Patents

Literature

63results about How to "No obvious smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

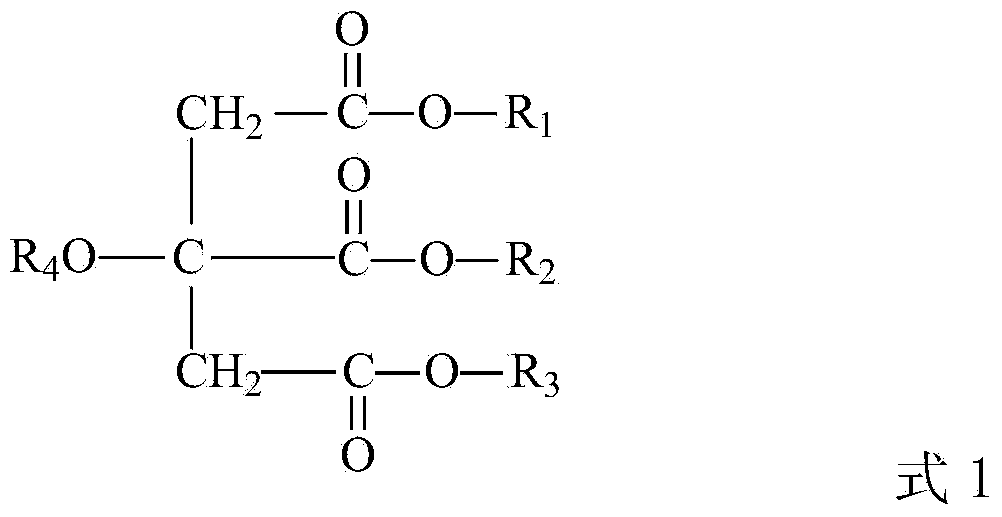

Novel plasticizer and preparation method thereof

ActiveCN103113617AReduce volatilityHigh plasticizing efficiencyOrganic compound preparationCarboxylic acid esters preparationAlcoholCITRATE ESTER

The invention relates to a novel plasticizer and a preparation method thereof, which overcome the defects that the existing low-carbon alcohol citrate plasticizers are non-transference-resistant, high in volatility and high in economic costs and high-carbon alcohol citrate plasticizers are low in efficiency. The novel plasticizer contains at least two types of citrate compounds. The novel plasticizer disclosed by the invention can be used as a plasticizer, and widely applied to the fields of plastic compositions and adhesives and the like.

Owner:山东万图高分子材料股份有限公司

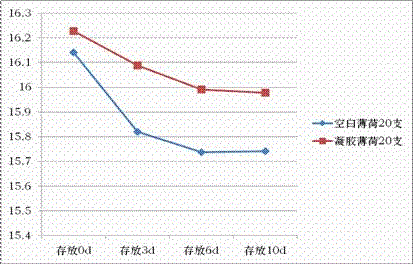

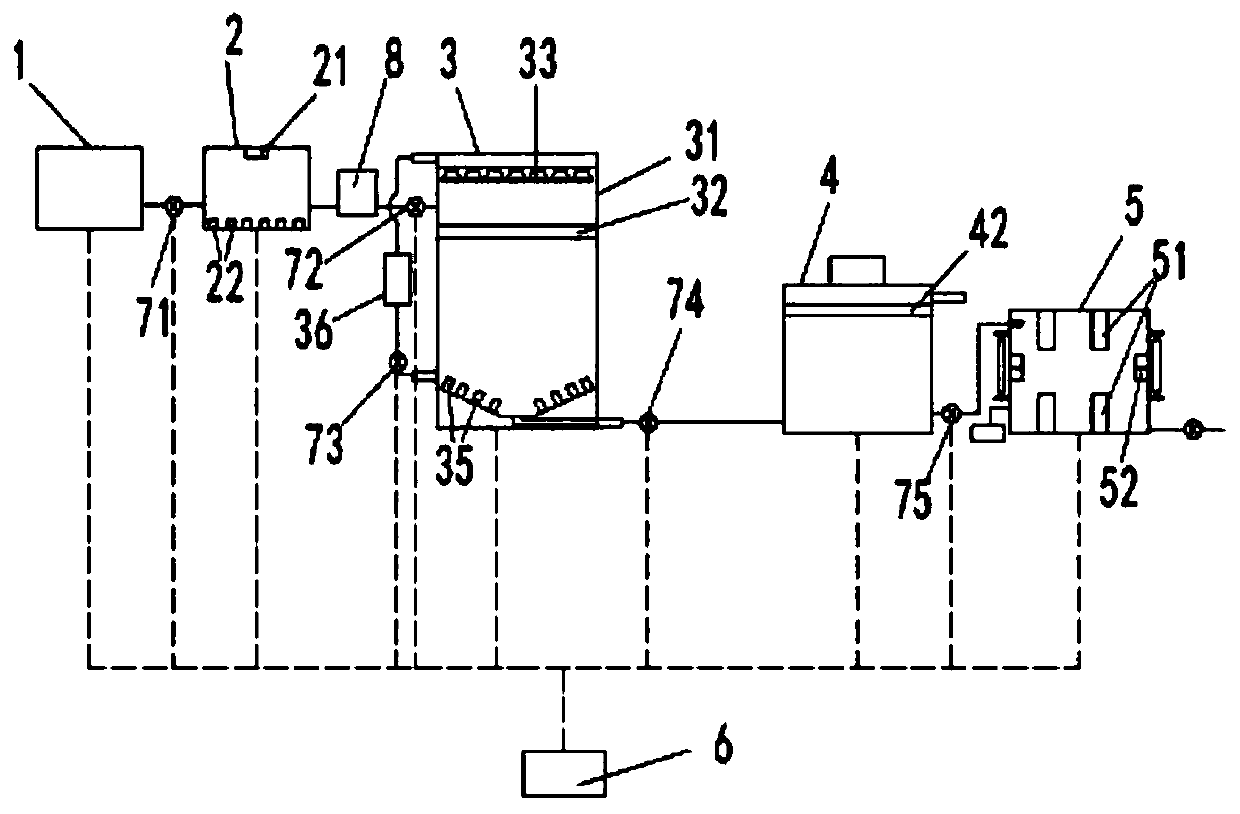

Temperature-variable controlled-release gel composite material and application thereof in cigarette filter stick

InactiveCN107173848ANo obvious smellImprove smellTobacco smoke filtersManufacturing technologyControl release

The invention provides a temperature-variable controlled-release gel composite material and application thereof in a cigarette filter stick, and belongs to the technical field of preparation of cigarette holders. A preparation method comprises the steps that gel is heated and melted; then the gel is conveyed into an infiltration tank with a heat preservation function; a common aroma-increasing core wire is wound through an unwinding mechanism and then guided to the infiltration tank, the core wire is immersed into the liquid gel, and the concentration of the liquid gel is adjusted so that the thickness of a gel layer attached to the surface of the aroma-increasing core wire can be larger than or equal to the diameter of the aroma-increasing core wire; then cooling and drying are conducted on the infiltrated aroma-increasing core wire, the gel is solidified into a solid which is attached to the surface of the aroma-increasing core wire, and accordingly the temperature-variable controlled-release gel composite material is obtained. According to the composite material prepared from the gel and the prepared filter stick, the forming degree and the aroma locking effect are good, production arrangement of the filter stick is facilitated, obtained products are relatively rich, and quick volatilization of the gel which is simply applied to the filter stick during smoking can be slowed down, so that a whole cigarette has a relatively balanced mouth feel.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

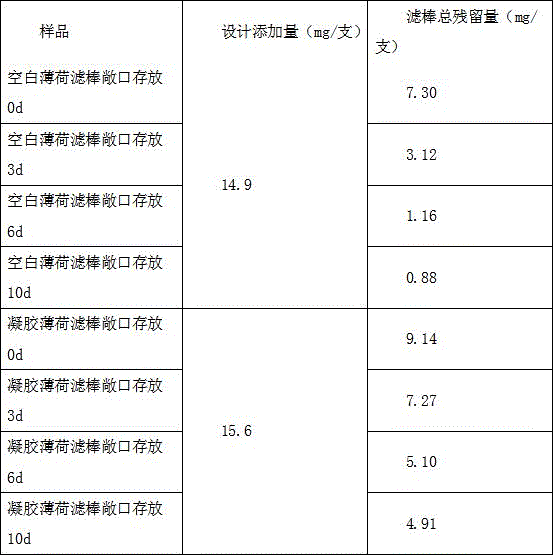

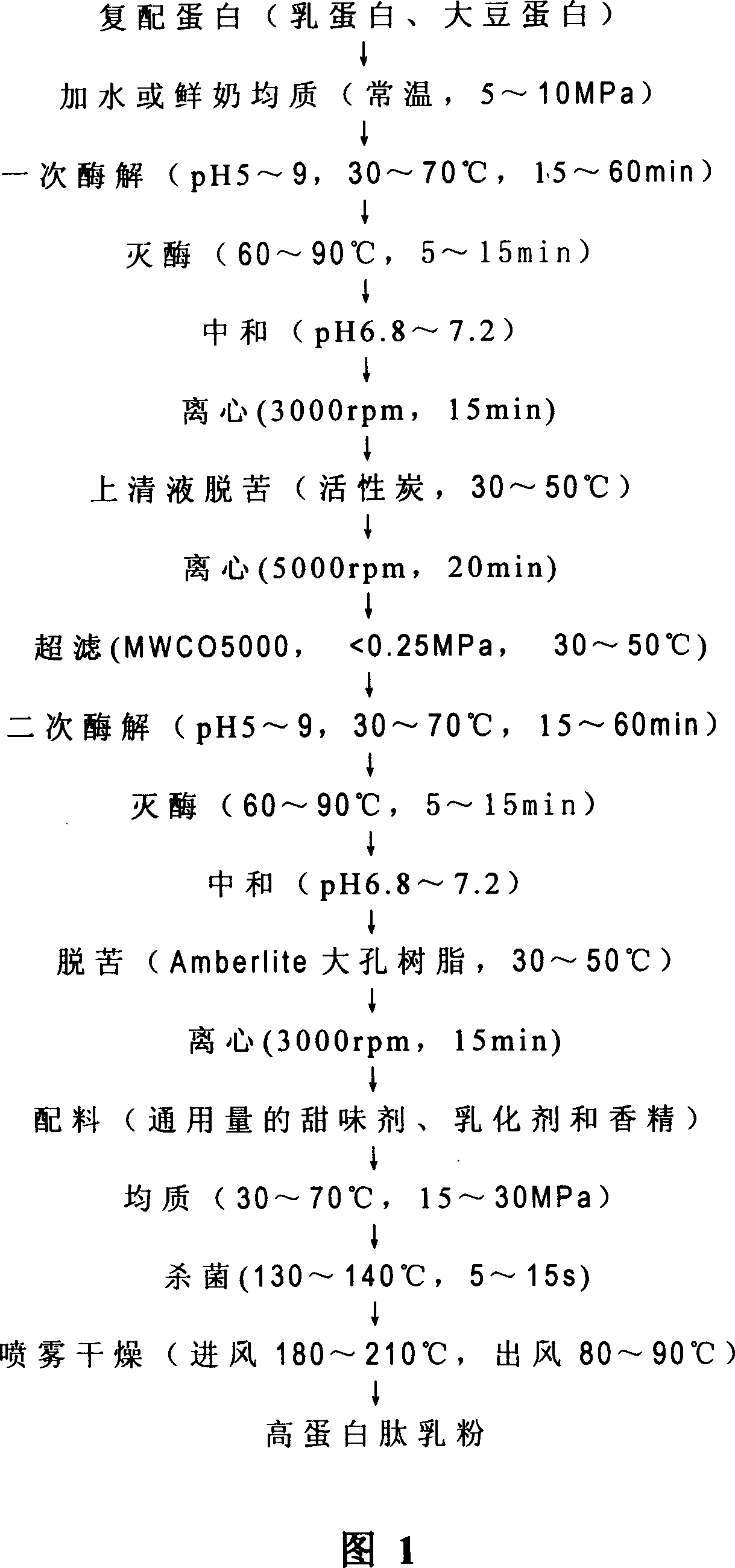

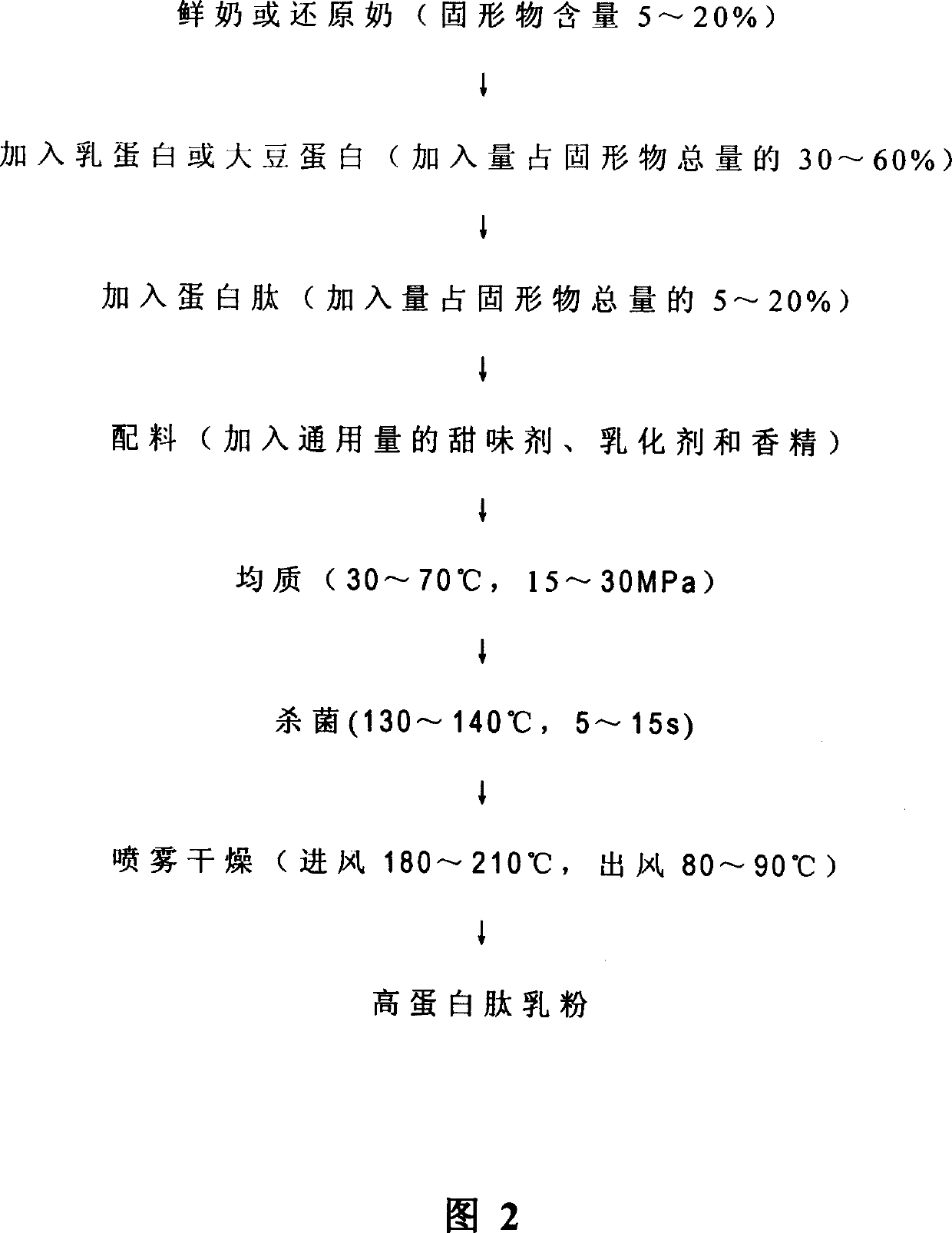

High protein peptide milk powder and its production process

InactiveCN1526290AMeet high protein requirementsSatisfy the need without overt bitternessMilk preparationSmall peptideCentrifugation

