Patents

Literature

62results about How to "Low residual oil rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

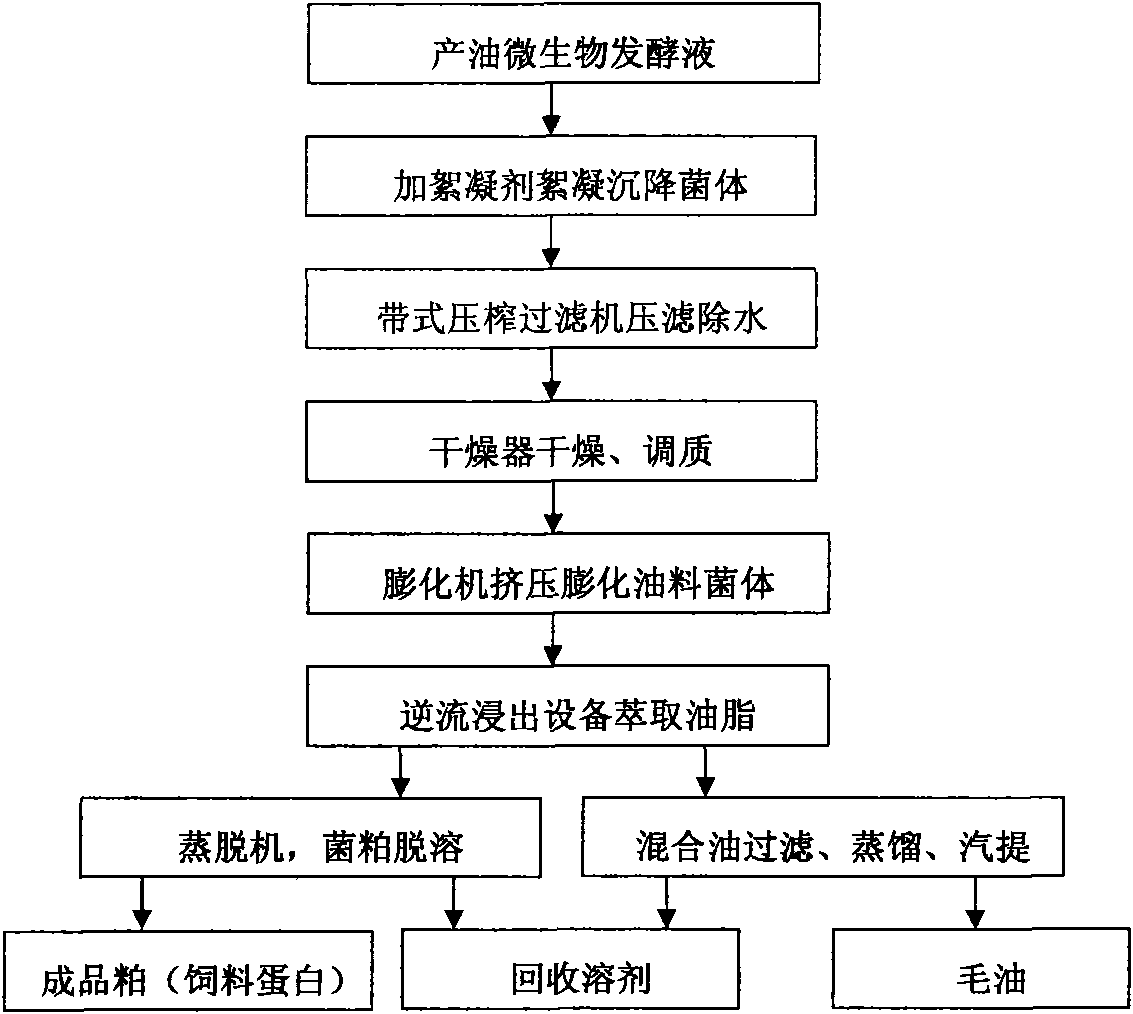

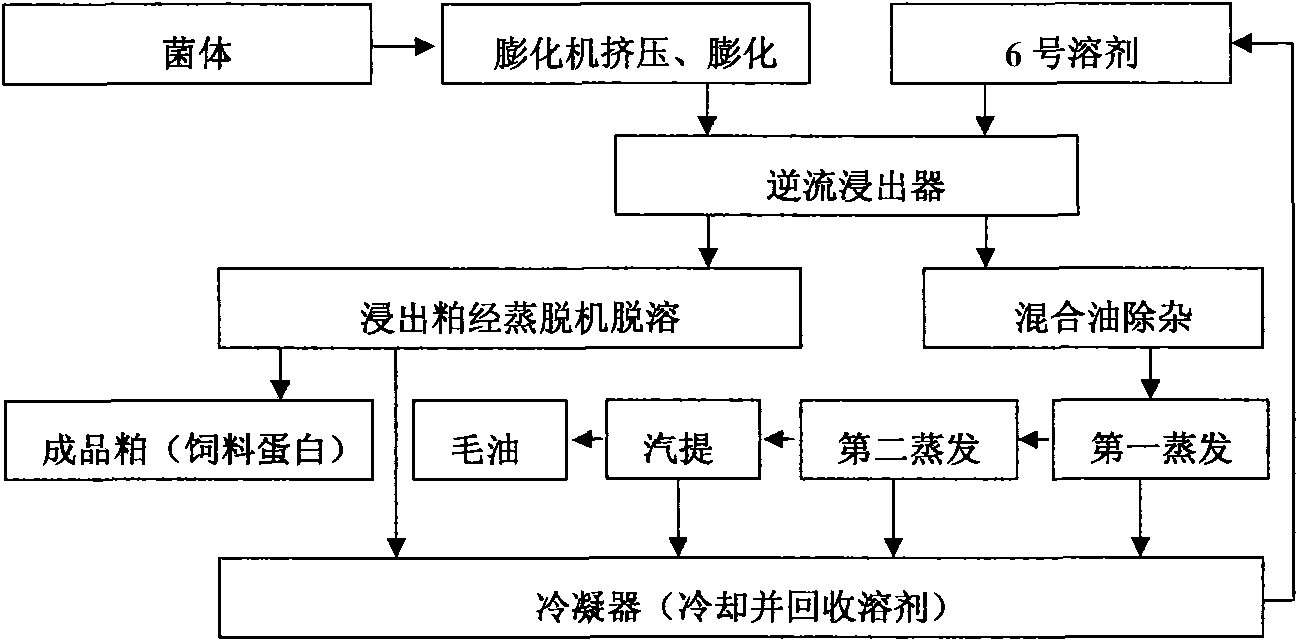

Method for preparing microbial oil and fat

InactiveCN101560440ASimple processImprove product qualityFermentationFatty-oils/fats productionOil and greaseMicrobial oil

The invention discloses a method for preparing microbial oil and fat, which comprises the following steps: (1) collecting microbial thalli; (2) performing filter pressing on the thalli obtained in the step (1) to obtain wet bacterial mud; (3) performing thermal refining, namely drying the wet bacterial mud obtained in the step (2) to remove most of free moisture and partial bound water in cells, and adjusting the temperature and the moisture content of the obtained dried thalli; (4) performing extrusion swelling, namely putting the dried thalli obtained in the step (3) into an extrusion swelling machine for extrusion and swelling; and (5) extracting and soaking the oil-bearing material dried thalli obtained in the step (4) to obtain mixed oil and soaked thalli residues. The method has the advantages of simple process, large handling capacity, low energy consumption and high product quality, and belongs to the field of oil and fat preparation.

