Integrated control aquaculture wastewater combined treatment technology and device

A breeding wastewater and treatment process technology, which is applied in animal husbandry wastewater treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of inability to completely treat multiple pollutants, low potential pollutant content, and large primary drainage, etc. problem, to achieve the effect of improving the driving force of oxygen transfer, high oxygen utilization rate and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

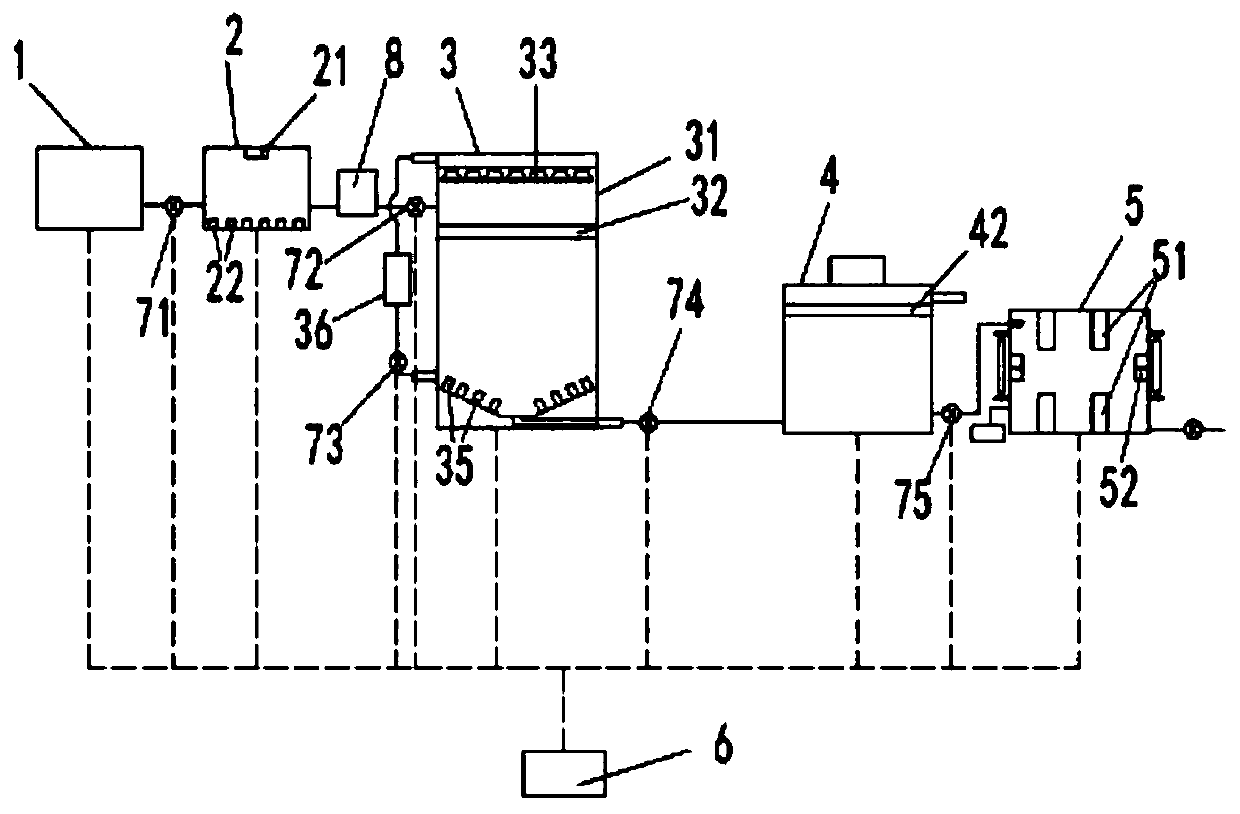

[0028] A combined treatment process for aquaculture wastewater with integrated control, comprising the following steps:

[0029] S1: Pretreatment: The aquaculture wastewater is roughly filtered through the filter tank, and then pumped into the adjustment tank, the pH value of the aquaculture wastewater is adjusted to 6, and the flocculant is added according to 0.1% of the influent quality, and then 0.1% of the influent quality is added. , stand still, carry out solid-liquid separation and take the supernatant; wherein, 10 minutes before adding the flocculant, carry out ultrasonic treatment with an ultrasonic frequency of 100 kHz, and stop the ultrasonic treatment after 5 minutes after the flocculation is completed;