The present invention is high protein peptide milk powder and its production process. The milk powder has high protein content of 40-60 wt% including small peptide content of 5-20 wt%; and conventional milk powder contents including carbohydrate 5-20 wt%, fat 10-20 wt%, ash less than 4.0 wt%, water less than 5.0 wt%, vitamins, etc. The product has obvious bitter and bad smell. The technological process of producing the milk powder includes the successive steps of: re-compounding protein, enzymolyzing with composite enzyme, centrifugation, ultrafiltering, adsorption to eliminate bitter, compounding, mixing, emulsification to homogenize, sterilization and microcapsule spray drying. The milk powder has fast absorption, fatigue resistance and rich nutrients.

Owner:HUNAN YAHUA SEED IND

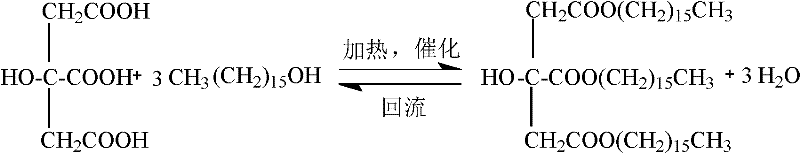

Preparation method of tripalmitin citrate

ActiveCN102643198AEasy to storeImprove plasticityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholPlasticizer

The invention relates to a preparation method of tripalmitin citrate, aiming at overcoming the defects that the existing citric low-carbon alcohol ester plasticizer is not transference-resistant and is high in volatility and economic cost, and solving the technical problem that the catalyst of the existing citrate esterification is not suitable for use. The preparation method takes zinc acetate and antimonous oxide as compound catalyst and enables citric acid and palmitin to have esterification so as to prepare the tripalmitin citrate. The prepared finished product can be taken as the plasticizer for use.

Owner:山东万图高分子材料股份有限公司

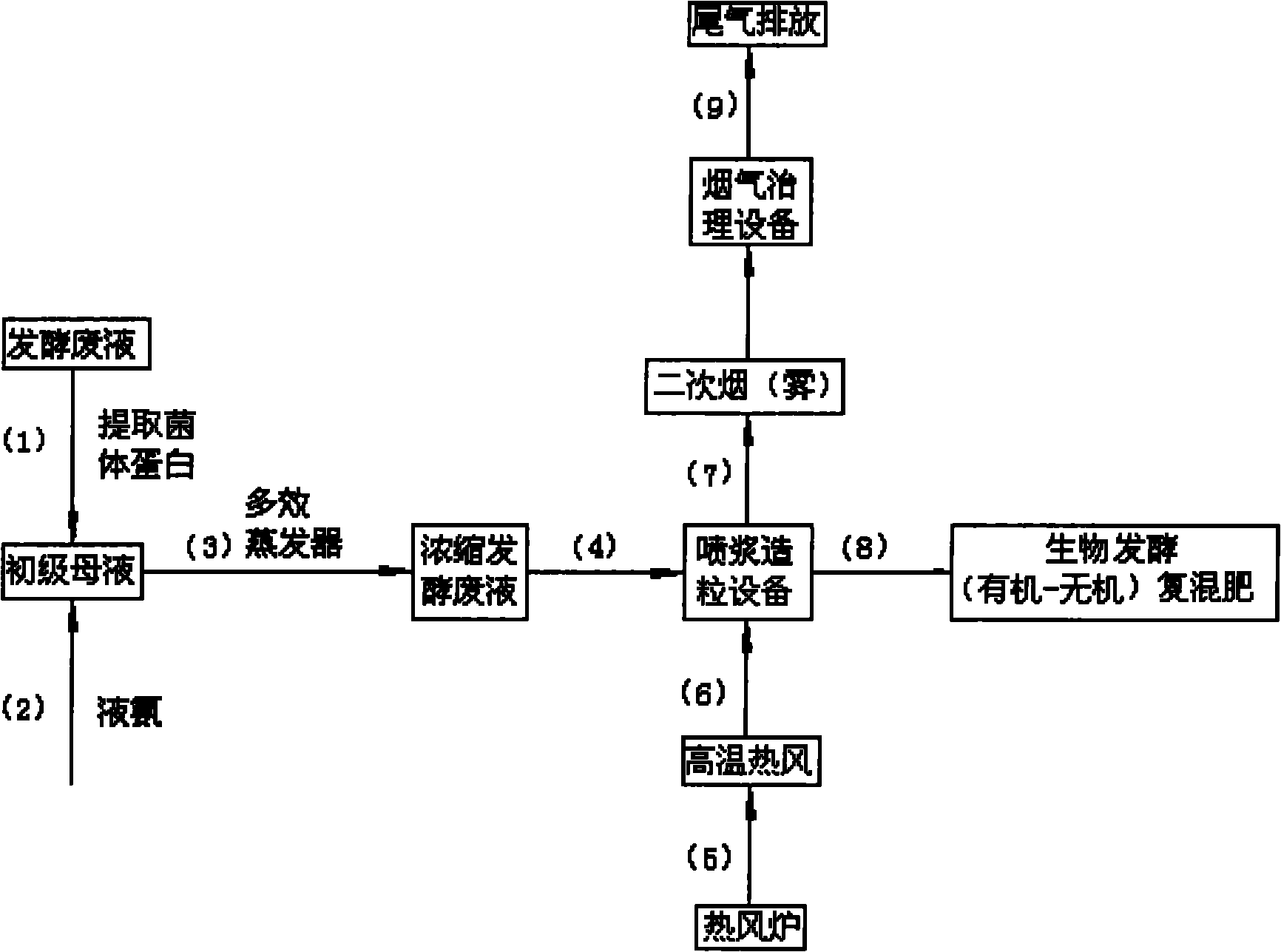

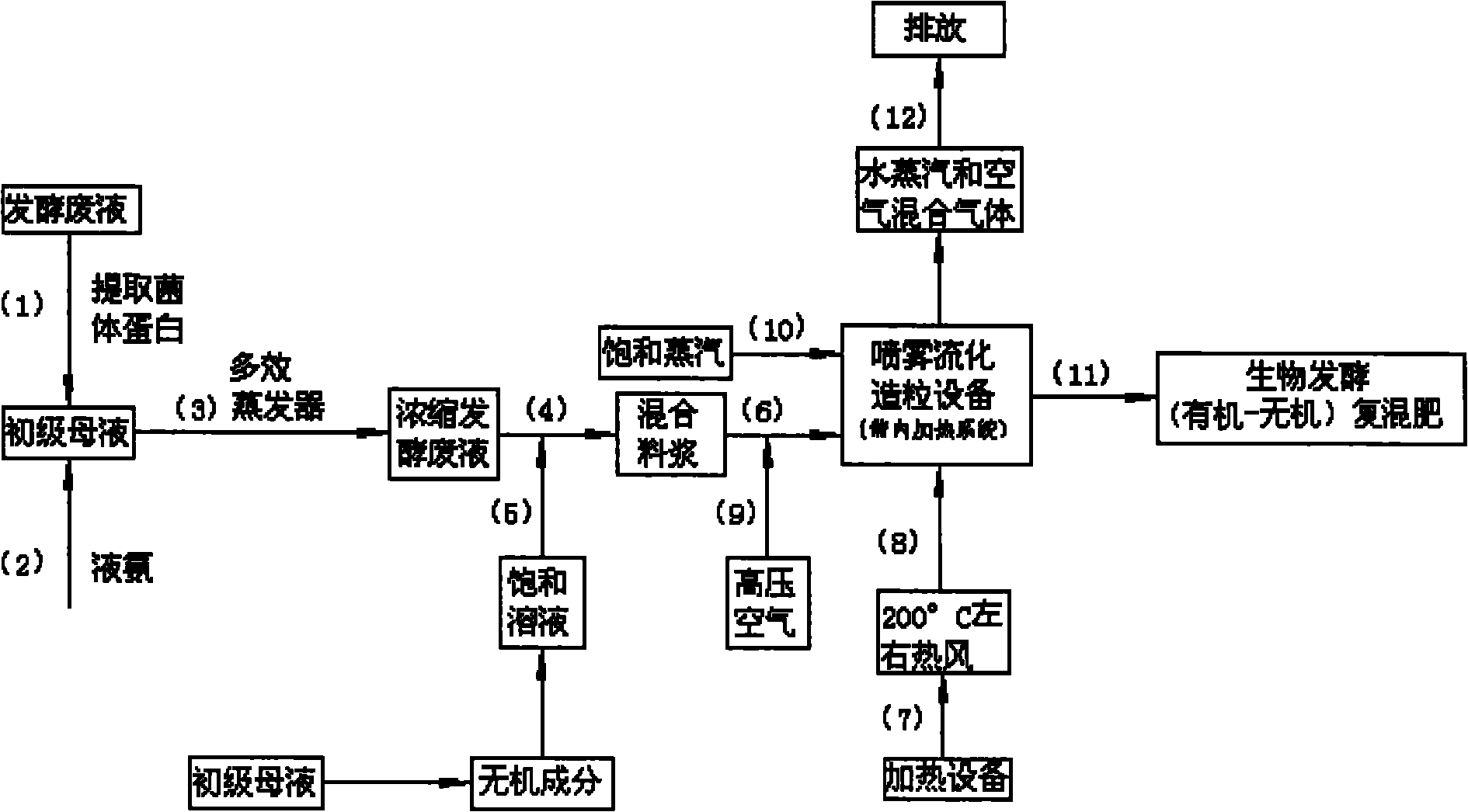

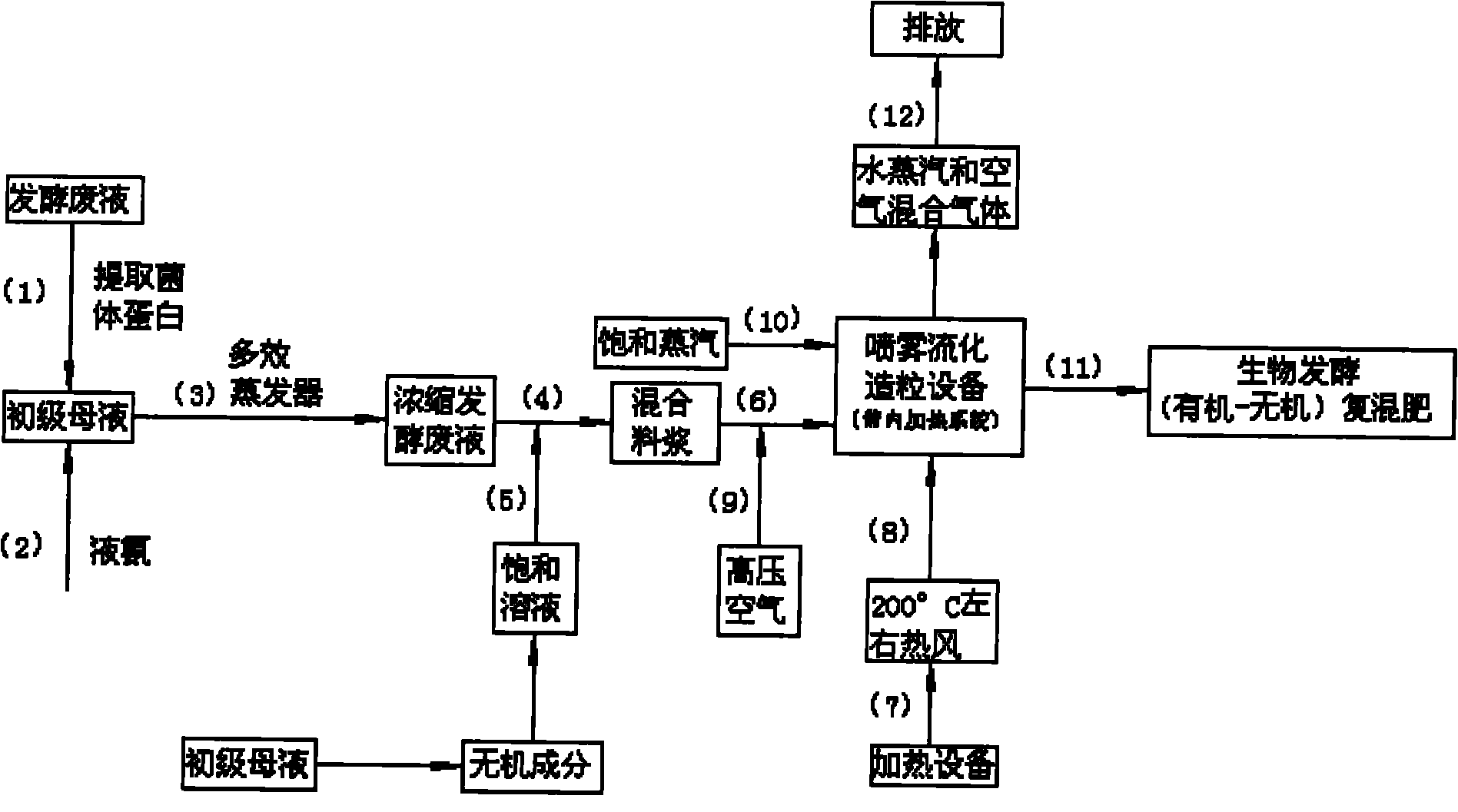

Method for producing biological fermentation compound fertilizer by fermenting organic waste water with glutamic acid

InactiveCN102093110ABiological fermentation compound fertilizer is goodNot prone to dehydration, coking and decompositionClimate change adaptationSewage/sludge fertilisersMycoproteinFungus protein

The invention discloses a method for producing a biological fermentation compound fertilizer by fermenting organic waste water with glutamic acid, which mainly comprises the following steps: carrying out multiple-effect evaporation concentration on waste liquor fermented by glutamic acid, extracting mycoprotein, carrying out multiple-effect concentration, carrying out low-temperature spraying fluidized granulation (adding inorganic constituents), screening, and cooling to obtain the finished biological fermentation compound fertilizer product. The method can overcome the defect that organic substance constituents can be coked and decomposed at high temperature, causing secondary pollution on the atmosphere and soil pollution caused by carbides in the spouting granulation technique, and develops a creative way for realizing zero discharge of organic waste water.