Owner:BEIJING UNIV OF CHEM TECH

Low-temperature cold pressing method for linseed oil

InactiveCN101275101AFully retain natural nutrientsPreserve natural nutrientsFatty-oils/fats productionLinseed oilPhenol

The present invention provides a low temperature cold pressed method of a linseed oil, the main process includes: directly processing disposable press after cleaning, quenching and tempering the linseed raw material, the press oil yield is less than 80 DEG C. The wool oil refining process adopts drying method and physical absorption method, completely processing under the normal temperature. The preparing method wholly retains all kinds of nutritious components of the linseed oil, linseed protein, flaxseed gum and wood phenol components in the oil cake are not damaged, further developed and utilized. The oil cake after pressed is directly utilized as a food nutritious additive composition.

Owner:刘洪举

Linseed kernel oil and production method thereof

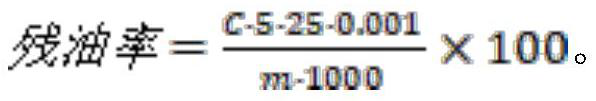

InactiveCN101602978AImprove oil yieldLow residual oil rateFatty-oils/fats productionEdible oils/fatsAlpha-Linolenic acidEdible oil

The invention discloses linseed kernel oil, which is extracted by pretreating and peeling linseed and taking linseed kernel as a raw material. A production method of the linseed kernel oil comprises the following steps: cleaning and drying linseed, separating peel and kernel; crushing, cooking the linseed kernel and squeezing out oil; and filtering and precipitating to obtain a finished product. The invention provides brand new edible oil. The processing technique of the product does not add any chemical reagent and is green and pollution-free, the product has no any chemical pollution, and the processing of the product is not subjected to high temperature, keeps alpha-linolenic acid in the linseed, and enables the content of the alpha-linolenic acid of the product to reach about 60 percent. The content of crude protein in byproduct, namely linseed kernel cake is improved by 10 percent compared with that of linseed cake and reaches about 43 percent, and the anti-nutritional factors are greatly reduced, widen the application of the linseed kernel cake and improve the additional value of processing. The product is novel, and the processing technology is mature, has high oil extraction rate and is easy to popularize.

Owner:高银阁

Preparation method of grape seed extract

ActiveCN105130941AHigh yieldHigh purityOrganic chemistryFatty-oils/fats productionGrape seedFermentation

The invention discloses a preparation method of grape seed extract. The preparation method includes the steps that 1, grape seeds are smashed, water and yeast are added, fermentation is performed at indoor temperature in a sealed mode, and after vacuum drying, pretreated grape seed powder is obtained; 2, subcritical extraction is performed on the pretreated grape seed powder with fluid composed of propane and dimethyl ether as an extraction agent, extractive matter, namely, grape seed oil is obtained, subcritical extraction is performed with absolute ethyl alcohol as an extraction agent after complete extraction of the grape seed oil, vacuum concentration is performed on the extractive matter, and after concentrated liquor is dried through active carbon adsorption, red brown powder, namely, the procyanidine extract is obtained. Various effective extraction methods are combined in the extraction method, the yield can be effectively increased, the purity of the extract can be effectively improved, and then the product with extremely high quality can be obtained.

Owner:杭州再生肌生物科技有限公司

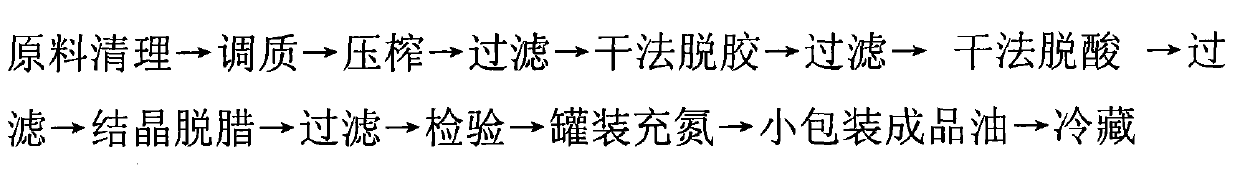

Preparation method of high oleic acid virgin peanut oil

InactiveCN101880594ALow residual oil rateImprove qualityFatty-oils/fats productionHigh oleic acidResidual oil

The invention relates to the technical field of preparation of peanut oil, in particular to a preparation method of high oleic acid virgin peanut oil, which is characterized by sequentially comprising the following steps: (1) screening varieties; (2) organically cultivating; (3) purchasing; (4) storing; (5) removing impurity; (6) drying at low temperature; (7) peeling; (8) breaking; (9) quenching; (10) cold pressing; (11) heating and stirring; and (12) centrifugally separating. The invention solves the problems that the existing pressing method has low oil extraction rate, high residual oil arte, poor smell of the peanut oil, and low content of oleic acid in the peanut oil. The invention has the following beneficial effects that: the production process is simple and easy to master and promote, and the production cost is low; and the nutrient content of the peanut oil is not damaged, the quality is better, and the nutrition value is higher. The method has higher oil extraction rate and lower residual oil rate.

Owner:SHANDONG PEANUT RES INST

Production technology of fresh zanthoxylum oil

ActiveCN101606676AHigh extraction rate of active ingredientsSimple processEdible oils/fatsFood preparationFruit juiceVegetable oil

The invention relates to a production technology of fresh zanthoxylum oil and aims at the defects of deficient and incomplete squeezing caused by an existing method that the fresh bunge prickly ash and edible vegetable oil after being mixed are squeezed, high residual oil content of waste residues and larger labor intensity. By the optimized procedures of material selection, pulverized manufacture of fruit juice, mixing, filtration, colloid removal, waxing, deposits and trace moisture thereof, the invention improves the production efficiency, shortens the production procedure, enhances the daily yield, lowers the rate of waste materials, lowers the cost, is timesaving and laborsaving, has better mouth feel, is more scientific and reasonable, improves the quality and the storage stability of a product, reflects the diversity of the product, increases the selectivity for consumers and enlarges the application range of production raw materials.