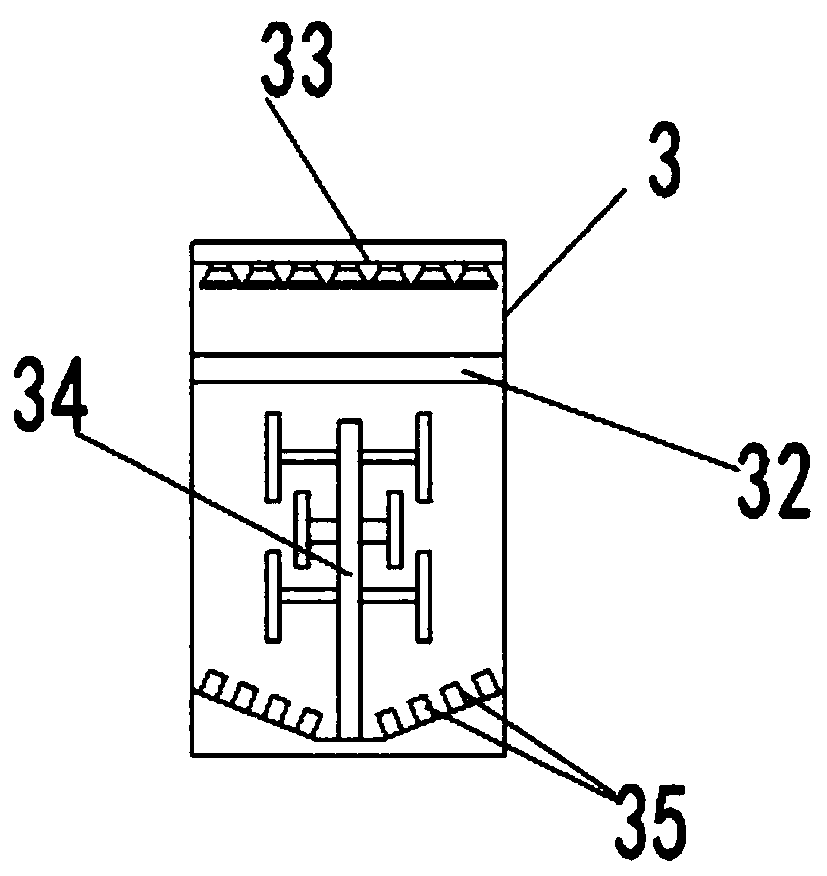

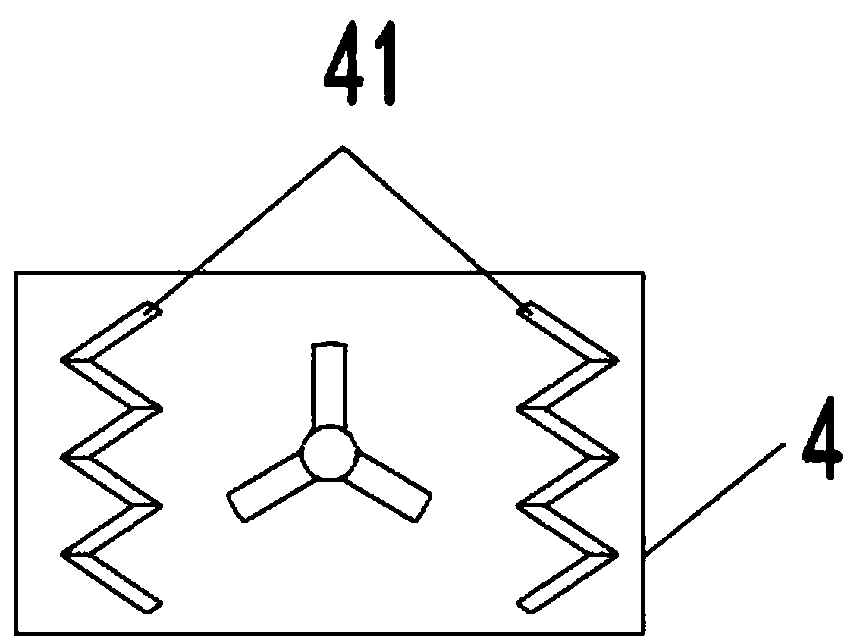

[0030] S2: Oxidation treatment: adjust the pH value of the supernatant in step S1 to 3, and then pump it into the decomposition tank for pulse aeration treatment with a pulse period of 5 minutes to maintain the gas circulation in the decomposition tank and control th...

Embodiment 2

[0037] Different from Example 1, a combined treatment process for aquaculture wastewater with integrated control comprises the following steps:

[0038] S1: Pretreatment: the aquaculture wastewater is roughly filtered through the filter tank, and then pumped into the adjustment tank, the pH value of the aquaculture wastewater is adjusted to 6.5, and the flocculant is added according to 0.2% of the influent quality, and then 0.2% of the influent quality is added. , stand still, carry out solid-liquid separation and take the supernatant; wherein, 10 minutes before adding the flocculant, carry out ultrasonic treatment with an ultrasonic frequency of 100 kHz, and stop the ultrasonic treatment after 5 minutes after the flocculation is completed;

[0039] S2: Oxidation treatment: adjust the pH value of the supernatant in step S1 to 3.5, and then pump it into the decomposition tank for pulse aeration treatment. The pulse period is 8 minutes to maintain the gas circulation in the decom...

Embodiment 3

[0044] Different from Example 1, a combined treatment process for aquaculture wastewater with integrated control comprises the following steps:

[0045] S1: Pretreatment: the aquaculture wastewater is roughly filtered through the filter tank, and then pumped into the adjustment tank, the pH value of the aquaculture wastewater is adjusted to 7, and the flocculant is added according to 0.3% of the influent quality, and then 0.3% of the influent quality is added. , stand still, carry out solid-liquid separation and take the supernatant; wherein, 10 minutes before adding the flocculant, carry out ultrasonic treatment with an ultrasonic frequency of 100 kHz, and stop the ultrasonic treatment after 5 minutes after the flocculation is completed;

[0046] S2: Oxidation treatment: adjust the pH value of the supernatant in step S1 to 4, and then pump it into the decomposition tank for pulse aeration treatment with a pulse period of 10 minutes to maintain the gas circulation in the decomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com