Owner:QEA INVESTMENT GROUP INNER MONGOLIA BIOTECH

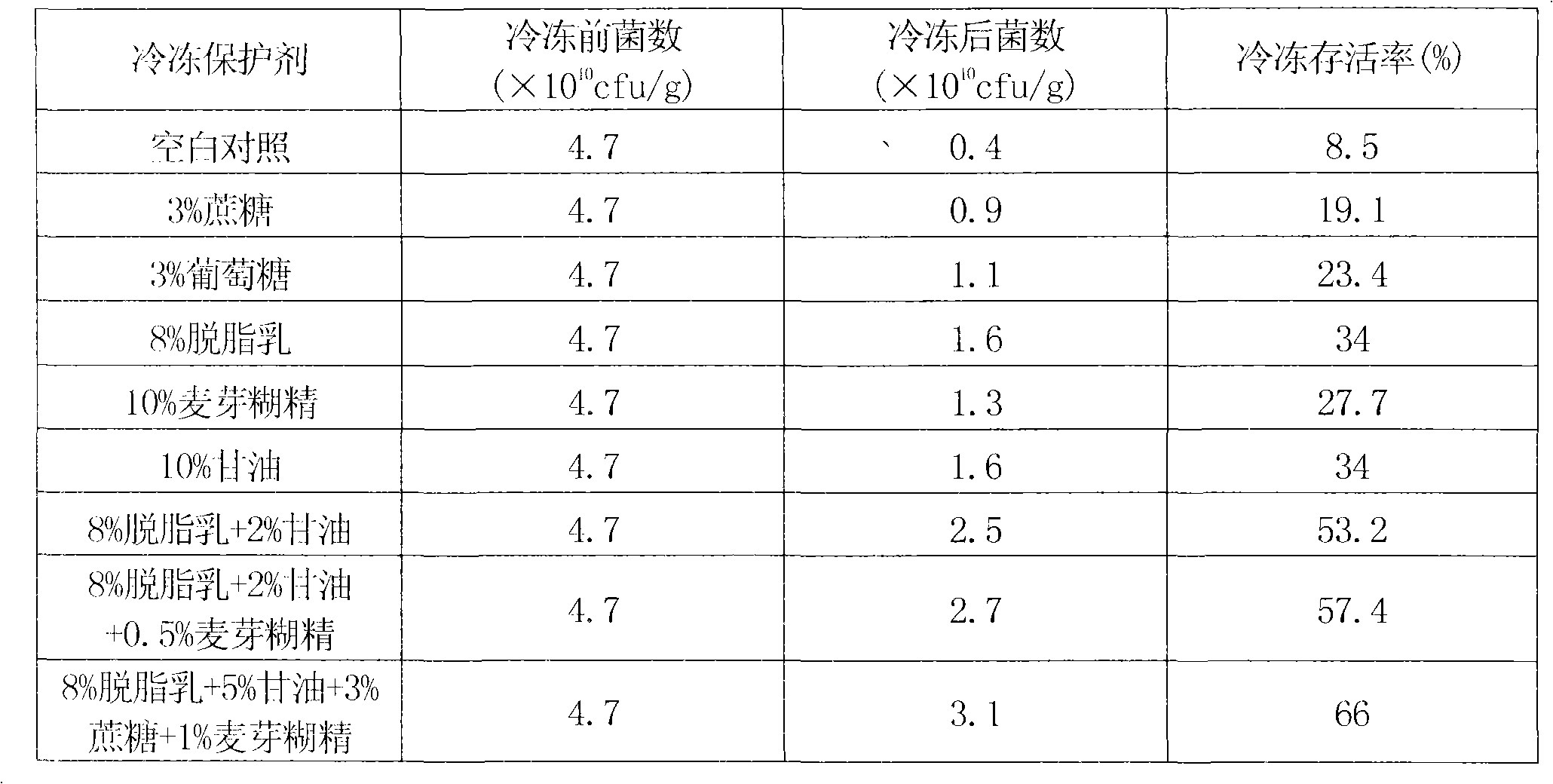

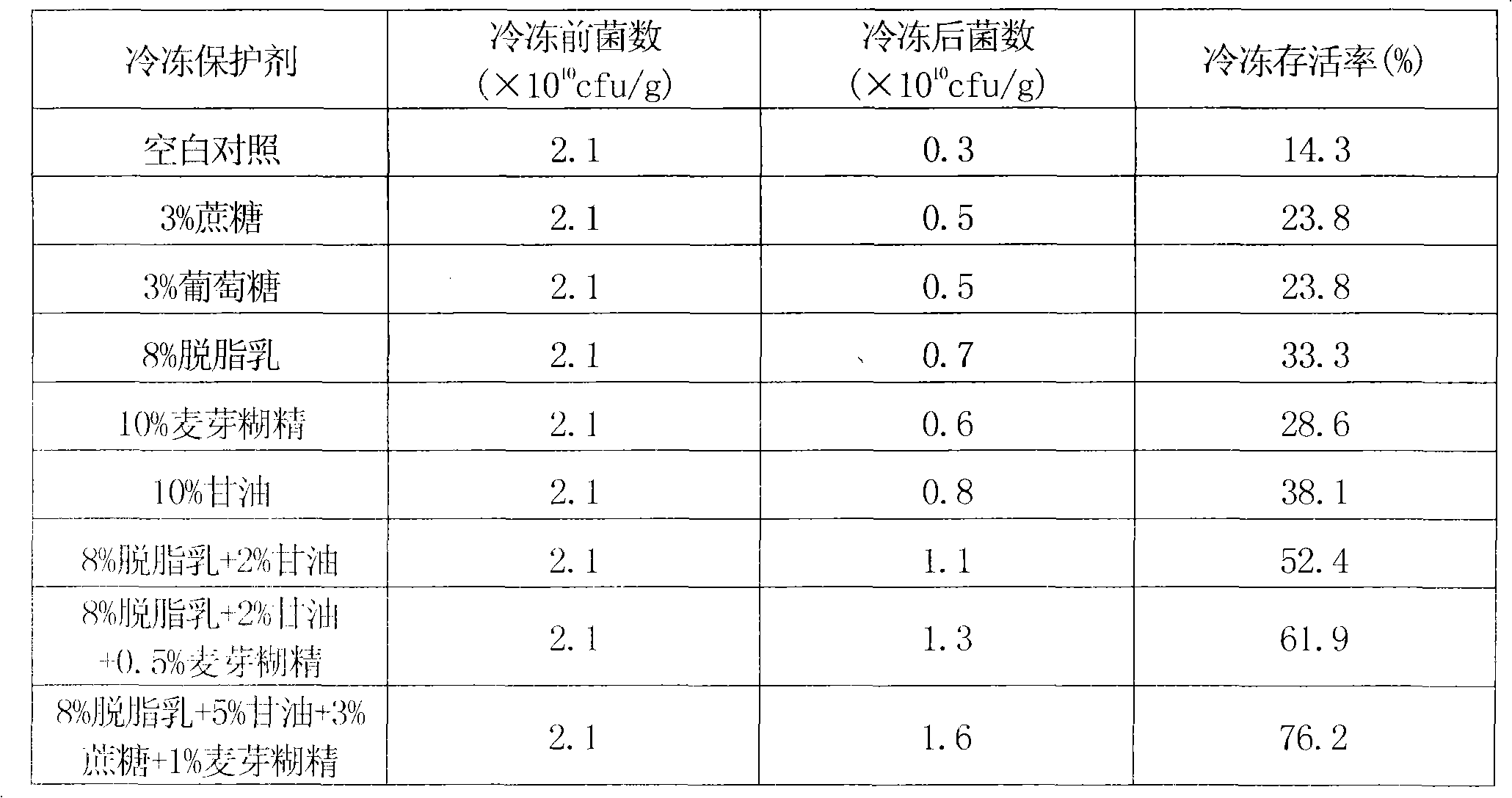

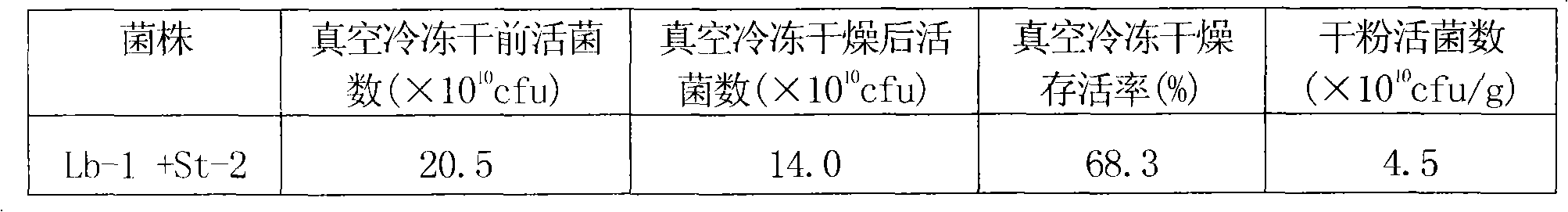

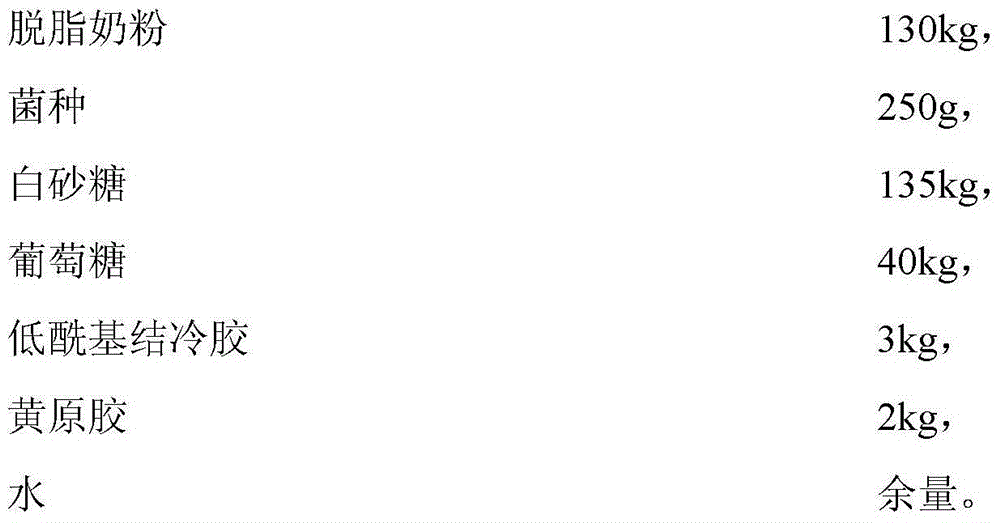

Preparation method for leavening special for goat milk yoghourt

A preparation method for a leavening special for goat milk yoghourt comprises the steps of conducting separation and purifying on lactic acid bacteria, conducting enrichment culture on the lactic acid bacteria, conducting centrifugal separation on the lactic acid bacteria, freezing bacterial sludge, freezing mixed bacterial sludge, vacuum cooling and drying the mixed bacterial sludge, and preparing the leavening special for the goat milk yoghourt. The leavening special for the goat milk yoghourt is used for producing the goat milk yoghourt, the goat milk yoghourt is smooth and fine in the curd state, special in the flavor, not obvious in the smelling of goat milk, and the prepared goat milk yoghourt achieves the requirements on acidified milk of GB 2746-1999 yoghourt and GB 19302-2010 national food safety standards, and the preparation method can be used for producing the goat milk yoghourt.

