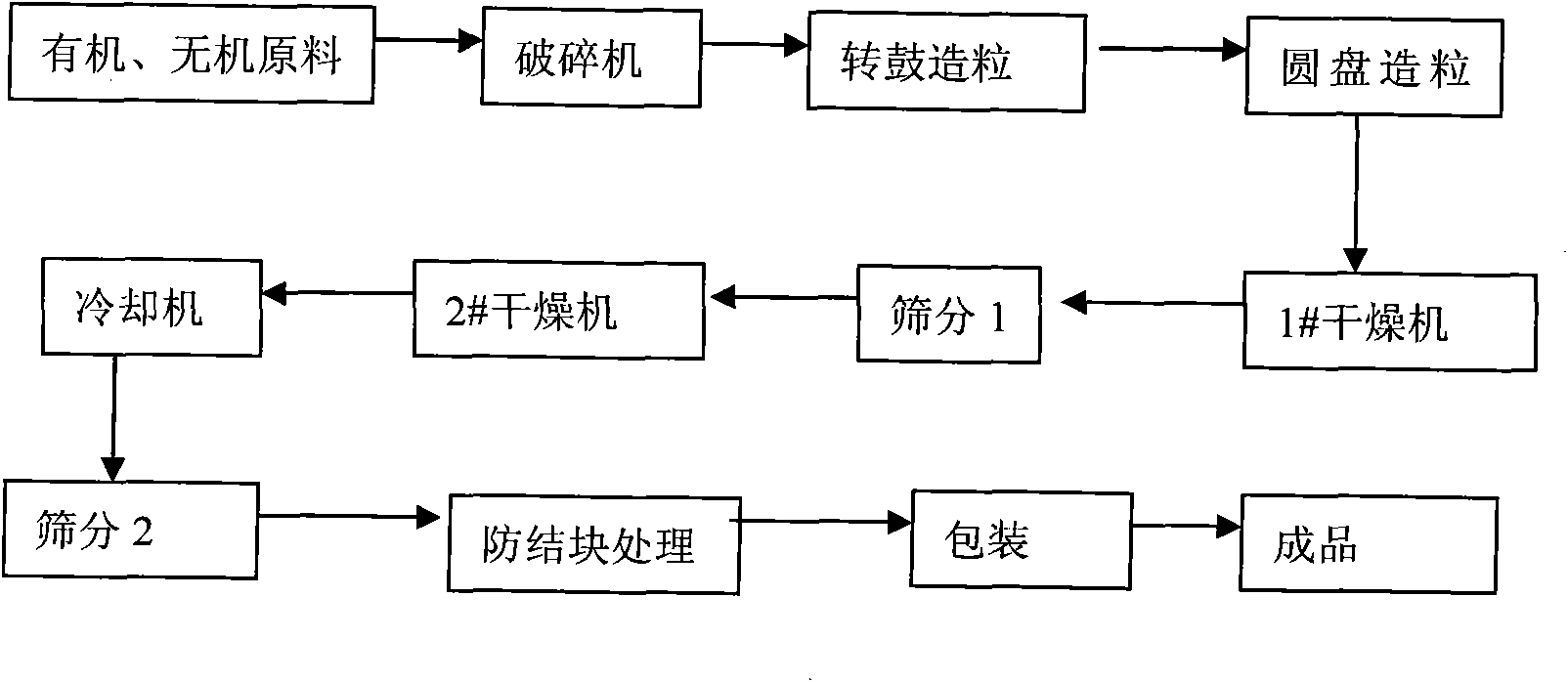

Production process of organic-inorganic compound fertilizer

InactiveCN101684051ASolve the problem of poor product appearance qualityHigh one-time ball forming rateFertiliser formsFertilizer mixturesCrusherOrganic fertilizer

A technology problem solved by the invention is to provide a production process of organic-inorganic compound fertilizer with high pelleting rate, round appearance and low moisture. The process has the steps of: fermenting organic raw materials into ecological organic fertilizer, adding inorganic raw material into a crusher; pelleting by assistantly adding water, steam and urine after crush of thematerial in the rotary drum comminutor; pelleting continuously using the material in the disk comminutor from the rotary drum comminutor; carrying out two-stage drying for the material after pelleting, and cooling the material; sieving macrobead in the cooled material; packing the sieved product after anti-blocking treatment and then delivering them out of factory. Using the technical scheme cansufficiently play the roles of the two kinds of pelleting methods, as well as solve the problems of bad appearance quality of product, and high moisture of pelleting.

Owner:河南财鑫实业化工有限责任公司

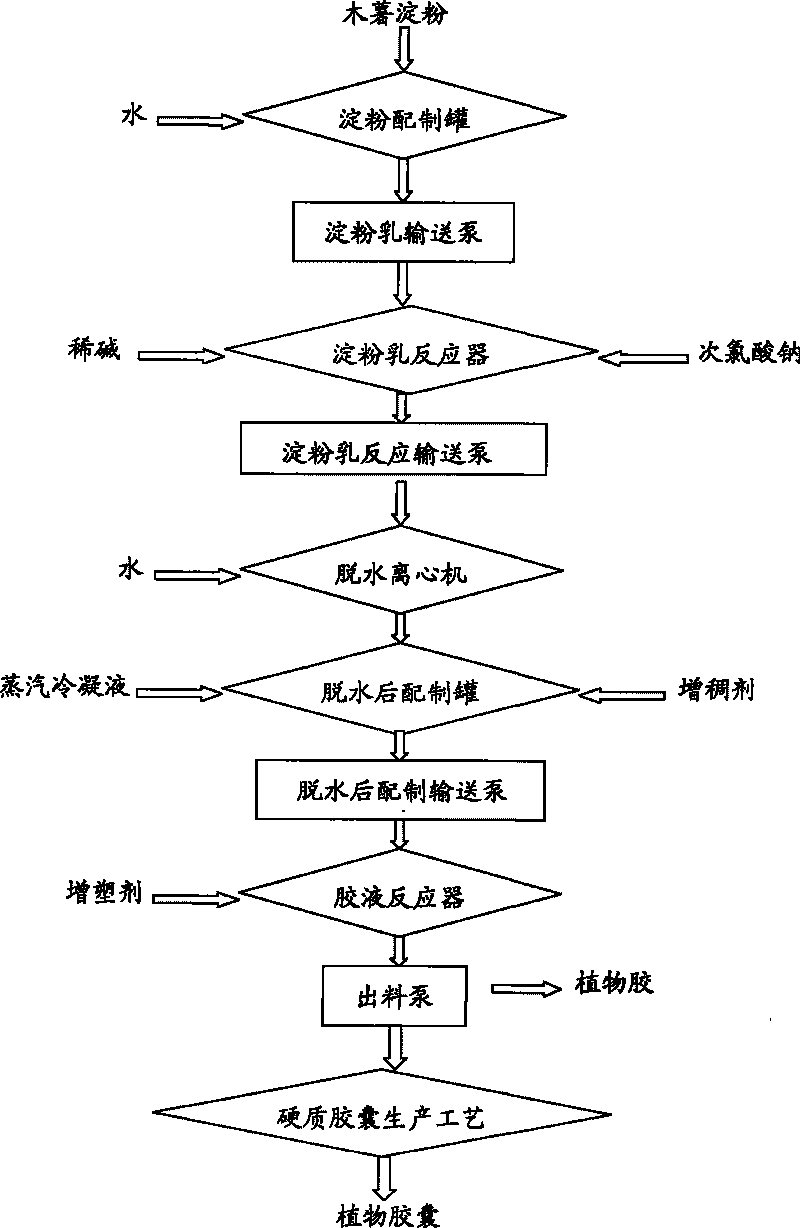

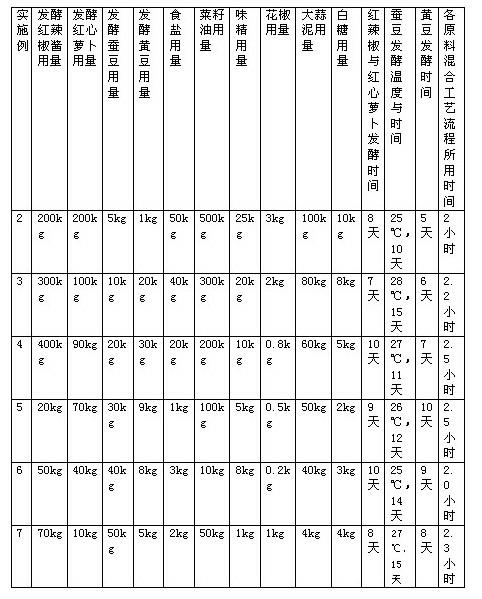

Technique of preparing cassava starch plant gum, the plant gum prepared thereby and plant capsules

ActiveCN101338045BIncrease planting areaReduce consumptionPharmaceutical non-active ingredientsCapsule deliveryBiotechnologyPlant Gums

The invention relates to a preparation method for cassava starch vegetable gum and vegetable gum and a vegetable capsule which are prepared by the preparation method. The preparation method mainly comprises the following steps: preparing starch milk, gelatinization reaction, dehydration, washing, preparation after dehydration and obtaining gel solution. The preparation method for cassava starch vegetable gum and the vegetable gum and the vegetable capsule which are prepared by the preparation method of the invention have stable product performance, low water content, wide application range, easy storage, no contamination, green environmental protection, wide raw material resources, simple preparation method and easy control.

Owner:刘雨微

Colored liquid-filled soft capsules and method of manufacture thereof

InactiveUS20070259035A1Easily be detected and removedLess moistureDrug compositionsCapsule deliveryCosmetic appearanceBiomedical engineering

The present invention relates to a coated liquid-filled soft capsule containing a colored shell and method for making same. The shell material contains a colorant incorporated in the material in an amount sufficient to provide a visual contrast between the capsule shell and any liquid fill that escapes from the capsule shell and resides on an exterior surface of the capsule shell. This allows leaking capsules as well as other capsules that get contaminated from the leaking capsules to be identified before they are coated. This prevents coating problems in pan and / or continuous coaters associated with leaking and / or contaminated capsules. The present invention also produces pharmaceutically elegant capsules uniform in appearance without the necessity of coloring the coating.

