Production technology for refined horse oil ethyl ester

A horse oil ethyl ester and production process technology, which is applied in the field of refined horse oil ethyl ester production technology, can solve problems such as difficult realization of large-scale industrial production and application, hindered research and development of horse oil products, immature complete process, etc. The effect of short time, high output and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

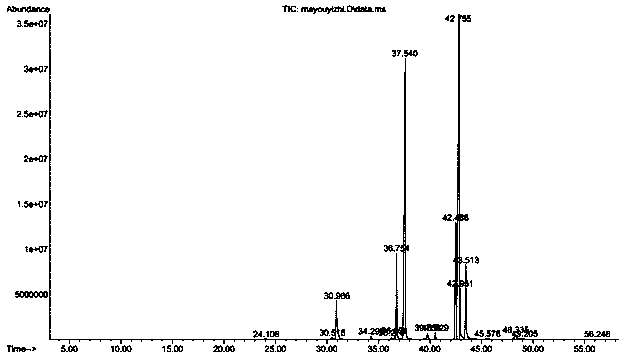

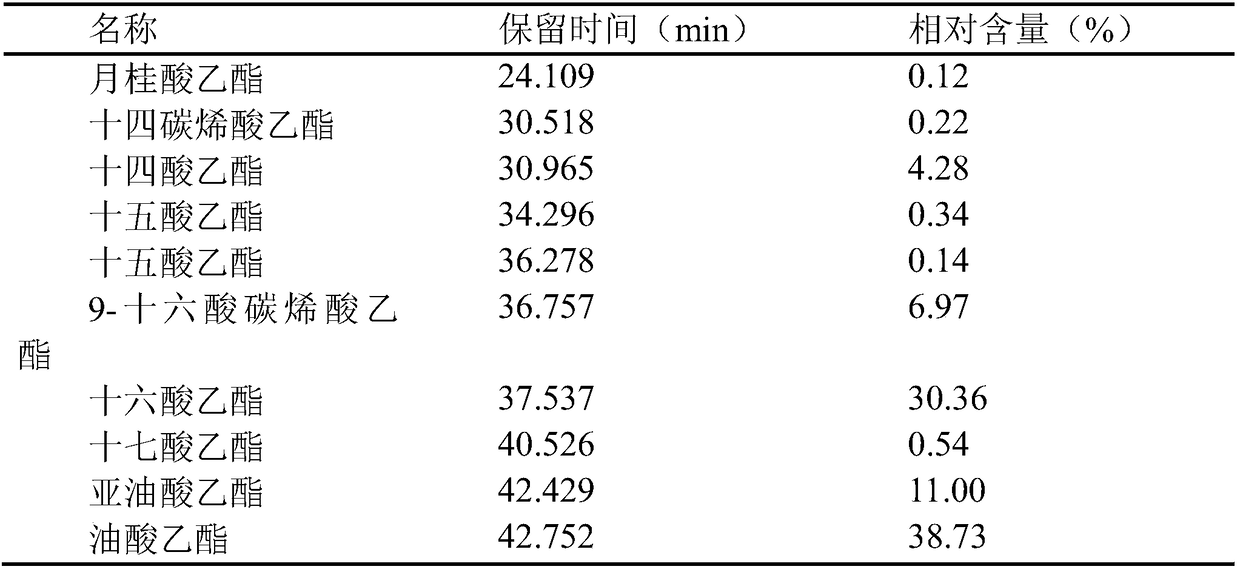

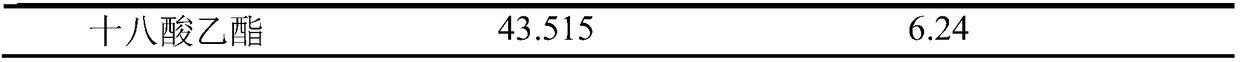

Image

Examples

Embodiment 1

[0028] Extraction of crude horse oil: at room temperature, grind fresh horse fat with a meat grinder, then add it to a stainless steel reaction kettle, heat to 80°C, stir for 4 hours, open the vent valve to release part of the water vapor, open the Horizontal condensing switch, vacuum dehydration at 100°C until the water separator no longer drips, then at 80°C, first filter with a stainless steel filter to collect the clear liquid of horse oil, and then filter the clear liquid with 250 mesh The cloth is subjected to secondary filtration, and the filtered product is collected to obtain crude horse oil with an oil yield of 78.7%.

[0029] Ethyl esterification of crude horse oil: First, add 3 kg of absolute ethanol to a stainless steel barrel, add 1.0 kg of caustic soda to it, roll and stir the alkali with a wooden stick, and carefully pour the ethanol dissolved in caustic soda into the barrel for the esterification reaction In the kettle, if there is still unmelted caustic soda ...

Embodiment 2

[0033] Extraction of crude horse oil: at room temperature, grind fresh horse fat with a meat grinder, then add it to a stainless steel reaction kettle, heat to 120°C, stir for 5 hours, open the vent valve to release part of the water vapor, open the Horizontal condensing switch, vacuum dehydration at 120°C until the water separator no longer drips, and then at 90°C, first filter with a stainless steel filter to collect the clear liquid of horse oil, and then filter the clear liquid with 250 mesh The cloth is subjected to secondary filtration, and the filtered product is collected to obtain crude horse oil with an oil yield of 79.1%.

[0034] Ethyl esterification of crude horse oil: First, add 3 kg of absolute ethanol to a stainless steel barrel, add 1.1 kg of caustic soda to it, roll and stir the alkali with a wooden stick, and carefully pour the ethanol with caustic soda dissolved in the barrel into the esterification reaction In the kettle, if there is still unmelted caustic...

Embodiment 3

[0038] Extraction of crude horse oil: at room temperature, grind fresh horse fat with a meat grinder, then add it to a stainless steel reaction kettle, heat to 120°C, stir for 4 hours, open the vent valve to release part of the water vapor, Turn on the horizontal condensation switch, vacuumize and dehydrate at 110°C until the water separator no longer drips, then at 80°C, first filter with a stainless steel filter to collect the clear liquid of horse oil, and then use the clear liquid with 300 mesh The filter cloth is subjected to secondary filtration, and the filtered product is collected to obtain crude horse oil with an oil yield of 78.9%.

[0039] Ethyl esterification of crude horse oil: first add 3 kg of absolute ethanol to a stainless steel barrel, add 1.2 kg of caustic soda to it, roll and stir the alkali with a wooden stick, and carefully pour the ethanol dissolved in caustic soda into the barrel for the esterification reaction In the kettle, if there is still unmelted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com