Owner:重庆市树上鲜食品(集团)有限公司

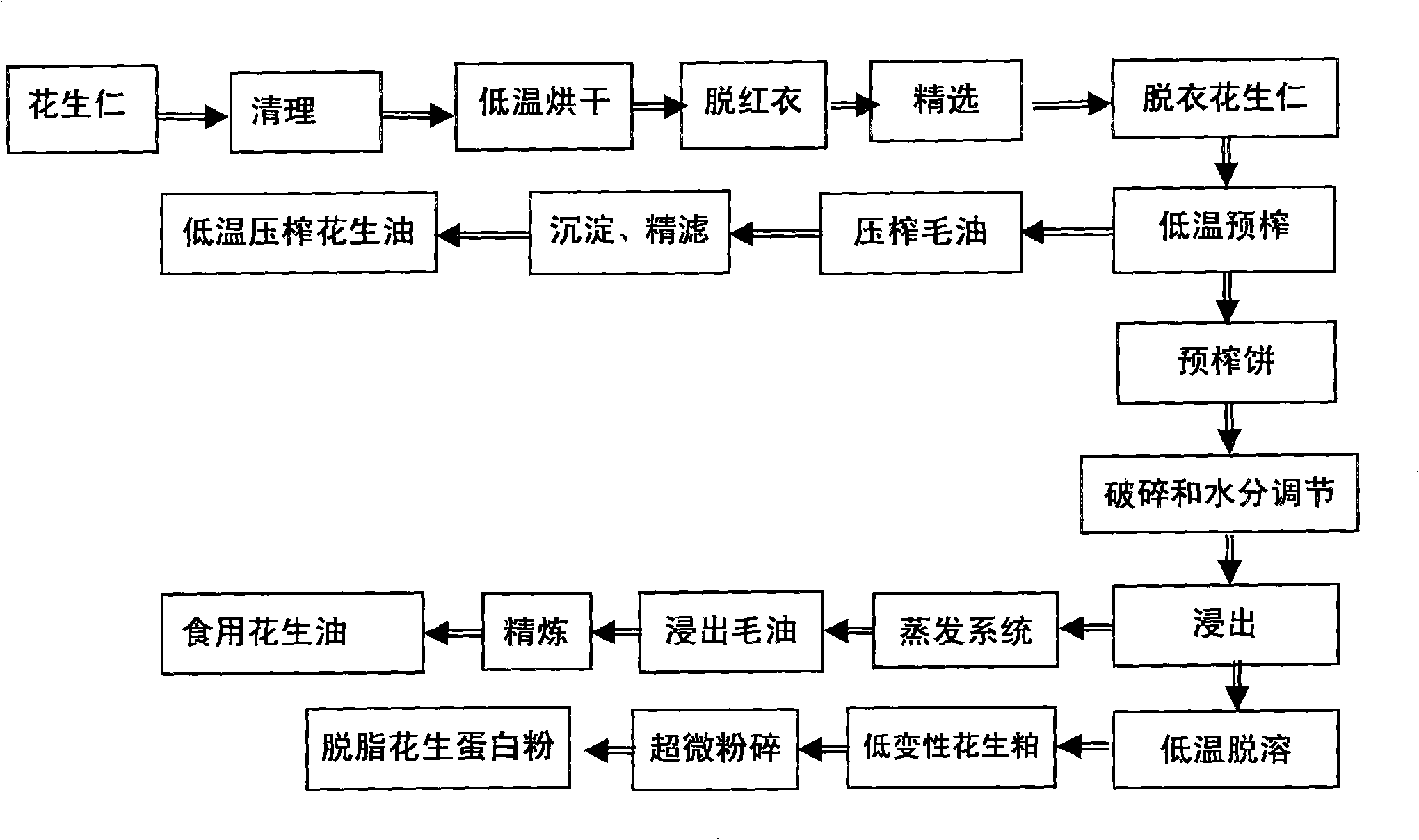

Method for producing degreasing peanut protein powder at low-temperature

InactiveCN101326952ALow residual oil rateReduce protein denaturationProtein composition from vegetable seedsFood preparationProtein contentProtein formation

The invention discloses a method for preparing defatted peanut protein powder under low temperature, which solves the problems that the NSI value of the prior defatted peanut protein powder is low, so that the functional characteristics of products, such as solubility, water and oil absorbility, emulsibility, etc. are low. The technical proposal comprises preparing the defatted peanut protein powder through the primary low-temperature pre-pressing, quality adjusting, leaching, low-temperature exsolution and super fine crushing to a defatted peanut after being dried with the red skin eliminated at low temperature; the whole production process is carried out under low temperature, and the obtained defatted peanut protein powder is in white or light yellow color, has less than 6.0 weight percent of water, less than 2 weight percent of fat, more than 60 percent of protein content (N*6.25, butt), and more than 60 percent of nitrogen solubility index, long storage time, good functional characteristics, such as solubility, water and oil absorbility, emulsibility, etc., good palatability and high peanut protein utility rate.

Owner:WUHAN POLYTECHNIC UNIVERSITY +1

Production method of cold-squeezed sacha inchi oil

InactiveCN107325878AImprove oil yieldLow residual oil rateFatty-oils/fats refiningFatty-oils/fats productionAqueous solutionImpurity

The invention discloses a production method of cold-squeezed sacha inchi oil. The production method comprises the following steps: (1) shelling; (2) screening and grading: putting selected sacha inchi kernels into an ultrasonic container containing 35% of a honey water solution, carrying out ultrasonic treatment at a temperature of 30 DEG C and an ultrasonic power of 550W-600W for 1 minute, standing for 6-8 seconds, respectively taking out the kernels on a middle upper layer, a middle layer and a middle lower layer of the ultrasonic container, respectively putting the three types of the kernels into an ultrasonic container containing deionized water, carrying out ultrasonic treatment at a temperature of 25 DEG C and an ultrasonic power of 450W-500W for 5 minutes, respectively putting the kernels into an ultrasonic container containing magnetized water, carrying out ultrasonic treatment at a temperature of 25 DEG C and an ultrasonic power of 600W-650W for 5 minutes, and drying at 35 DEG C until the water content is lower than 10%; and (3) crushing and cold squeezing: respectively crushing the three types of the kernels, drying, squeezing oil, mixing oil, and removing impurities. According to the production method, the oil extraction rate of the cold-squeezed sacha inchi oil is remarkably increased.

Owner:广西宁明县星雨生物资源开发有限公司

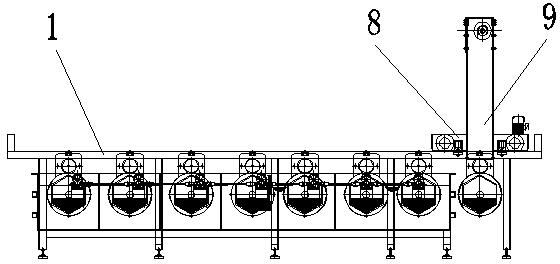

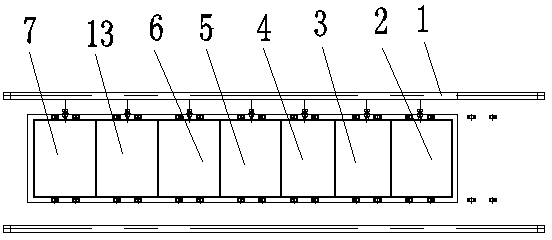

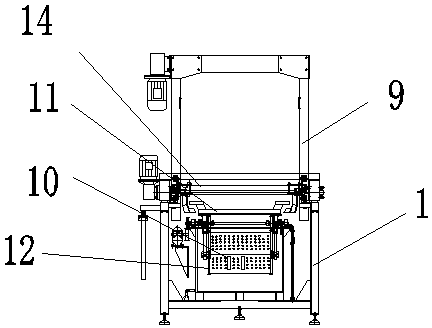

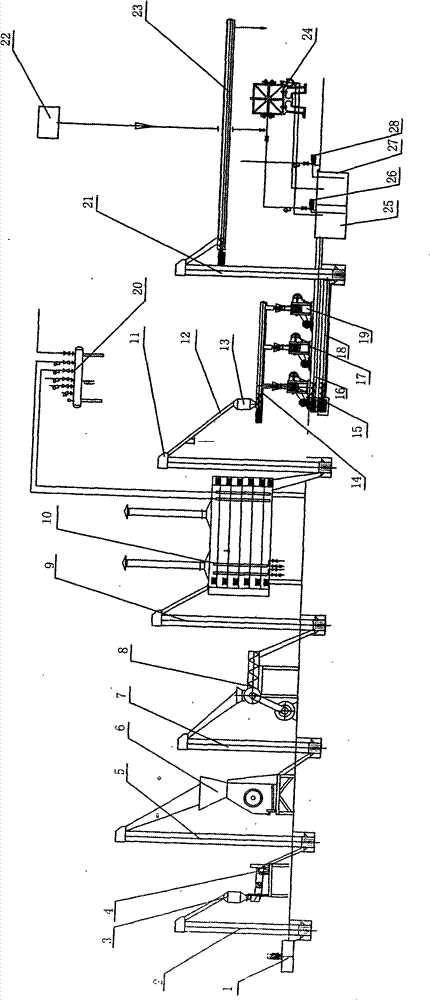

Annular brazing filler metal cleaning method and cleaning device

ActiveCN103361657ARealize automatic controlPrecise time controlMetallic material coating processesBenzotriazoleCleansing Agents