Owner:SHAANXI NORMAL UNIV

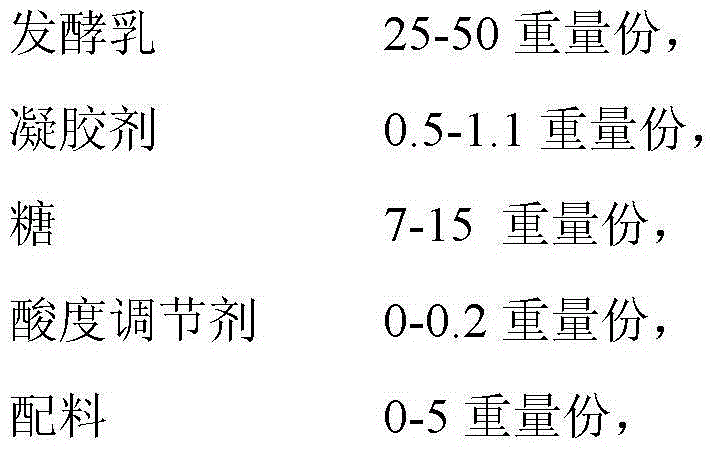

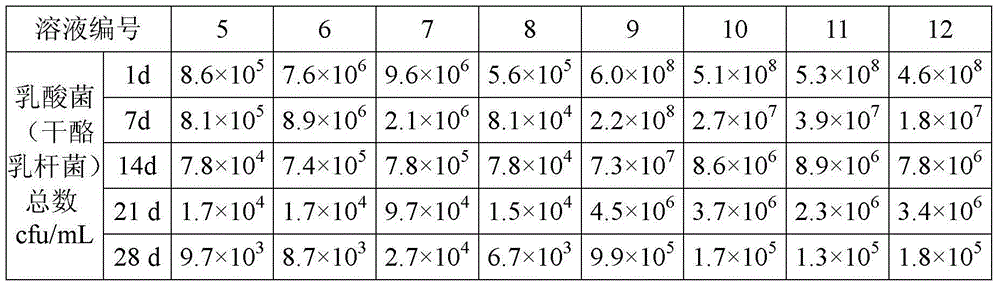

Active lactobacillus beverage containing jelly and preparation method thereof

The invention provides an active lactobacillus beverage containing jelly, which comprises the following ingredients by weight part according to 100 weight parts of raw material: 25-50 weight part of acidified milk, 0.5-1.1 weight part of gelata, 7-15 weight part of sugar, 0-0.2 weight part of acidity adjusting agent, 0-5 weight part of burdening, and the balance of water. According to the invention, pure lactobacillus beverage is changed to the active lactobacillus beverage containing jelly, the active lactobacillus beverage containing jelly provides nutrition to user and brings new experience to user. Constance of total live bacteria of lactobacillus of the active lactobacillus beverage in a shelf life can be kept, and live bacteria after refrigeration for 21 days at 2-10 DEG C is kept at greater than 2*10<6>cfu / ml.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

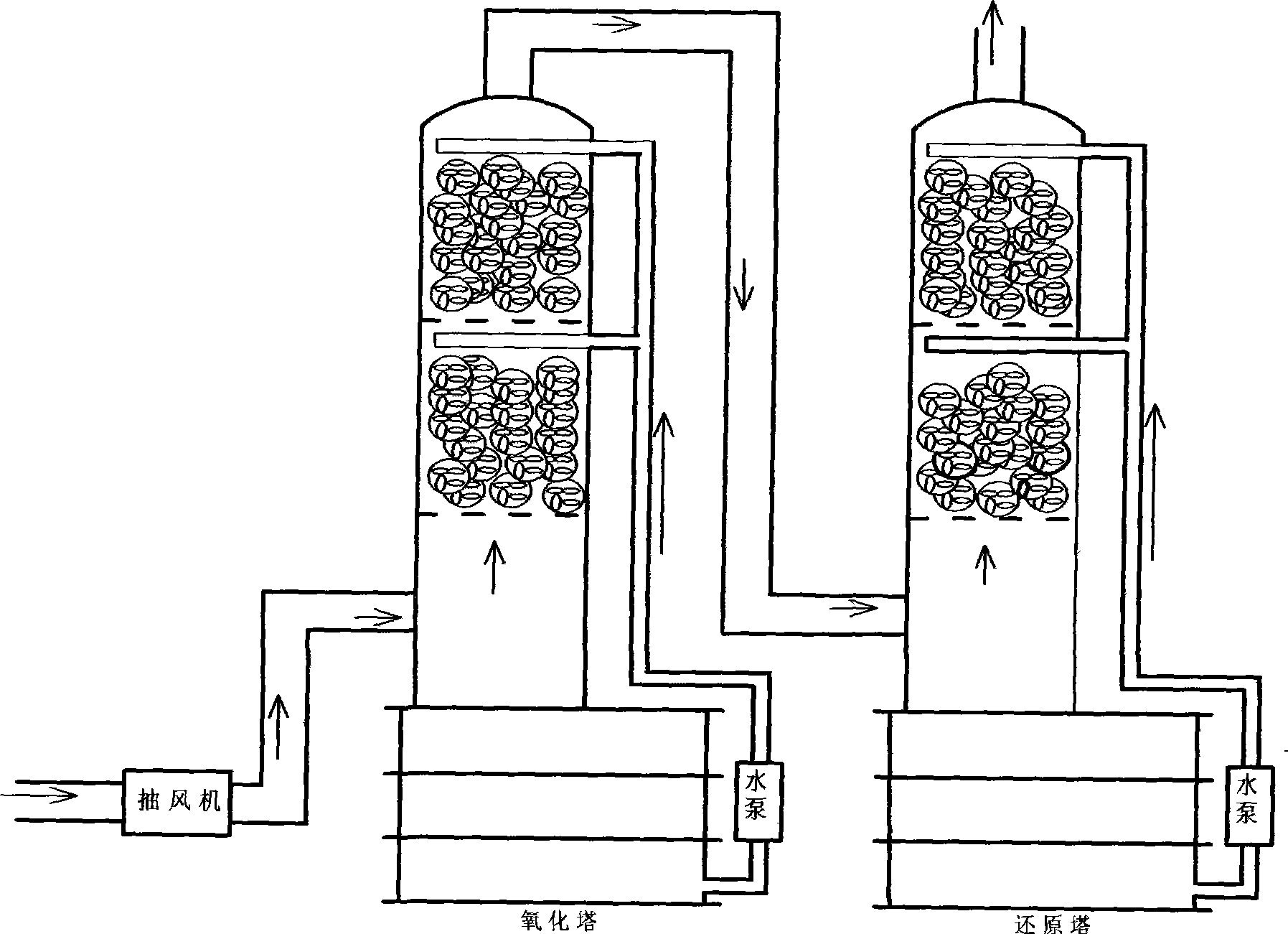

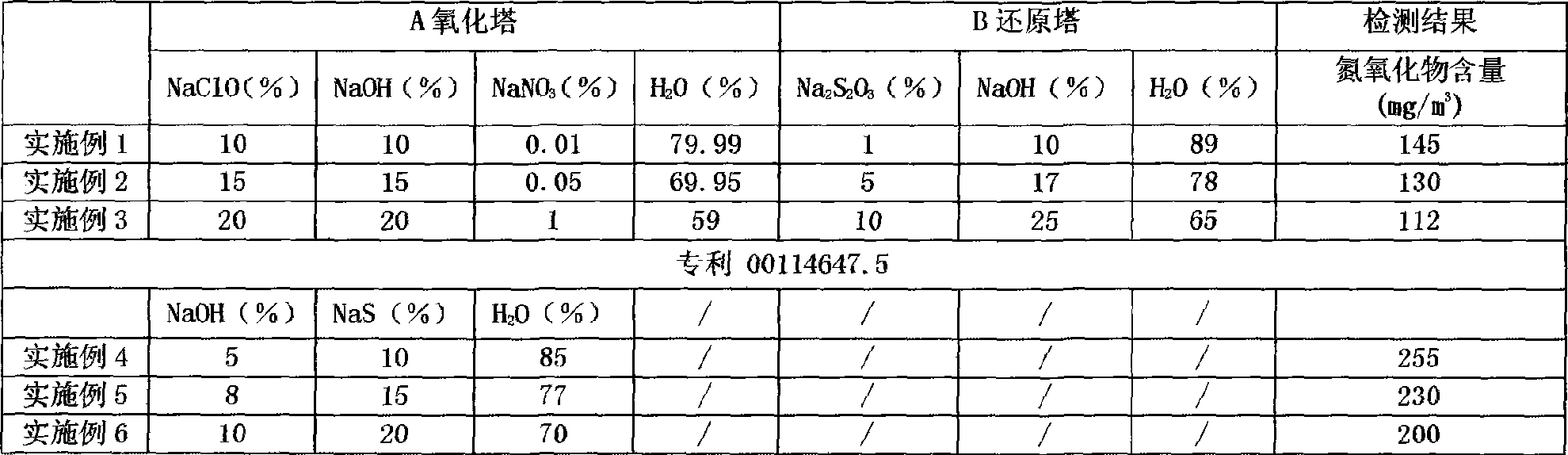

Method for processing nitrogen oxide exhaust

InactiveCN101530728AEasy to handleLow costDispersed particle separationNitrogen oxidesReduction treatment

The invention discloses a method for processing nitrogen oxide exhaust, including: carrying out two steps, in combined manner, as oxidation and recovery to nitrogen oxide exhaust using special oxidation treating fluid and special recovery treating fluid, that is, the nitrogen oxide residual exhaust processed by oxidation tower is further processed via a recovery tower. Formulation and constituent of the oxidation treating fluid are as follows: NaCIO 10%-20%; NaOH 10%-20%; NANO3 0.01%-1%; H2O allowance. Formulation and constituent of the recovery treating fluid are as follows: Na2S2O3 1%-10%; NaOH10%-25%; H2O allowance. Through this invention, the processed exhaust has neither distinct odor nor distinct colour, which meets exhaust discharge requirement in PRC emission standard of air pollutants GB16297-1996. Further, it is low in treating fluid cost and stable, and the fluid prepared at a time can be utilized for 2 months.

Owner:CHONGQING POLYCOMP INT

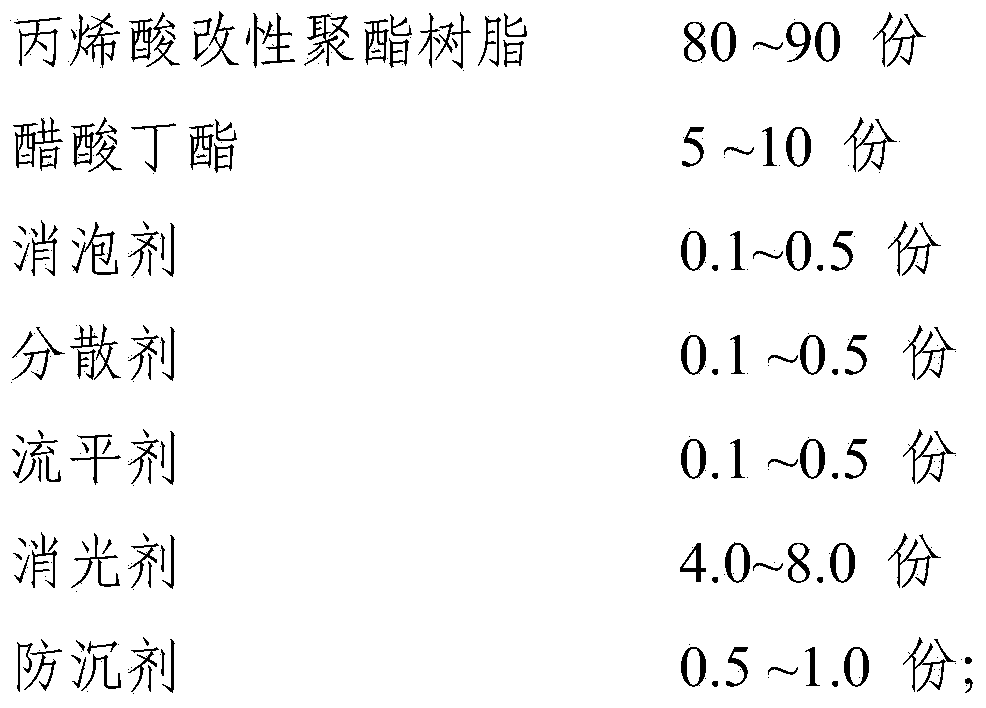

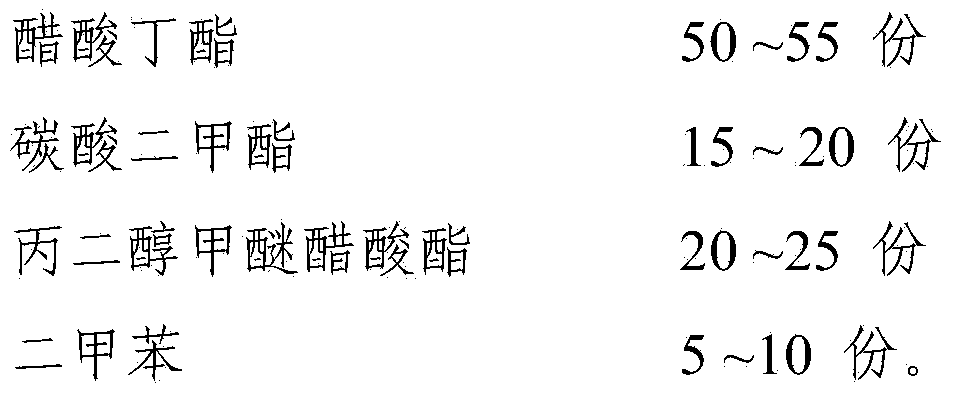

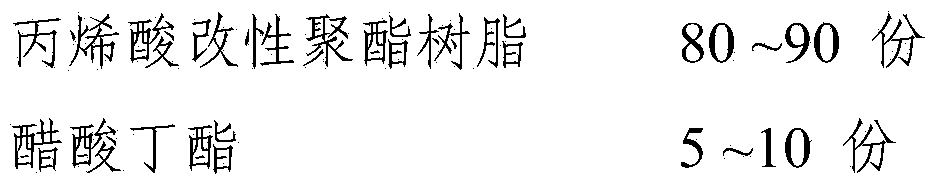

PU smell removing polyurethane coating as well as preparation and application thereof

ActiveCN103881551AImprove fullnessFast dryingPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides a PU smell removing polyurethane coating which consists of a component A, a component B and a component C, wherein the component A comprises a crylic acid modified polyester resin, n-butyl acetate, a defoaming agent, a dispersing agent, a leveling agent, a delustering agent and an anti-settling agent; the component B comprises polyisocyanates, a co-polymer and n-butyl acetate; the component C comprises n-butyl acetate, dimethyl carbonate, propylene glycol monomethyl ether acetic ester and dimethylbenzene. According to the PU smell removing polyurethane coating, by modifying the double-component hydroxy acrylic resin, the characteristic that the hydroxy acrylic resin is rapid in releasing a solvent is maintained, and the fullness of the hydroxy acrylic resin is remarkably improved; the PU smell removing polyurethane coating provided by the invention not only has the characteristics of rapid drying speed, high hardness and excellent fullness, but also is small in smell. A good synergistic effect of various components of the coating is brought into play, and particularly through interaction and balancing of the resin, the solvent and the hardening agent, the coating is free of conspicuous smell after the coating is constructed and dried for 48 hours.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