Owner:LEINER HEALTH PRODUCTS

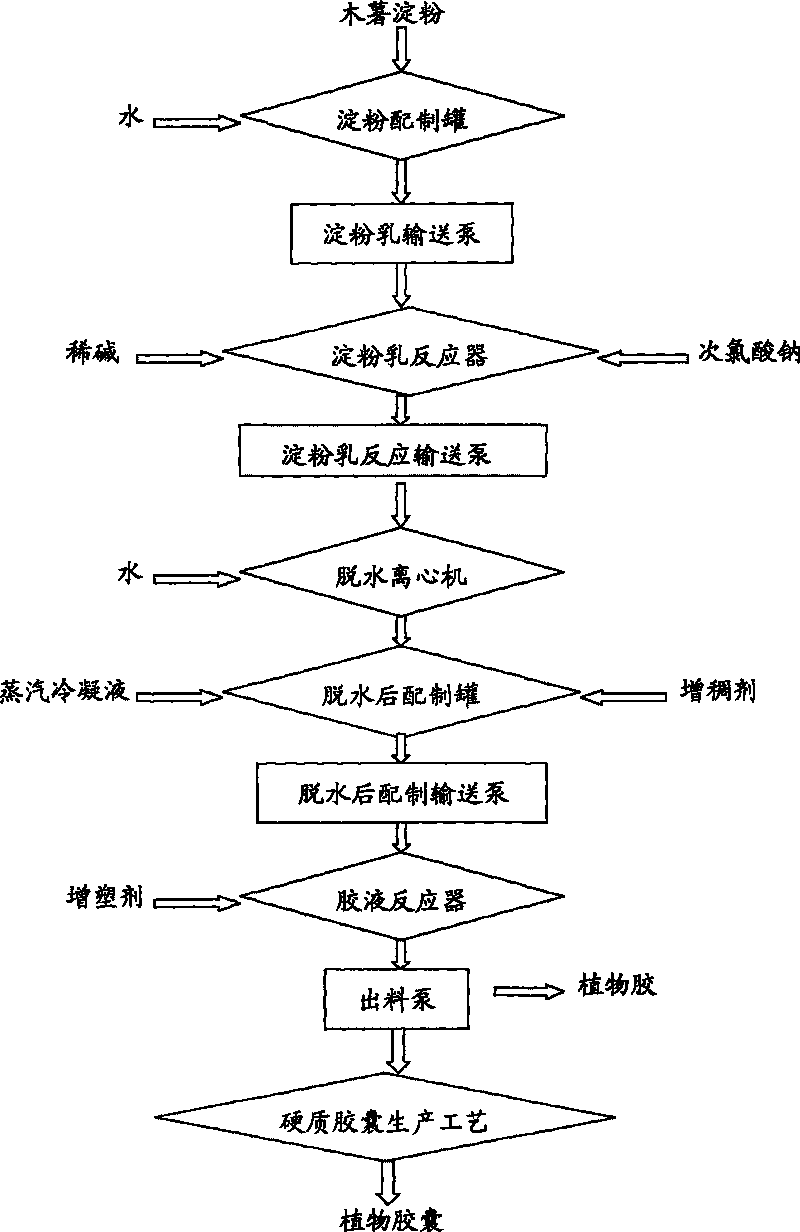

Chilli sauce and preparation method thereof

InactiveCN101904487ARadish red pigment highIncrease contentFood preparationBiotechnologyNatural product

The invention discloses chilli sauce, which is prepared by mixing raw materials of chilli, red heart radish, broad bean, soybean, aginomoto, salt and oil according to an effective ratio. The chilli, the red heart radish, the broad bean and the soybean are all fermented. The chilli sauce has the advantages of simple preparation method, simple equipment and convenient industrial production on a large scale; the chilli sauce has the quality guarantee period between 12 and 18 months at normal temperature, crisp mouthfeel, bright red color and authentic biting taste, and is pure natural product according to the raw materials and the process flow, is not added with any additive or pigment, has rich nutrients and more effectively ensures the health of consumers.

Owner:周红

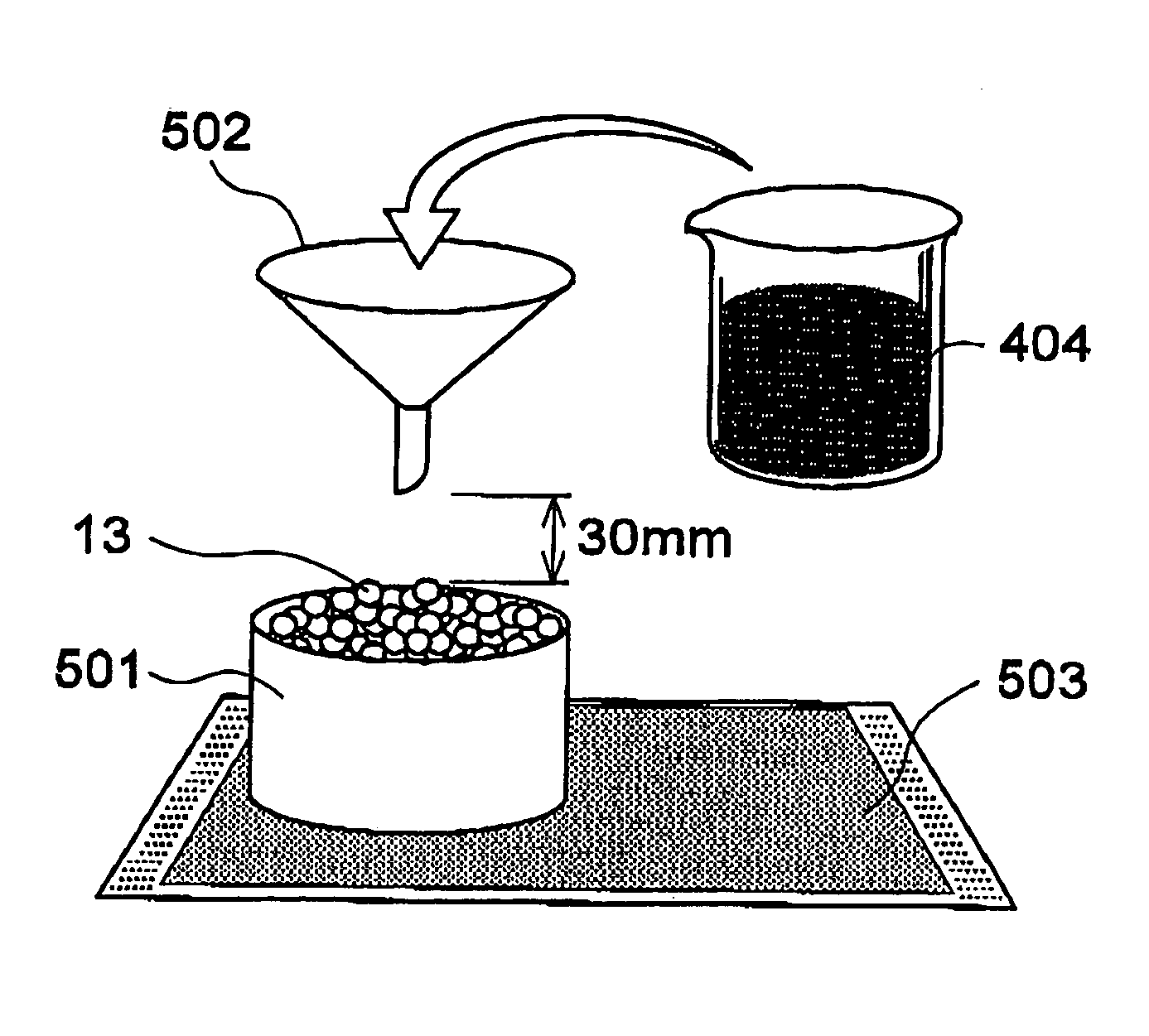

Animal litter

ActiveUS7467600B2Absorption speed can be suppressedDry stateAnimal housingOther apparatusAnimal scienceGranular material

Provided is a litter, related to litter used for animal litter, which suppresses odors due to excretory substances remaining in litter and litter container using thereof.This animal litter comprises a plurality of granular materials, one part of a surface thereof comprising first granular material having water-shedding properties and second granular material having liquid-absorbing properties.

Owner:UNI CHARM CORP

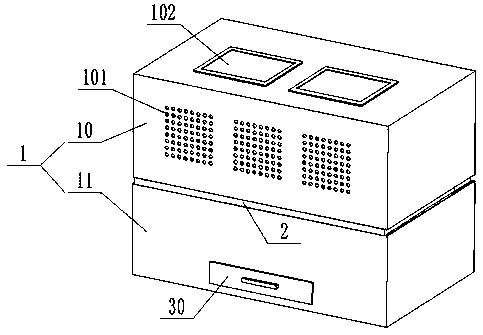

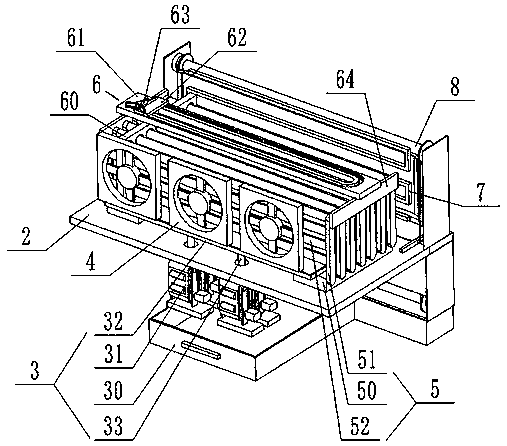

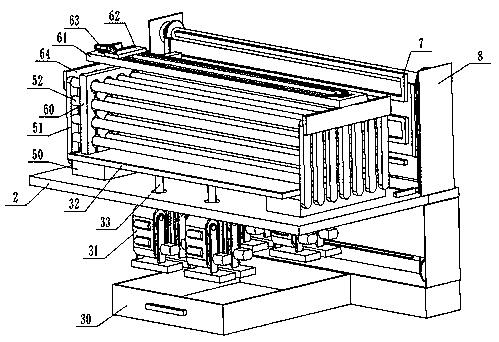

Object drying device

InactiveCN111121400ALess moistureEasy to storeDrying solid materials without heatDrying gas arrangementsThermodynamicsMechanical engineering

The invention discloses an object drying device. The object drying device comprises exhaust fans, a box body, a partition plate, a refrigerating mechanism, a water draining mechanism, a water scrapingmechanism and a heating mechanism; the box body is partitioned into an upper box body and a lower box body which are independent of each other through the partition plate; the refrigerating mechanismand the water scraping mechanism are located in the upper box body; the refrigerating mechanism comprises a compressor, longitudinal transition pipes and transverse condensation pipes; the water scraping mechanism comprises a water scraping plate and a first linear driving assembly; the water draining mechanism comprises a water collecting box, water sucking assemblies, rotary rolling assembliesand a water draining drawer, and each water sucking assembly comprises a sponge pad, a sponge column located at the bottom of the sponge pad and a sponge plate connected with the sponge column; and the exhaust fans and the heating mechanism are installed on the portions, located at an air inlet hole and an air outlet hole, of the inner wall of the upper box body. According to the object drying device, the drying efficiency is high, the water content is low after an object is dried, long-time preservation of the object is facilitated, and the quality of the object can be improved.

