Method for producing soybean protein concentrate

A technology of concentrated soybean protein and soybean meal, which is applied in plant protein processing, textured treatment, food science, etc., can solve the problems of reduced daily output, poor ethanol penetration effect, and reduced protein extraction rate, achieving high cost and ensuring normal Effect of running, increasing protein content and water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

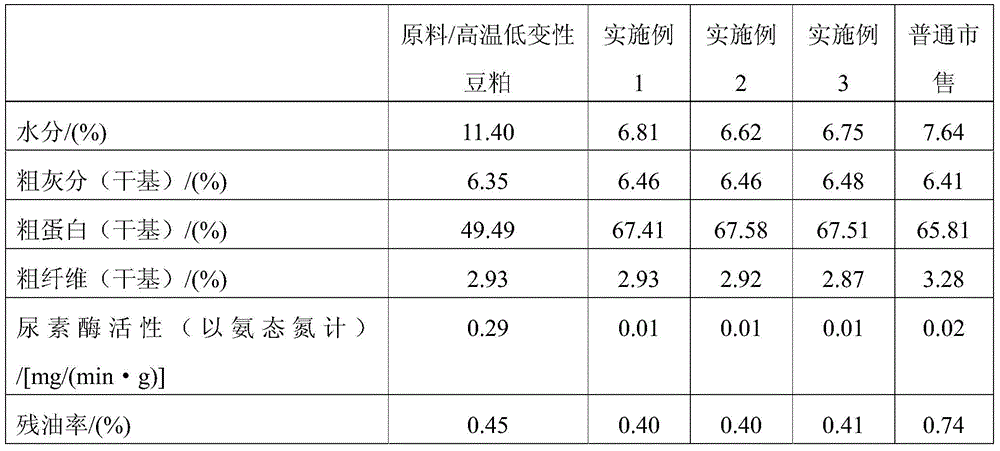

Examples

Embodiment 1

[0023] The described method for producing soybean protein concentrate, comprises the following steps:

[0024] (1) Screening: use the low-denatured soybean meal produced by the high-temperature soybean meal production line to sieve out finer powder in a vibrating sieve, and take the sieve for subsequent use;

[0025] (2) Alcohol eluting sugar: according to the mass ratio of 1:3, the low-denatured soybean meal after sieving is added to the ethanol solution with a mass concentration of 64%, and pre-soaked in the collecting hopper for 0.6 hours. The ethanol solution enters the extractor together for leaching, and the soybean meal and the ethanol solution move towards each other in the extractor to extract water-soluble and alcohol-soluble substances, and then separate the solid-phase wet meal from the solution. The leaching temperature is 60°C and the time is 4-hours ;

[0026] (3) Extrusion desolventization and vacuum drying: the wet meal after alcohol washing is first sent to ...

Embodiment 2

[0029] The described method for producing soybean protein concentrate, comprises the following steps:

[0030] (1) Screening: use the low-denatured soybean meal produced by the high-temperature soybean meal production line to sieve out finer powder in a vibrating sieve, and take the sieve for subsequent use;

[0031] (2) Alcohol eluting sugar: according to the mass ratio of 1:6, the low-denatured soybean meal after sieving is added to the ethanol solution with a mass concentration of 75%, and it is pre-soaked in the collecting hopper for 1 hour. The ethanol solution enters the extractor together for leaching, and the soybean meal and the ethanol solution move towards each other in the extractor to extract water-soluble and alcohol-soluble substances, and then separate the solid-phase wet meal from the solution, wherein the leaching temperature is 65°C and the time is 5 hours;

[0032] (3) Extrusion desolventization and vacuum drying: the wet meal after alcohol washing is first...

Embodiment 3

[0035] The described method for producing soybean protein concentrate, comprises the following steps:

[0036] (1) Screening: use the low-denatured soybean meal produced by the high-temperature soybean meal production line to sieve out finer powder in a vibrating sieve, and take the sieve for subsequent use;

[0037] (2) Alcohol eluting sugar: according to the mass ratio of 1:4, the low-denatured soybean meal after sieving is added to the ethanol solution with a mass concentration of 70%, and pre-soaked in the collecting hopper for 0.8 hours. The ethanol solution enters the extractor together for leaching, and the soybean meal and the ethanol solution move towards each other in the extractor to extract water-soluble and alcohol-soluble substances, and then separate the solid-phase wet meal from the solution. The leaching temperature is 62°C and the time is 4.5 hours;

[0038] (3) Extrusion desolventization and vacuum drying: the wet meal after alcohol washing is first sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com