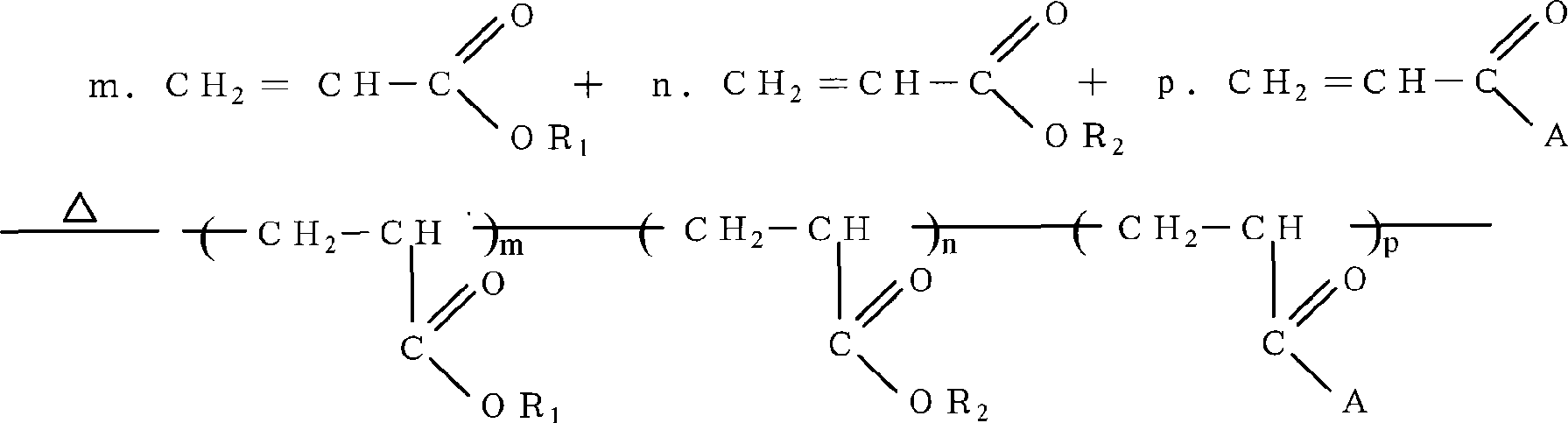

Method for producing acrylic ester copolymer

The invention relates to a method for producing acrylic ester copolymer, which belongs to the technical field of organic adhesives. The method comprises the following steps: preparing a monomer solution; preparing an emulsifying agent solution; preparing an emulsion; preparing a bed charge solution; preparing an initiator solution; and heating up the bed charge solution to a temperature of between 40 and 50 DEG C, adding the initiator solution, and stirring the mixture sufficiently to obtain a semi-finished product; heating up the semi finished product continuously to a temperature of between 80 and 85 DEG C, when the reflux inside temperature reaches between 85 and 90 DEG C, dripping the emulsion and the initiator solution for 1 to 5 hours, then keeping temperature for 1 to 3 hours, cooling the mixture to a temperature of less than 40 DEG C, and filtering the mixture to discharge the materials. The method has the advantages of reasonable design, simple operation and low production cost; and the obtained acrylic ester copolymer adhesive has reasonable adhesive property and unobvious burning peculiar smell, improves the performances of tensile strength, flexible bendability, appearance and color and the like of a gasket if the acrylic ester copolymer adhesive is applied to a gasket, reduces the burning peculiar smell, is convenient for subsequent packaging processing of a catalyst product and the like, and makes the quality of gasket products reach or exceed that of similar products in other countries.

Owner:奇耐联合纤维(上海)有限公司

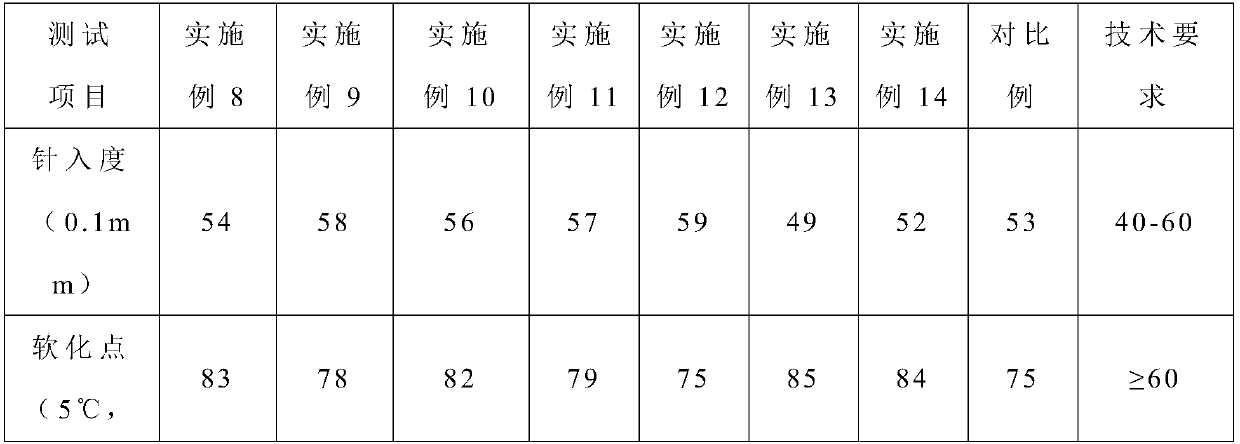

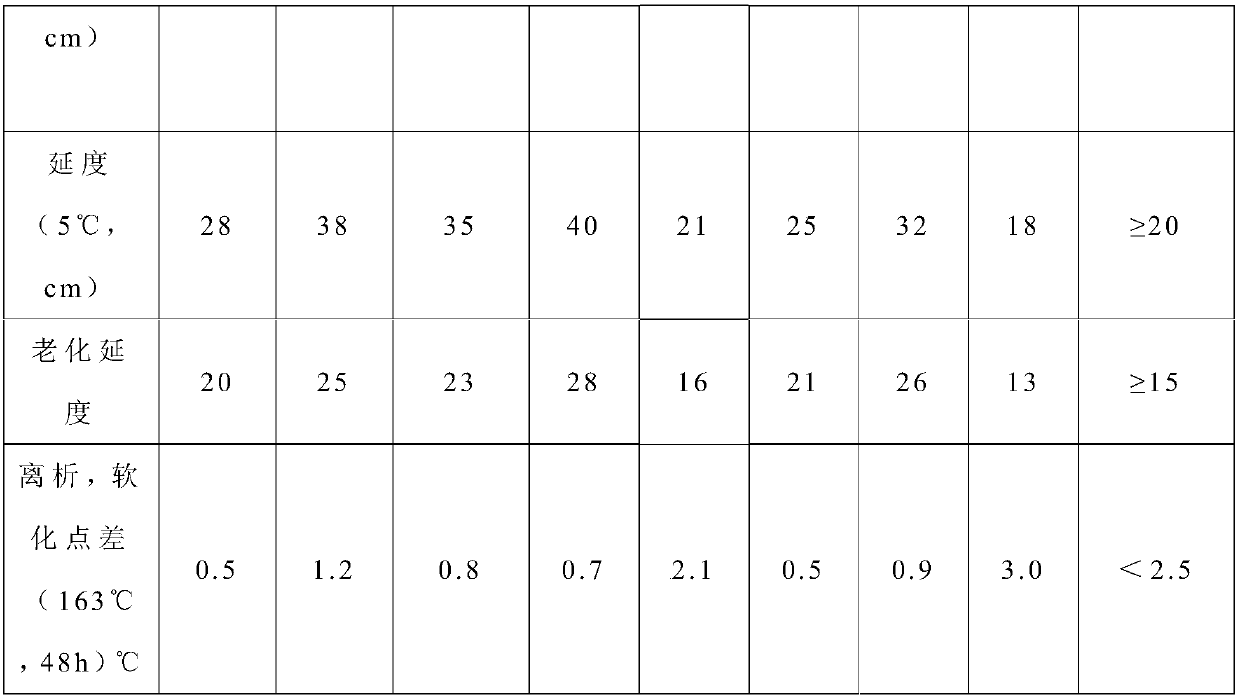

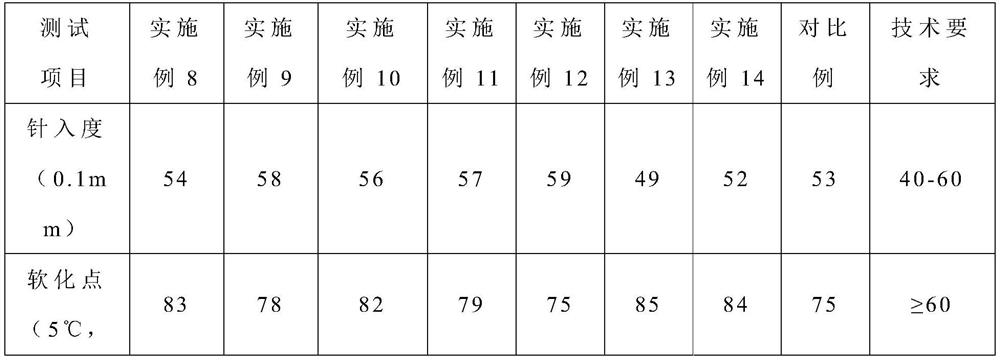

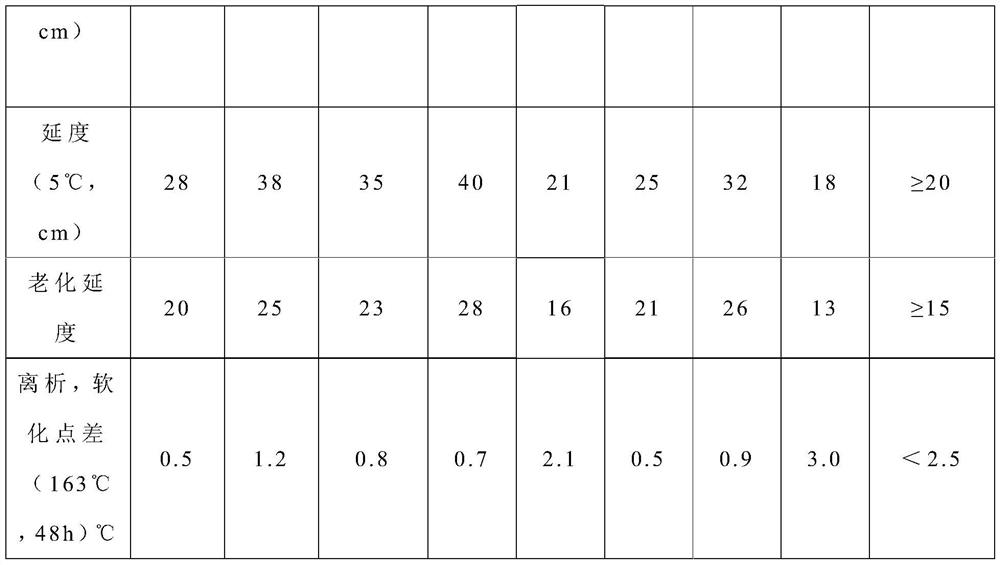

SBS modified asphalt auxiliary agent and SBS modified asphalt

The invention relates to the technical field of asphalt materials, particularly discloses an SBS modified asphalt auxiliary agent and SBS modified asphalt, wherein the SBS modified asphalt auxiliary agent comprises the following raw materials by mass: 30-50 parts of modified sulfur, 50-100 parts of white oil, 0.5-2 parts of an antioxidant, 1-5 parts of a suspending aid, and 1-5 parts of a plasticizer. According to the present invention, by adding the SBS modified asphalt auxiliary agent to the SBS modified asphalt, the storage stability, the ductility and the aging ductility of the SBS modified asphalt can be significantly improved.

Owner:SUZHOU TOPOLINE TECH

Fixing agent and method for controlling nicotine loss during tobacco waste composting

InactiveCN104478619ASettle the lossImprove insecticidal effectBio-organic fraction processingExcrement fertilisersCompostLivestock manure