The invention relates to an annular brazing filler metal cleaning method. The annular brazing filler metal cleaning method comprises the following steps of: (1) deoxidizing an annular brazing filler metal in an acid solution for 180-24 seconds; (2) rinsing for 30-60 seconds with water; (3) removing oil from the annular brazing filler metal with a metal cleaning agent aqueous solution with the mass percent concentration of 2-5% at the temperature of 40-60 DEG C; (4) rinsing for 30-60 seconds; (5) polishing by using a polishing agent containing acid with the mass percent concentration of 8-12% and a brightening agent with the mass percentage concentration of 0.5-1% for 180-240 seconds; (6) rinsing for 30-60 seconds; and (7) passivating a solution containing 0.3-0.8% of benzotriazole for 5-20 seconds. The invention also relates to an annular brazing filler metal cleaning device for realizing the method.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Method for preparing oil by low aqueous enzymatic method and organic solvent extraction

InactiveCN102181321ALow residual oil rateRaise the denaturation rateFatty-oils/fats productionPectinaseOrganic solvent

The invention discloses a method for preparing oil by a low aqueous enzymatic method and organic solvent extraction. The method comprises the following steps of: based on 100 Kg of oil plants, dissolving 0.5 to 3.0 Kg of complex enzyme which comprises cellulolytic enzyme, pectinase, protease, and flavourzyme in a ratio of 2 to 3 to 4 to 3 in 40 to 70L of buffer solution with the pH value of 5.0 to 7.0 to obtain enzyme solution; cleaning the oil plants and removing impurities, crushing and sieving, wherein the particle diameter is 40 to 80 meshes; spraying the enzyme solution onto the crushed oil plants, stirring uniformly, and reacting at the constant temperature of between 40 and 55 DEG C for 2 to 4 hours; placing the reacted materials in a drying oven at the temperature of between 40 and 65 DEG C and drying for 2 days; hardening and tempering the materials to ensure that the moisture content is kept to be 3+ / -5 percent; and extracting the dried, hardened and tempered materials by anorganic solvent at the temperature of between 50 and 70 DEG C for 1 to 2 hours to obtain the extraction oil and egg oil material cakes. The method is high in oil yield, and the obtained oil and cake have high quality.

Owner:GUIZHOU UNIV

Grease decoloring agent

ActiveCN103706322ABleaching excellentExcellent purificationOther chemical processesFatty-oils/fats refiningFiltrationResidual oil

The invention discloses a grease decoloring agent, relates to a purification and adsorption material, and especially relates to the grease decoloring agent of aluminum-based hydrate composite materials and a preparation method thereof. The grease decoloring agent is characterized by being prepared by selecting two or more than two aluminum-based hydrates having the adsorption property, carrying out mixing homogenization and then adding an acidic modifying agent for modification and activation. The grease decoloring agent is a mixture of the aluminum-based hydrate composite materials. The materials have the advantages of less using amount, good decoloring effect, easy filtration and separation, small residual oil rate and the like; moreover, the decolorizing agent does not contaminate products; after medium temperature roasting after decolorization, the decolorizing agent can be used in a raw material of a high temperature coating layer material, thereby reducing the decoloring agent cost; and the grease decoloring agent fully meets the requirements of food-grade grease on indicators of the chromaticity and the impurity content, and is easy to popularize and apply.

Owner:中铝郑州有色金属研究院有限公司

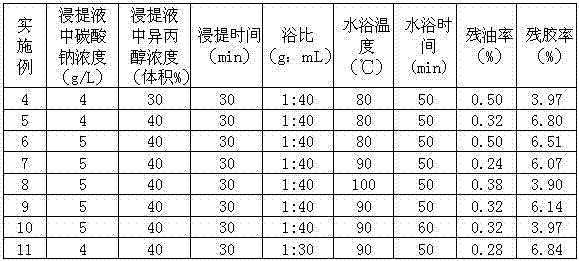

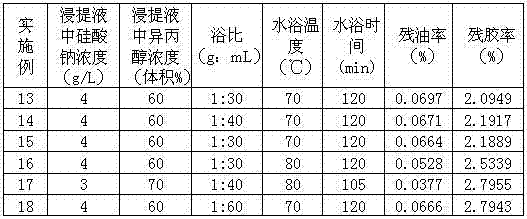

Deoiling and degumming treatment method for waste bave

InactiveCN103572382ALow boiling pointEasy to recycleAnimal materialDe-gumming silkResidual oilNational standard

The invention relates to a deoiling and degumming treatment method for waste bave. The method comprises the following steps of: A, deoiling and degumming treatment, namely, adding a leaching solution which is a isopropyl alcohol aqueous solution containing sodium carbonate or sodium silicate at a certain concentration to the waste bave, and reacting for 40 to 120 minutes under 70 to 100 DEG C, wherein the concentration of sodium carbonate or sodium silicate in the leaching solution is 3 to 6g / L, and the volume concentration of isopropyl alcohol is 20 to 70%, and the ratio of the mass of the waste bave to the volume of the leaching solution is 1g: 30 to 60mL; B, washing with water, namely, taking out the waste bave after the reaction is finished, and washing with water; C, drying, namely, drying the waste bave washed with water, wherein the waste bave is long silk waste or silk floss. The method has a good deoiling and degumming effect, is short in treatment time and low in temperature; after the deoiling and degumming, both the residual oil ratio and residual glum ratio of the long silk waste easily reach the national standard in which the residual glum ratio of refined waste silk is 3 to 7%, and the residual oil ratio is not more than 0.55%; moreover, the whiteness of the long silk waste is obviously improved; the residual oil ratio of the silk floss is far less than 1.5% of that as specified by the national standard, and the residual glum ratio is relatively small.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Extraction method of eucommia seed oil

InactiveCN103087816ALow residual oil rateReduce extraction costsFatty-oils/fats productionResidual oilEucommia

The invention relates to an extraction method of eucommia seed oil. The extraction method comprises the following steps of: firstly peeling and carrying out cold-pressing on an eucommia seed kernel; then smashing cold-pressed seed meal, and carrying out CO2 supercritical extraction; and merging cold-pressing and extraction to obtain the eucommia seed oil. The extraction method of the eucommia seed oil has the advantages of low residual oil ratio, sufficient raw material utilization and low extraction cost.