Owner:HUNAN BIOLOGICAL & ELECTROMECHANICAL POLYTECHNIC

Method of extracting Water-soluble antler extract product

The present invention relates to the preparation technology of pilose antler product. Pilose antler material is prepared into the purified water-soluble pilose antler extractive through the technological process including the steps of drying, crushing, decoction, concentration, freeze drying and other steps. In the preparation, mild mode and advanced vacuum freeze drying technique are adopted to extract water-soluble components in pilose antler. The preparation process is simple and reasonable, and has no damage and loss of the nutrients in pilose antler, and the product has high dissolvability, high purity, no organic solvent residue and wide applicable range.

Owner:白秀娟

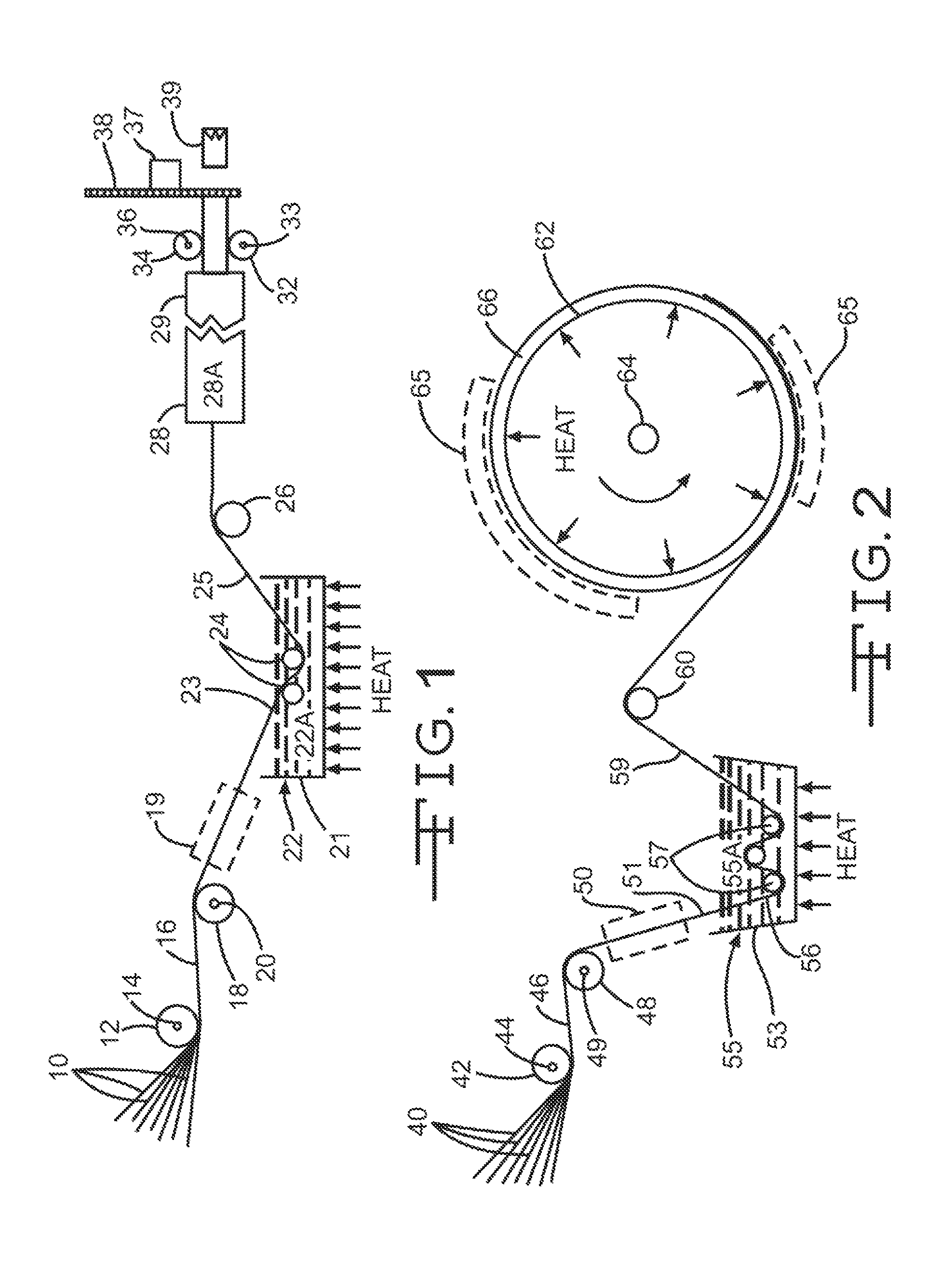

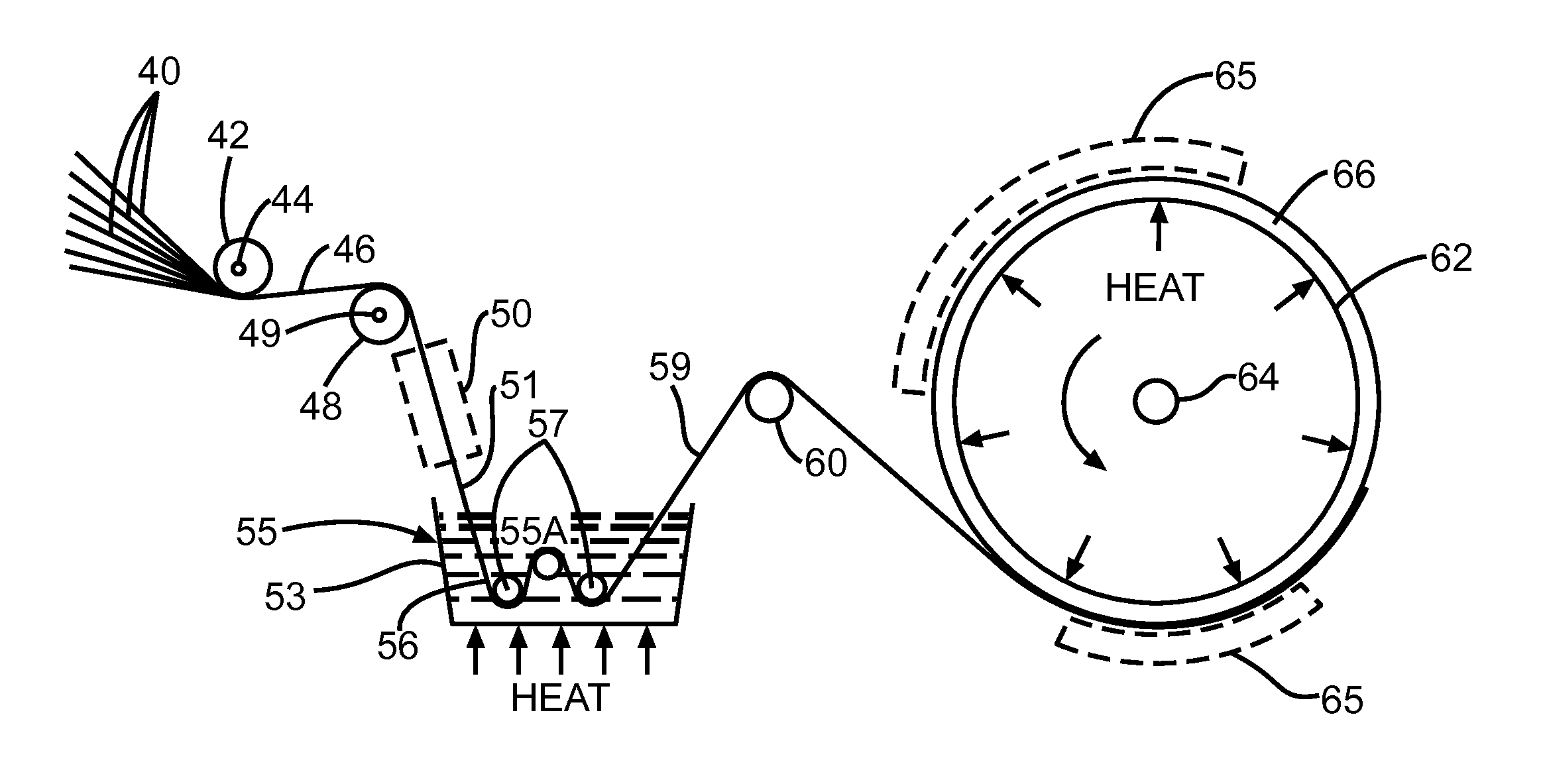

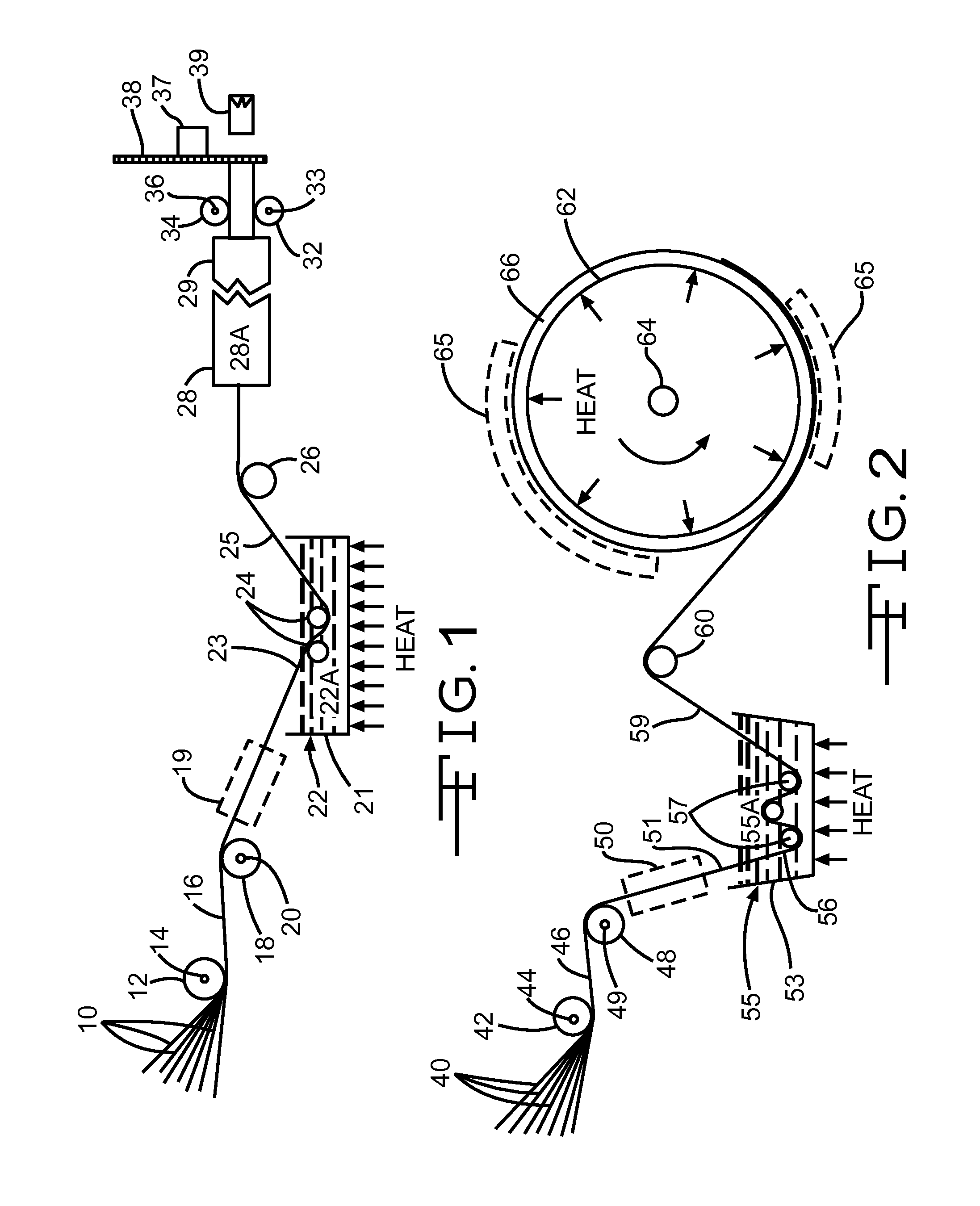

Methods for making reinforced thermoplastic composites using reactive fibers and/or reactive flakes

ActiveUS8883908B2Low viscosityHigh viscositySpecial tyresChemical/physical/physico-chemical processesPolymer scienceIn situ polymerization

Various methods and systems of making inorganic fiber / flake reinforced composites having a thermoplastic matrix are disclosed. The methods use systems similar to those used to make inorganic fiber / flake reinforced products having a thermoset matrix, but the systems and methods are modified to use thermoplastic precursor monomer(s) followed by in situ polymerization of the monomer(s) during and / or following forming of the desired shape of the products. These methods permit the manufacture of superior inorganic fiber reinforced thermoplastic matrix composites in large and very large shapes heretofore not possible, or practical.

Owner:JOHNS MANVILLE CORP

Ecological method for transporting high-density earthworm

The invention relates to an ecological method for transporting earthworm with high density. The invention employs clean water sponge as carrier. Firstly putting sponge into black plastic bag, then putting earthworm into black bag, packing the bag, and putting it into shipping box. The invention solves problem of transporting commercial earthworm and strain earthworm under high density for long distance, improves earthworm survival rate and reduces transportation cost.