Owner:ANHUI SCI & TECH UNIV

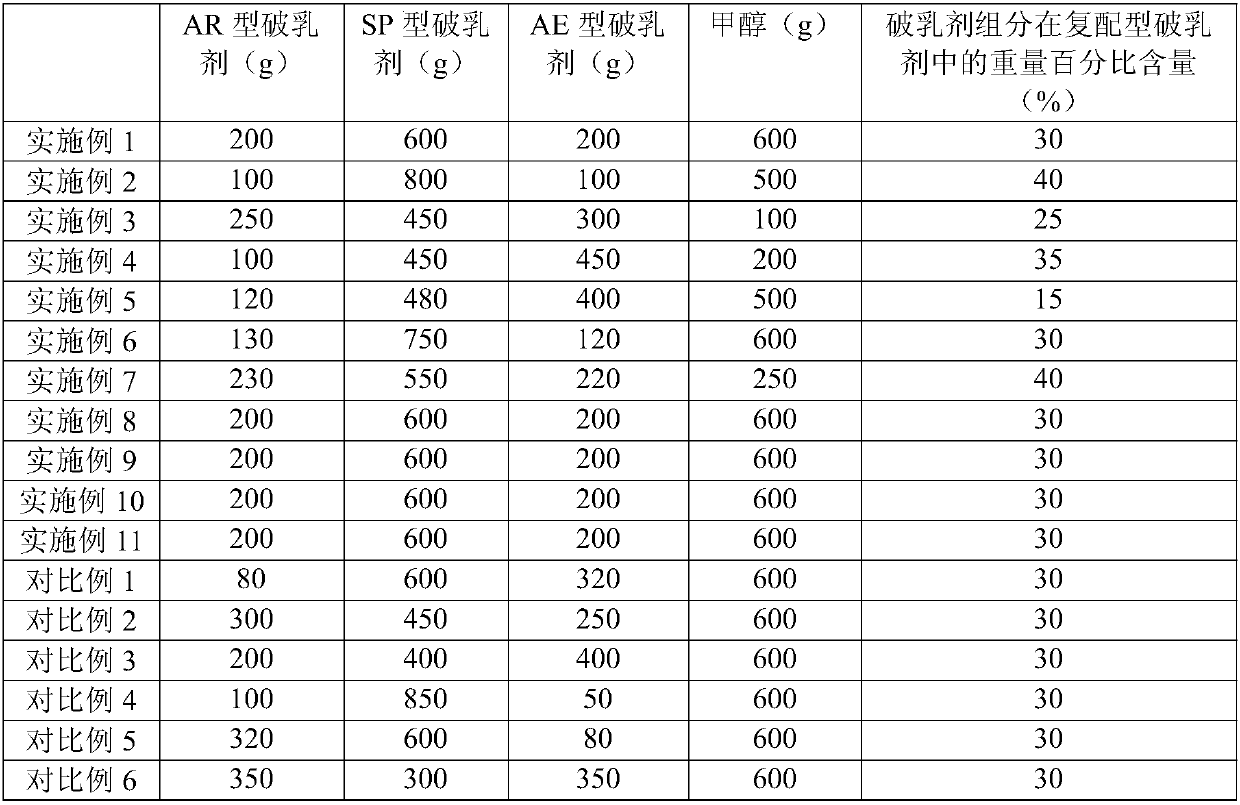

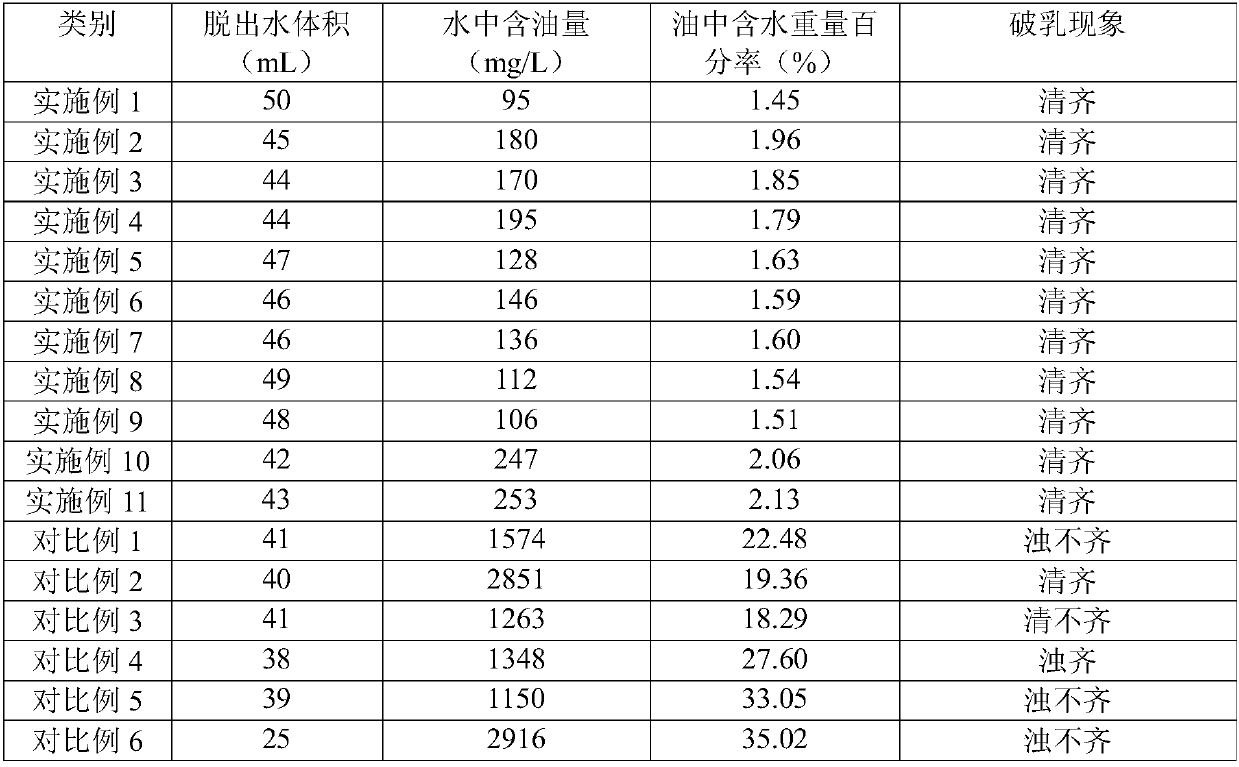

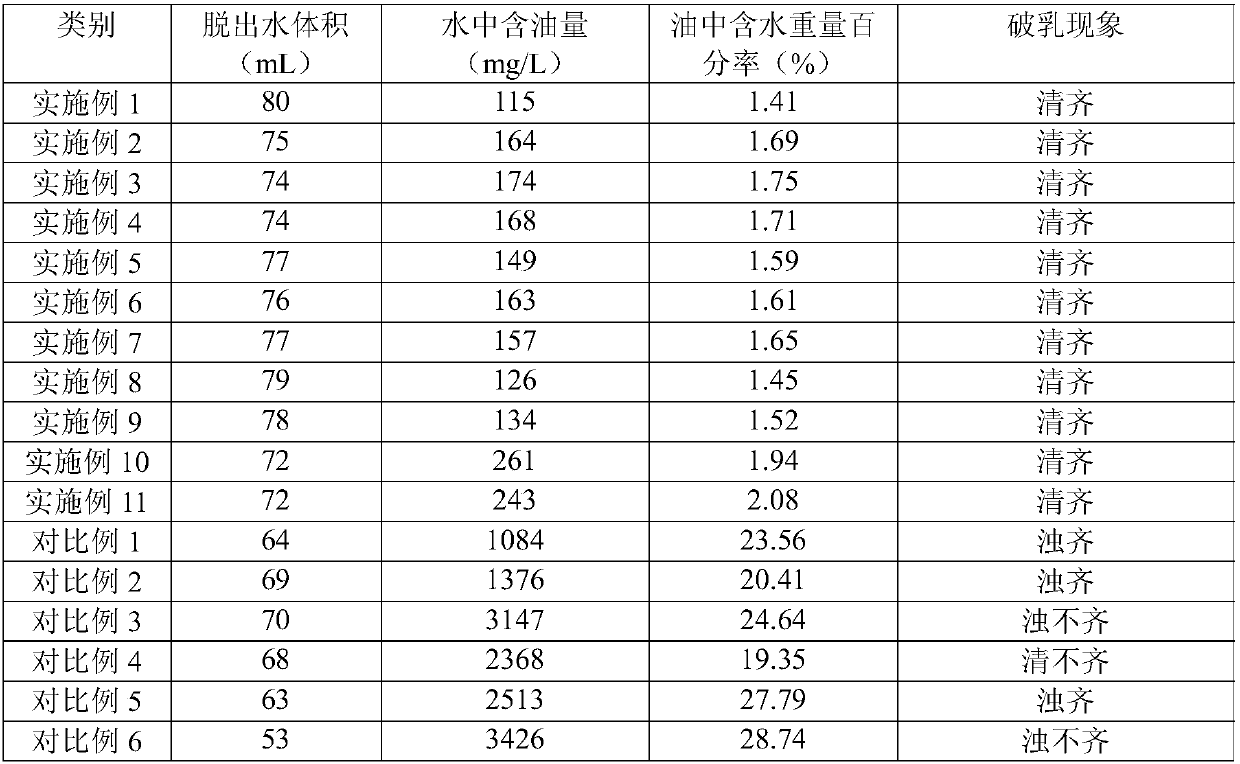

Compounded demulsifier composition and demulsifier used for alkali-surfactant-polymer (ASP) combination flooding produced liquid

ActiveCN109705896AWeak corrosiveNo obvious smellDewatering/demulsification with chemical meansDemulsifierWastewater

The invention provides compounded demulsifier composition and a demulsifier used for an ASP combination flooding produced liquid. The compounded demulsifier composition includes a demulsifier component, which includes an AR demulsifier, a SP demulsifier and an AE demulsifier according to the following weight ratio: 10-25% of the AR demulsifier, 45-80% of the SP demulsifier and 10-45% of the AE demulsifier, wherein the weight percentages of the three demulsifiers are based on solid content of 80%. The demulsifier produced from the demulsifier composition has the advantages of high demulsification dehydration rate, ordered oil-water interface, clear and clarified separated water, and greatly reduced oil content in demulsified wastewater and weight percentage of water in purified oil when being used for demulsification on the ASP combination flooding produced liquid containing high contents of alkalis, surfactants and polymers.

Owner:PETROCHINA CO LTD

Novel plasticizer and preparation method thereof

ActiveCN103113617BEasy to storeImprove performanceOrganic compound preparationCarboxylic acid esters preparationAlcoholCITRATE ESTER

The invention relates to a novel plasticizer and a preparation method thereof, which overcome the defects that the existing low-carbon alcohol citrate plasticizers are non-transference-resistant, high in volatility and high in economic costs and high-carbon alcohol citrate plasticizers are low in efficiency. The novel plasticizer contains at least two types of citrate compounds. The novel plasticizer disclosed by the invention can be used as a plasticizer, and widely applied to the fields of plastic compositions and adhesives and the like.

Owner:山东万图高分子材料股份有限公司

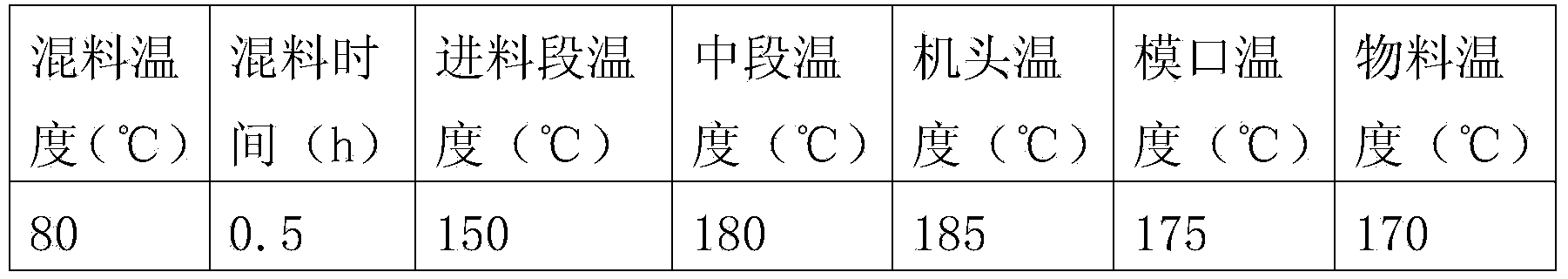

Method for extracting water-soluble haematochrome from lovastatin crystallization mother liquor

ActiveCN103013161ASimple processLow equipment requirementsNatural dyesWater insolubleAlkaline hydrolysis

The invention provides a method for extracting water-soluble haematochrome from lovastatin crystallization mother liquor. The method comprises the following steps of: 1) carrying out concentration on the lovastatin crystallization mother liquor; 2) carrying out alkaline hydrolysis on the concentrated liquor; 3) adding a first precipitator in the hydrolysis liquor so that colloidal impurities in the hydrolysis liquor are precipitated, filtering the obtained object, and collecting filter liquor; 4) adding a second precipitator in the filter liquor so that water-soluble lovastatin acid salts are converted into water-insoluble lovastatin acid salts, filtering the obtained object, and collecting filter liquor; 5) acidifying the filter liquor by using an acidifying agent until the pH value of the filter liquor is below 3.5, and carrying out organic solvent extraction so as to obtain extract liquor; 6) carrying out concentration on the extract liquor so as to obtain concentrated liquor; 7) carrying out alkalization on the concentrated liquor by using an alkali solution, filtering the obtained object, and collecting filter liquor; and 8) carrying out concentration and drying on the filter liquor so as to obtain the water-soluble haematochrome. According to the invention, water-soluble haematochrome is successfully extracted from the lovastatin crystallization mother liquor for the first time; and the method is simple in process, has low requirements for equipment, and is suitable for industrialized continuous production.

Owner:NEW FOUNDER HLDG DEV LLC +2

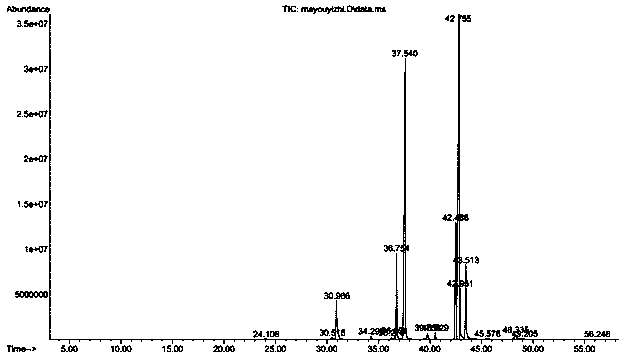

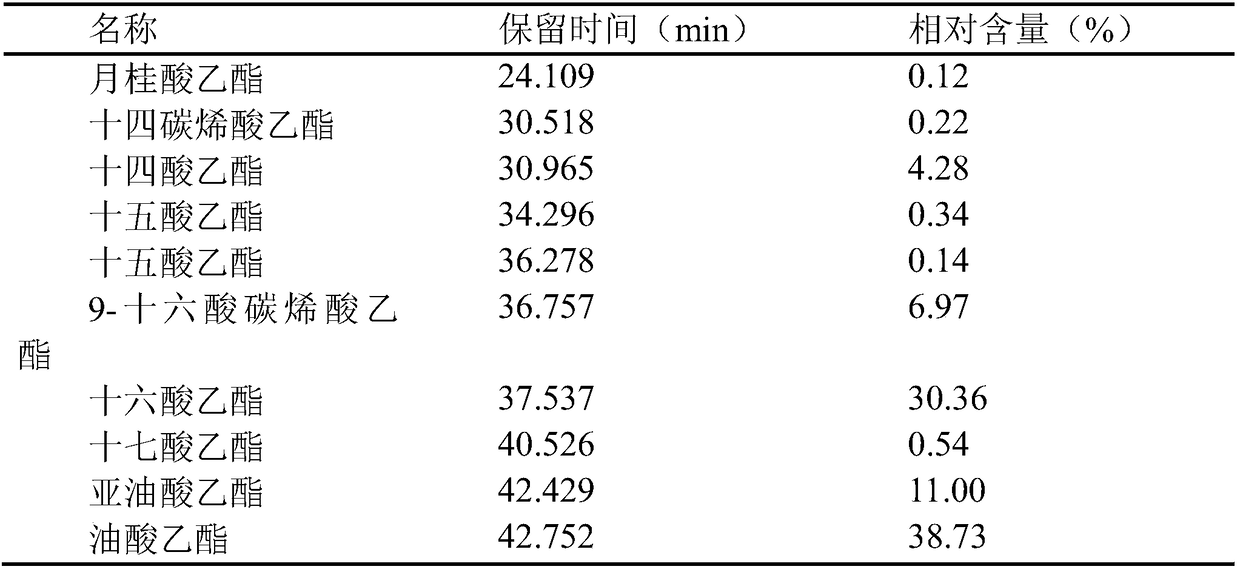

Production technology for refined horse oil ethyl ester

ActiveCN109181883AImprove oil yieldLight colorFatty acid esterificationFatty acids production/refiningUnsaturated fatty acidChemistry

The invention discloses a production technology for refined horse oil ethyl ester. The production technology comprises the following steps: boiling horse fats, and carrying out extracting and purifying treatment to obtain crude horse oil; carrying out an ethyl esterification reaction on the crude horse oil to obtain crude horse oil ethyl ester; and refining and purifying the crude horse oil ethylester by a thin film evaporation method to obtain the refined horse oil ethyl ester. The production technology significantly improves the oil yield of the horse oil, the yield of the crude horse oil ethyl ester and the yield of the refined horse oil ethyl ester on the premise of reserving rich unsaturated fatty acids in the horse oil in order to obtain the high-quality and high-yield refined horseoil ethyl ester; and the technology has the advantages of simple flow, good repeatability and good economic values.