Owner:LINGBAO JINDI EUCOMMIA IND

Low temperature extrusion-multienzyme synergistic degradation material pretreatment method

Owner:ZIBOHUICHUANG BIOLOGICAL SCI TECH LTD +1

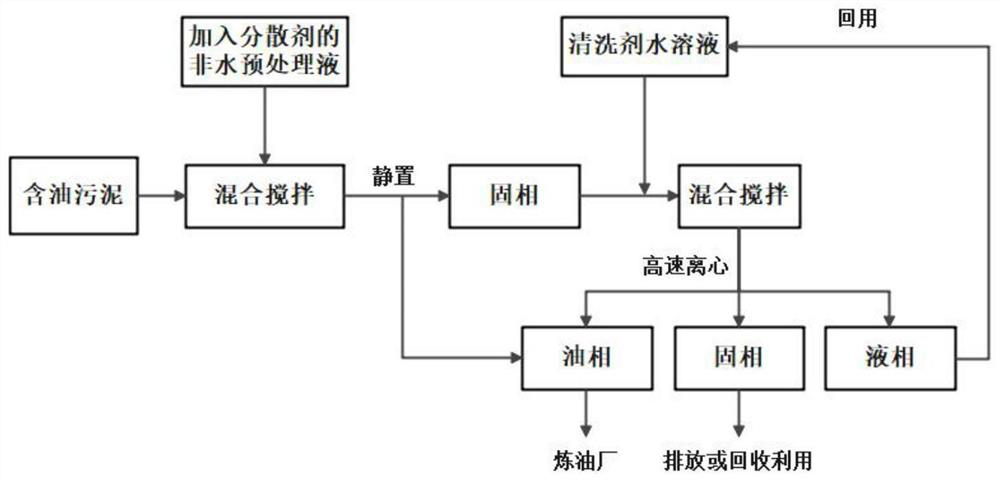

Pretreatment liquid, application of pretreatment liquid, and treatment method of heavy oil sludge

InactiveCN113754213APrevent self-aggregationEvenly dispersedSludge treatment with immiscible liquidsPhysical chemistryHeteroatom

The invention belongs to the technical field of treatment of oil-containing sludge polluted by crude oil, and particularly relates to pretreatment liquid, application of the pretreatment liquid and a treatment method of heavy oil sludge. The pretreatment liquid containing the asphaltene dispersing agent and the non-polar solvent provided by the invention is used for pretreating the heavy oil sludge, asphaltene in the heavy oil sludge is a polar component, and the asphaltene dispersing agent has the effects of being combined with asphaltene and forming hydrogen bonds with heteroatoms such as S and N on the surface of asphaltene molecules, so that the self-aggregation of asphaltene in the heavy oil sludge can be prevented; the asphaltene and other substances can be easily stripped from the particle surface so as to disperse the asphaltene in the heavy oil sludge in the non-polar solvent for a long time, the severely cemented oil sludge is uniformly dispersed in the pretreatment liquid, most of the oil phase, especially the polar oil phase difficult to clean, is removed in the pretreatment stage, and the pretreated heavy oil sludge still has more residual oil; and further, residual oil on the surface of the solid is cleaned off by adopting thermochemical cleaning, so that the emission standard is reached.

Owner:SHANDONG UNIV

A production process of ultrasonic-assisted freezing and vacuum-frying edible mushrooms

ActiveCN103892255BEasy to removeAvoid affecting heat transfer efficiencyFood dryingFood ultrasonic treatmentVacuum pressureUltrasonic assisted

The invention relates to an ultrasonic-assisted freezing and vacuum frying production process of edible fungi. The process is used for solving the problem that no relatively perfect pre-drying technique for the vacuum low-temperature frying of the edible fungi exists at present. The process disclosed by the invention comprises the following steps: (1) selecting edible fungus raw materials; (2) carrying out ultrasonic pre-drying at the ultrasonic frequency of 28kHz, at the ultrasonic power of 80-120W, under the vacuum pressure of 5-10kPa and at the temperature of 20-45 DEG C till the water content is 20-30%; (3) carrying out quick-freezing at the temperature of minus 50-minus 30 DEG C till the edible fungi are completely frozen; (4) carrying out vacuum frying for 5-20 minutes under the vacuum pressure of 0.1-5kPa and at the oil temperature of 80-90 DEG C; (5) carrying out vacuum deoiling under the vacuum pressure of 0.1-5kPa; (6) carrying out seasoning; (7) carrying out inert gas filling packaging to obtain finished products. The process disclosed by the invention is capable of stably maintaining the shape and the color of the fried edible fungi.

Owner:ZHEJIANG FORESTRY ACAD

Method for producing soybean protein concentrate

InactiveCN105685368AIncrease protein content and water contentHigh utilization rate of raw materialsProteins working-up by texturisingFood ingredientsMoistureFood processing

The invention discloses a method for producing a soybean protein concentrate and belongs to the technical field of food processing. The method is used for solving the problem of low protein content and moisture content of soybean protein concentrate produced by an existing method. The method comprises the following steps: (1) screening; (2) performing ethanol washing and saccharide removal; (3) extruding, desolventizing and vacuum-drying; (4) grinding by use of an ultrafine grinder. The method disclosed by the invention is used for producing soybean protein concentrate.

