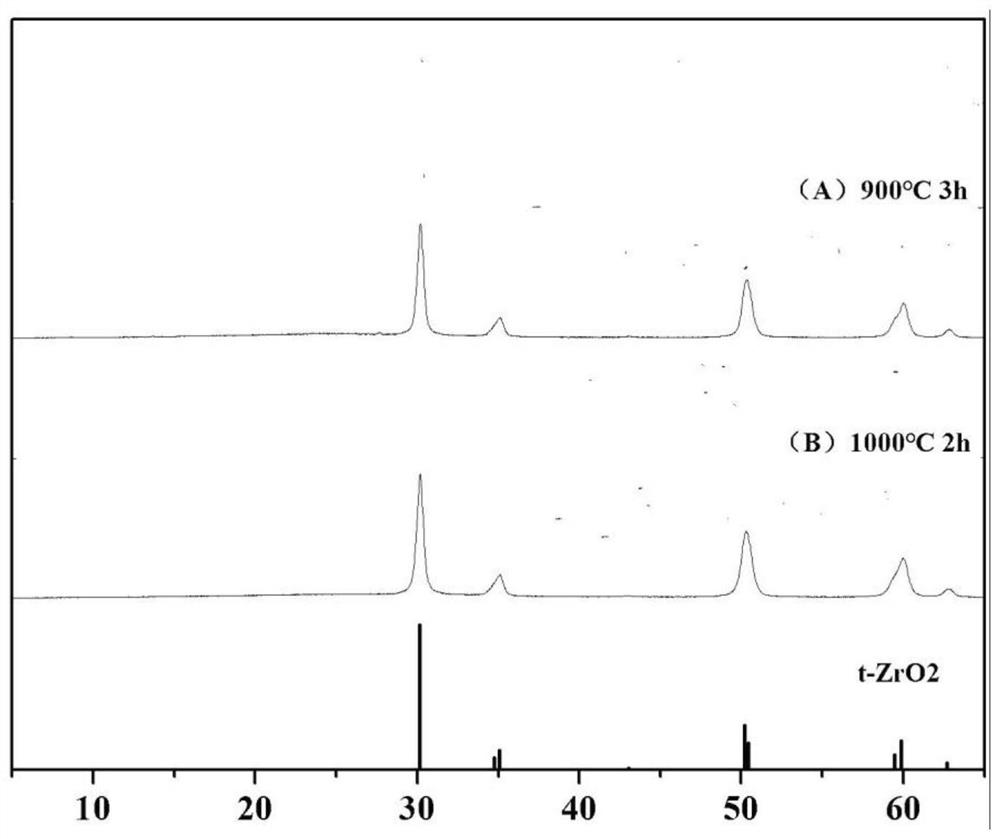

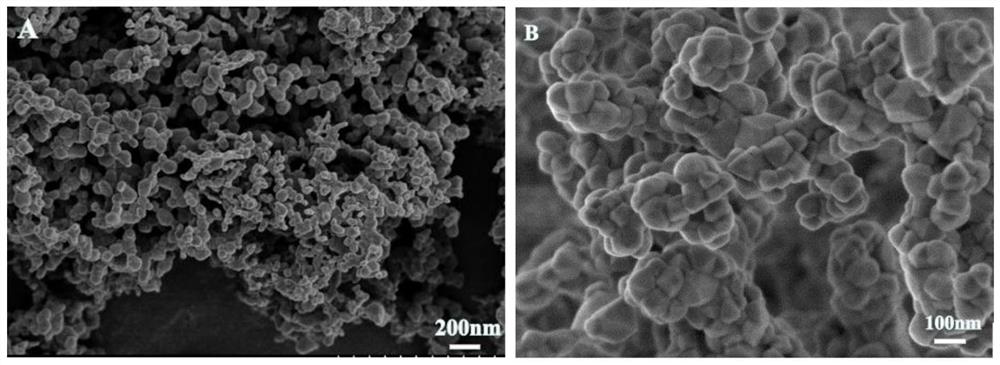

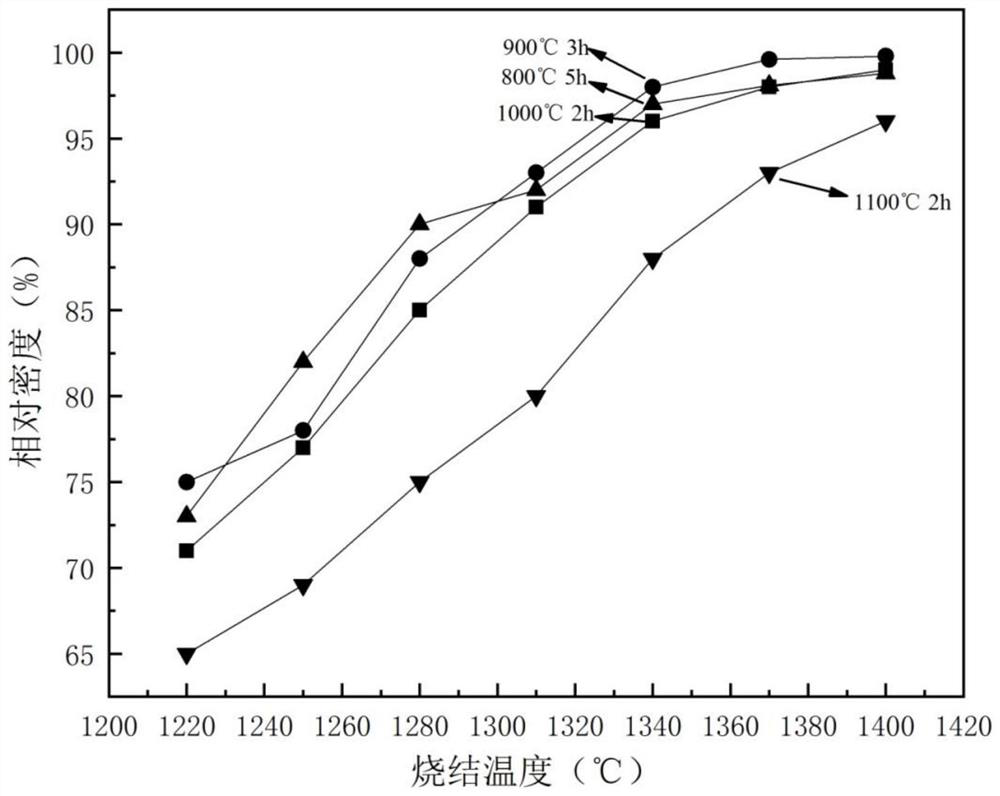

Preparation method of high-sintering-activity zirconium oxide powder

A technology of sintering active zirconia powder, which is applied in the field of ceramic powder preparation, which can solve the problems of unstable crystal form, easy agglomeration of powder, and difficult sintering, etc., and achieve the effects of less water content, easy access to raw materials, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of highly sintered active zirconia powder, comprising the following steps:

[0038] (1) Preparation of Zr and M basic precipitated salts: Zirconium oxychloride is used as the main raw material, magnesium nitrate is used as the auxiliary agent, and ammonium bicarbonate is used as the precipitating agent, which are respectively configured into zirconium inorganic salt solutions with a concentration of 0.2g / mol , a concentration of 0.1g / mol metal M nitrate aqueous solution, a concentration of 2g / mol aqueous solution; according to the mass ratio of 16:1, zirconium inorganic salt solution and metal M nitrate aqueous solution are mixed uniformly to obtain Zr-M salt mixed solution;

[0039] (2) According to the mass ratio of 1:1, add the prepared Zr-M salt mixture dropwise to the ammonium bicarbonate aqueous solution while stirring, and age at 20-40°C for 6-18h to obtain a white precipitate;

[0040] (3) Suction-wash the prepared white precipitate with de...

Embodiment 2

[0046] A preparation method of highly sintered active zirconia powder, comprising the following steps:

[0047] (1) Preparation of Zr and M basic precipitated salts: Zirconium oxychloride is used as the main raw material, magnesium nitrate is used as the auxiliary agent, and ammonium bicarbonate is used as the precipitating agent, which are respectively configured into zirconium inorganic salt solutions with a concentration of 0.2g / mol , a concentration of 0.1g / mol metal M nitrate aqueous solution, a concentration of 2g / mol aqueous solution; according to the mass ratio of 16:1, zirconium inorganic salt solution and metal M nitrate aqueous solution are mixed uniformly to obtain Zr-M salt mixed solution;

[0048] (2) According to the mass ratio of 1:1, add the prepared Zr-M salt mixture dropwise to the ammonium bicarbonate aqueous solution while stirring, and age at 20-40°C for 6-18h to obtain a white precipitate;

[0049] (3) The prepared white precipitate was filtered and was...

Embodiment 3

[0055] A preparation method of highly sintered active zirconia powder, comprising the following steps:

[0056] (1) Preparation of Zr and M basic precipitated salts: Zirconium oxychloride is used as the main raw material, magnesium nitrate is used as the auxiliary agent, and ammonium bicarbonate is used as the precipitating agent, which are respectively configured into zirconium inorganic salt solutions with a concentration of 0.2g / mol , a concentration of 0.1g / mol metal M nitrate aqueous solution, a concentration of 2g / mol aqueous solution; according to the mass ratio of 16:1, zirconium inorganic salt solution and metal M nitrate aqueous solution are mixed uniformly to obtain Zr-M salt mixed solution;

[0057] (2) According to the mass ratio of 1:1, add the prepared Zr-M salt mixture dropwise to the ammonium bicarbonate aqueous solution while stirring, and age at 20-40°C for 6-18h to obtain a white precipitate;

[0058] (3) Suction-wash the prepared white precipitate with de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com