Owner:新疆天然芳香农业科技有限公司

Environment-friendly and efficient kitchen oil dirt detergent

InactiveCN105670826AHigh oil removal efficiencyNon-oxidizingOrganic detergent compounding agentsNon-ionic surface-active compoundsSURFACTANT BLENDCooking process

Kitchen oil dirt comes from the cooking process and needs to be frequently cleared away, otherwise, attractiveness is affected, and bacteria can be spread. Existing detergent products mostly comprise strong-basicity ingredients, volatile solvent ingredients, oxidizing ingredients, enzyme preparation ingredients or ingredients having obvious harm to the environment, and adverse influences may be caused to devices, human bodies and the environment. Thus, the invention provides an environment-friendly and efficient kitchen oil dirt detergent. The environment-friendly efficient kitchen oil dirt detergent is prepared from, by weight, 0.1-10% of compound surfactant, 1-20% of a contact regulating agent, 1.5-40% of a reaction regulating agent, 0.02-2% of an ion regulating agent and the balance water and has the advantages that the oil removing efficiency is high, and the detergent is safe, free of irritation, obvious odor and oxidability , stable and reliable.

Owner:宋德安

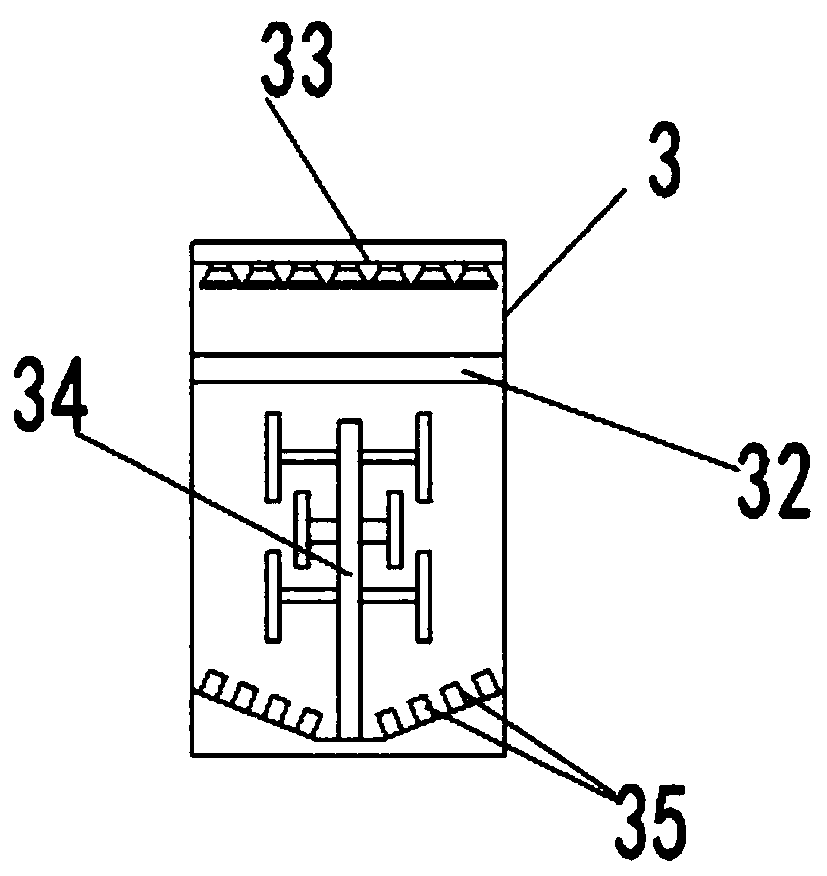

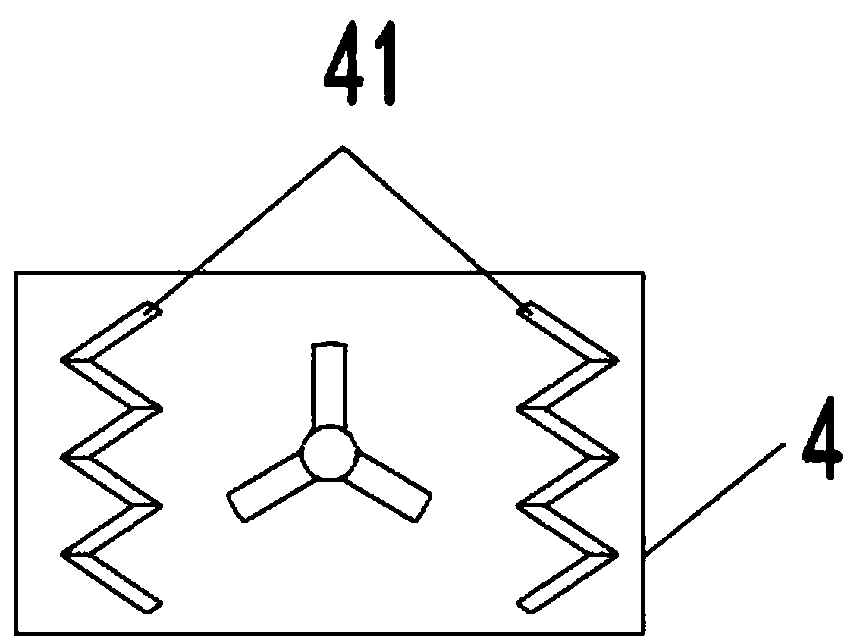

Integrated control aquaculture wastewater combined treatment technology and device

ActiveCN109650617AHandling process safetyNon-toxic treatment processWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsDecompositionFiltration

The invention discloses an integrated control aquaculture wastewater combined treatment technology and device. The technology includes the following step of S1, pretreatment; S2, oxidation; S3, filtration; S4, adsorption. The device mainly comprises a filtering tank, an adjusting tank, a decomposition tank, a pulse electric floating tank, an adsorption tank, water suction pumps and a PLC; the adjusting tank is communicated with the filtering tank through a first water inlet pump, the pulse electric floating tank is communicated with the decomposition tank through the fourth water suction pump,and the adsorption tank is communicated with the PLC through the fifth water suction pump and the pulse electric floating tank and is electrically connected with the filtering tank, the adjusting tank, the decomposition tank, the pulse electric floating tank, the adsorption tank, the water suction pumps and the PLC. The treatment technology is safe, free of pollution, excellent in degradation effect and capable of meeting emission standards.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

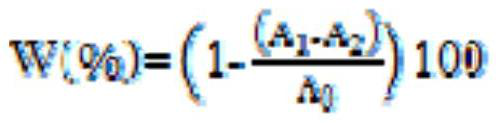

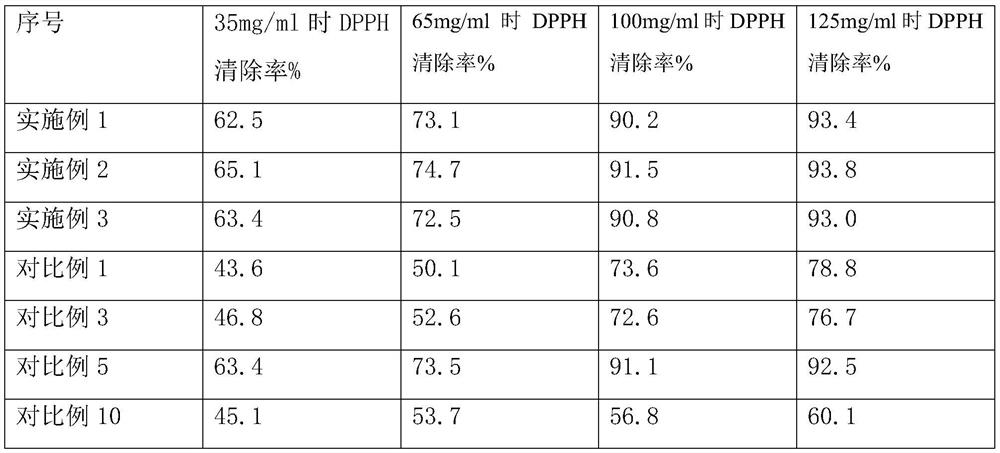

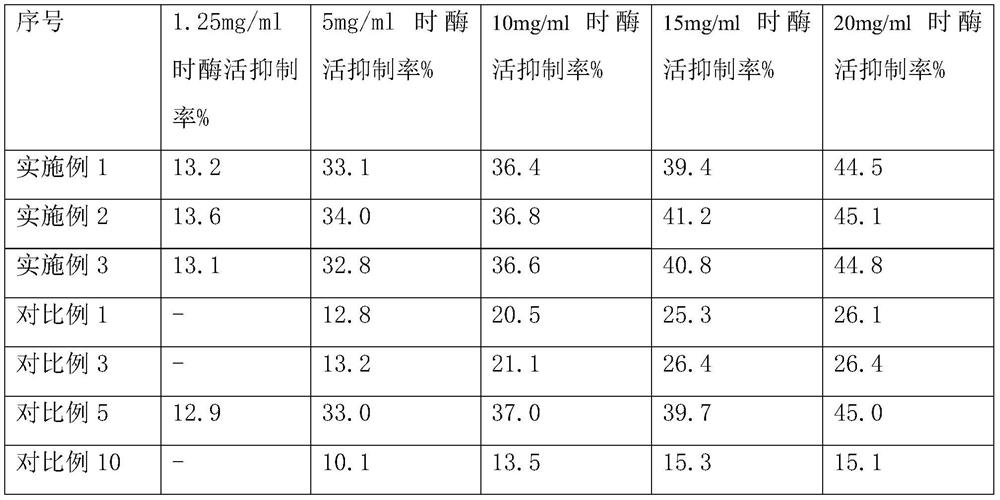

Preparation method of fish scale collagen and application of fish scale collagen as antioxidant and enzyme inhibitor

PendingCN113461806AReduce adverse effectsAffect qualityFood ingredient as antioxidantConnective tissue peptidesSpray driedHydrolytic Process

The invention provides a preparation method of fish scale collagen. The preparation method comprises the following steps: boiling fish scales to a pasty state, then adding compound protease for hydrolysis, keeping a temperature at 40-45 DEG C in a hydrolysis process, keeping a pH value at 6.0-7.0 in a hydrolysis process, adjusting the pH value to 6.0-6.5 after hydrolysis, carrying out primary filtration, collecting a filtrate, carrying out membrane filtration on the filtrate to obtain thinner liquid, subjecting the obtained thinner liquid to decoloration treatment while the pH value is kept at 4.0-4.5 in a decoloration process, adjusting the pH value to 6.0-6.5 after decoloration to obtain decolored material liquid, concentrating the decolored material liquid to obtain a concentrated liquid with a solid content of 21-28%, and then conducting spray drying to obtain the powdery fish scale collagen. The fish scale collagen obtained by the invention can also be used as an antioxidant and a carbohydrase inhibitor for practical application. The method provided by the invention is efficient in processing, and meanwhile, the appearance and smell characteristics of the fish scale collagen are improved.

Owner:湖北瑞邦生物科技有限公司

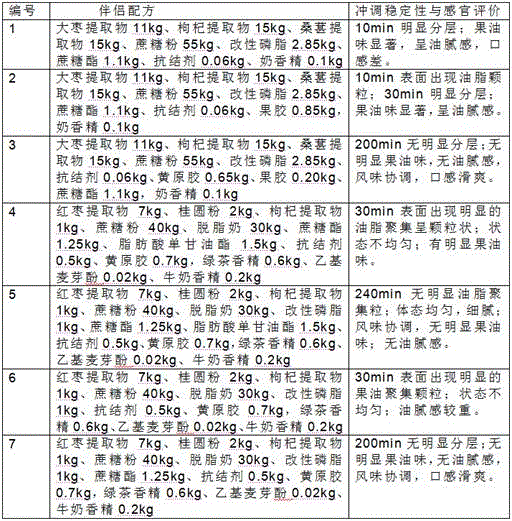

Sacha inchi oil partner and preparation method thereof

ActiveCN105901466AFlavor harmonyNo obvious smellFood ingredient as thickening agentFood ingredient as anti-caking agentIcing sugarFlavor

The invention relates to a sacha inchi oil partner and a preparation method thereof, belonging to the technical field of food processing. The partner comprises the following components in percentage by weight: 5-50% of sacha inchi oil congeners, 0-40% of skim milk powder, 40-60% of powdered sugar, 0-5% of soybean peptides, 0-10% of sodium caseinate, 1-8% of modified phospholipids, 0-6% of phospholipid, 0-8% of fatty acid monoglyceride, 0-1.5% of sucrose ester, 0.05-1% of an antitackiness agent, 0.2-1% of a thickening agent, and 0.01-1% of edible essence, totaling 100%. The partner disclosed by the invention is coordinated with sacha inchi oil flavor, is high in mixed dissolving ability, is dissolved to form uniform and stable oil-in-water emulsion, is excellent in mouthfeel and not greasy, and does not have an obvious sacha inchi oil flavor. Meanwhile, the partner disclosed by the invention is compounded with sacha inchi oil to achieve an effect of enhancing the nutrition, the consumption demands of modern consumers on mouthfeel and nutrition are met, and the market prospects are wide.

Owner:XISHUANGBANNA YINQI BIOLOGICAL RESOURCE DEV

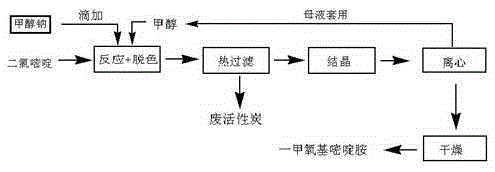

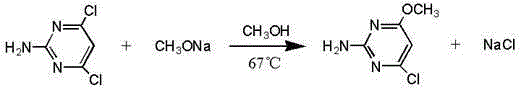

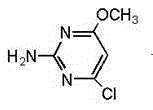

Preparation method of mono-methoxyl pyrilamine

InactiveCN105294572AAvoid it happening againHarm reductionOrganic chemistrySodium methoxideCentrifugation

The invention discloses a preparation method of mono-methoxyl pyrilamine. According to the method, dichloropyrimidine and sodium methoxide are used as raw materials for performing nucleophilic substitution reaction. The method comprises the steps including reaction decoloration, thermal filtration, crystallization, centrifugation and drying. The reaction and the decoloration are completed in one step, so that the synthesis steps are greatly reduced; the operation work procedure is simplified. Crude product refining is not needed. Compared with the existing preparation method, the preparation method has the obvious advantages in the aspects of reducing the production cost, reducing the environment harm, maintaining the human body health and the like.