Owner:SHANDONG CHANGRUN BIOLOGICAL CO LTD +1

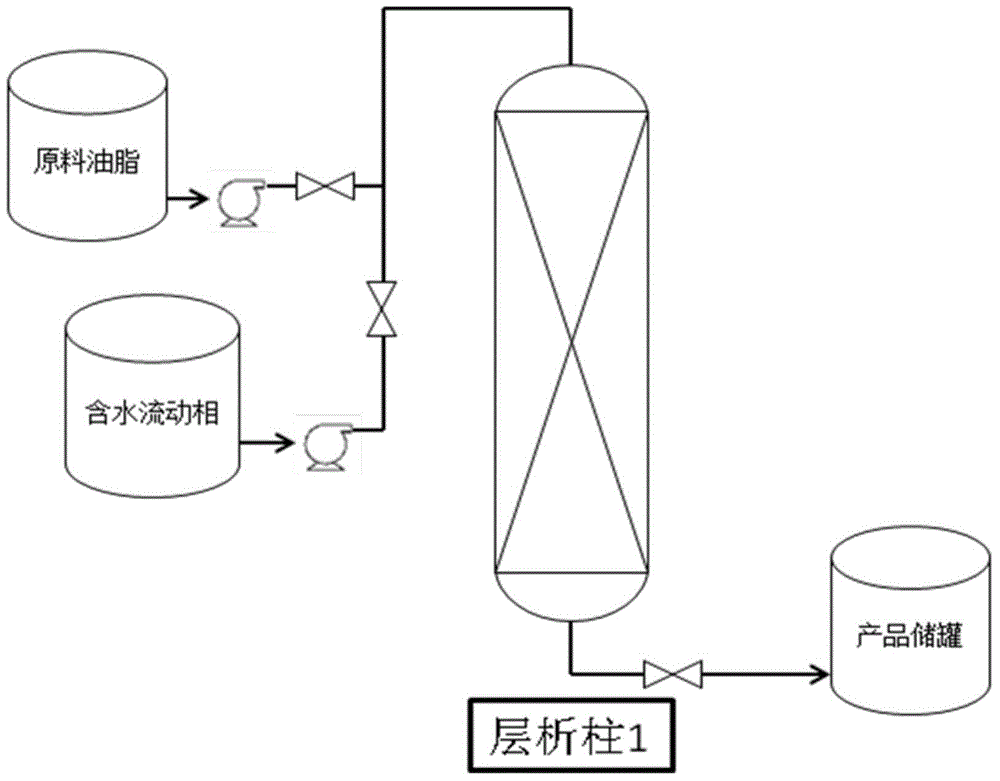

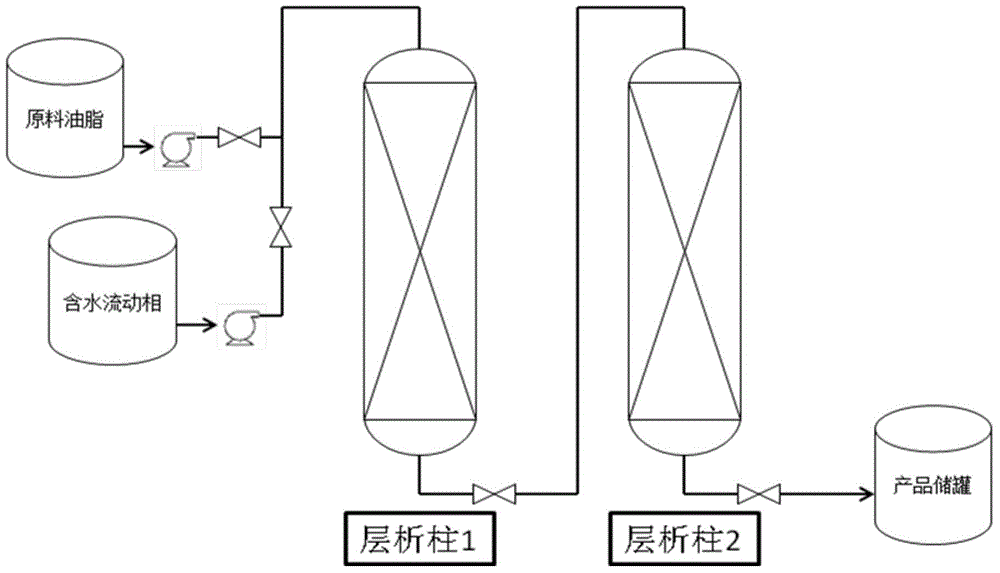

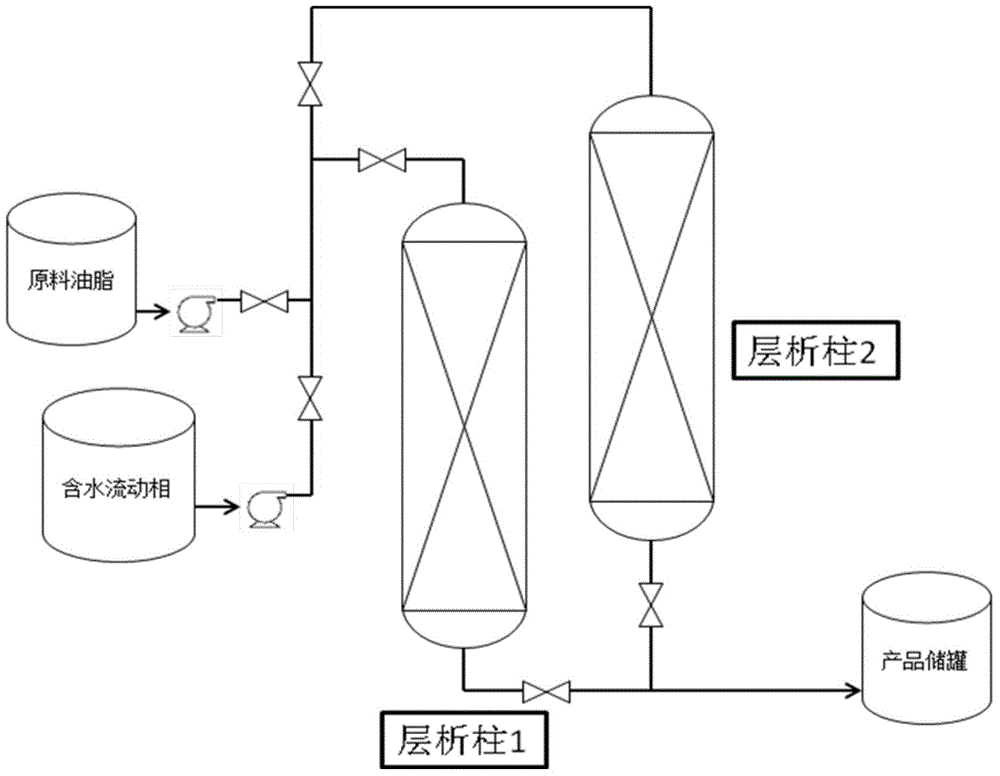

Treatment method for grease adsorbed adsorbent

ActiveCN104673498AReduce residual oilReduce manufacturing costFatty oils/acids recovery from wasteFatty substance recoveryChemistryPost treatment

The present invention provides a treatment method for a grease adsorbed adsorbent, wherein a water-containing mobile phase is added to the grease adsorbed adsorbent. According to the present invention, on the base of the existing equipment, the residual grease in the adsorbent is reduced, and the post-treatment step is simplified so as to solve the technical problems of high equipment cost and complex post-treatment in the prior art; and after the treatment through the method of the present invention, the index of the grease desorbed from the adsorbent and the quality of the grease treated by the adsorbent are the same, and the residual grease in the treated adsorbent is low.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Method for leaching cold press peeled vegetable seed cake oil by using mixed solvent

InactiveCN101323814AReduce cake residueIncrease productivityFatty-oils/fats productionSolventChemistry

The invention provides a method for the extraction of cold-pressing de-skinned rapeseed meal oil by adopting a component solvent, which is characterized in that: after the cold-pressing de-skinned rapeseed meal is ground by a grinder, a certain amount is taken, put in a flask and mixed with the mixed liquor of isopropyl alcohol and cyclohexane of certain volume; at the temperature of 62 DEG C, continuous digestion is carried out in a rotatory evaporator, during digestion, the solid-liquid ratio is 1.5:1 to 5:1, the volume ratio of isopropyl alcohol and cyclohexane is 0.5:1 to 5:1 and the digestion lasts 20min to 100min and is carried out for 1 to 2 times. The impurity in the obtained oil drops by 2.6 percent compared with isopropyl alcohol and residual oil rate drops by 0.56 percent compared with n-hexane and by 0.17 percent compared with isopropyl alcohol, which explains that the application of mixing polar solvent and non-polar solvent can well restrain polar substances in meal from extraction, thereby reducing working load in practical production and being capable of effectively improving the output of extracted oil.

Owner:中粮工科(西安)国际工程有限公司

Raw material oil pressing process with separated rapeseed shell and kernels

The rapeseed shell-kernel separating and raw material oil pressing process includes the steps of eliminating repeseed shell, separating rapessed shell from kernel, separated treatment of shell, squeezing oil with kernal at 35-80 deg.c and the condition of no change in protein property to obtain rapeseed cake and oil, and filtering oil to obtain product oil. The present invention is simple, low incost, high product quality and high in side product value.

Owner:罗永宗

Puffing squeezing technology of rapeseed

InactiveCN103923738AImprove permeabilityReduce usageFatty-oils/fats refiningFatty-oils/fats productionOil and greaseHeat losses

The invention discloses a puffed squeezing technology of rapeseeds. After an embryo flake preparing process to the rapeseeds, a puffing process without oil generated is carried out to the rapeseeds for enabling puffed particles to destroy cell walls of oil plants in a compulsory manner, thereby a purpose of gathering oil on surfaces of the oil plants is achieved. A drying process is carried out to remove moisture through a flat-plate dryer for enabling moisture content of the oil plants to be about 6%, and then a squeezing process is carried out. The leaching time during a subsequent leaching technology can be reduced since pre-squeezed cakes after being processed through the puffing process are in shapes of small particles and are very strong in penetrability; heat loss is very little since steam is directly contacted with oil plant embryos during the puffing process; a large amount of steam is saved since the operation time is short; and usage amount of steam is decreased since oil residue rate of cakes is reduced. Effects of improving oil extraction rate and saving energy are achieved.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