Owner:河南省科学院河南省发展计划委员会地理研究所

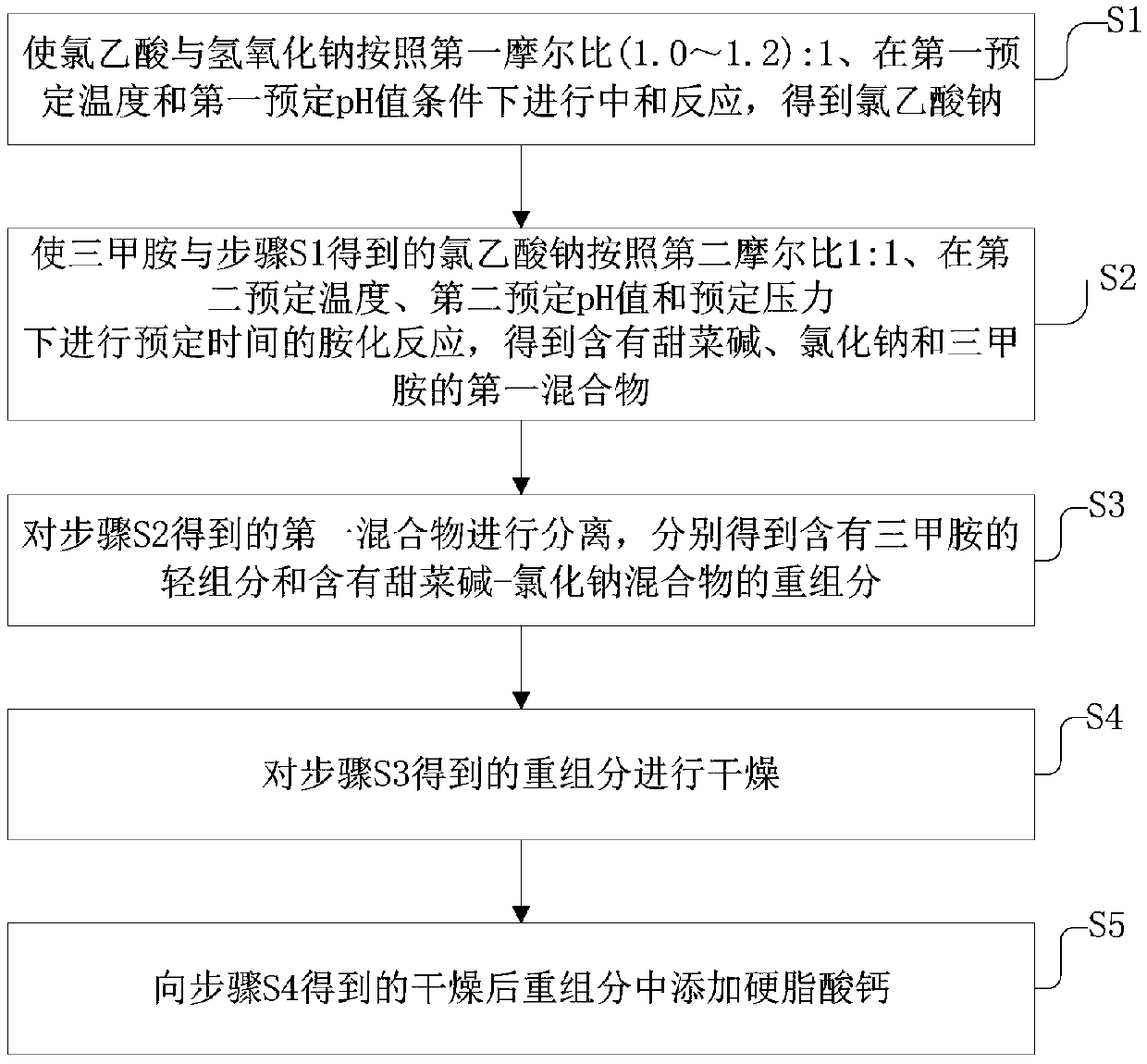

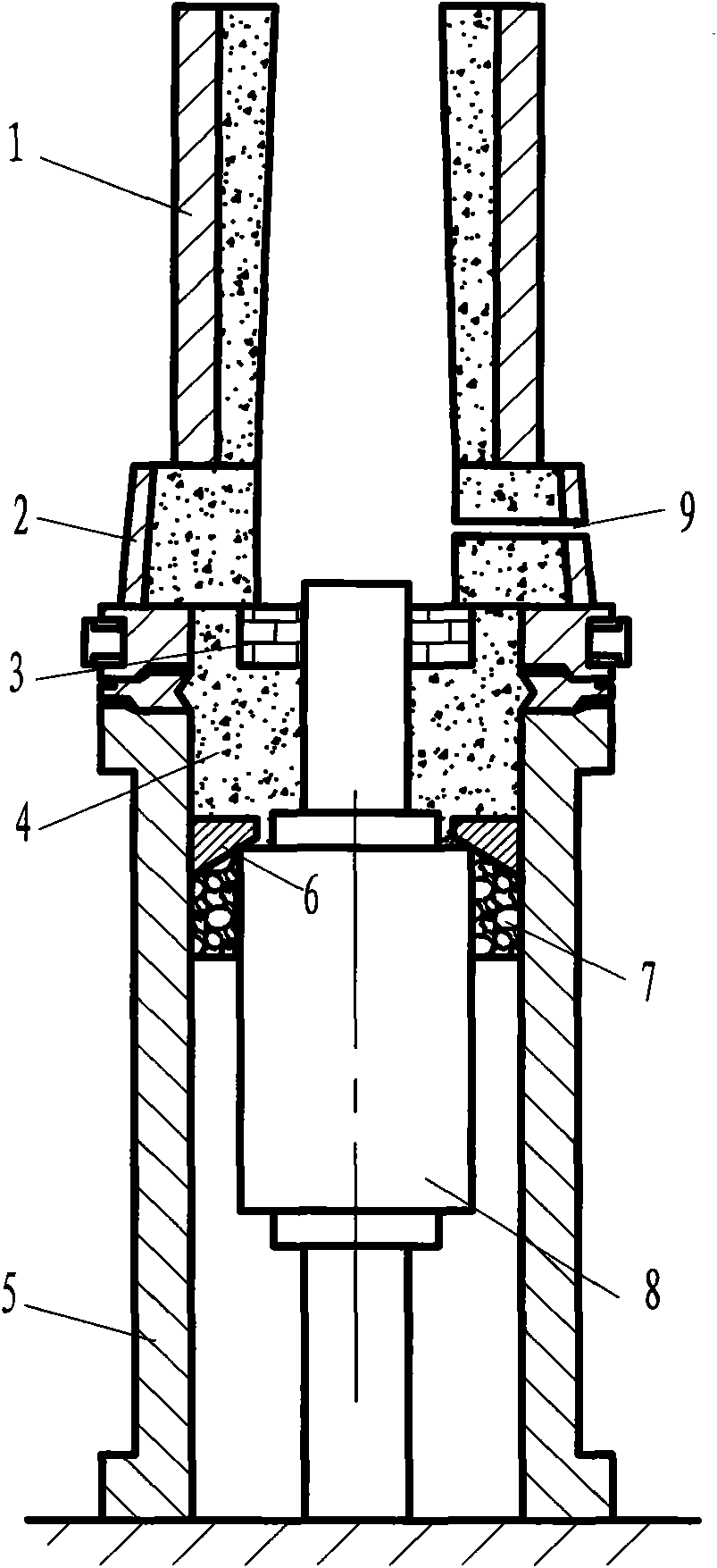

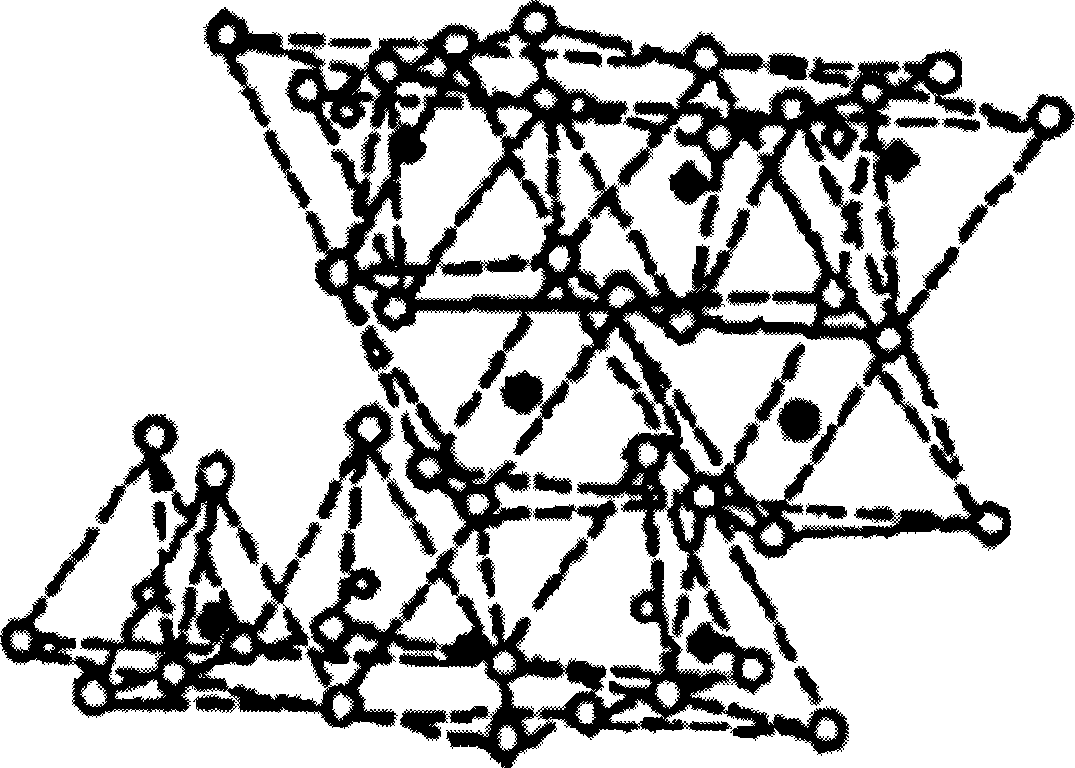

Method for producing 650 betaine

InactiveCN105494951ALess moistureReduce pollution and wasteOrganic compound preparationAccessory food factorsChemistryElectrodialysis

The invention provides a method for producing 650 betaine. The method comprises steps as follows: chloroacetic acid and sodium hydroxide in the mole ratio being (1.0-1.2):1 have a neutralization reaction at the first preset temperature and under the condition of the preset pH value, and sodium chloroacetate is obtained; trimethylamine and sodium chloroacetate in the mole rate being 1:1 have an amination reaction for preset time at the second preset temperature under the conditions of second preset pH value and preset pressure, and a mixture containing betaine, sodium chloride and trimethylamine is obtained; the mixture is separated, and a light component containing trimethylamine and a heavy component containing a betaine and sodium chloride mixture are obtained; the heavy component is dried; additives such as calcium stearate and the like are added to the dried heavy component. According to the method, concentration, salt filtration and purification of betaine through electrodialysis are not required, and the method has higher economical performance and environmental friendliness.

Owner:山东祥维斯生物科技股份有限公司

Cold-type casting welding method of roller necks

The invention discloses a cold-type casting welding method of roller necks, comprising: a procedure of adjusting the verticality of a cold-type neutral roller and fixing by an oblique iron, a fill forging process, a baking process, a mould assembling process, a wash melting process and a pouring process, wherein, in the fill forging process, the periphery of the roller neck on the oblique iron is filled and forged by water glass self-hardening sand until the height approaches to the height of the cross section of the roller neck; 1-4 layers of prefabricated fireproofing tiles are tightly arranged on the surrounding of the excircle of the roller neck; the end-face external diameter of the fireproofing tile is larger than the internal diameter of an overflow box; the upper flat surface of the fireproofing tile is lower than the cross section of the roller head; in the baking procedure, the water glass self-hardening sand automatically hardens for over 2 hours, and then the roller head fracture surface is baked and preheated by coal fire for 24 hours; and after the baking process is finished, the mould assembling process, the wash melting process and the pouring process are carried out. By the method provided by the invention, the defect of the air vents of the cast soldering products can be avoided, the casting quality is ensured, and the repair time of the roller is greatly shortened.