Owner:ANHUI HONGDE CHEM THECHNOLOGY CO LTD

Antifogging application of radiation curing composition

InactiveCN110964374AGood application effectGood chemical resistanceInksPigment dispersionPhotopigment

The invention discloses an antifogging application of a radiation curing composition containing a pigment dispersion body. The radiation curing composition includes the pigment dispersion body (A), acationically polymerizable compound (B), and a cationic photoinitiator (C), does not use volatile solvents, is environmentally friendly, has excellent applicability to printing on a plastic film, andcan be quickly cured to show excellent production efficiency; a cured layer formed after the radiation curing composition is cured has excellent antifogging performance on the basis of ensuring excellent chemical resistance, scratch resistance, adhesion fastness with various base materials and traceability in a shrinkage process.

Owner:CHANGZHOU GREEN PHOTOSENSITIVE MATERIALS CO LTD

Water-based polyurethane color paint

InactiveCN109943214AReduce pollutionLess irritatingAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedOrganic solvent

The invention discloses water-based polyurethane color paint. The paint comprises basic paint which is prepared from the following components in parts by weight: 40-55 parts of water-based polyurethane resin, 1-3 parts of a water-based thickening agent, 0.2-0.5 part of a water-based defoaming agent, 0.5-1 part of water-based wetting agent, 0.5-1 part of a water-based flatting agent, 3-5 parts of acoalescing agent, 25-35 parts of water-based color paste and 8-20 parts of deionized water, a curing agent which is hexamethylene diisocyanate-based hydrophilic aliphatic polyisocyanate, and a diluting agent which is deionized water. The water-based polyurethane color paint only contains a small amount of volatile organic compounds, has low VOC, no remarkable odor, small irritation for human bodies and small environmental pollution, can be well painted and adhered to the surface of a plastic workpiece, does not contain organic solvent, and does not corrode the plastic layer; and the paint layer formed by the color paint has the characteristics of abrasion resistance and corrosion resistance.

Owner:惠州市双信达实业有限公司

Preparation technique of special fertilizer for flowers

InactiveCN104961531ANo waste of power resourcesLow costBio-organic fraction processingOrganic fertiliser preparationElectric powerNutrient

The invention discloses a preparation technique of a special fertilizer for flowers, which comprises the following steps: preparing materials, potting, fermenting, taking the fertilizer, diluting, diluting the liquid concentrated fertilizer with water to prepare the special fertilizer for flowers, which can be directly used. The fertilizer is prepared by mixing and naturally fermenting the multiple raw materials. Thus, the technique does not waste any electric power resource, is green and efficient, and lowers the production cost. The fertilizer has the advantages of abundant nutrient elements and no obvious peculiar smell, can be absorbed more easily, and is suitable for planting flowers.

Owner:苏州维登农业有限公司

Treatment method for cyclohexanone device waste water

ActiveCN105502552AReduce energy consumptionWater clarificationOther chemical processesOxygen compounds purification/separationActivated carbonCyclohexanone

The invention provides a treatment method for cyclohexanone device waste water through adsorption by means of activated carbon supporting metal. In the method, an activated carbon adsorbent supporting 1-5% by mass of the metal is employed. The treatment method particularly includes the steps of: after the activated carbon adsorbent is prepared, the cyclohexanone device waste water is subjected to adsorption treatment at a low temperature and then is subjected to desorption through a cyclohexane washing adsorbent at a high temperature, wherein the adsorbent after the desorption can be recycled. The treated cyclohexanone device waste water is 80-90% in COD removal ratio after the adsorption treatment, is clear in water quality and is free of obvious odor. The method reduces energy consumption of treating the cyclohexanone device waste water and saves treatment cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of high temperature resistant coating for imitating ceramic fake material of real fire fireplace

ActiveCN109666316BEasy to adjustLow costFireproof paintsAnti-corrosive paintsAqueous solubilityAqueous solution

A high-temperature resistant coating for true fire fireplace simulating ceramic materials relates to the technical field of building and decorating materials. The high-temperature resistant coating for the true fire fireplace simulating ceramic materials is prepared by uniformly and proportionally mixing ceramic pigments, paint grade talcum powder, bentonite, 0.01-1% cationic polyacrylamide aqueous solution, aluminum sol or silica sol and water and emulsifying the mixture at high speed in an emulsifying machine. The high-temperature resistant coating for the true fire fireplace simulating ceramic materials is water-soluble, convenient to dilute and regulate, low in cost, resistant to acid and alkali, heat-resisting, free from obvious smell and capable of avoiding cracking at high-temperature as well as over-thick surface layers caused by excessive permeation.

Owner:宜兴市爱博纤维制品有限公司

Peppermint essential oil extraction method

InactiveCN107653057AReduce dosageHigh recovery rateFatty-oils/fats productionPeppermintsSodium glycerophosphate

The invention discloses a peppermint essential oil extraction method. The method includes the steps of 1), cleaning and cutting peppermint into small pieces prior to spreading out the small pieces inthe shade with the thickness of 2cm, spraying a sodium glycerophosphate solution 0.3% in volume fraction on the surface of the small pieces once a day with the amount of 100-120g / m<2>, and turning over the peppermint pieces; 2), after 4 days, placing the peppermint pieces in to a grinder for grinding; 3), putting dry powder into a vacuum freezing type dryer to be dried completely; 4), placing thepeppermint dry powder into a hexane solution with the weight of 3-4 times as heavy as the peppermint dry powder, and adding sodium dodecyl lysine with the weight of 001-0.03 times as heavy as the hexane solution; 5), at the environment of 50DEG C, performing auxiliary extraction by adopting ultrasonic, extracting a filtrate after 60-70 minutes, and recovering an organic solution from the filtratein decompression to obtain peppermint essential oil. The extraction method has the advantages of short extraction time, less dosage of the solvent, high extraction rate, high solvent recovery, low cost, low investment and the like.

Owner:安徽恒达药业有限公司

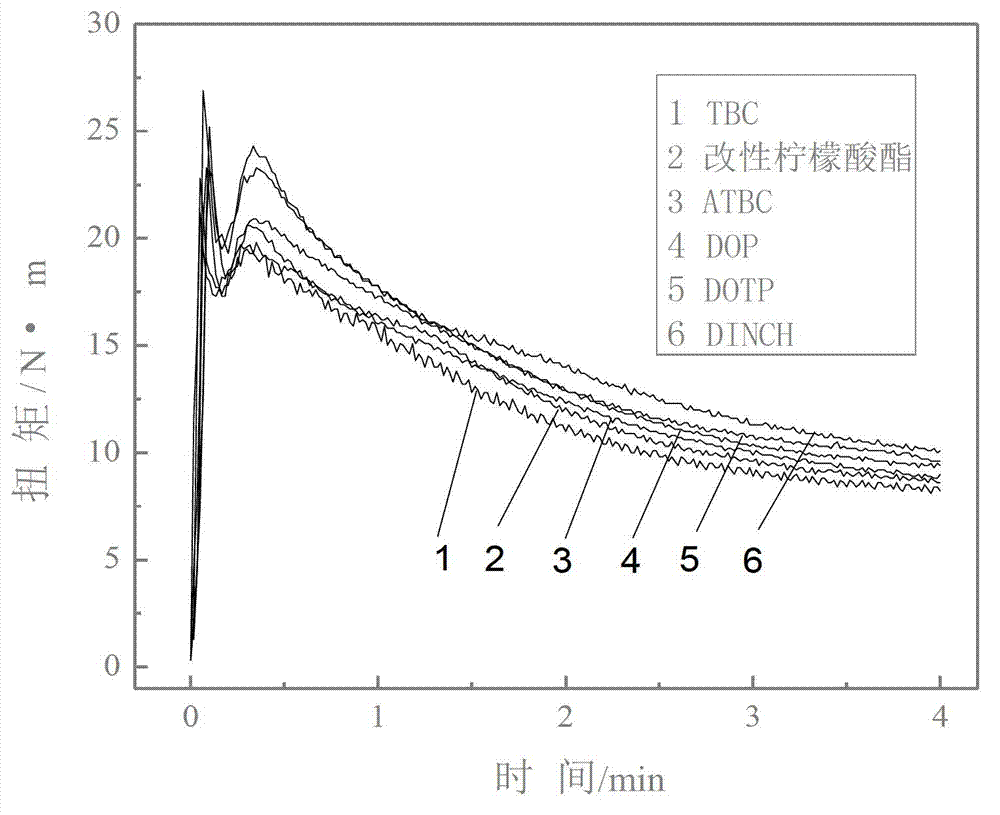

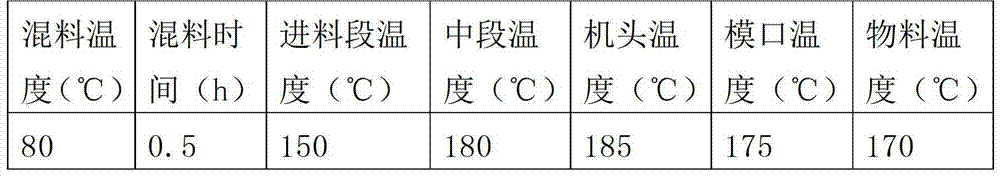

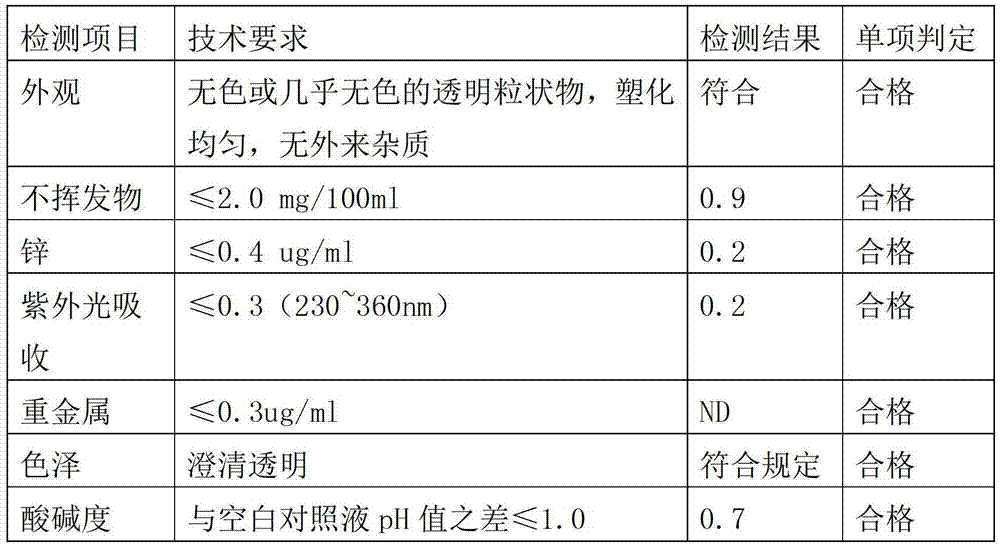

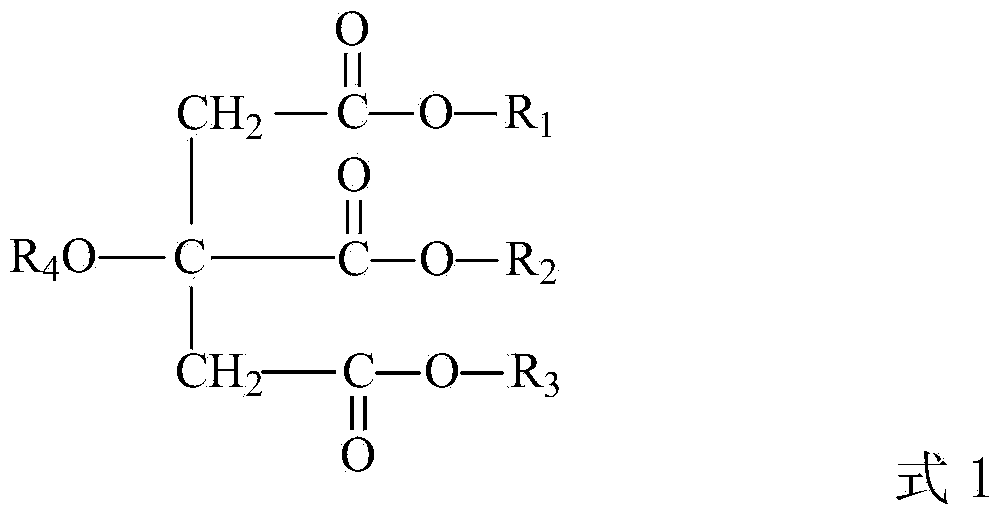

Preparation method of polyvinyl chloride (PVC)-based material granule plasticized by non-benzene plasticizer for preparing hard or semi-hard products

The invention relates to a preparation method of polyvinyl chloride (PVC)-based material particle plasticized by non-benzene plasticizer used for preparing horniness or half horniness products, aiming at solving the technical problems that the existing plasticizer has certain toxicity, is not transference-resistant and has odor. The PVC-based material comprises PVC and the non-benzene plasticizer, wherein the weight ratio between the PVC and the non-benzene plasticizer is 100: 5-200. The PVC-based material can be widely used for producing disposable plastic medical supplies, pharmaceutical package sheet, toys for children and artificial leather.

Owner:山东万图高分子材料股份有限公司

A kind of sbs modified asphalt additive and sbs modified asphalt

ActiveCN109553989BImprove ductilityImprove anti-aging propertiesBuilding insulationsPolymer sciencePlasticizer

The invention relates to the technical field of asphalt materials, and specifically discloses an SBS modified asphalt additive and SBS modified asphalt. The SBS modified asphalt additive of the present invention comprises the following raw material components in parts by mass: 30-50 parts of modified sulfur, 50-100 parts of white oil, 0.5-2 parts of antioxidant, 1-5 parts of suspension aid, 1 ~5 parts plasticizer. The SBS modified asphalt additive of the present invention is added to the SBS modified asphalt, which can significantly improve the storage stability, ductility and aging ductility of the SBS modified asphalt.

Owner:SUZHOU TOPOLINE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com