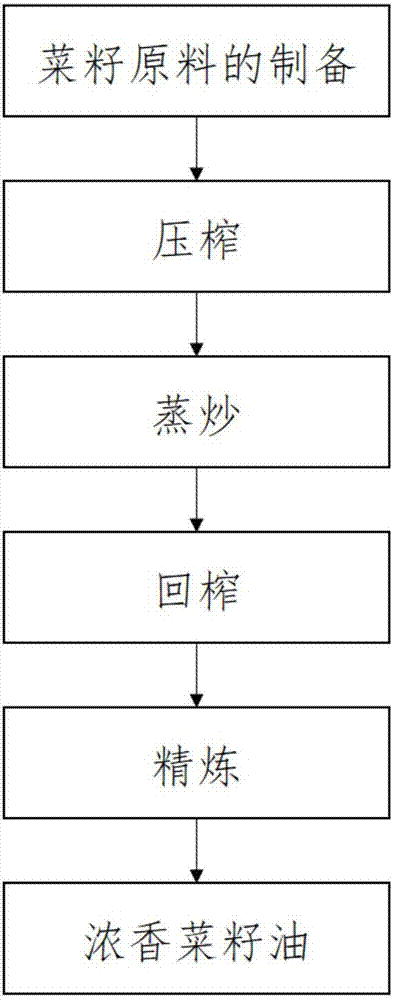

Preparation method of strongly-fragrant rapeseed oil

ActiveCN107488498AFragrance stimulationTo preventFatty-oils/fats refiningFatty-oils/fats productionRapeseedPress cake

The invention discloses a preparation method of strongly-fragrant rapeseed oil. The preparation method comprises the following steps: preparing and obtaining rapeseed materials, dividing the rapeseed materials into pressing rapeseed materials and back-pressing rapeseed materials; carrying out pressing treatment on the pressing rapeseed materials to obtain pressing rapeseed crude oil and pressed cakes; crushing the pressed cakes, mixing with the back-pressing rapeseed materials to obtain mixed rapeseed materials, and carrying out steaming and frying treatment on the mixed rapeseed materials to obtain steamed and fried rapeseed materials; carrying out back-pressing treatment on the steamed and fried rapeseed materials to obtain back-pressing rapeseed crude oil; and mixing the pressing rapeseed crude oil with the back-pressing rapeseed crude oil to obtain rapeseed crude oil to be refined, and carrying out hydrating treatment on the rapeseed crude oil to be refined to obtain finished aromatic rapeseed oil. The preparation method disclosed by the invention has the advantages that the process is simple, safe and reliable, fragrant substances in the prepared rapeseed oil cannot be lost due to excessive refining, and the fragrance is stronger and more lasting.

Owner:成都市新兴粮油有限公司 +1

Method of water-extraction-method ground sesame seed oil technology for adding water to extract oil

InactiveCN110747051AReduce labor intensityReduce vibration and oil outFatty-oils/fats productionEdible oils/fatsProcess engineeringBiology

The invention discloses a method of a water-extraction-method ground sesame seed oil technology for adding water to extract oil. The method comprises the six steps of (1) screening of a raw material,(2) rinsing of the raw material, (3) stir-frying, (4) blowing off of smoke, (5) grinding, and (6) water adding and stirring: adding hot water into slurry oil obtained through grinding at a low constant speed at once, and completing a high-speed stirring stage, a medium-speed stirring stage, a low-speed stirring stage and an oscillating oil extraction state through a stirring effect of a stirring blade. The method of the water-extraction-method ground sesame seed oil technology for adding the water to extract the oil is used for producing the ground sesame seed oil through a water extraction method.

Owner:HEZE BRANCH QILU UNIV OF TECH(SHANDONG ACAD OF SCI

Preparation method for peony seed oil

PendingCN109370763AFully retain nutrientsPromotes rapid oxidationFatty-oils/fats productionAlkaline proteasePectinase

The invention provides a preparation method for peony seed oil, and belongs to the technical field of edible oil processing. The method comprises the following steps: 1), shelling and crushing penoy seeds to obtain peony seed kernel powder; 2), mixing the peony seed kernel powder in step 1) and an enzyme preparation aqueous solution for enzymolysis to obtain an enzymolysis solution; 3), drying andpressing the enzymolysis solution in the step 2) to obtain the peony seed oil; the enzyme preparation in the step 2) comprises one or more of cellulase, neutral protease, alkaline protease and alpha-amylase, pectinase and hemicellulase; the pressing temperature in the step 3) is 50-80 DEG C. The method has the advantages of high pressing efficiency, high oil yield and low residual oil rate of seed meal.

Owner:NORTHEAST FORESTRY UNIVERSITY

Camellia oil and processing process thereof

InactiveCN108485797AImprove stabilityImprove antioxidant capacityFatty-oils/fats refiningFatty-oils/fats productionFood additiveFiltration

The invention discloses camellia oil and a processing process thereof. The processing process comprises the following steps: a, firstly, performing camellia seed collection and storage treatment on araw material; b, after the step a is completed, pretreating the raw material; c, after the step b is completed, treating with a cold pressing machine; d, after the step c is completed, performing oil-residue separation through plate frame filtration; e, after the step d is completed, performing secondary extraction on oil cakes; f, after the step e is completed, processing pressed crude camellia oil through alkali refining. On the basis of cold pressing, food additives are added, so that the stability, the anti-oxidation effect and the thermal stability of oil can be improved; secondly, a leaching method is implemented, since oil cells are not completely damaged in a pretreatment process, and albuminous degeneration is not very thoroughly achieved, barrel pressure is not very large, and the oil residue rate of pressed cakes is relatively high, an effect of extracting oil from oil cakes twice can be achieved together with the leaching method, the oil residue rate is reduced, the oil extraction effect is improved, and convenience can be brought to popularization and application.

Owner:平湖市超越时空图文设计有限公司

Production technology of fresh zanthoxylum oil

ActiveCN101606676BHigh extraction rate of active ingredientsSimple processEdible oils/fatsFood preparationFruit juiceVegetable oil

The invention relates to a production technology of fresh zanthoxylum oil and aims at the defects of deficient and incomplete squeezing caused by an existing method that the fresh bunge prickly ash and edible vegetable oil after being mixed are squeezed, high residual oil content of waste residues and larger labor intensity. By the optimized procedures of material selection, pulverized manufacture of fruit juice, mixing, filtration, colloid removal, waxing, deposits and trace moisture thereof, the invention improves the production efficiency, shortens the production procedure, enhances the daily yield, lowers the rate of waste materials, lowers the cost, is timesaving and laborsaving, has better mouth feel, is more scientific and reasonable, improves the quality and the storage stability of a product, reflects the diversity of the product, increases the selectivity for consumers and enlarges the application range of production raw materials.

Owner:重庆市树上鲜食品(集团)有限公司

Treatment technology of cotton seed piece

InactiveCN1830286AReduce equipment investment and production costsGood colorProtein composition from vegetable seedsAnimal feeding stuffSolventGossypol

A process for treating the cotton seed embryo flakes to obtain cotton seed protein used for feed and edible oil includes such steps as extracting from the cotton seed embryo flakes in acetone, rectifying the liquid extract, evaporating to obtain gross cotton seed oil and gossypol anthranilate, cooling the liquid extract, deoiling the cotton seed embryo flakes, continuous vacuum drying to obtain cotton seed protein used to prepared feed, and refining said gross oil to obtain class-two edible oil.