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

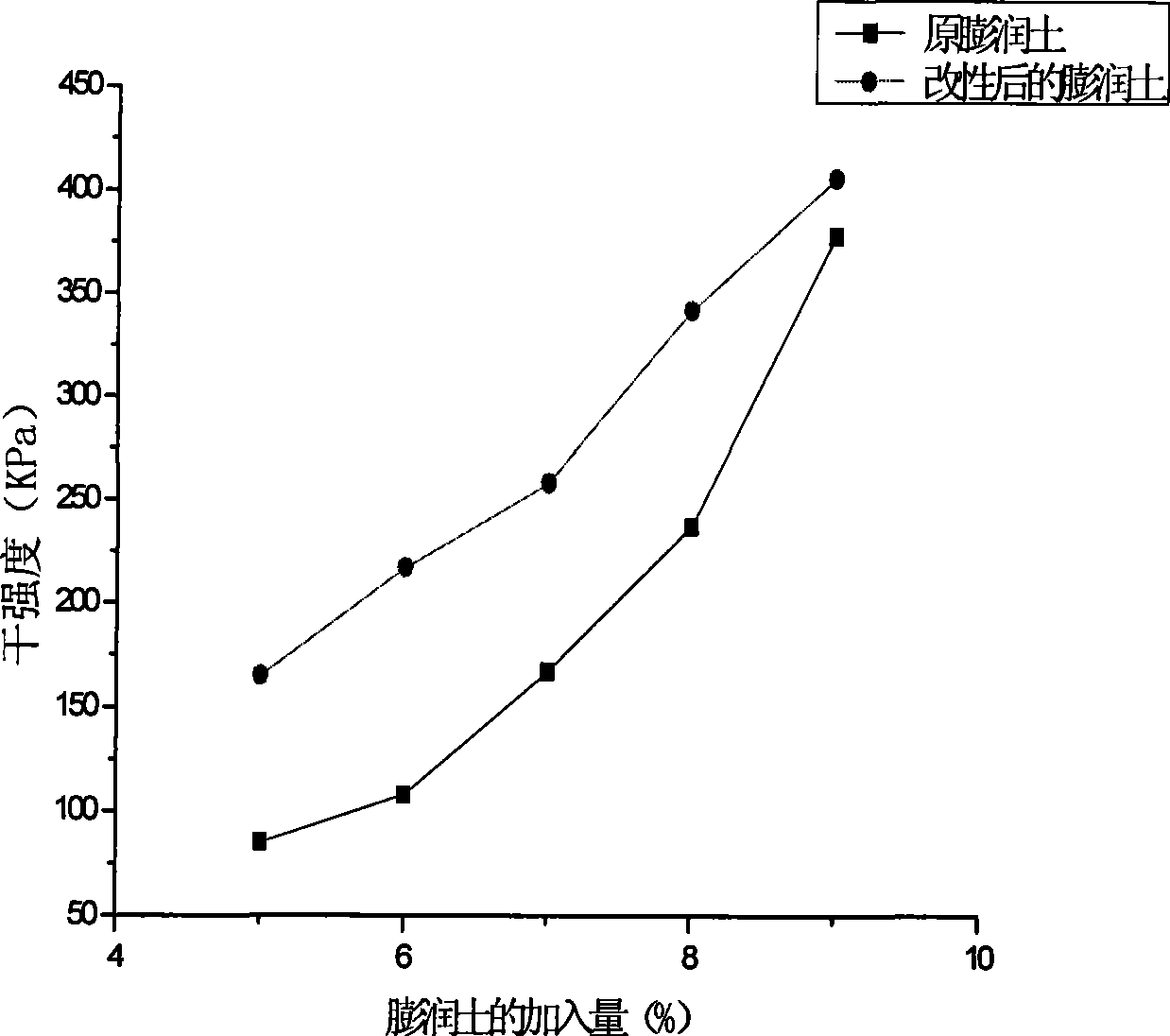

Use method of modified bentonite by lithiation in casting dry type clay sand

InactiveCN101376160AReduce intensityHigh strengthFoundry mouldsFoundry coresWater wetSodium Bentonite

The invention discloses an application method of lithiation modified bentonite clay in moulding dry clay sand and comprises the following steps: original sand is composed of 50-90 percent (wt) of old sand with the grain size of 15Q (H), and 50-90 percent (wt) of new sand with the grain size of 15Q (H); according to the reference of 100 weight parts of the original sand, lithiation bentonite clay accounting for 2-10 percent of the weight of the original sand is added to mix with 0-8 percent of calcium bentonit clay, and 5-7 percent of water is added when the moulding sand is wet-mixed; the mixed production is conducted by using an ordinary sand roller mill, the new sand, the old sand, the lithiation bentonite clay and the calcium bentonit clay are dry-mixed for two minutes, and then the wet mixture is conducted by adding the water for ten minutes; the drying temperature is 120-160 DEG C, the drying time is 60 minutes, and finally the dry pressing intensity of the obtained moulding sand is 360-405KPa.

Owner:SHANGHAI INST OF TECH

Methods and systems for making reinforced thermoplastic composites, and the products

ActiveUS20150011706A1Low viscosityHigh viscosityTailstocks/centresConfectioneryPolymer scienceIn situ polymerization

Various methods and systems of making inorganic fiber / flake reinforced composites having a thermoplastic matrix are disclosed. The methods use systems similar to those used to make inorganic fiber / flake reinforced products having a thermoset matrix, but the systems and methods are modified to use thermoplastic precursor monomer(s) followed by in situ polymerization of the monomer(s) during and / or following forming of the desired shape of the products. These methods permit the manufacture of superior inorganic fiber reinforced thermoplastic matrix composites in large and very large shapes heretofore not possible, or practical.

