A method for increasing straw content in oil

A straw and content technology, applied in the field of increasing the content of straw in oil, can solve the problems of low straw content and low utilization efficiency of hydrogenation devices, and achieve the effects of high bulk density, favorable transportation and increased solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

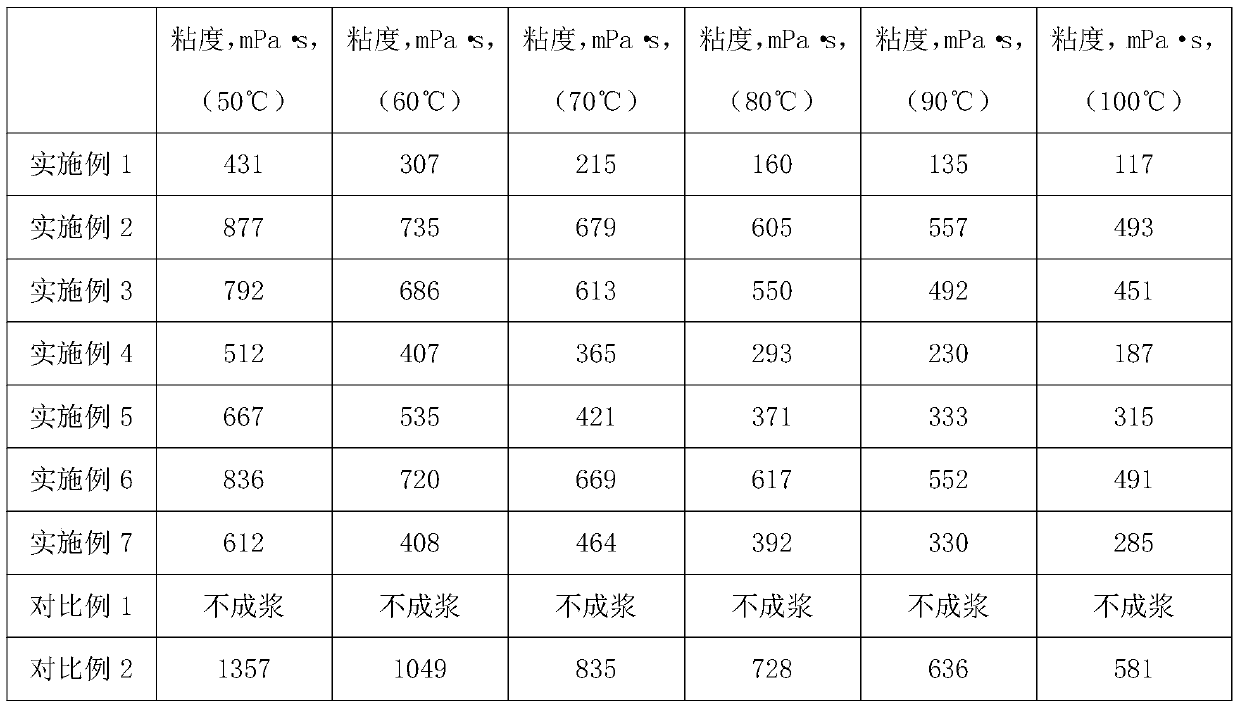

Examples

Embodiment 1

[0024] A method for increasing the content of straw in oil, comprising the following steps:

[0025] (1) Drying and dehydrating the collected corn stalks, the drying temperature is 60°C, the drying time is 4h, and then pulverized by a ball mill until the median particle size (D50) is 100 μm;

[0026] (2) compressing the crushed stalks in step (1) with a tablet press, the compression pressure is 3MPa, and the compression temperature is 30°C;

[0027] (3) The straw after compression molding in step (2) is pulverized again with a ball mill until the median particle size (D50) is 50 μm to obtain straw powder with a bulk density of 400 kg / m 3 ;

[0028] (4) Mix 30 kg of straw powder in step (3) with 70 kg of waste oil, and use a mixer to grind and make pulp. The grinding and pulping time is 8 minutes to obtain a slurry with a concentration of 30 wt%.

Embodiment 2

[0030] A method for increasing the content of straw in oil, comprising the following steps:

[0031] (1) Drying and dehydrating the collected wheat straw, the drying temperature is 55°C, the drying time is 4.5h, and then pulverized with a hammer mill until the median particle size (D50) is 300 μm;

[0032] (2) compressing and molding the stalks pulverized in step (1) by a layering machine, the compression pressure is 0.5MPa, and the compression temperature is 60°C;

[0033] (3) The stalks compressed and formed in step (2) are pulverized again with a hammer mill until the median particle size (D50) is 30 μm to obtain straw powder with a bulk density of 300 kg / m 3 ;

[0034] (4) 50kg of straw powder in step (3) is mixed with 50kg of washing oil, ground and pulped to obtain a slurry with a concentration of 50wt%.

Embodiment 3

[0036] A method for increasing the content of straw in oil, comprising the following steps:

[0037] (1) Drying and dehydrating the collected peanut stalks, the drying and dehydration temperature is 50°C, the drying and dehydration time is 5h, and then crushed with a jet mill until the median particle size (D50) is 200 μm;

[0038] (2) Compressing the crushed straw in step (1) with a tablet press, the compression pressure is 1MPa, and the compression temperature is 40°C;

[0039] (3) The stalks compressed and formed in step (2) are pulverized again with a jet mill until the median particle size (D50) is 40 μm to obtain straw powder with a bulk density of 350 kg / m 3 ;

[0040] (4) 35kg of straw powder in step (3) and 65kg of waste engine oil were ground and pulped to obtain a slurry with a concentration of 35wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com