Owner:王建设

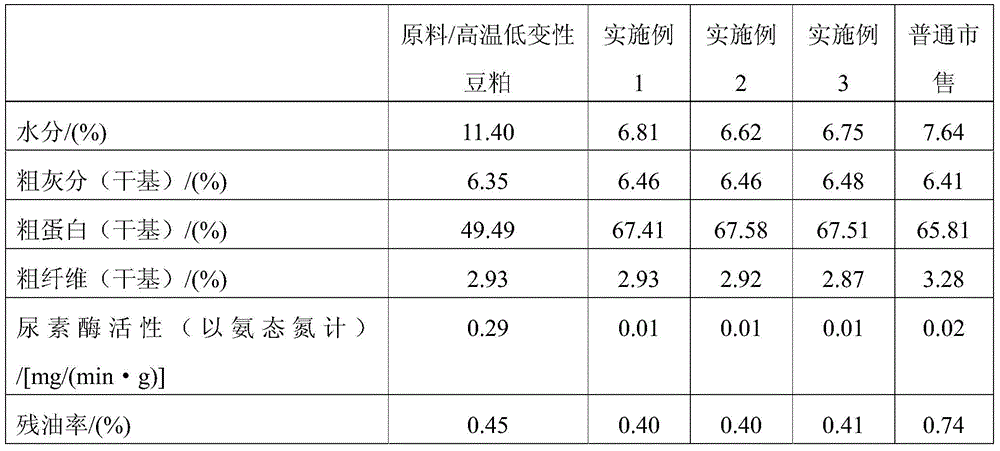

Method for extracting soybean protein concentrate through high-temperature low-denaturing soybean meal

ActiveCN106071040ANo smellImprove protein solubilityProtein composition from vegetable seedsHigh energySoybean protein

The invention discloses a method for extracting a soybean protein concentrate through high-temperature low-denaturing soybean meal, and belongs to the field of food processing. The problems of high cost, high energy consumption, low daily production capacity, low protein purity and poor nitrogen dissolving index existing in the production of the soybean protein concentrate in the prior art can be solved. According to the method disclosed by the invention, low-denaturing soybean meal produced by a high-temperature soybean meal production line is used as a raw material, and the production method comprises a production technology of producing the low-denaturing soybean meal through the high-temperature soybean meal production line, and an extraction technology of the soybean protein concentrate. The method disclosed by the invention is suitable for production of the soybean protein concentrate.

Owner:山东中阳生物科技有限公司

Refining method of snakegourd seed oil

InactiveCN105542944ASimple processEasy to operateFatty-oils/fats refiningFatty-oils/fats productionWater contentProtein content

The invention relates to a refining method of snakegourd seed oil. The refining method comprises the following steps: cleaning snakegourd seeds, and drying until the water content is 5%-8%; shelling the partial snakegourd seeds, so as to obtain snakegourd seed kernels; sequentially putting the snakegourd seeds and the snakegourd seed kernels in a seed frying machine, frying until 60%-70% of mature degree of the snakegourd seeds; heating a spiral oil press to 120-150 DEG C, pouring the snakegourd seeds and the snakegourd seed kernels, and squeezing, so as to obtain crude snakegourd seed oil; and refining the crude snakegourd seed oil by virtue of a centrifugal oil refining machine, so as to obtain the finished snakegourd seed oil. The refining method has the beneficial effects that the process is simple, the operation is easy, and the production cost is low; by shelling the partial snakegourd seeds before frying, the defects that equipment is complex, the pretreatment cost is high, pressure is difficultly produced in a squeezing chamber of the oil press, the oil pressing operation is difficult in a full-shelling process are avoided, and meanwhile, the defects that the residual oil ratio in cakes is high, protein content in the cakes is low, the load of the oil press is increased in a non-shelling process are avoided.

Owner:桐城市放牛娃家庭农场有限公司

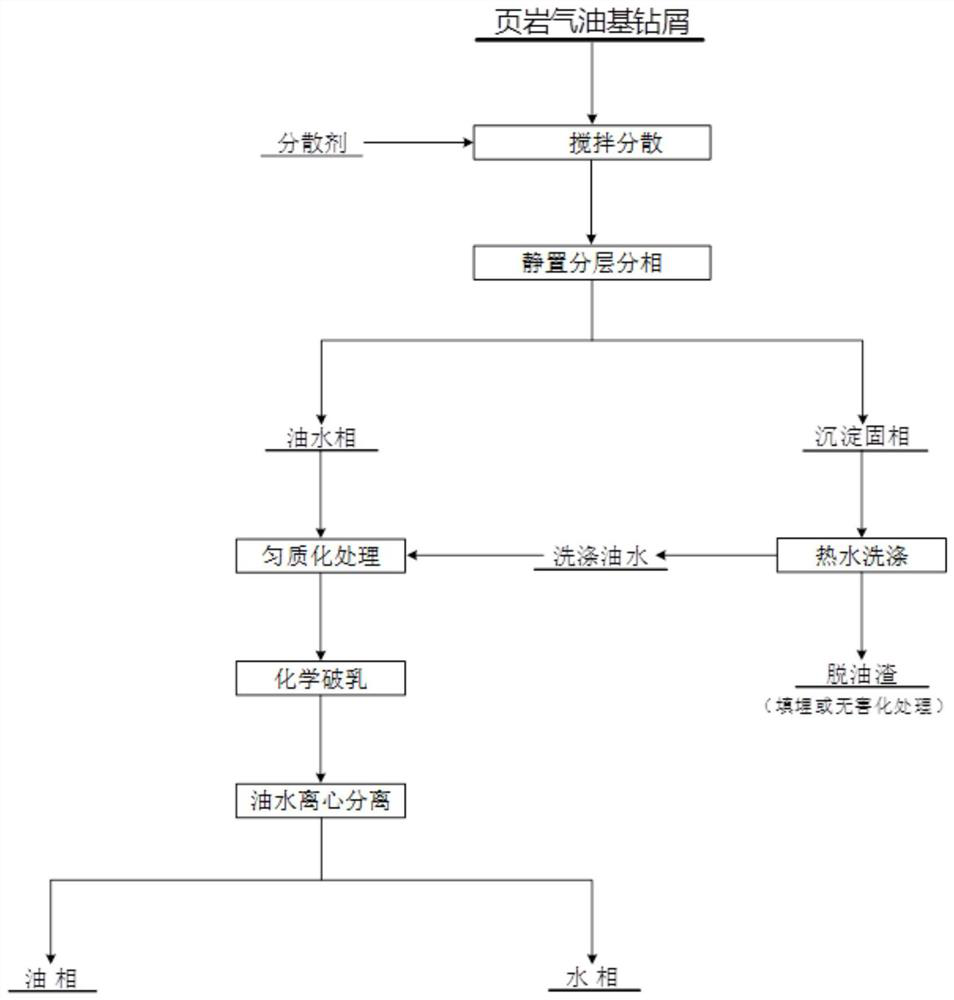

Dispersing agent for removing oil from shale gas oil-based drilling cuttings

InactiveCN111604002AThe processing method is simpleSimple equipmentTransportation and packagingSolid waste disposalShale gasActive agent

The invention relates to a dispersing agent for removing oil from shale gas oil-based drilling cuttings. The dispersing agent is prepared from the following raw materials in parts by mass: 10-40 partsof inorganic alkali, 0.01-2 parts of organic alkali, 0.01-2 parts of a surfactant, 0.01-0.5 parts of a defoaming agent and 5-30 parts of sodium hexametaphosphate. Oil-based drilling cuttings and thedispersing agent are mixed at room temperature, oil and rock debris solid phases are well separated, layered separation and respective recovery are performed, an oil-water phase is further subjected to acid-adding homogenization and emulsification treatment, and finally, the oil phase can be recovered through oil-water separation. The dispersing agent is easily available in components and non-toxic, can be industrially applied to oil phase treatment of shale gas oil-based drilling cuttings, and turns waste into wealth.

Owner:重庆长能环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com