Owner:JOHNS MANVILLE CORP

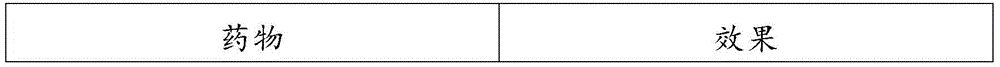

Pesticide applied through unmanned aerial vehicle and preparation method thereof

ActiveCN105454224AIncrease loading capacityReduce the number of repeated take-off and landing dosingBiocideDead animal preservationInternal pressureUncrewed vehicle

The invention belongs to the technical field of pesticides, and relates to a pesticide applied through an unmanned aerial vehicle. The pesticide is prepared from water-soluble film, gas and a gel composition; the water-soluble film forms a sealed capsule body which is filled with the gel composition and the gas, and the internal pressure of the capsule body is greater than the external pressure of the capsule body. The invention further relates to a preparation method of the pesticide. When the pesticide is used, the loading capacity of one-time effective components of the unmanned aerial vehicle is large, and the frequencies of repeated pesticide adding are reduced; pesticide spraying is completed by means of the spray force of the pesticide in the capsule body, the unmanned aerial vehicle does not need to conduct large-area spraying, the effect can be achieved by only putting the pesticide on multiple points, and the operation efficiency is improved.

Owner:创客帮(山东)科技服务有限公司

Manufacturing method for bamboo strip vertical environment-friendly composite board

InactiveCN105082271AStrong natural wood feelingTake advantage ofLaminationLamination apparatusSolid woodEucalyptus oil

The invention provides a manufacturing method for a bamboo strip vertical environment-friendly composite board. The manufacturing method includes the steps that firstly, one face of a veneer is sanded, natural eucalyptus oil is sprayed to the face of the veneer, drying is conducted for 2 or more hours, and then environment-friendly three-bean glue is sprayed; secondly, the two faces of a bamboo strip vertical layer are coated with environment-friendly three-bean glue; thirdly, hot pressing is conducted on a composite board blank of the wood, bamboo and wood three-layer structure; fourthly, the composite board plank is posput for 3 or more days for health maintenance, and then an environment-friendly composite material is obtained; and fifthly, grooves and tongues are sequentially formed in the four faces, namely, the two ends and the two sides, of the environment-friendly composite material, sanding is conducted, and a finished product is obtained after UV paint lines are arranged and decoration paint are sprayed on six faces. A floor manufactured from the bamboo strip vertical layer manufactured according to the method has a quite high natural solid wood sense and is environment-friendly, direct plate splicing is achieved, timber is fully used, and resources are saved; and the transverse or longitudinal flatly-placed bamboo-wood structures of bamboo strips are broken, so that the bearing strength of the bamboo strip vertical environment-friendly composite board is higher, the vertical structure of the bamboo strips and the transverse structure of veneers can fully restrain each other, and the bamboo strip vertical environment-friendly composite board is not prone to deformation.

Owner:上海红晨木业有限公司

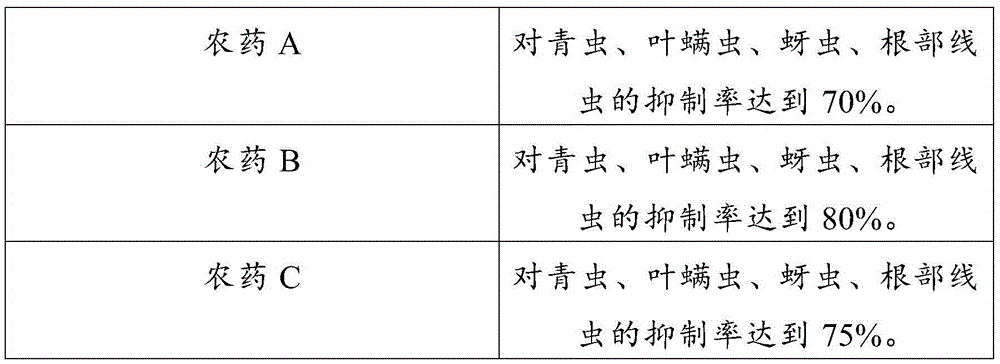

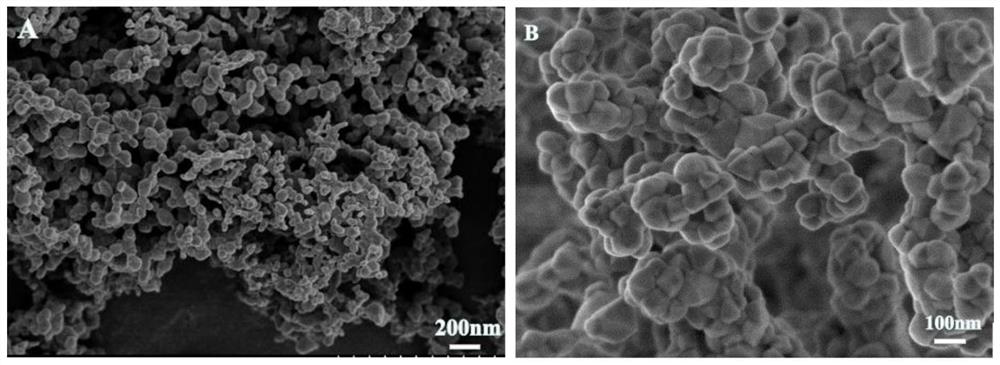

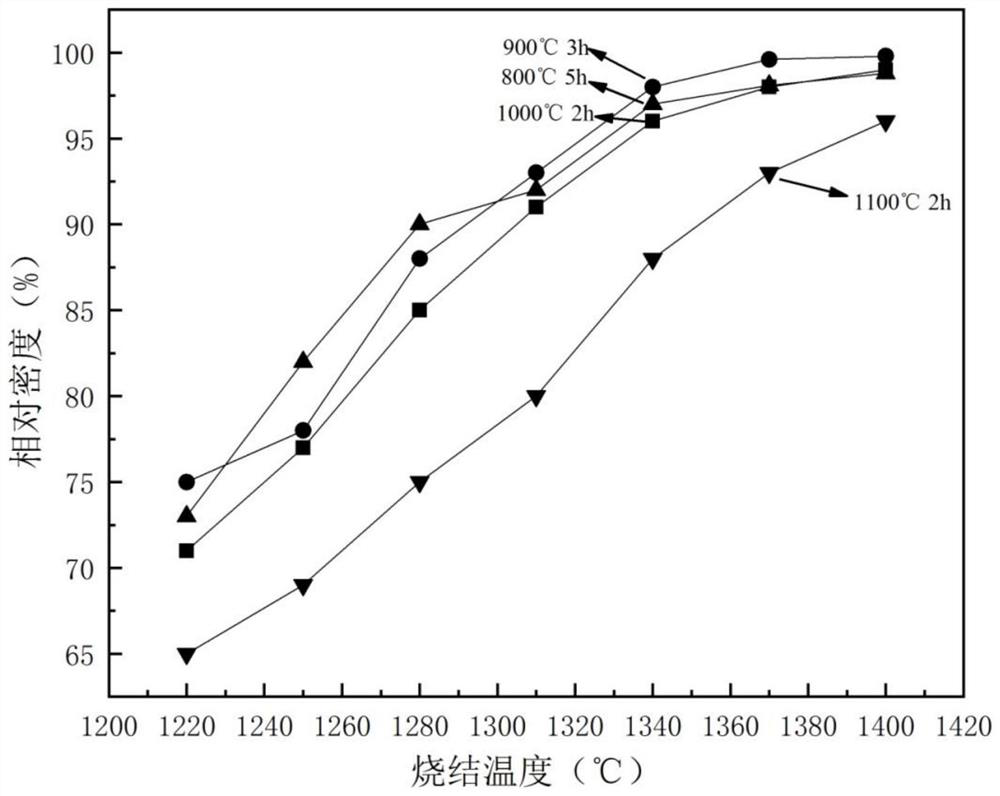

Preparation method of high-sintering-activity zirconium oxide powder

The invention discloses a preparation method of high-sintering-activity zirconium oxide powder, relates to the technical field of ceramic powder preparation, and aims at solving the problems that existing zirconium oxide powder is easy to agglomerate, unstable in crystal form and not easy to sinter. The preparation method comprises the following steps: preparing basic precipitation salt containingzirconium and M by taking a zirconium inorganic salt as a main raw material and a metal M nitrate as an additive, and then performing ball milling, hydrothermal reaction and high-temperature calcination to prepare the high-dispersion tetragonal-phase zirconium oxide nano powder. The obtained white precipitate is in a non-colloidal state, contains less moisture, has small capillary force action inthe drying process, and is easy to obtain precursor powder which is less in agglomeration and loose; and through a two-step synthesis method, auxiliary agent metal ions are more easily and uniformlydissolved into crystal lattices of zirconium oxide in a solid solution manner in hydrothermal, high-pressure and low-temperature environments after dry gel is crushed and ball-milled, and the preparedzirconium oxide powder is uniform in particle and good in dispersity, and has obviously improved sintering performance compared with industrial zirconium oxide.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

