Method for producing 650 betaine

A technology of betaine and ph value, which is applied in chemical instruments and methods, preparation of organic compounds, additional food elements, etc., can solve the problems of high production cost, high energy consumption, low product yield, etc., and achieve low moisture content, Pollution and waste reduction, high economical and environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

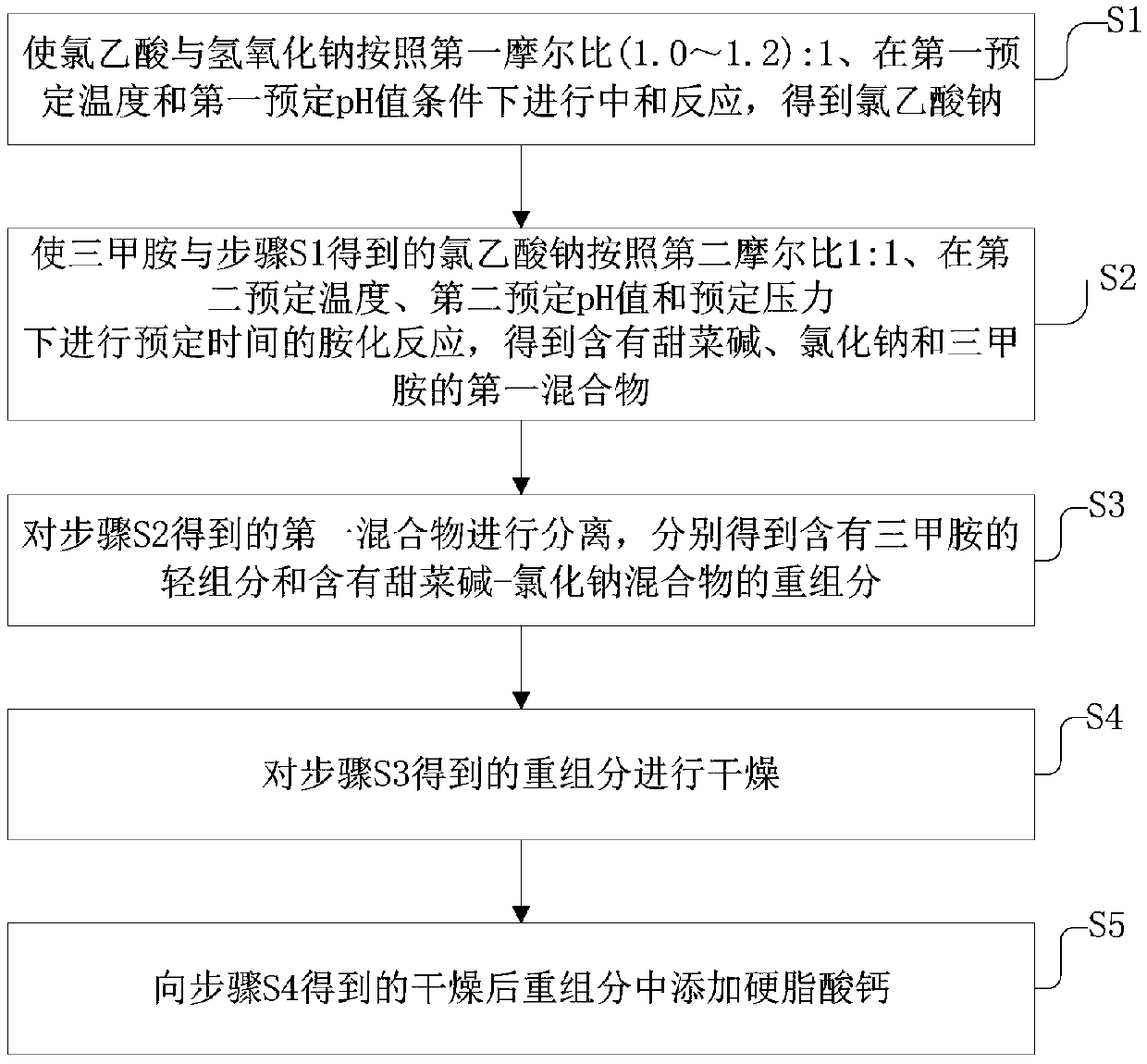

Method used

Image

Examples

example 1

[0025] Dissolve 3000kg of chloroacetic acid in 1380kg of water at a ratio of 6:2.75. The chloroacetic acid solution and sodium hydroxide solution are accurately metered by the automatic control valve and then enter the reactor in parallel with a molar ratio of 1.03:1. The continuous feeding and discharging process is in progress. For the reaction, the temperature is controlled at 45℃±5℃, and the pH value is controlled at 5-7. The yield of sodium chloroacetate in this section can reach more than 98%.

[0026] After the neutralization reaction, the trimethylamine and sodium chloroacetate solution were controlled by DCS to conduct a fixed-point reaction at a molar ratio of 1:1. The reaction is conducted at a temperature of 35°C to 46°C and a pressure of -20KPa to 10KPa for 5h to 6h, and the pH value of the aminating solution (a mixture containing betaine, sodium chloride and trimethylamine) is 10-12.

[0027] The amination liquid is separated in a vacuum distillation tower with a pre...

example 2

[0031] Dissolve 3,500 kg of chloroacetic acid in 1610 kg of water at a ratio of 6:2.75. The chloroacetic acid solution and sodium hydroxide solution are accurately measured by the automatic control valve and then flow into the reactor at a molar ratio of 1.1:1 in parallel. The continuous feeding and discharging process is in progress. For the reaction, the temperature is controlled at 50°C±5°C, and the pH value is controlled at 7-9. The yield of sodium chloroacetate in this section can reach more than 98%.

[0032] After the neutralization reaction, the trimethylamine and sodium chloroacetate solution are automatically controlled by DCS to conduct a fixed-point reaction at a molar ratio of 1:1. The reaction is carried out at a temperature of 46℃~58℃ and a pressure of 10KPa~40KPa for 6h~7h, and the pH of the aminating solution is 8~11.

[0033] The amination liquid is separated in a vacuum distillation column with a pressure of -0.07MPa to -0.02MPa, a tower top temperature of 65°C t...

example 3

[0037] Dissolve 4000kg of chloroacetic acid in 1840kg of water at a ratio of 6:2.75. The chloroacetic acid solution and sodium hydroxide solution are accurately measured by the automatic control valve and then enter the reactor in parallel with a molar ratio of 1.2:1. The new process of continuous feeding and discharging is adopted. In the neutralization reaction, the temperature is controlled at 55°C±5°C, and the pH value is controlled at 9-11. The yield of sodium chloroacetate in this section can reach more than 98%.

[0038] After the neutralization reaction, the trimethylamine and sodium chloroacetate solution were controlled by DCS to conduct a fixed-point reaction at a molar ratio of 1:1. The reaction is carried out at a temperature of 58℃~70℃ and a pressure of 40KPa~70KPa for 7h~8h, and the pH of the aminating solution is 6~9.

[0039] The amination liquid is separated in a vacuum distillation column with a pressure of -0.07MPa to -0.02MPa, a tower top temperature of 65°C to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com