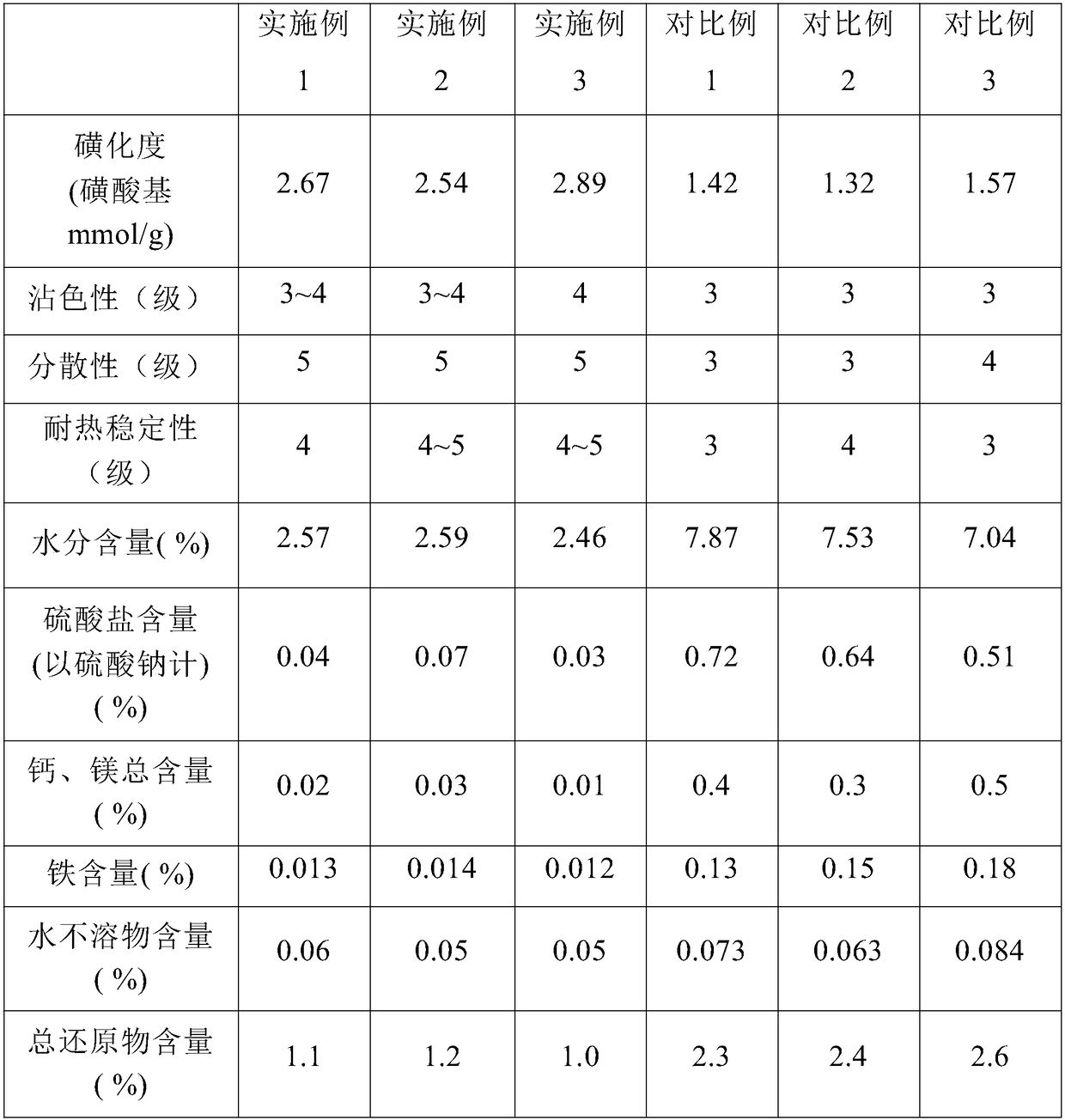

Method for preparing lignin sulfonate by utilizing papermaking black liquid

The invention discloses a method for preparing lignin sulfonate by utilizing papermaking black liquid. The method comprises the following steps: S1, preparing raw materials: preparing the raw materials such as the papermaking black liquid, anhydrous sodium sulfite and formaldehyde, wherein the use amount of the sodium sulfite is 2.9 to 3.2 mmol per gram of lignin, the use amount of the formaldehyde is 0.8 to 1.2 mmol per gram of lignin, and the formaldehyde is prepared into a formaldehyde solution; S2, performing reaction: adding the papermaking black liquid into a reaction kettle, adding thesodium sulfite and the formaldehyde solution, stirring and heating, gradually heating to 158 to 165 DEG C, and continuously stirring to perform reaction for 2.5 to 3.5 hours, wherein the consumed timein the heating process is 80 to 100 minutes and the temperature is increased by 1 to 5 DEG C per minute; and S3, discharging: cooling after the reaction, and discharging when the temperature is reduced to 60 to 70 DEG C. The lignin sulfonate prepared by the method has high sulfonation degree and excellent tainting property, dispersibility and heat-resistant stability, has low water content and low content of sulfate, calcium, magnesium, iron, water insoluble matters and total reducing matters, has excellent comprehensive quality and can be widely applied in various fields.

Owner:HAINAN JINHAI PULP & PAPER

Method for extracting anise seed oil

InactiveCN104140881AHigh purityLess moistureFatty-oils/fats productionEdible oils/fatsVacuum dryingMoisture

The invention discloses a method for extracting anise seed oil. The method comprises the following preparation steps of smashing anise seeds subjected to impurity removing, cleaning and drying to obtain anise seed powder; adding Vitamin E into the anise seed powder and putting the mixture into a magnetic field to be processed; feeding the anise seed powder subjected to magnetization processing into an extraction kettle to perform supercritical CO2 extraction to obtain crude oil; performing vacuum drying on the crude oil to obtain the anise seed oil. According to the method for extracting the anise seed oil, the magnetic field extraction technology, the supercritical CO2 extraction technology and the vacuum drying technology are combined, extraction pressure and temperature of supercritical CO2 extraction are reduced, extraction time is shortened, and extraction efficiency is increased. In addition, the obtained anise seed oil is high in purity and less in moisture, and preservation time of the anise seed oil is prolonged. Therefore, the method can extract the anise seed oil safely and efficiently.

Owner:叶新

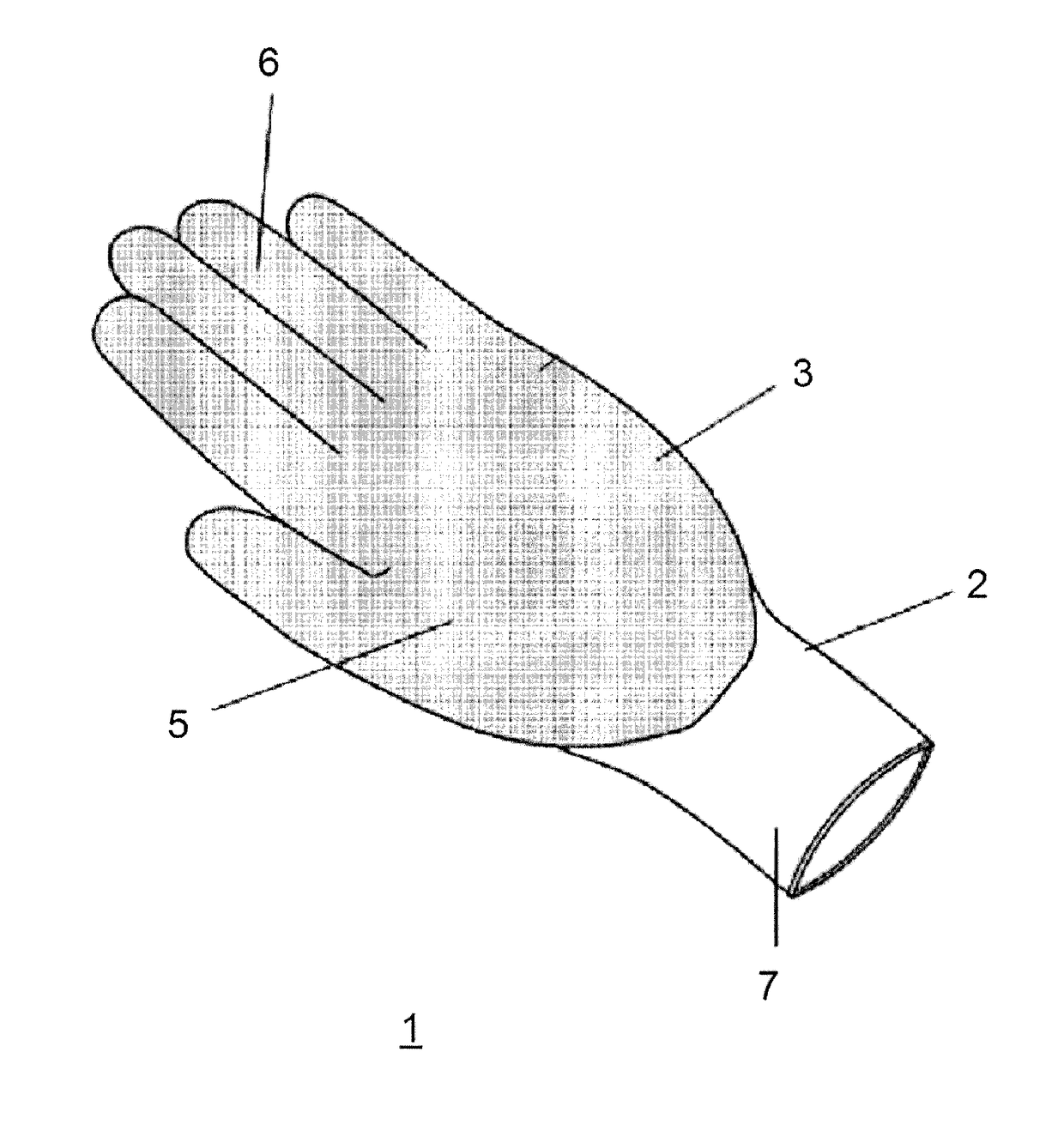

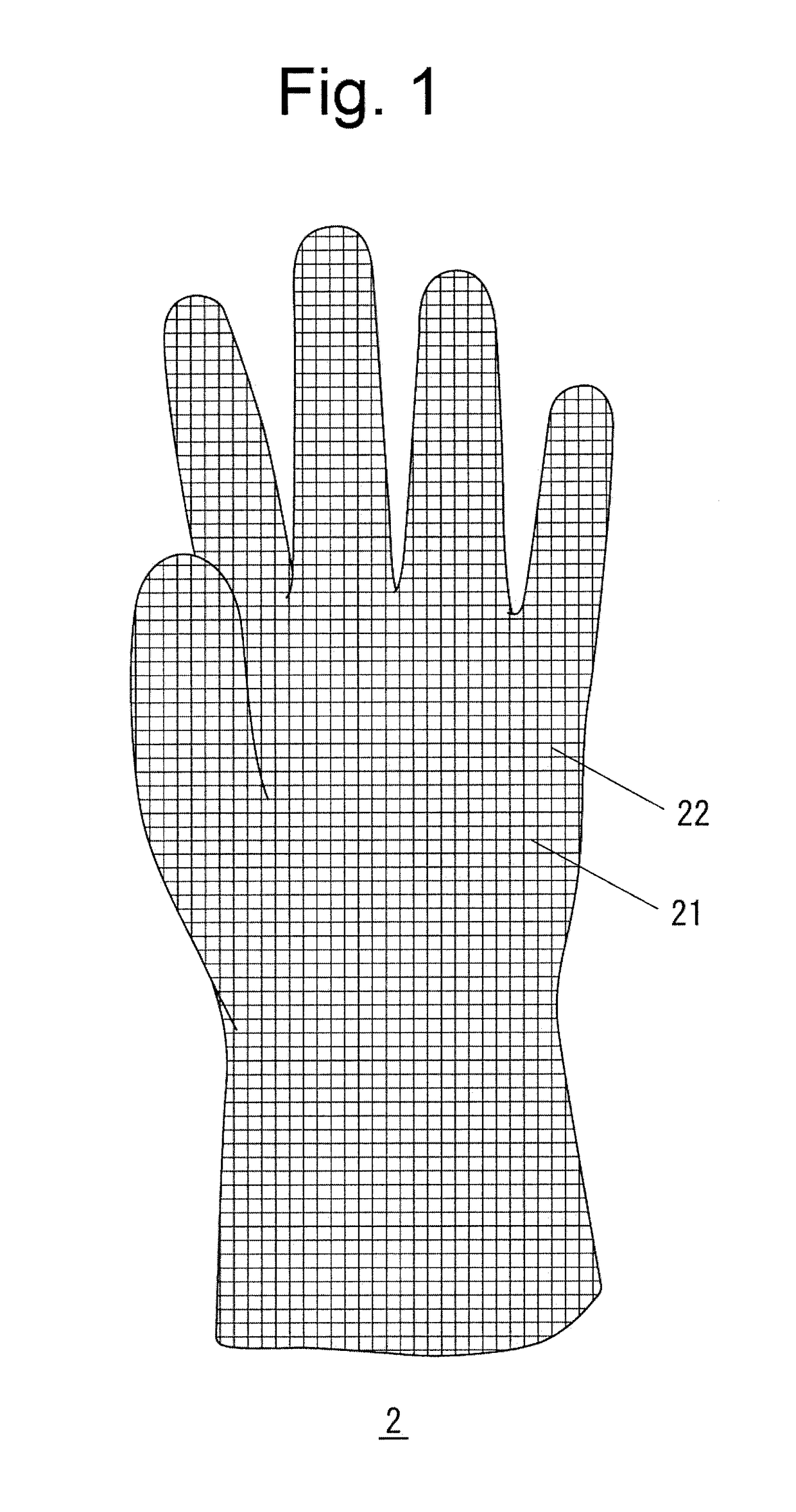

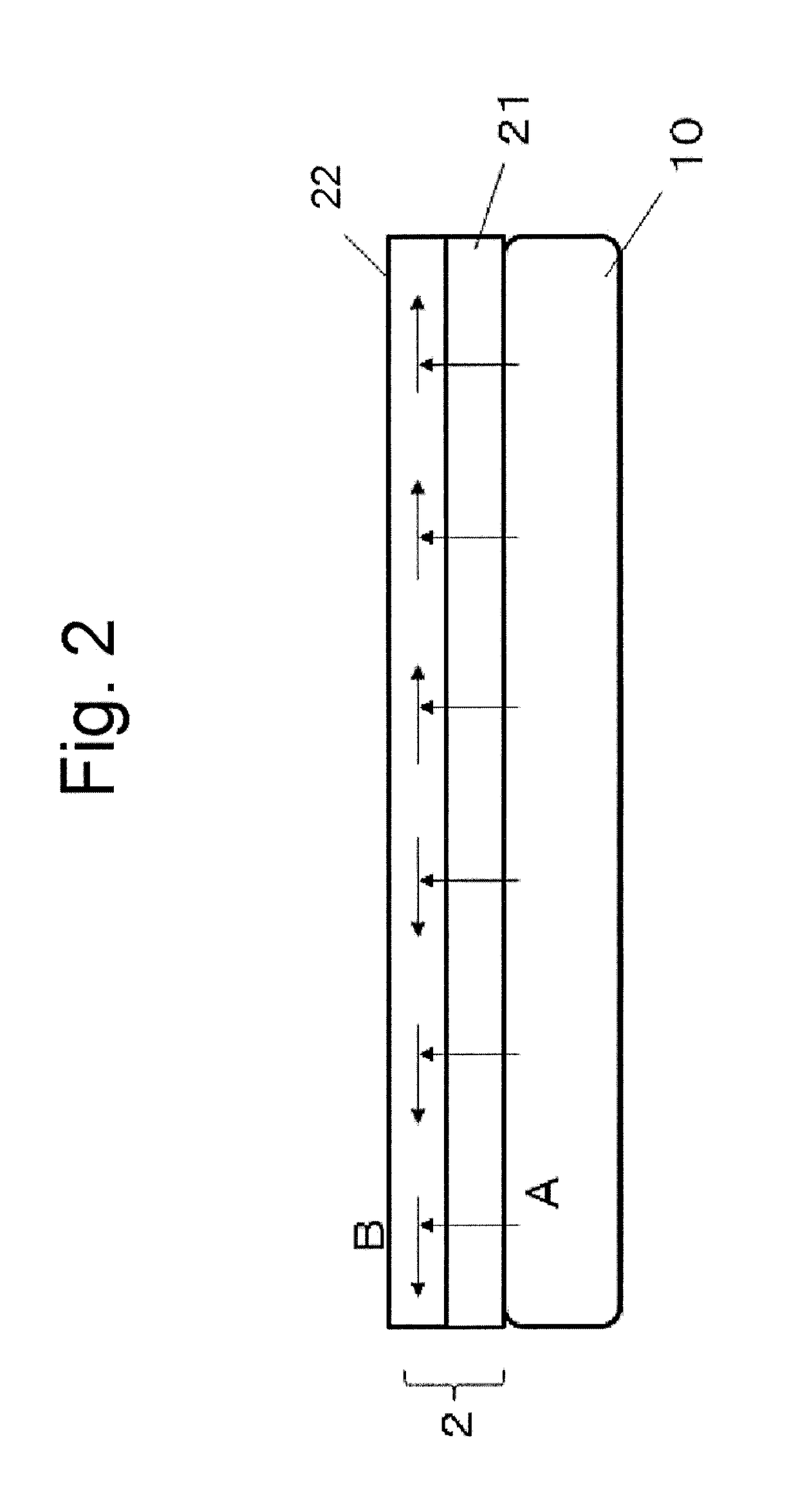

Glove base and glove

ActiveUS20170099890A1Reliably absorb moistureLess discomfortGarment special featuresGlovesFiberEngineering

[Problem] To provide a glove base and glove which enhance water-absorbing properties for moisture on a surface of a hand and easily release moisture to the outside from the entire glove even if the glove is configured only of a fiber-made base or even if coating is provided to a surface of the glove.[Solution] A glove base of the present invention is a glove base made of fiber and having a hand shape, wherein water-absorbing properties of a first fiber exposed mainly to inside of the glove base are higher than water-absorbing properties of a second fiber exposed mainly to outside of the glove base, the first fiber absorbs and moves moisture on a surface of a hand on the inside to the second fiber, and the second fiber moves the moisture moved from the first fiber mainly in a surface direction.

Owner:TOWA

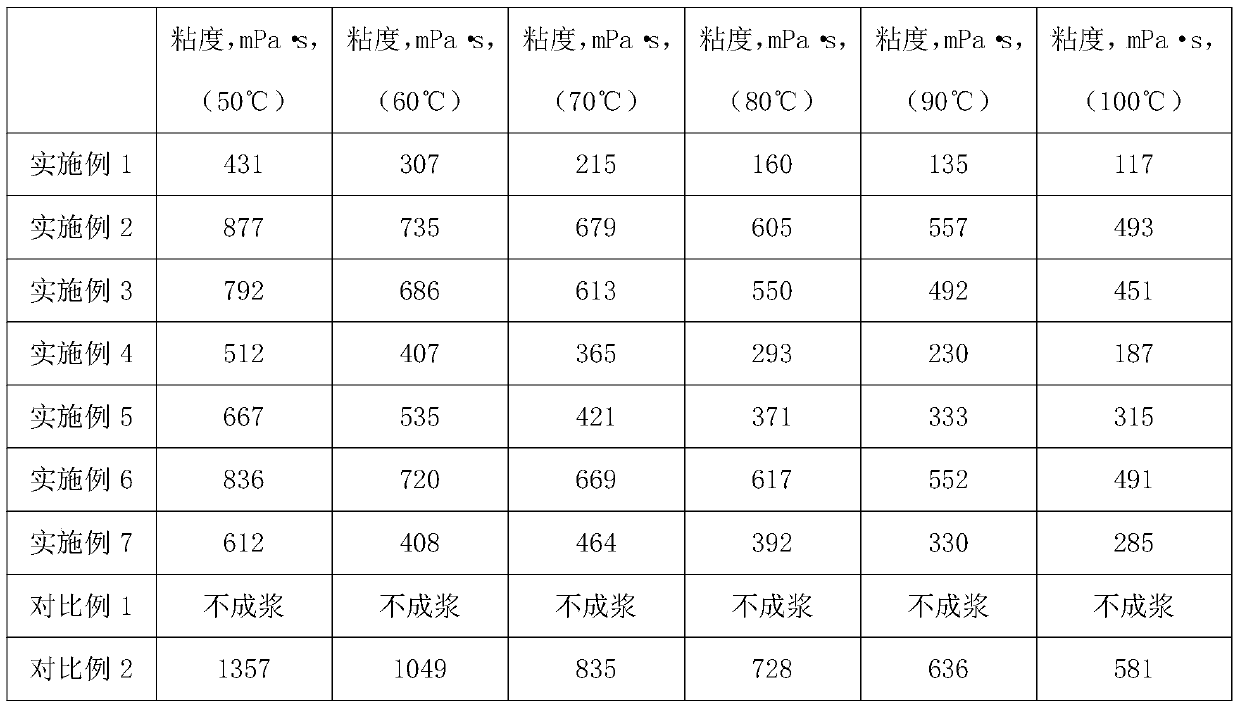

A method for increasing straw content in oil

ActiveCN108300520BIncrease contentReduce contentBiofuelsSolid fuelsCompression moldingPulp and paper industry

The invention belongs to the technical field of biomass reutilization, and particularly relates to a method for improving the content of straws in oil. The method comprises the following steps: (1) drying and dehydrating collected straws, and crushing the straws to a median particle diameter (D50) of 100-300 [mu]m; (2) performing compression molding on the crushed straws obtained in step (1) undera compression pressure of 0.5-3 MPa at a compression temperature of 30-60 DEG C; (3) crushing the compression-molded straws obtained in step (2) to a median particle diameter (D50) of 30-50 [mu]m inorder to obtain straw powder; and (4) mixing the straw powder obtained in step (3) with oil in proportion, and performing grinding pulping to obtain a slurry having a concentration of 30-60 wt%. The method makes the solid content of the straws in the oil reach 30-60 wt%, and the viscosity of the slurry is only 500-1400 mPa.s (50 DEG C), so the slurry has good slurry ability and a high fluidity, can be easily conveyed, meets feeding requirements of a subsequent processing process, and improves the utilization efficiency of a device.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com